Freeze Food Counting Machine: The Complete Buying Guide in 2025

Do you find manually counting frozen food products to be a tiresome and time-consuming task? Would you like your inventory management to be more accurate and effective? Are you looking for a reliable solution that can help streamline your operations and reduce waste?

If you said "yes" to any of these queries, our “Freeze Food Counting Machine” could be your ideal choice.

The freeze food counting machine is a technical innovation developed to ensure accuracy and save time by streamlining the counting procedure. This innovative tool will completely change how frozen goods are handled, giving companies a dependable and effective way to improve their operations.

In this blog, we will explore the cutting-edge capabilities and advantages of the frozen food counting machine and how it might revolutionize the frozen food sector. So, stick to this guide till the very end.

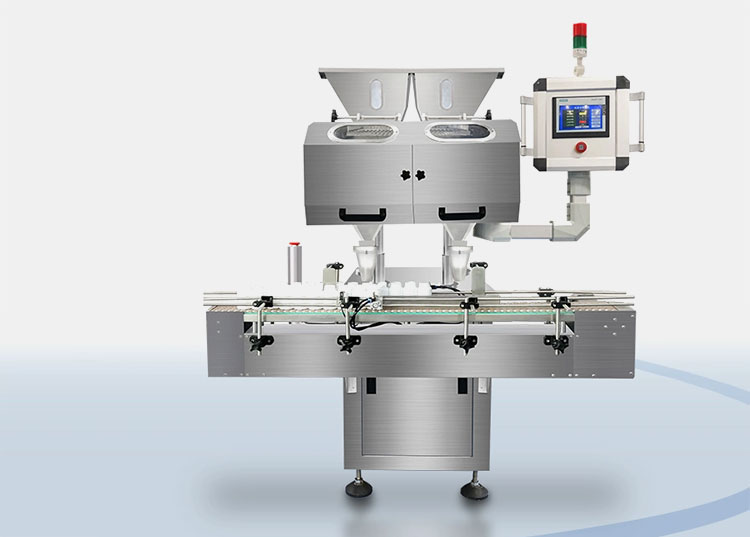

1.What is a freeze food counting machine?

Freeze Food Counting Machine

A freeze food counting machine is an incredible technological innovation designed for counting and packaging frozen goods accurately. The device is frequently used in food processing and packaging for frozen items such as cheese sticks, butter bars, chocolates, and ready-to-use food products.

It offers a robust way of counting and efficiently packaging goods into various containers to maintain product integrity. The freeze food counting machine improves the precision, efficacy, and hygienic aspects of the packing process for frozen foods, assisting producers in achieving production targets and preserving product quality.

2.What is the significance of the freeze food counting machine?

The freeze food counting machine brings high value to businesses, enhancing product quality, increasing shelf life, and ultimately satisfying the customers, leading to business growth. Some notable benefits of this amazing equipment are listed below:

| Efficient Processing

The freeze food counting machine can handle large volumes of the product quickly and efficiently. Process automation reduces the need for manual labor, lowering operational costs and allowing staff to focus on other tasks. |

|

| Precise Counting

The device ensures consistent counting and packaging of items in each package, which is crucial for maintaining product quality and satisfying customers’ expectations. |

Picture Courtesy: Water Butlers |

| Maximizing Production Output

Device automation significantly reduces human involvement and increases production rates compared to manual counting, enabling manufacturers to meet large market demands. |

|

| Quality Consistency

The equipment assists in upholding strict criteria for product quality and consistency by precisely portioning and rejecting faulty goods. Moreover, automation lessens the chances of human mistakes, resulting in more consistent and dependable outcomes. |

Picture Courtesy: Daiya Foods |

| Cost-effectiveness

Although initially, the device requires a large investment, the long-term savings and efficiency gains make it a worthy investment. Automation increases overall profitability by reducing material |

Picture Courtesy: Remap Consulting |

| Versatility

The freeze food counting machine is a versatile equipment that can handle various items efficiently and thus can be adopted across multiple industries. |

|

3.Which industries can adopt the freeze food counting machine?

