Functional Chocolate Counting Machine: The Complete Buying Guide In 2025

Functional Chocolate Counting Machine: The Complete Buying Guide In 2025

Accurate chocolate counting is one of the difficult tasks to do especially when volume is such large. Similarly, presence of defective chocolate also creates bad impression of your brand. Thus, to avoid these complexities a Functional Chocolate Counting Machine is used.

The machine is highly automatic with innovative features to deal with different types of chocolates. It can enhance your production efficiency and counting accuracy while processing these chocolates through safe process. It has simple operational procedure, compact body, and wide applications. So, let's explore all these facets along with other aspects of a Functional Chocolate Counting Machine!

1.What Is Functional Chocolate Counting Machine?

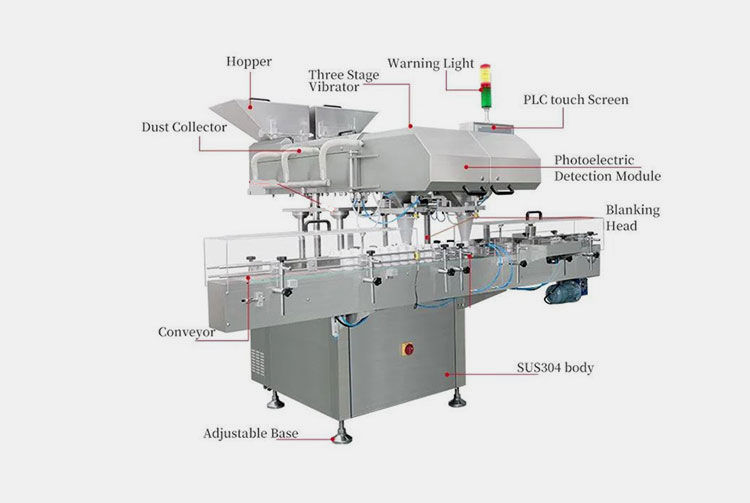

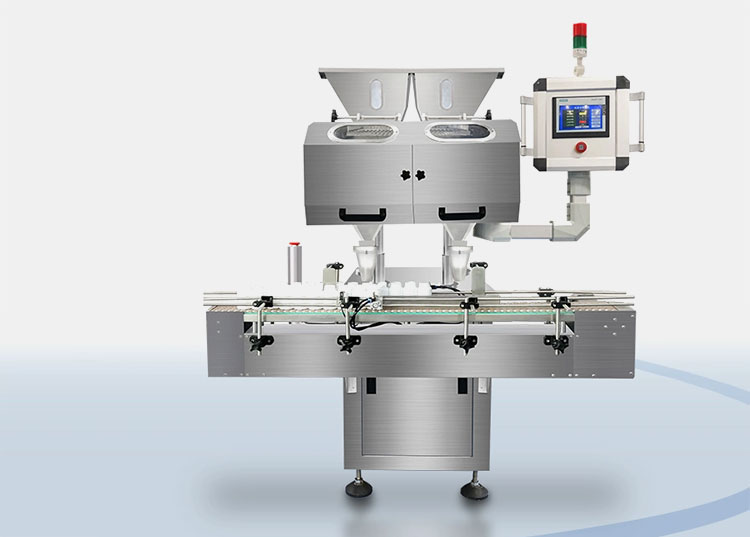

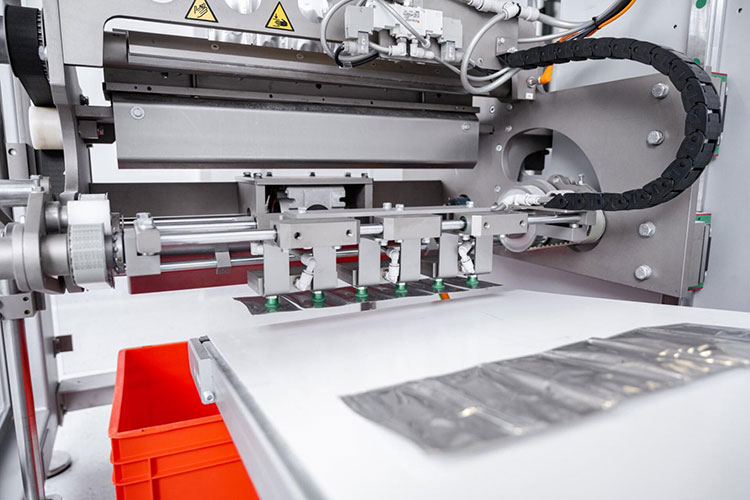

Allpack- APC-24 Automatic Counting Production Line/capsule /tablet counting machine

As kids, youngsters, and older people we always love to enjoy the delicious taste of chocolate in all its form whether chocolate bar, balls, or lentils. Similarly, we get these chocolates after their thorough processing of which the most essential step is chocolate counting, and this is done by using a functional chocolate counting machine.

Functional chocolate counting machine refers to the equipment which is specialized in counting any shape or size of chocolate which may or may not have primary packaging. Moreover, it utilizes optical sensors and automatic features during operation to ensure high counting accuracy.

2.Enlist The Features And Advantages Of A Functional Chocolate Counting Machine?

Functional chocolate counting machine brings with it immense features among which prominent ones are highlighted below. These include:

High Productivity

High productivity of functional chocolate counting machine- Picture Courtesy: cremer.com

The machine is highly automatic and come up with multiple counting channels. In this way, it reduces the need for labor and increase the overall production efficiency. Hence, you can meet your daily production targets with the machine's output ratio of 6000 pieces per minute.

Counting Accuracy

High counting accuracy of chocolates- Picture Courtesy: cremer.com

With advanced detection system and automatic rejection mechanism, a functional chocolate counting machine maintain high counting accuracy throughout operation and collect inconsistent or foreign objects in a separate chamber.

Safety

Hygienic body of functional chocolate counting machine- Picture Courtesy: cremer.com

The machine is creation of highly safe stainless steel body which is corrosion resistant and antibacterial. It also maintains the hygiene of products during processing by extracting the possible dust or waste material. In addition to it, the alarm system and emergency stop help user know the fault while keeping himself in a safe condition.

Versatility

Applications of a functional chocolate counting machine- cremer.com

Another most significant attribute of a functional chocolate counting machine is its ability to not only count the chocolates of various sizes and shapes but also other materials such as capsules, tablets, laundry pods, and candies etc.

Long-term Use

Long term bill board

Functional chocolate counting machine is fully automatic, and its features allow it to work consistently without any interruption. Similarly, it can be integrated with other machines for enhancing production. Hence, it can help you meet your growing needs in future by simply employing regular maintenance.

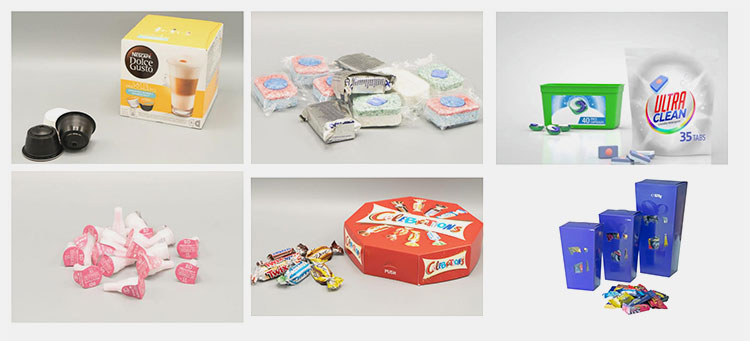

3.What Type Of Chocolate And Other Products Can Be Processed By A Functional Chocolate Counting Machine?

Well, this question carries great significance as manufacturers tend to process different products by using the same machine. Similar is the case with a functional chocolate counting machine. It is capable of counting myriad of products with same proficiency. So, let's know what these products are!

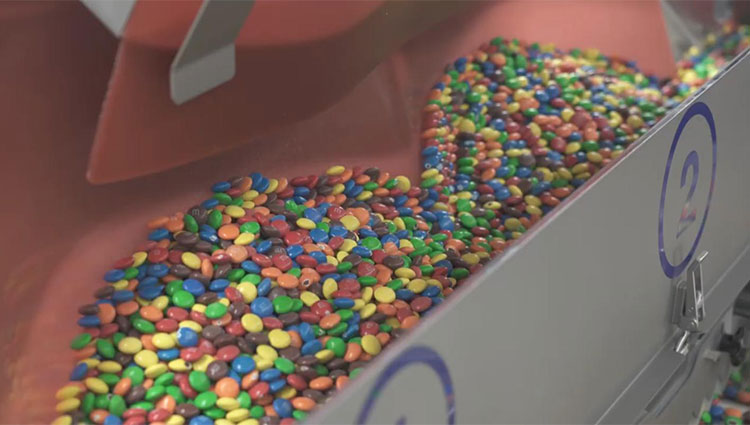

Chocolate Balls & Lentils

Chocolate lentils- Picture Courtesy: eatthis.com

Chocolate balls are spherical confections made from chocolate. They are the most favored and consumed by chocolate lovers. Chocolate balls may have coating or dipped in sprinkles. Thus, a functional chocolate counting machine is best suitable to count small to large chocolate balls and chocolate lentils.