In addition to the food industry, a freeze food counting machine finds widespread use in many other sectors for various purposes. Here are some of the common sectors where freeze food counting machine plays a crucial role:

Frozen Food Industry

Applications of the Freeze Food Counting Machine in the Frozen Food Industry

Businesses producing frozen ready-to-use meals, such as nuggets, sausages, and finger fish, can benefit from the freeze food counting machine to ensure accurate ingredient count in each package, improving quality control and customer satisfaction.

Baking Industry

Applications of the Freeze Food Counting Machine in the Baking Industry

The freeze food counting machine is also used in the baking industry for efficient counting and packaging of items, like pre-portioned frozen dough balls, bread sticks, rolls, and frozen pastries (croissants, danishes, and puff pastries).

Dairy Industry

Applications of the Freeze Food Counting Machine in the Dairy Industry

In the dairy industry, the freeze food counting machine is often employed to count frozen dairy goods. These goods include cheese sticks, butter bars, frozen yogurt, and milk sticks.

Healthcare Industry

Applications of the Freeze Food Counting Machine in the Healthcare Industry – Picture Courtesy: Eureka Direct

Yes, you got it right. The freeze food counting machine is also frequently used in the healthcare sector. This device efficiently counts and packages several medical items like medical sticks and other ingredients.

Confectionery Industry

Applications of the Freeze Food Counting Machine in the Confectionery Industry

In the confectionery industry, the freeze food counting machine is adopted to count and package several goods, such as ice creams, chocolate bars, candy sticks, and truffles. The device ensures accurate counting and packaging of items and reduces waste.

Pet Food Industry

Applications of the Freeze Food Counting Machine in the Pet Food Industry – Picture Courtesy: Guidolin Gianni

The freeze food counting machine enables pet food producers to precisely measure and package servings, guaranteeing uniformity and fulfilling legal requirements.

4.Describe the basic parts of the freeze food counting machine.

A freeze food counting machine has several components working in collaboration for a seamless counting and packaging process. The basic parts of the machine are discussed below:

Components of the Freeze Food Counting Machine

| Components | Description |

| Hopper | It is a large, funnel-shaped hollow structure positioned at the top of the freeze food counting machine. It holds the bulk frozen food goods, before being fed into the counting mechanism. It keeps blockages at bay and maintains constant feeding rates by ensuring a steady and regulated flow of goods into the machine. |

| Detection Module | The detection module has sensors to detect and count the materials as they pass through. It ensures precise count and package of the goods, using advanced technology. |

| Cylinder Module | The cylinder module comprises one or more pneumatic cylinders that assist in directing and arranging the materials inside the device. These cylinders provide seamless and effective management of the flow of goods through various stages of the counting process. |

| Sleeve-Type Hopper | More exact control over the flow of frozen food products is achieved with an adjustable sleeve mechanism found in sleeve-type hoppers, which are specialized versions of regular hoppers. This aids in sustaining a steady feed rate, particularly for goods with smaller or atypical shapes. |

| Double Cylinder | The dual-cylinder layout has two cylinders operating in tandem to regulate the movement and positioning of the processing items, improving the device’s efficiency and accuracy, particularly while operating at high speeds. |

| Photoelectric Eye | The photoelectric sensor uses a light beam to detect items as they pass through. The sensor registers a count as the passing item interrupts the light beam. This advanced technology is crucial for precise counting and maintaining high-speed operations. |

| PLC Touch | A PLC (Programmable Logic Controller) with a touch interface allows operators to control and monitor the machine's functions. The touch-screen interface offers a convenient way of adjusting the process settings and performance tracking, improving the device’s reliability and efficiency. |

| Warning Light | A warning light, a visual indication, serves to notify operators regarding several machine situations, including mistakes, low product levels, and other operational problems. It contributes to seamless operations by giving quick feedback on the state of the equipment. |

| Emergency Stop | It is a safety feature that enables the operators to cease the operation in case of an emergency quickly. This ensures the operator’s safety and avoids damage to the device or product. |

| Rejection | Reject systems are made to identify and remove faulty and wrongly tallied products from the manufacturing line. In doing so, the total quality of the product is improved since only well-positioned and superior goods get to the packing stage. |

| SUS304 Body | The SUS3034 implies the device’s construction using stainless steel (SUS304). The material is renowned for its durability, corrosion resistance, and ease of cleaning, making it ideal for use in the food sector, where hygiene is critical. |

5.How does a freeze food counting machine work?

Working of the Freeze Food Counting Machine – Picture Courtesy: Velec Systems

The freeze food counting machine comprises several mechanical and electrical components, each having a distinct function. These components work together for smooth operation. The basic functional steps of a freeze food counting machine are stated below:

Working Steps of the Freeze Food Counting Machine

Bulk Loading of Items into the Hopper: A significant quantity of the items to be counted are loaded into the hopper. This step is done manually or an automated mechanism can be integrated. The hopper will regulate how much of the item gets into the feeder trays.

In automatic variants, there are sensors installed within the hopper that control the product level within feeder trays. After leaving the trays, the product will move toward the conveyor section.

Counting of Items: In this step, the conveyor’s moving speed must be regulated. The sensors will detect the passing of each item and will register the count, rejecting the unfit item during the process (if any). The entire process can be monitored via the PLC screen.

Discharging of Counted Items for Packaging: When the counting is done, the items are discharged via the conveyor for further processing, usually packaging.

6.What maintenance is required to keep the freeze food counting machine running smoothly?

Maintenance of the Freeze Food Counting Machine

Due to the maintenance ease of the freeze food counting machine, you will not have to worry much about it. Any industrial equipment must have regular maintenance to ensure its lifetime and optimal operating condition. Here, we will discuss the fundamental upkeep procedures for a freeze food counting machine.

Regular maintenance, such as wiping and cleaning the entire instrument, is necessary to ensure that the equipment lasts a long time without deteriorating the quality.

Deep cleaning of the component is required to avoid any residue accumulation.

Ensure the smooth functioning of the dynamic parts of the device by keeping them lubricated.

Every component should have a routine examination for corrosion, damage, or wear and tear.

Consider repair or changeover of the damaged components to avoid device breakdown.

The maintenance of the device should be done regularly and must performed by trained personnel.

7.What quality standards should a freeze food counting machine comply with?

Standard Certifications

For industrial equipment, particularly dealing with food and medical products, to ensure the safe and effective processing of the products without sacrificing their quality, it must follow standard/criterion requirements.

The primary requirements for quality that an instrument must meet are;

Current Good Manufacturing Practices [cGMP]

Current good manufacturing practices (cGMP) are regulations that specify the bare minimum needed for appropriate planning, oversight, protocols, and supplies used during the product's packaging process.

Food and Drug Administration [FDA]

The FDA’s clearance suggests that the product complies with regulatory requirements related to safety and efficacy.

European Conformity [CE]

The CE (Conformité Européenne/European Conformity) certification certifies that the product meets several authorized environmental, health, and safety requirements.

National Sanitation Foundation [NSF] International

The NSF provides thorough evaluation guidelines for sustainability and public health in the food industry. The NSF certification symbol represents a promise of quality. It means the product continuously meets or surpasses requirements, giving customers, merchants, and regulators confidence in its quality and safety.

International Organization for Standardization [ISO]

The ISO certification attests to the product's efficiency, quality, and safety under defined standards.

8.What are the potential challenges faced by using the freeze food counting machine and how to rectify them?

The freeze food counting machine is a sophisticated device but even the most incredible equipment encounters problems. An early diagnosis of the issue is crucial for a prompt resolution and to avoid significant losses of machine or product resources.

Some of the major challenges faced while using a freeze food counting machine and their possible solutions are described below:

Counting Inaccuracy

Counting Inaccuracy

The possible reasons for the non-consistent counting are incorrect timing, operating speed being too high, variability in the product size, and defective sensors.

Solution: adjust the timing and operating speed. Ensure uniformity in the product size. Replace the defective sensors.