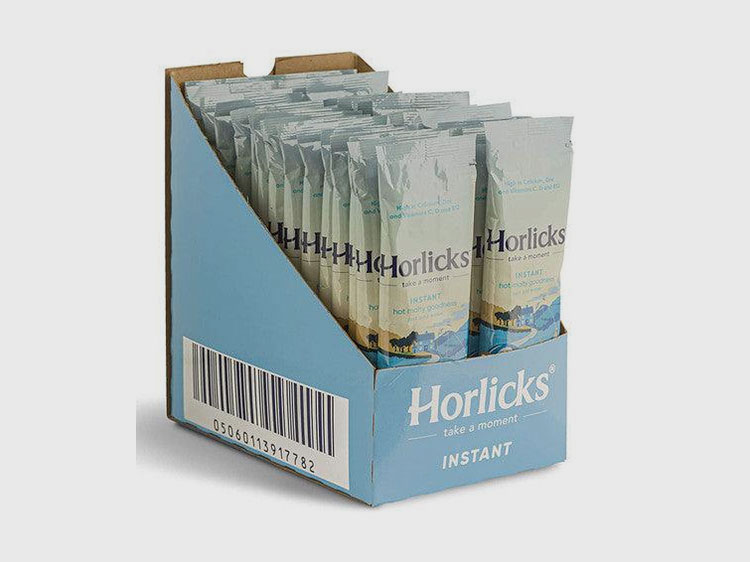

Chocolate Bars

Chocolate bars- Picture Courtesy: godiva.com

You must be familiar with chocolate bar which is a common form in which chocolate is delivered. It may inside have multiple layers of wafer or nuts. That's why, chocolate bars are often packed in primary packages and then used for secondary packaging in bottles and pouches for which this equipment is ideally recommended.

Gummies

Gummies- Picture Courtesy: candyclub.com

Gummies and jellies are gelatin-based sweets which are good source of sugar. They are really enjoyed by kids and adults for their chewable nature. So, you can employ a functional chocolate counting machine to count variety of gummies.

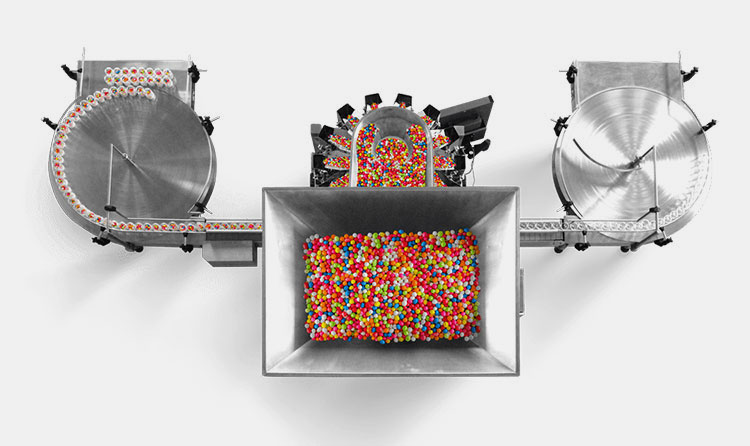

Bubble Gum

Bubble gum balls

Bubble gum is a soft and cohesive confection which is chewable and not meant for swallowing. It is derived from gum base along with sweetener and flavor. As bubble gum come in different shapes with often being made in small to medium size, a functional chocolate counting machine can easily count it.

Candies

Multicolor candies- Picture Courtesy: flicker.com

In addition to above mentioned confectioneries, candies are the most popular ones. They are hard in texture with sugar as a principal ingredient combined with certain flavors or liquid filled in center. The thing important to note here the machine's applicability to process these candies.

Pills

Pills spilling from bottle- Picture Courtesy: Freepik

Apart from confectioneries, functional chocolate counting machine is brilliant enough to count sterile and sensitive products like tablets, pills, insulin pens, and capsules etc.

Laundry Pods

Laundry pods- Picture Courtesy: treehugger.com

As the use of laundry pods is increasing, a surge has been witnessed in its production. That's why, to enable manufacturers in accurate counting and packaging, a functional chocolate counting machine can be used.

Water Balls

Multicolor water balls- Picture Courtesy: kol.deals

Water balls are flexible balls filled with pure water or colored water. They are used for different purposes such as shooting and playing etc. Therefore, to accurately count them during packaging, a functional chocolate counting machine is suitable.

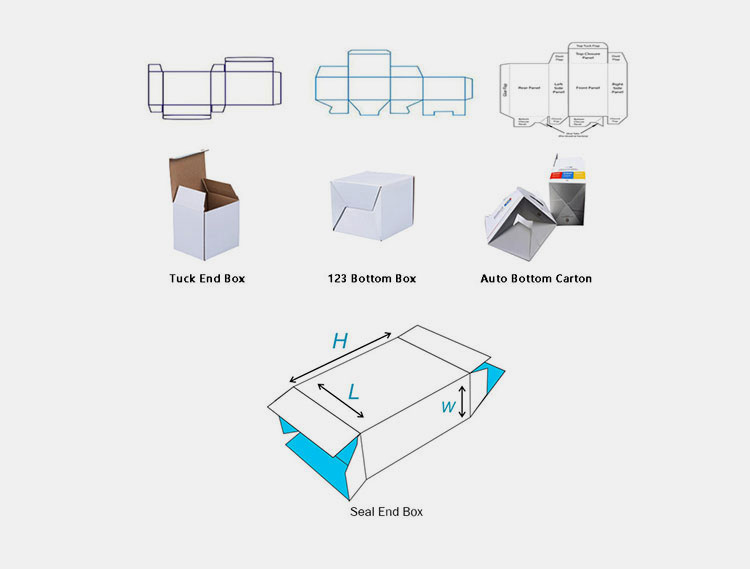

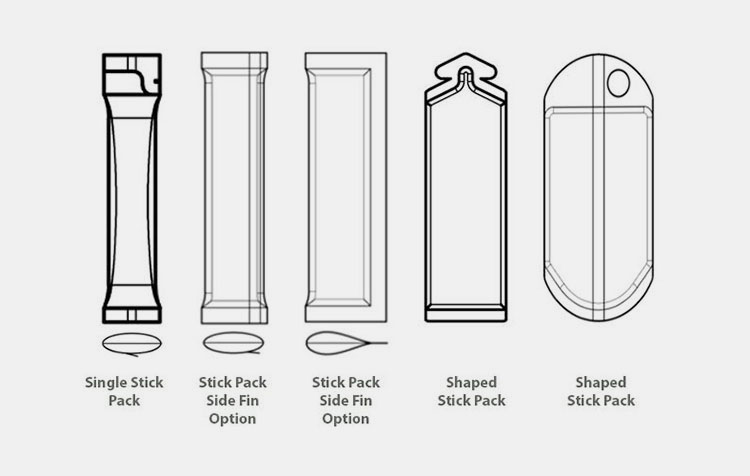

4.Name The Packages And Containers Which A Functional Chocolate Counting Machine Support?

Depending upon the type of machine being integrated, a functional chocolate counting machine support multiple packages and containers. These are enlisted below:

Bottles

Chocolate lentils bottle- Picture Courtesy: patissland.fr

Bottles are small containers with narrow neck and a lid for covering. They are made from plastic, glass, and occasionally of metal. Hence, a functional chocolate counting machine is able to support bottles of different shapes and sizes.

Jars

Bubble gum jar- Picture Courtesy: walmart.com

Jars are large size containers made from glass. Mostly, chocolate and candies are delivered in jars, so, that their quality could be well retained. Therefore, functional chocolate counting machine support jars for dispensing counted chocolate, detergent pods, and gummies etc.

Boxes

Cardboard candy box- Picture Courtesy: cremer.com

Functional chocolate counting machine is capable of supporting boxes of various types such as premade cardboard boxes, small buckets, and plastic boxes etc.

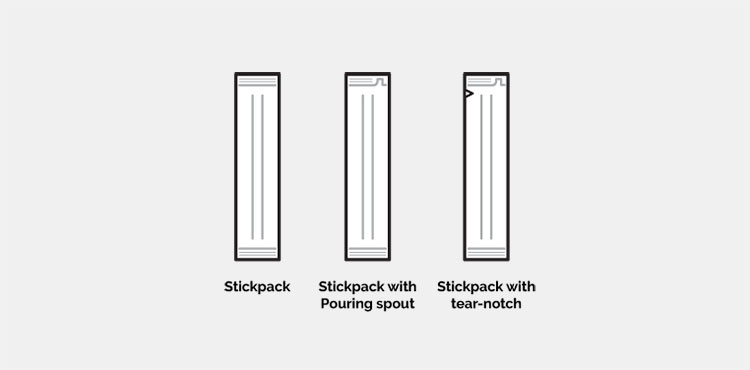

Pouches

Candy corn pouch- Picture Courtesy: Dieline

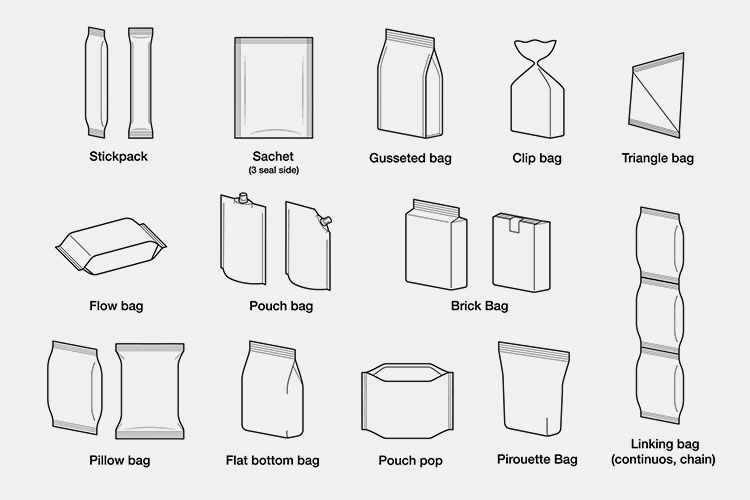

Pouches are flexible packages such as standup pouch, gusseted bags, stick pouch, pillow pouch or retort pouches etc. They are often used for encasing prepacked chocolate bars and balls. Similarly, a functional chocolate counting machine can be used to count and discharge chocolates into pouches.

Cans

Functional chocolate can packaging- Picture Courtesy: bigw.com.au

Cans are metallic containers mostly used for gifting chocolates and confectionaries due to their appealing look. That's why, you can also process cans of eclectic types by a functional chocolate counting machine.

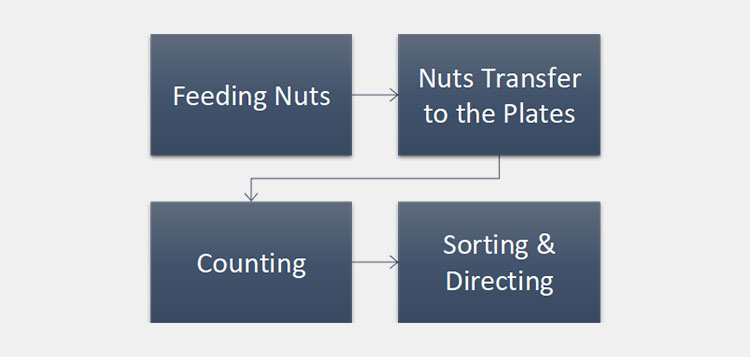

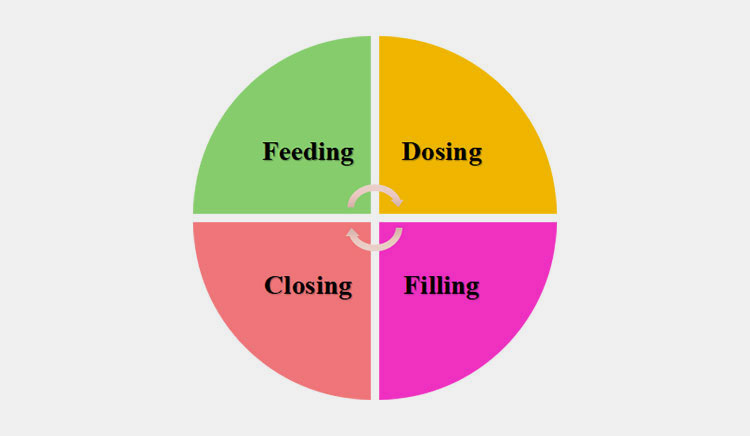

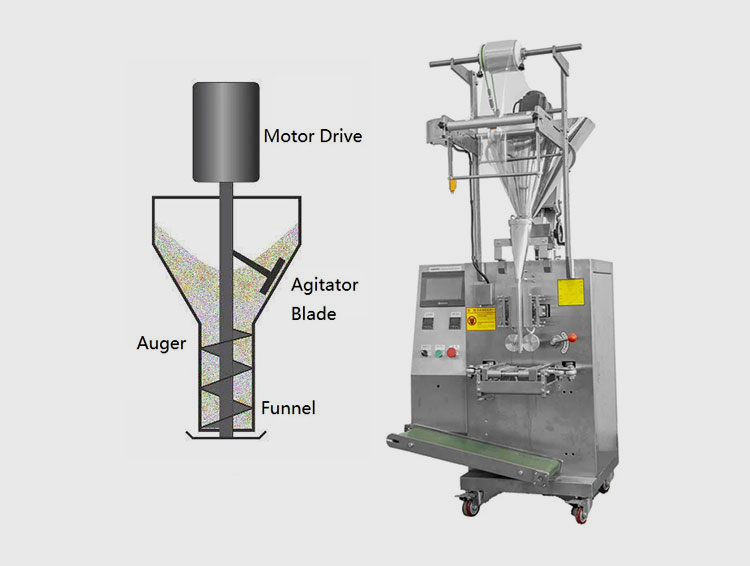

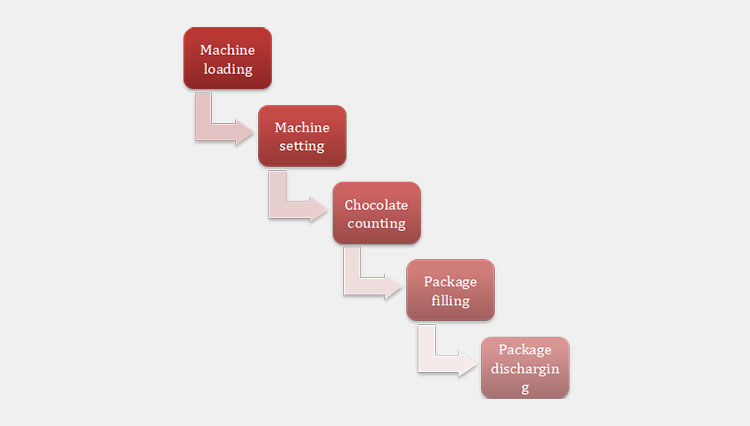

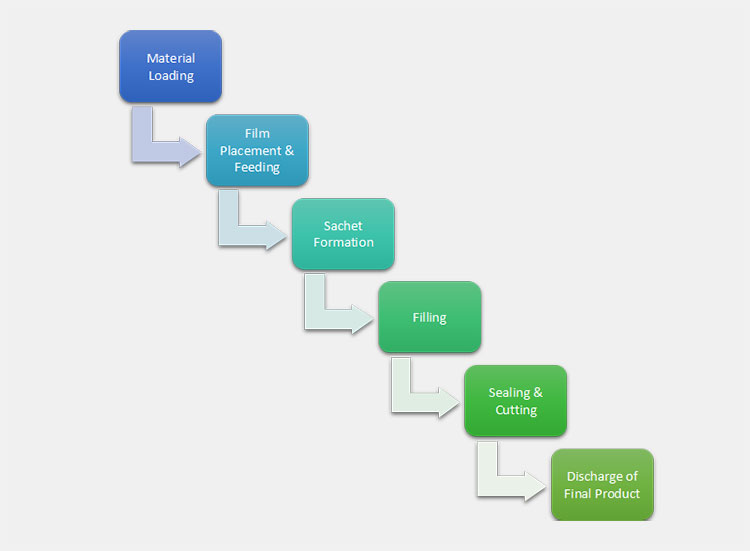

5.Explain The Working Process Of A Functional Chocolate Counting Machine?

The working process of a functional chocolate counting machine is quite simple with few steps which are explained below for your understanding:

Machine Loading

Chocolate lentils loading into machine hopper- Picture Courtesy: cremer.com

Firstly, the operator is required to load the machine with objects and materials needed for processing. It will include pouring bulk of chocolate into the hopper of machine and at the same time supplying machine with adequate number of containers which are meant for filling with counted chocolates.

Machine Setting

Machine setting- Picture Courtesy: cremer.com

After loading, conducting the setting of machine is also very important. For this, user will adjust the amount of chocolates for counting, the frequency of vibratory trays, and activate detection system for precise counting.

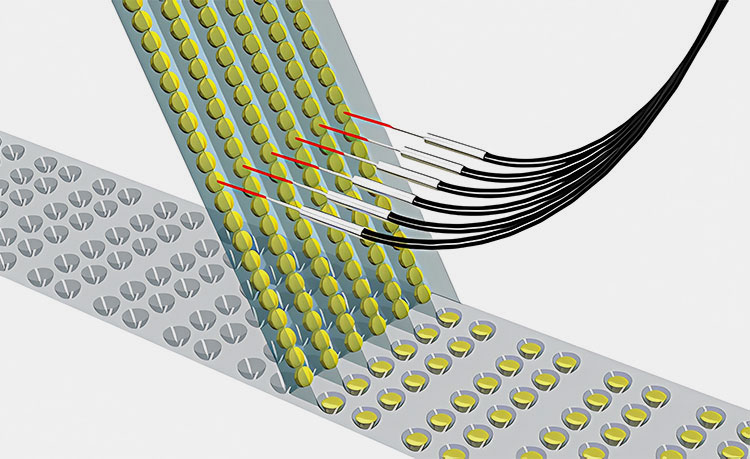

Chocolate Counting

Chocolate counting- Picture Courtesy: cremer.com

Now, the machine is ready to be started. As the power button is switched on, the chocolates in hopper will begin falling over the vibratory trays from hopper. The constant vibratory force leads to the dispersion of chocolates over trays in a synchronized way. Similarly, these chocolates are then counted through optical sensors and dropped into a counting compartment where further counting is carried out before discharging.

Package Filling

Pouch filling- Picture Courtesy: cremer.com

At this point, the counted chocolates which were gathered in counting compartment are released from it and filled into the containers. During this phase, the container detector is activated, and it enables the machine for timely discharging of chocolates by detecting the presence of container to avoid waste.

Package Discharging

Finally, each container being filled with chocolates is discharged from the machine through a conveyor belt and moved for further processing or secondary packaging.

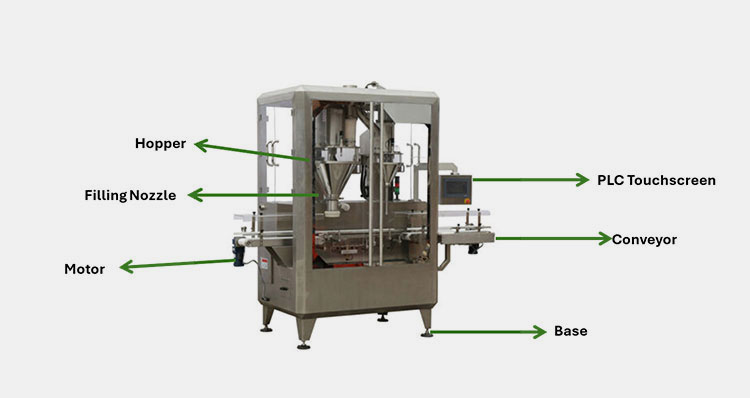

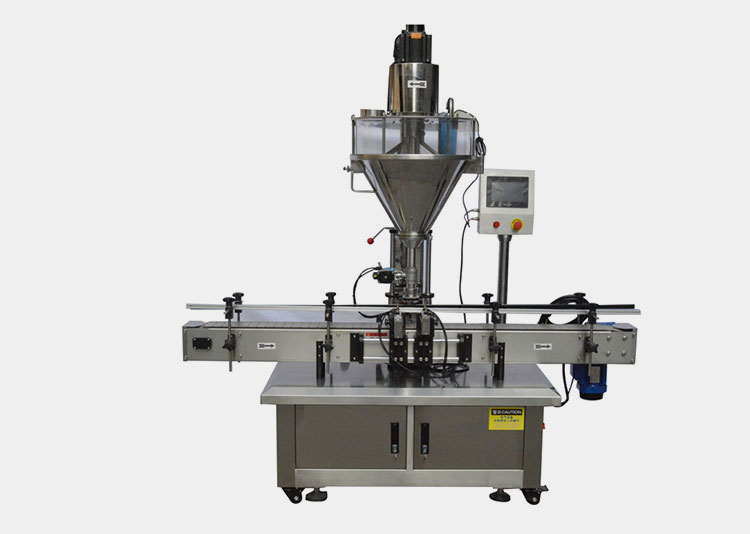

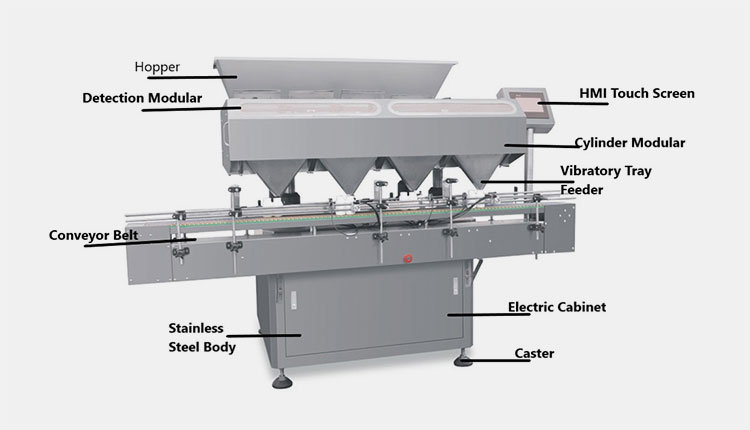

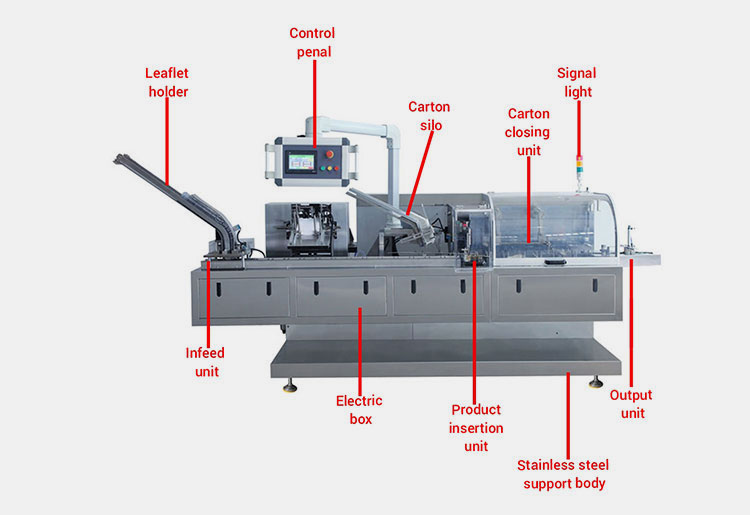

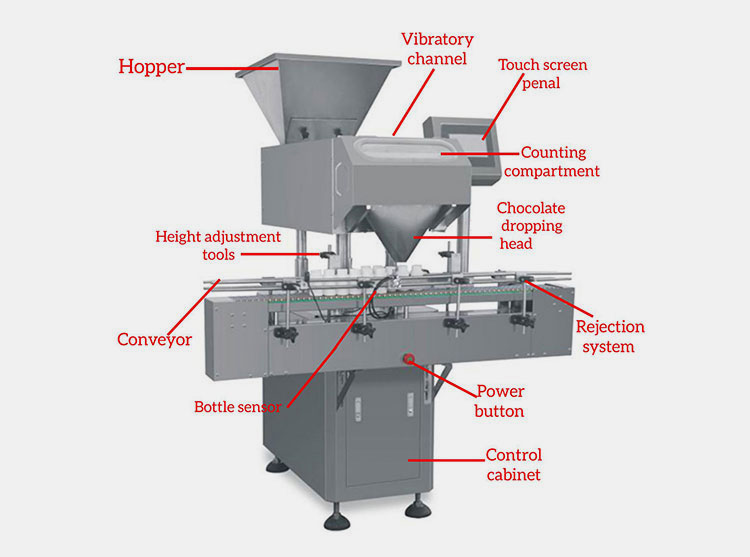

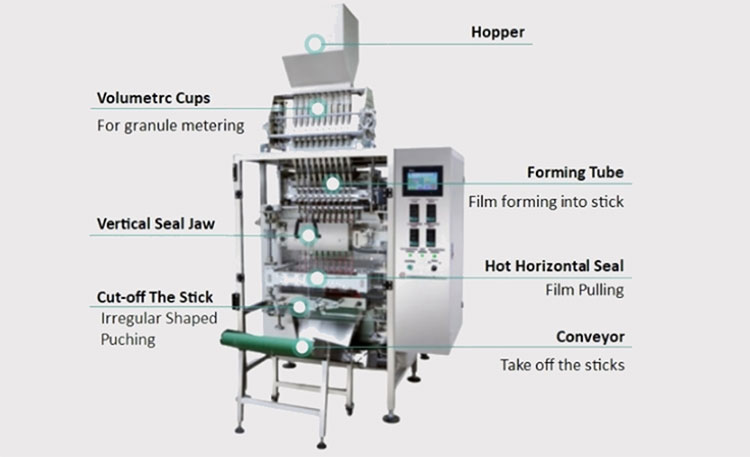

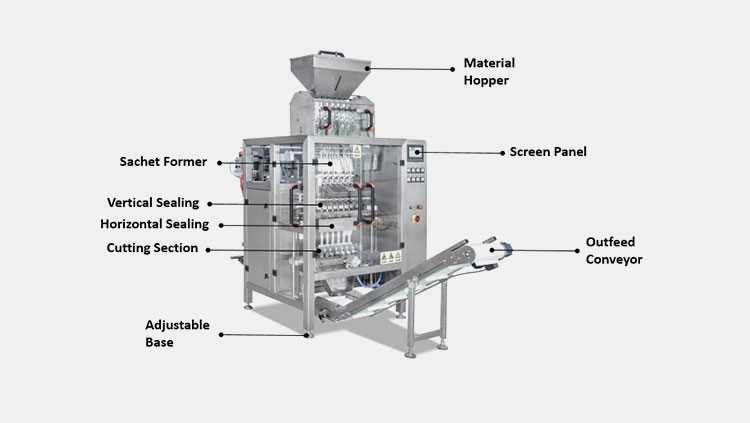

6.Describe The Components Of A Functional Chocolate Counting Machine?

Functional chocolate counting machine is made up of different tools which are known as its components. Each component of the machine performs particular task which are described below:

Allpack's APC-12 Automatic Tablet/ Chocolate Counting Machine

Hopper

Hopper is a large funnel type device located at the top of machine. It works as a feeder where bulk of chocolate is poured for counting. These chocolates are then transferred for processing through the narrow end of hopper.

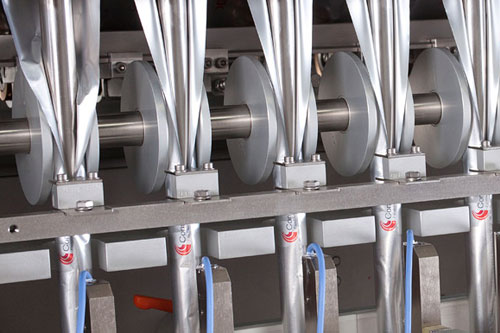

Vibratory Channel

Another essential component of a functional chocolate counting machine is vibratory channel which consists of multiple trays located over one another. These trays vibrate constantly to segregate chocolate for quick and easy counting.

Touch Screen Panel

The machine has a touch screen through which user interact with the machine and set basic parameters for executing machine such as the amount of chocolate to be counted for each bottle and the speed of conveyor etc.

Counting Compartment

Counting compartment is the core part of a functional chocolate counting machine which is responsible for counting the chocolates gathered in it through optical sensors.

Chocolate Dropping Head

It is the filling head which is made from hygienic stainless steel. It helps in the safe discharging of counted chocolates by taking them from counting compartment and dropping into passing containers.

Height Adjustment Tool

Multiple adjustment tools are fixed in the machine among which height adjustable tool is eminent one. It helps in allowing the machine to support packages of small to large sizes.

Conveyor

Conveyor is a transmission device which is responsible for moving the empty containers from inlet, move it for filling, and discharge it from machine at the end.

Bottle Sensor

Bottle sensor is a crucial part which is greatly beneficial for eliminating the errors by detecting the presence of containers and notifying machine accordingly. For instance, the machine will not discharge counted chocolates until the bottle sensor detect bottle under filling head.

Power Button

Power button is a knob situated on the front of machine. By pressing it, the machine gets started and begin functioning.

Control Cabinet

Control cabinet is the power house of machine which encases sensitive electrical components, circuits, and fuses etc.

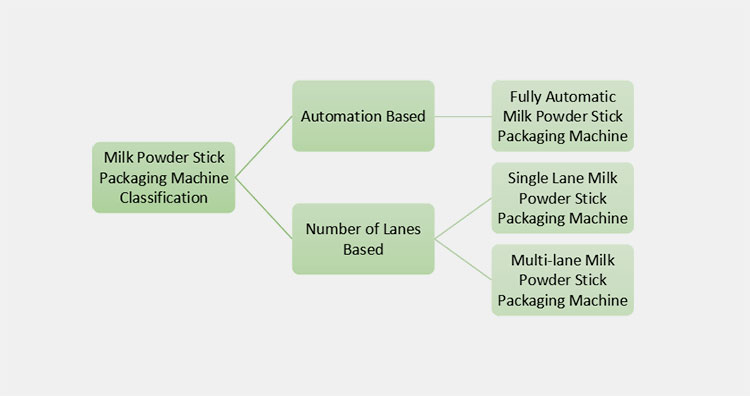

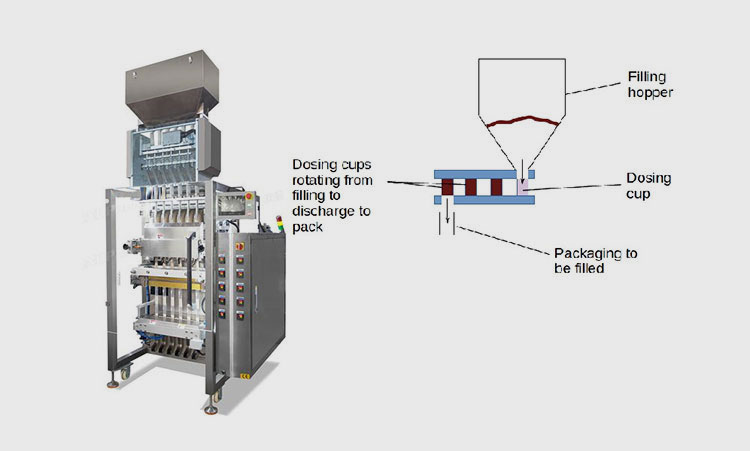

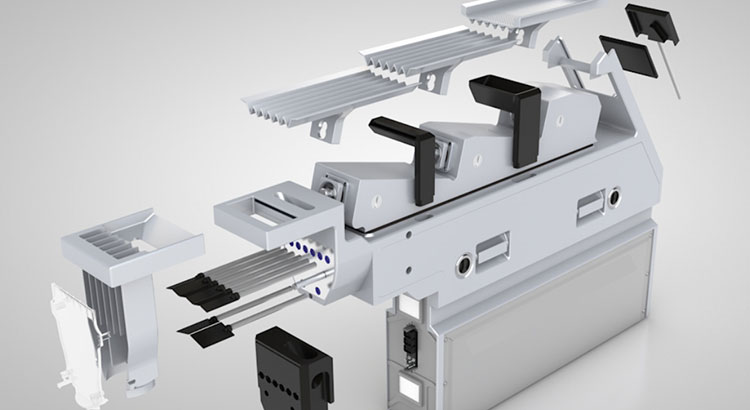

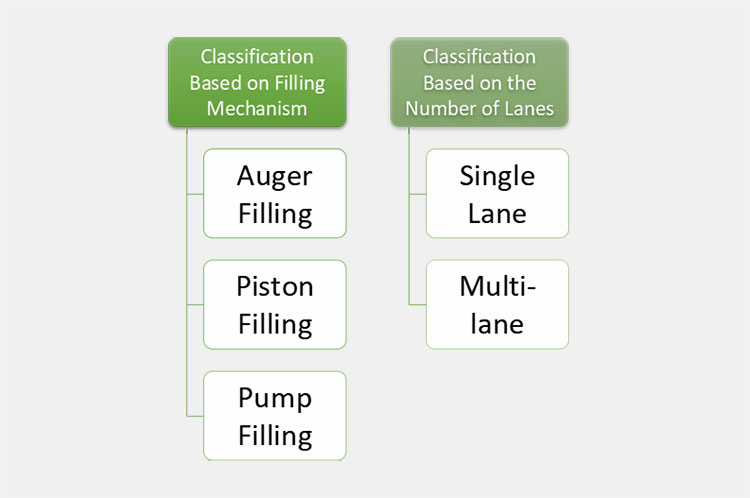

7.What Is The Classification Of A Functional Chocolate Counting Machine?

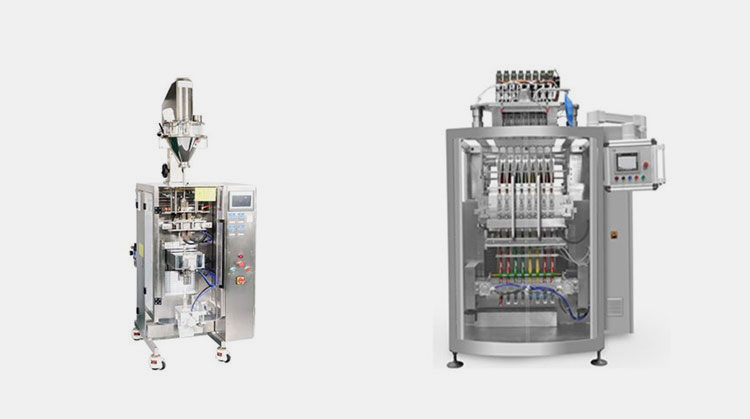

Functional chocolate counting machine is available in different types depending upon the level of automation and number of channels. Brief description of each type is provided as under:

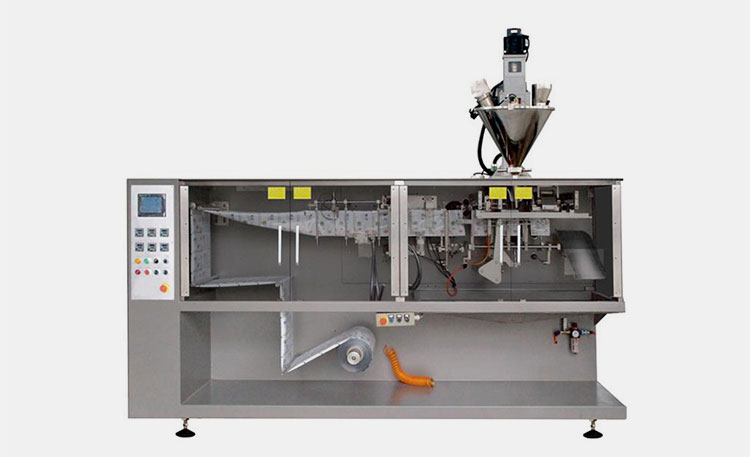

Fully Automatic Functional Chocolate Counting Machine

Allpack- APC-32 auto counter 32 channel tablets counting machine

Fully automatic functional chocolate counting machine is highly advanced and sophisticated machine that comes with automatic technology. It administers the entire processing independently and maintain high high accuracy in terms of counting and precision. The machine is available in 6-32 channels with multiple filling heads. It can be used for all shapes and sizes of chocolates, gummies, tablets, and capsules etc.

Structure

The structure of machine is complex with many parts. It can also be integrated with other machines to make a production line. Its major components include a large hopper, multiple vibratory trays, electric sensors, control unit, filling heads, and conveying mechanism etc.

Working Process

The machine follows a consistent way for operation where the chocolates are automatically transferred from hopper into the trays. Similarly, the vibration of trays creates smooth flow of chocolates and they start separating and moving towards counting compartment. Here, with the help of optical sensors, chocolates are counted and discharged via filling heads into packages.

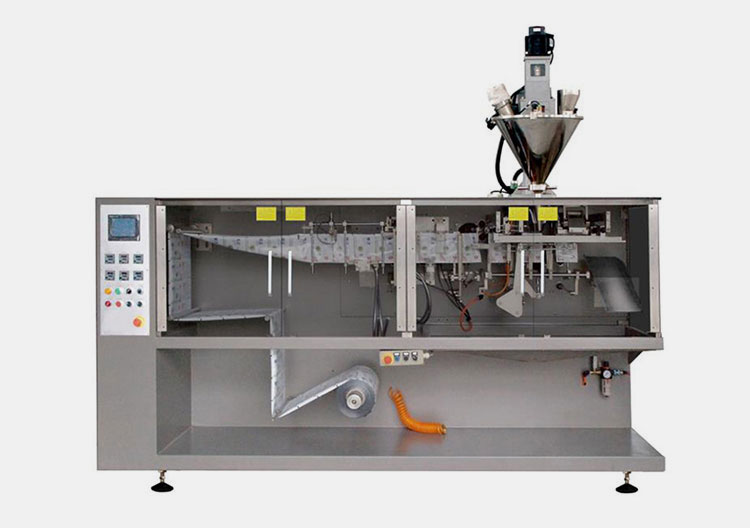

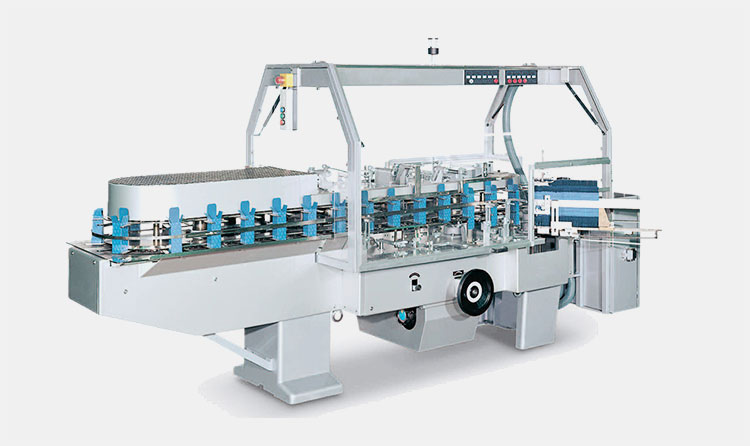

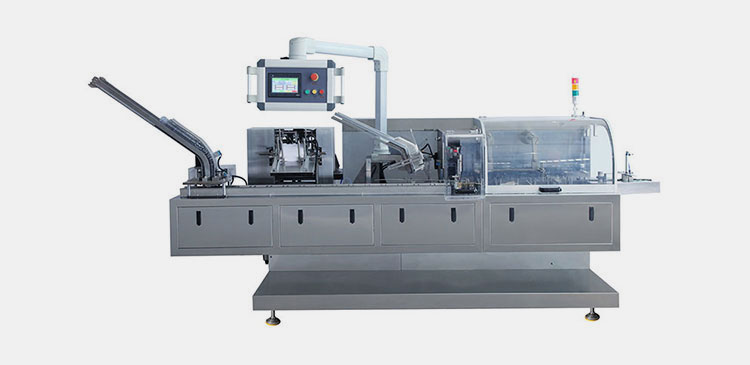

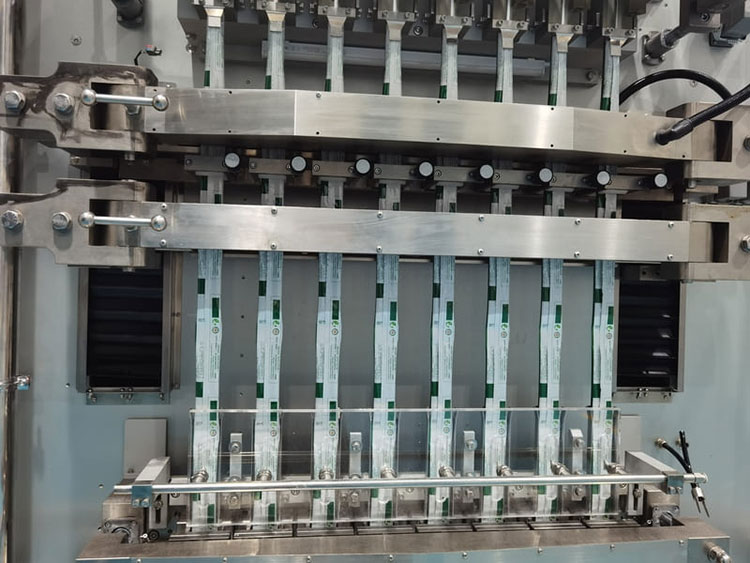

Semi-Automatic Functional Chocolate Counting Machine

Semi-automatic functional chocolate counting machine- Picture Courtesy: cremer.com

Semi-automatic functional chocolate counting machine has small footprint, and it comes in semi-automatic technology where operator intervention is necessary to operate machine. It can be integrated with other machines for fully automatic functioning such as form, fill, and seal machine and cartoning machine etc. It is capable of processing both lentil type chocolate as well as chocolate bars which comes with primary packaging.

Structure

The body of machine is precise and compact with few parts including a hopper, multi channel vibratory trays, transparent window, control board, counting compartment, filling head, and overall body.

Working Process

It requires operator to load the hopper with chocolates after which it processes these chocolates till counting. Once the counting is done, the operator with hold a package under the filling head and the counted chocolates will be discharged into package.

8.Where Can A Functional Chocolate Counting Machine Can Be Used?

There are multiple industries which require a functional chocolate counting machine for their products such as:

Confectionery Industry

Various confectioneries- Picture Courtesy: partyarts.com.au

First of all, confectionery industry is an area where the production and processing of products like candies, chocolates, gummies, jellies, and chewing gum is carried out. Similarly, it requires an advanced and sophisticated machine which is fully automatic to perform the accurate counting and no doubt, it is the one and only functional chocolate counting machine.

Pharmaceutical Industry

Multiple softgel & pills bottles- Picture Courtesy: Dieline

Pharmaceutical industry deals with manufacturing of tablets, pills, and capsules for treating various diseases and illnesses. Therefore, for their hygienic counting a functional chocolate counting machine can be used to retain quality and ensure precision during packaging.

Veterinary Industry

Doctor treating cat- Picture Courtesy: cattime.com

Drugs used for animals and pets are called veterinary medicines. Similar to other drugs, they are also packed in a proper way for preservation. That's why, during packaging, accurate counting is necessary for which a functional chocolate counting machine is always preferred.

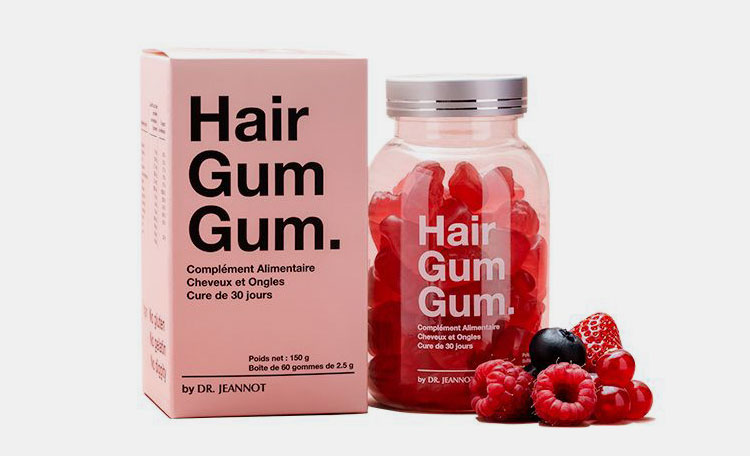

Cosmetic Industry

Beauty gummies- Picture Courtesy: vogue.fr

Now a day, most of the cosmetic products are available in form of capsules and balls such as beauty softgels and wax beans etc. These all can be processed by a functional chocolate counting machine before their filling or packaging into containers and boxes.

Detergent Industry

Detergent pods & tabs- Picture Courtesy: cremer.com

The time has gone when only detergent powder was used for washing clothes. Now, new and innovative ways are being adopted among which the creation of detergent pods is eminent one. These detergent pods encase liquid cleaning agents and are easy to use. Since, their size is small, they need counting during packaging for which a functional chocolate counting machine is employed.

Chemical Industry

Chlorine tablets

Another application of a functional chocolate counting machine is chemical industry where products like chlorine tablets and ceramic balls are produced. In this way, the machine intelligently count these objects as well as maintaining product integrity.

Hardware Industry

Multiple fruit erasers

Hardware industry is among other uses of a functional chocolate counting machine to count mini plastic balls, stationary items, marble balls, screws, and nuts etc.

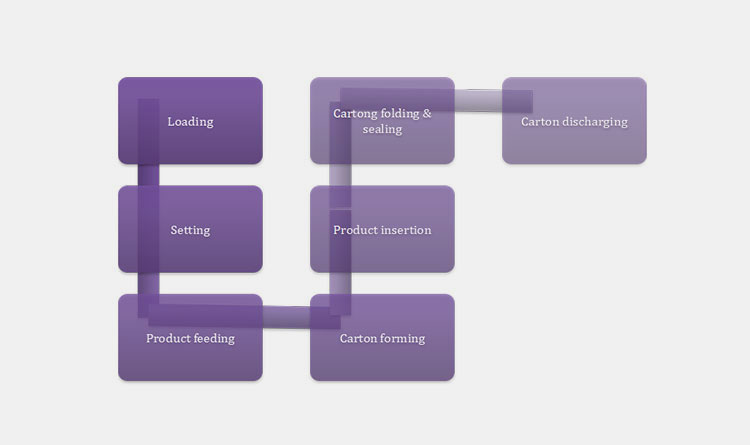

9.Is There Any Production Line For A Functional Chocolate Counting Machine?

The answer to your question is yes! There is a full-fledged production line for a functional chocolate counting machine that consists of several machines which can transform your production and packaging. So, let's know about this production line in a bit detail!

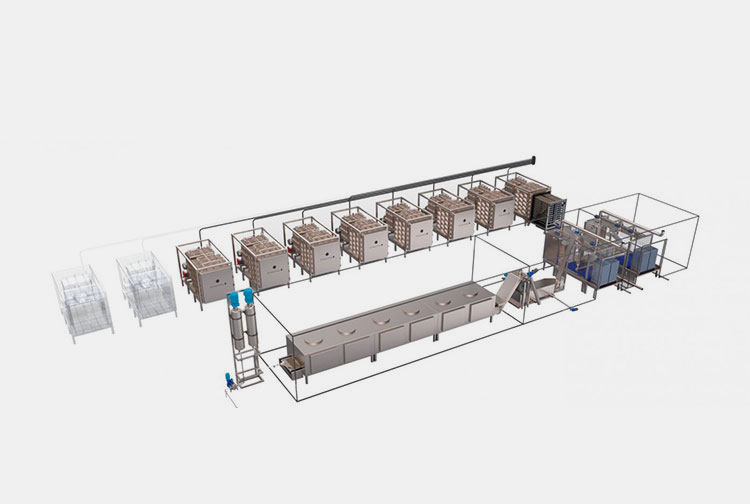

Allpack High Speed Automatic Multifunction Capsule/ Tablet/ Pill/ Chocolate Counting Line

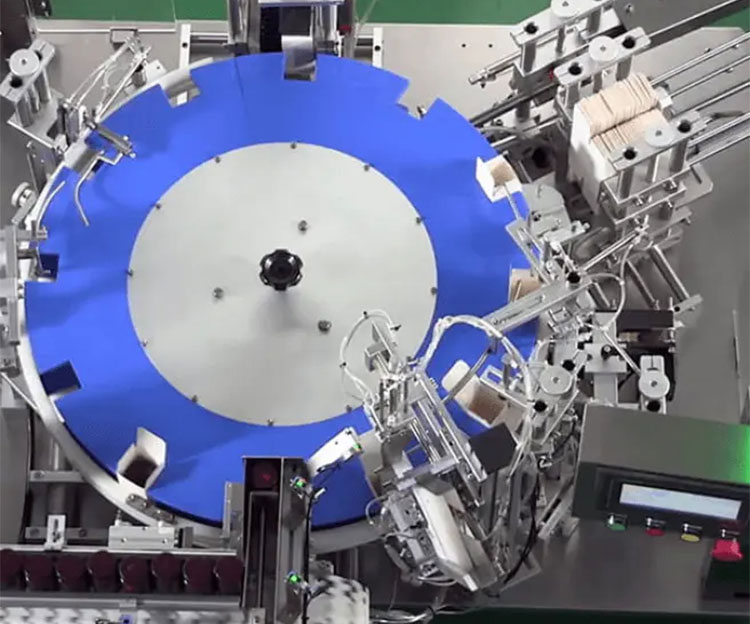

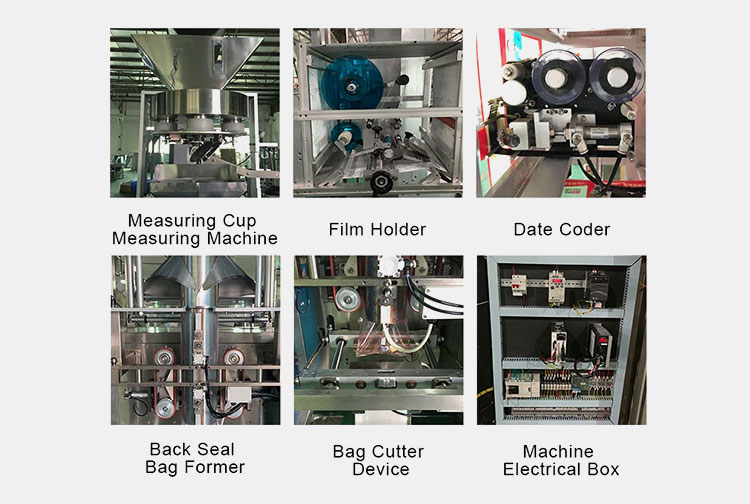

Bottle Unscrambler

Bottle unscrambler is the first unit of a functional chocolate counting production line which is made up of several components. These include a hopper, movable disc, aligner, taper plate, control system, and a transparent window for protection. Its main function is to process randomly positioned bottles and provide the production line with unscrambled aligned bottles.

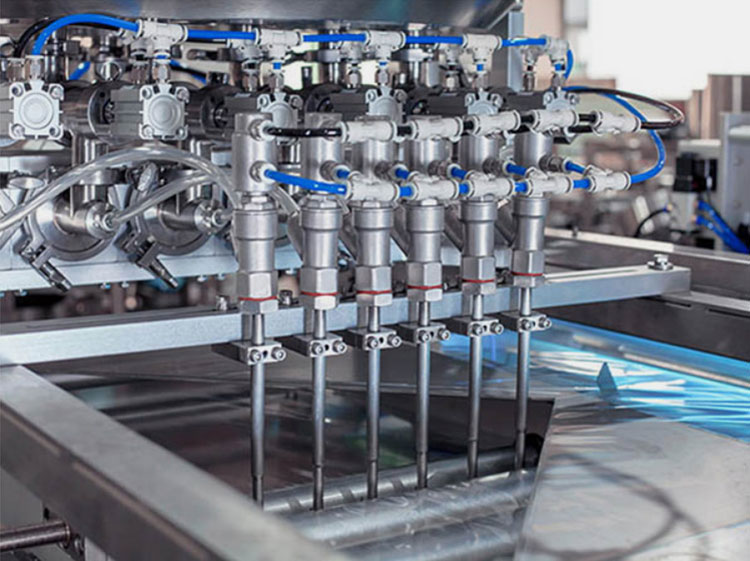

Chocolate Counting Machine

It is another most important machine of the production line which perform the actual task of chocolate counting. Its body is made up of corrosion resistant and antibacterial stainless steel along with other core parts comprising a hopper, counting channels, filling heads, and conveying system etc. It simply works by processing the bulk of chocolates through vibratory trays till their accurate counting.

Desiccant Inserting Machine

Moisture ruins the texture of chocolates, pills, and other confectioneries and make them stick together which ultimately result in the loss of their essence. That's why a desiccant inserting machine has been made part of the production line. It is used to provide the chocolate filled container with a desiccant bag.

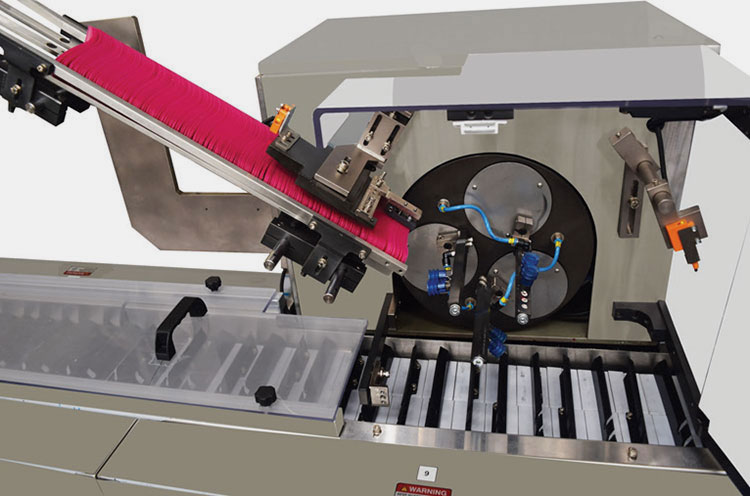

Bottle Capping Machine

Bottle capping machine is yet another crucial equipment of the production line which is utilized for the capping of bottles. Several components make up the body of this unit including a cap feeder, chuck cappers, capping head, stepper motor, photoelectric sensor, and control system etc. It carries out the capping task by taking cap and placing it over container. Afterwards, the cap is tightly screwed for application.

Induction Sealer

Another unit of a functional chocolate counting production line is induction sealer. It is an advanced machine which generate heat by using electromagnetic radiation to create tamper-evident seal in a way where the foil inside cap stick to the mouth of bottle. The machine is made up of a host, induction coil, control system, and a conveyor etc.

Bottle Labeling Machine

The last unit of the production line is bottle labeling machine. It is made with innovative features to apply sticker labels to different shapes and sizes of bottles. The machine is an assembly of various components including a label roll, pressing wheels, electric eye, and control system etc. It undertakes the task by taking labels from rollers and applying them over the passing bottles which are further tightened to the bottles by a fur brush. Simultaneously, the labeled bottles are discharged by the conveyor.

10.What Are The Maintenance Requirements Of A Functional Chocolate Counting Machine?

It is important to conduct regular maintenance for your functional chocolate counting machine in order to keep it on right track. In this way, we have highlighted some of the significant points which will be helpful for you. These are as follows:

Maintenance of a functional chocolate counting machine- Picture Courtesy: cremer.com

Required Environment:Pay attention to the environment in which you keep and operate your machine. So, it should be in room temperature to avoid chocolate melting and machine warming as it can result in both the product loss as well as machine

Regular Cleaning:Cleaning your machine on daily basis is as important as the machine itself. It is because a dirty or uncleaned machine will not be able to work consistently and meet your daily production targets. Thus, it is necessary to use recommended cleaning agents and tidy cloth for thorough cleaning of machine especially parts like hopper, vibratory channels, and sensors etc.

Regular Maintenance:Maintenance include the internal parameters setting of machines such as number of chocolates to be counted and vibration frequency. It also covers the adjustment of the height adjustment tools, the placement of trays, and repairing of damaged parts.

Lubrication:Lubrication of the movable parts is also very important to reduce friction and sudden breakdowns of machine. For this, you need to add the recommended grease after every week.

11.How To Solve The Common Pitfalls Of A Functional Chocolate Counting Machine?

When using a functional chocolate counting machine, you may confront unexpected errors which can affect your production. Dealing with such issues require proper knowledge while some problems may be tackled easily. Therefore, we have come up with few common pitfalls caused by a functional chocolate counting machine along with possible solutions:

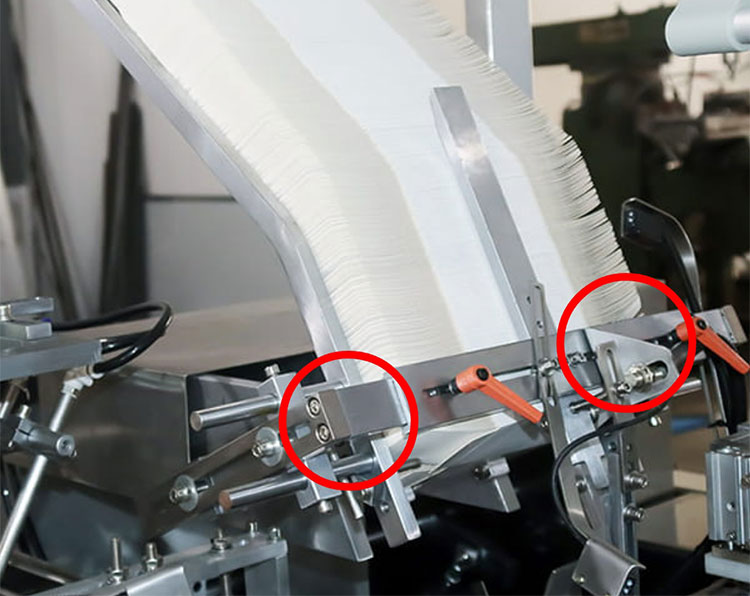

Jamming of chocolates

Chocolates jamming- Picture Courtesy: cremer.com

Cause:

It is a common issue caused by the high speed of machine due to which chocolates stuck in machine.

The vibratory channels may be misaligned due to which they have more space for chocolates jamming.

Overloading the hopper with chocolate may also result in chocolate jamming.

Solution:

Reduce the speed of machine for smooth flow of chocolates.

Readjust the vibratory trays as per manual's instructions and tight the loose screws.

Keep the 1/3 place of hopper free, so, that the chocolates will easily move from hopper over the trays.

Sensor incorrect counting

Sensor false counting- Picture Courtesy: cremer.com

Cause:

It is one of the serious issues caused by the accumulation of dust over the sensor.

Another reason can be the loss of sensitivity of the counting sensor.

Solution:

Clean the sensor with soft dry cloth to remove out dirt and pollution.

In this case, you need to turn the sensor's little adjustment knob until it gets back to the prior normal condition.

Sudden alarm sounds and noise

Encircled alarm- Picture Courtesy: ipharmachine.com

Cause:

The alarm is indicating dust buildup over sensor.

Lack of bottles may be the reason for alarm sound.

The loose vibratory trays may also causing noise.

Solution:

Keep the sensors clean from dust to function smoothly.

Provide adequate bottles during operation to reduce interruption.

Tight the vibratory trays to end noise.

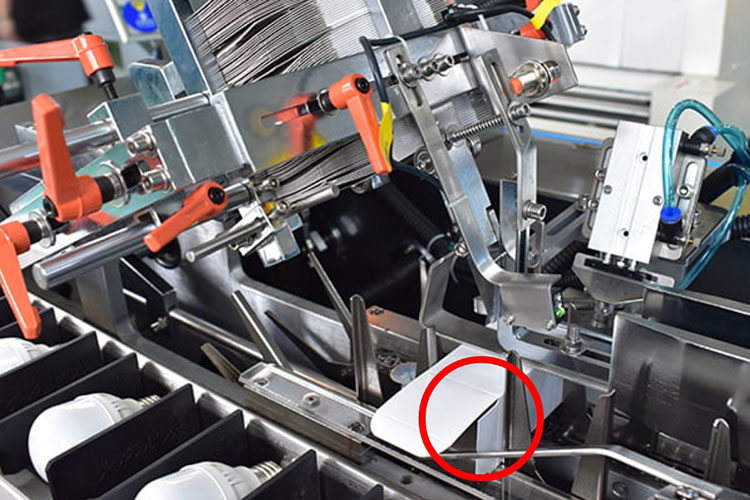

Chocolates spilling during discharging

Scattered chocolate chips- Picture Courtesy: Freepik

Cause:

There is a gap between the package and chocolate dropping head.

The speed of conveyor belt is not correct.

Solution:

Reduce the gap by modifying the height adjustment tools in accordance with container diameter.

Adjust the conveyor belt speed as per products requirements.

12.Tips For Choosing The Best Functional Chocolate Counting Machine?

Every manufacturer aspire to have the top-notch functional chocolate counting machine for their production line. However, most of them get puzzled in choosing the right machine. Therefore, we are here to solve your conundrum by presenting you some of the valuable tips. Consider these all!

Type of Product

Chocolate, almonds & beans- Picture Courtesy: pngtree.com

The very first tip for choosing the right machine starts from you which is to determine the type of product you are working on. In case of chocolates, you need to fix whether you want to process chocolate lentils or chocolate bars. Similarly, the type of chocolate you process will help you opt for the machine having all the necessary specifications.

Production Volume

Bulk gummies loading- Picture Courtesy: cremer.com

Secondly, it is crucial to know your current production volume because there are multiple types of machines available in market. You can select the best machine only when you will have the information about your production volume. For instance, functional chocolate counting machine is available in semi-automatic and fully automatic and if divided further, fully automatic machine also has 6-32 channels.

Quality

Quality icon- Picture Courtesy: syntaxbox.cloud

Quality is what matters the most and should never be comprised when choosing a functional chocolate counting machine. But how to check the quality of machine? For this, international quality standards have been established to keep an eye on the production and processing of goods and products related to food and drugs.

In this way, ISO, FDA, GMP, and CE are the notable quality standards which a functional chocolate counting machine should meet with.

Price

Price icon- Picture Courtesy: greatpeopleinside.com

No doubt earning more and spending less is prime concern of every manufacturer. Therefore, you need to be vigilant and estimate the overall cost of machine you will have to bear. It will include the original price of machine along with installation, maintenance, and parts changeover cost.

Conclusion

To sum up this detailed buying guide about a Functional Chocolate Counting Machine, we are enthusiastic to have enabled you to identify the vary uses of a functional chocolate counting machine. This machine is highly Adaptable, easy-to-use, and has multiple types to suit your vary needs. It can transform your production in a positive way by employing its efficiency and accuracy with advanced technology. Besides that, Allpack has an extensive line of machines as well as production line for functional chocolate counting which come with one year of warranty. So, don't make any delay and contact us now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Functional Chocolate Counting Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Price - Sourced: price2spy

Price - Sourced: price2spy