Jamming of the Conveyor

Jamming of the Conveyor

The conveyor belt can be jammed due to obstruction in the belt path, debris or residue accumulation, the belt is damaged or misaligned, or the conveyor is overloaded.

Solution: clear the obstruction and accumulated residues. Replace or properly align the damaged conveyor belt. Manage the load on the conveyor.

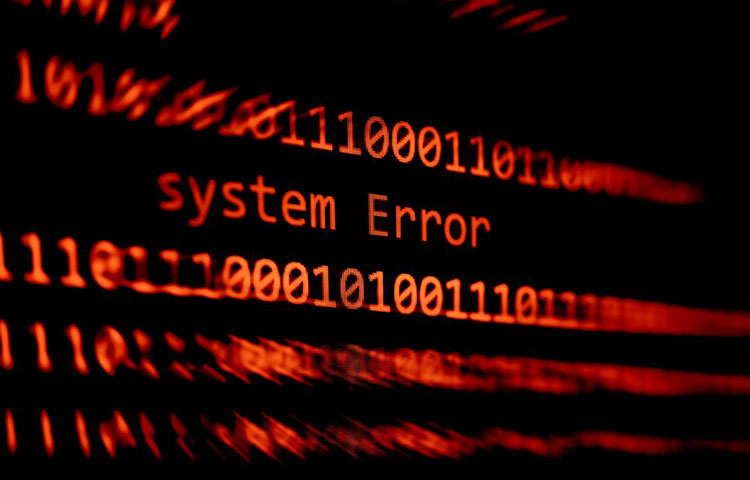

Display Error

Display Error

If the screen display is showing an error, it may be because of outdated software or the incompatibility of the software with the device.

Solution: restart the device, if still showing the error, update the software to the latest version. Install software that is compatible with the device variant.

Faulty Sensors

Faulty Sensors – Picture Courtesy: Packaging Digest

The sensors may not be functioning properly due to dust on the sensors, the power supply is not uniform, or the sensors are damaged.

Solution: regularly clean the sensors. Ensure uniform electric supply. Replace the faulty sensors.

Slipping of Packaging Containers

Slipping of Packaging Containers

The packaging containers may slip off the conveyor. It may occur due to the high operating speed or incorrect dispensing time settings.

Solution: adjust the operating speed and dispensing timing.

9.What are the key factors when selecting a freeze food counting machine?

Okay, so every manufacturer desires to get an ideal and efficient device for their businesses. Selecting the right device is crucial for optimal performance as per your needs. Here we will discuss some key parameters to evaluate before buying a freeze food counting machine.

Capacity of Production

Capacity of Production

You must be aware of your production demands and get knowledge about the production capacities of different machine variants. The right device selection will help your business grow, offering great value. Opt for the device with efficient performance that poises with your needs.

Budget

Budget

It is an important factor to evaluate. Estimate your finances and choose an affordable device with efficient working performance. Remember to consider operational and maintenance costs along with the initial investment.

Device Adaptability

Versatility & Adaptability

The capability of a single device to handle multiple products is a remarkable feature. If affordable, one should choose the device that offers greater flexibility with minimal changeovers.

Operational Ease

Operational Ease

The device with the advanced technological specs is an ideal one. The device with a PLC touchscreen is easy to operate and provides real-time operational monitoring. It does not require extensive training of operators, reducing the costs.

Warranty and After-Sales Services

Warranty and After-Sales Services

Always buy your freeze food counting machine from a reputable manufacturer that provides a significant warranty and after-sales technical and maintenance services to avoid difficulty in the device’s maintenance, technical issues, and spare parts.

Conclusion

To conclude, the freeze food counting machine is a remarkable innovation of the technological world that can count and package various frozen food goods and other ingredients. The device offers reliability, efficiency, and accuracy. It helps in achieving the production demands while maintaining product quality and reducing costs, resulting in business growth. There are several models of the device available on the market. Selecting an ideal one of them for your needs is crucial. If you want to buy this amazing piece of equipment, contact Allpack and we will assist you in getting the right machine!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide