Plastic Wrapping Machine: The Complete Buying Guide In 2025

Plastic Wrapping Machine: The Complete Buying Guide In 2025

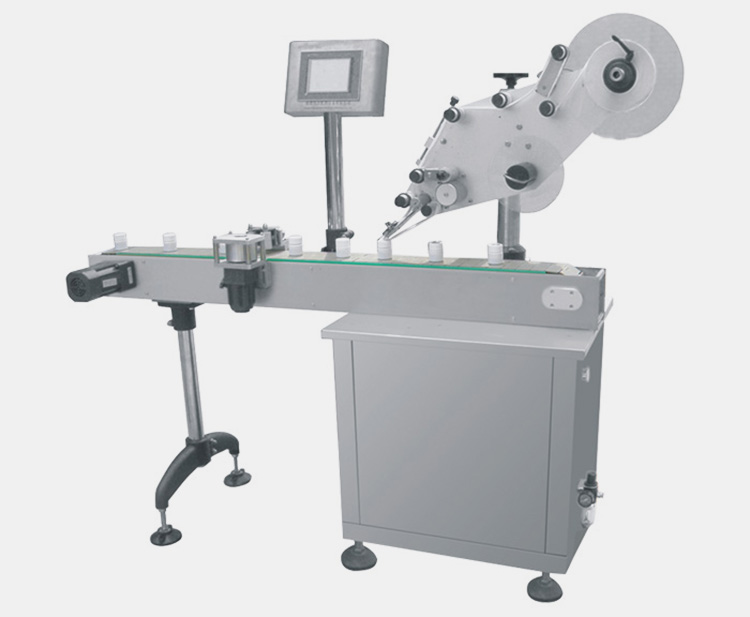

Various industries manufacture hundreds of different kinds of products. These include goods from pharmaceutical, chemical, food, cosmetic and other different kinds of industries. These products have to be packed in a safe and hygienic way before shipping them out for sale. In order to make sure that these products are sent to their destination as safely as possible, they are wrapped with plastic with the help of plastic wrapping machine.

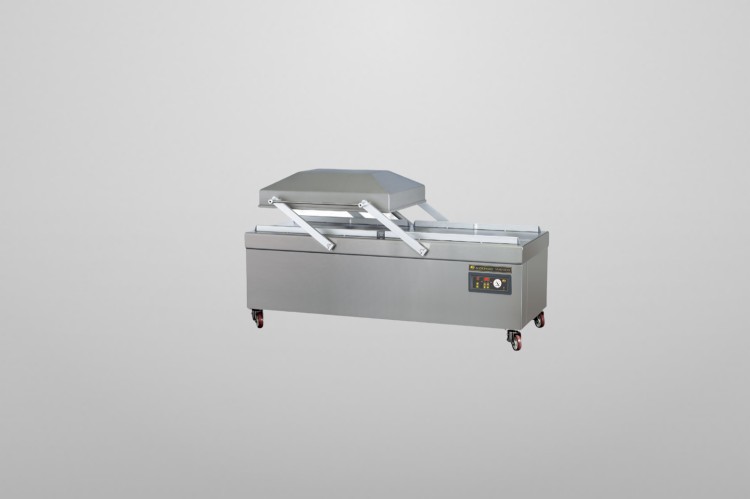

1.What is plastic wrapping machine?

Plastic wrapping machine, as the name suggests is used to wrap manufactured products to protect them from any harm. This step is important since the machine helps to make the products safe and secure so that they can be shipped to their final destination without getting damaged by external factors. Due to the growing population, this machines’ demand has been increasingly growing because of the benefits it offers and its safe use.

2.What are the advantages of buying plastic wrapping machine?

Plastic wrapping machine has a number of advantages it can offer. Let us discuss some of them below.

a)Protect from external environment

One of the most important advantage of using this machine is that it protects the goods from getting damaged by dust, moisture and other pollutants. It also prevents oxidation of goods inside preventing them from degradation.

b)Easy to operate

The working principle of this machine is quite simple and it does not require a complex mechanism to operate. Thus it can easily be monitored by any worker.

c)Increased profit margin

Since this machine provides a strong protection to the products, it prevents any losses which can occur if the products were to get damaged. Thus, it increases the profit margin, earning more money for the industry.

d)Versatility

Plastic wrapping machine has the ability to wrap products of any shape, size or design. Thus it can be used in a number of industries like pharmaceutical, chemical and food industry, thus making it a highly flexible machine.

e)Environmental friendly

Plastic wrapping machine does not pose a threat to the environment as compared to the other machines, thus the customer can easily install this machine in his production line, without worrying about posing any harm to the environment.

f)Easy to maintain

This machine can easily be maintained by conventional method and does not require special methods for maintenance.

3.What are the applications of plastic wrapping machine?

Plastic wrapping machine can be used in various industries like pharmaceutical, chemical, food, agriculture and cosmetic industry. Let us discuss each of these industry below.

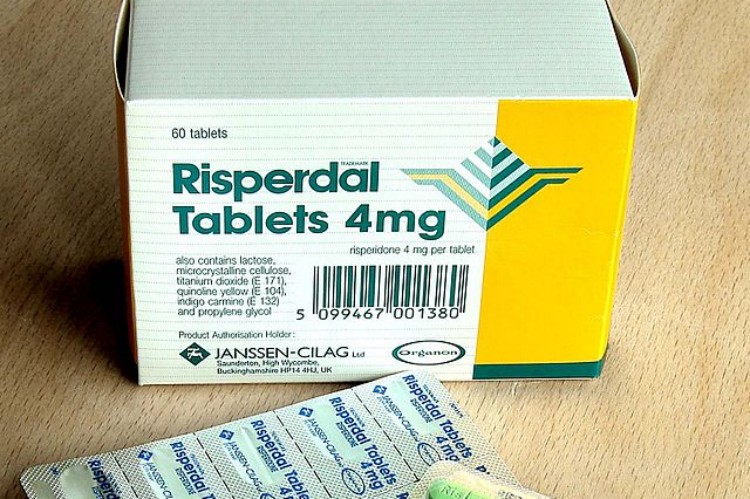

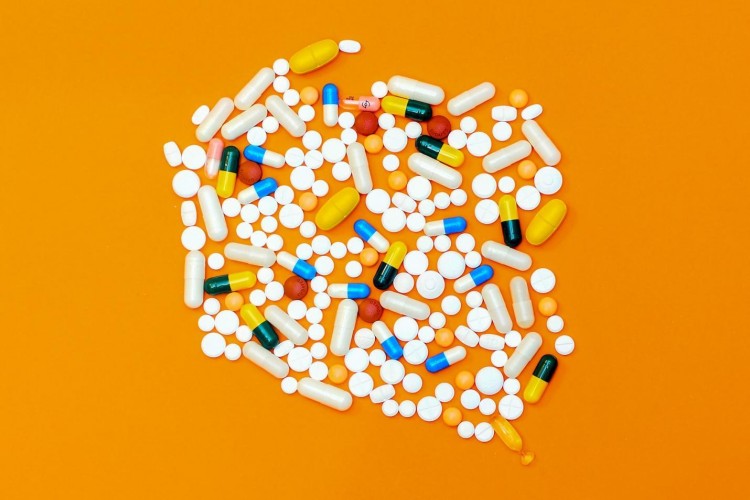

a)Pharmaceutical industry

Pharmaceutical industry deals with the manufacture of medicines and drug which are used to cure diseases and improve the standard of living of many communities living together. These medicines are highly vulnerable to even the slightest of damage, making them lose their efficacy.

Plastic wrapping machine can wrap these medicines in a safe and secure way, protecting them from any harm.

b)Chemical industry

This industry produces lots of chemical products like paints, solvents and many other substances which are then used in other industries to make final products. These products too are highly sensitive to dust, moisture and oxygen and would degrade if they come into contact with any of these factors.

This machine can wrap these volatile products safely which can then be shipped to the market for sale.

c)Agriculture industry

This industry produces a number of goods like barley, oats, wheat and even fertilizers. These products are then wrapped in plastic film with the help of this machine, which are then sent to their final destination.

d)Cosmetic industry

Cosmetic industry deals with the production of many beauty products like shampoo, serums, soaps, lotion, facial masks etc. their production has been increasingly growing over the past few years due to a high demand. These high volume products need to be packaged as safely as possible which are then shipped to their final destination.

This machine has the ability to package these high volume products efficiently, making its use in cosmetic industry a critical step.

e)Food industry

Food industry is a vast industry which is responsible for making a variety of food items like beef, mutton, chicken, soda drinks, confectionery etc. these items have a given shelf life and would spoil if not consumed before their expiry date.

The use of plastic wrapping machine increases their shelf life and preserves their freshness before they become stale and inedible.

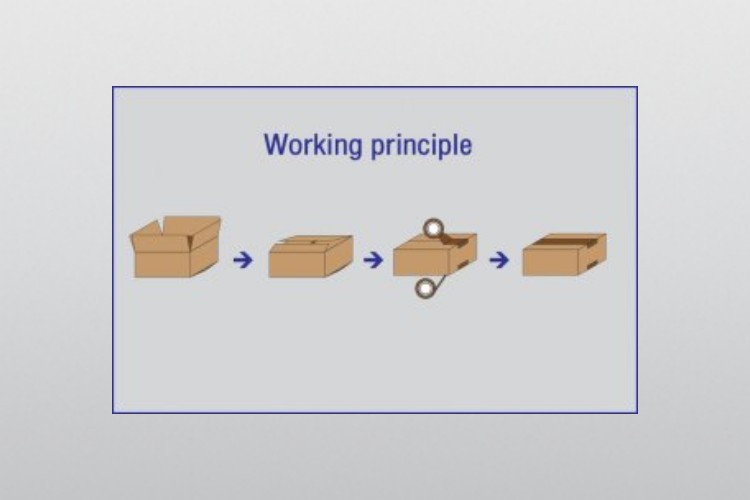

4.What is the working principle for a Plastic wrapping machine?

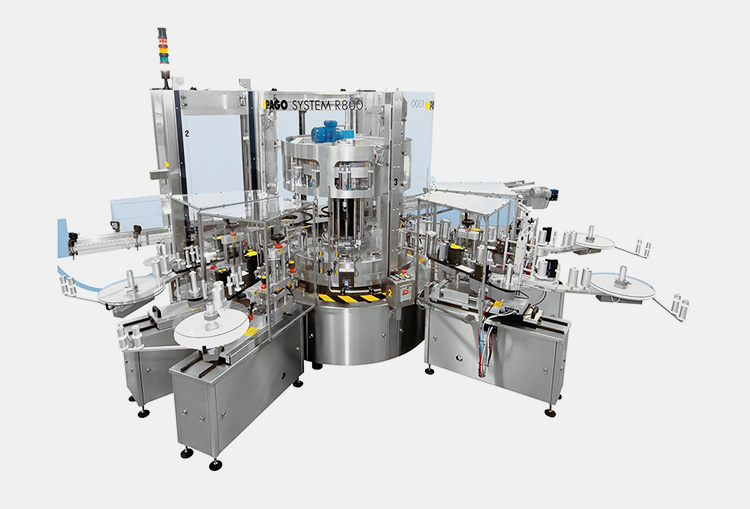

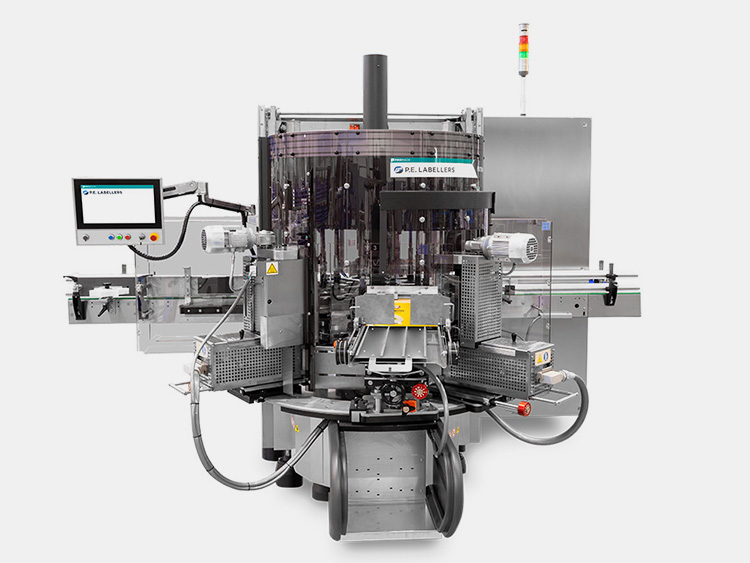

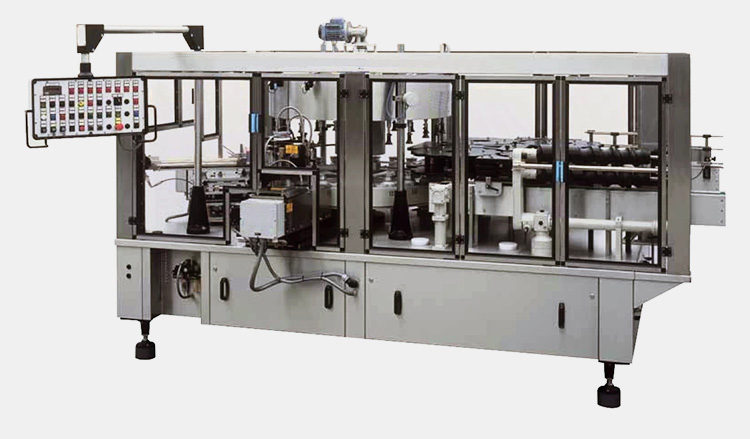

Plastic wrapping machines have the most widely applicable and easily understandable working principle. This equipment works on both principles – automatic and manual.

a)Automatic Plastic Wrapping Machine

The automatic plastic wrapping machine works via well-calibrated software, allowing you to achieve various packaging sizes and shapes according to the specimen. The packaging film in the wrapping machine is placed in a rotating film roll. Once the information on the dimensions of the product is fed into the software, the plastic film rolls outward and folds around the product.

During this streamlined flow of the film, the plastic film enters various cylinders where it first undergoes longitudinal sealing and later horizontal sealing. The package dimensions are well-operated by the inbuilt metering system.

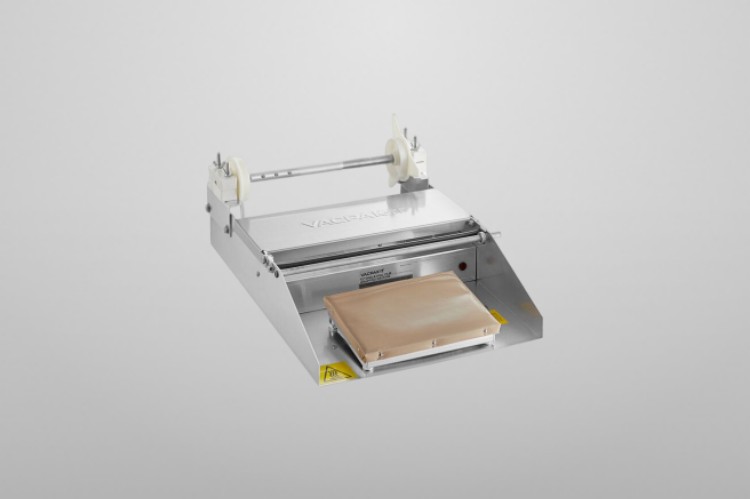

b)Manual Plastic Wrapping Machine

In conventional plastic wrapping machines, the operators carry out the assembling and handling process. The primary product is placed in a doubled plastic film and the surrounding areas are sealed by pressing the film between the heating wire and seal bar. Most of the traditional plastic wrapping machines allow temperature and length manipulation for secure and efficient sealing.

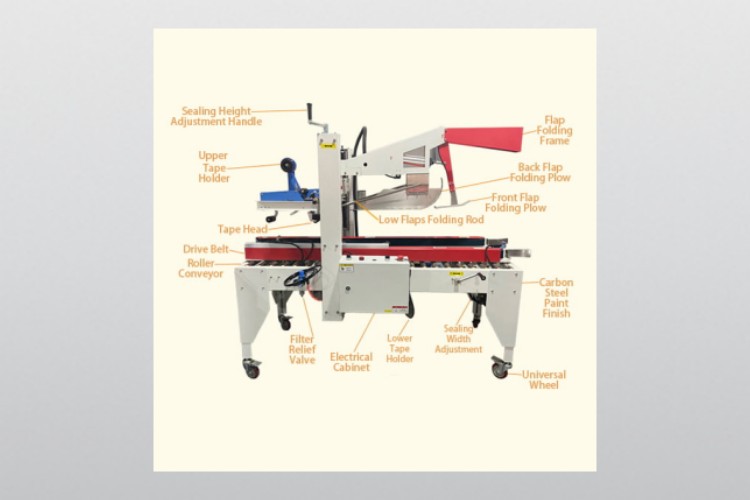

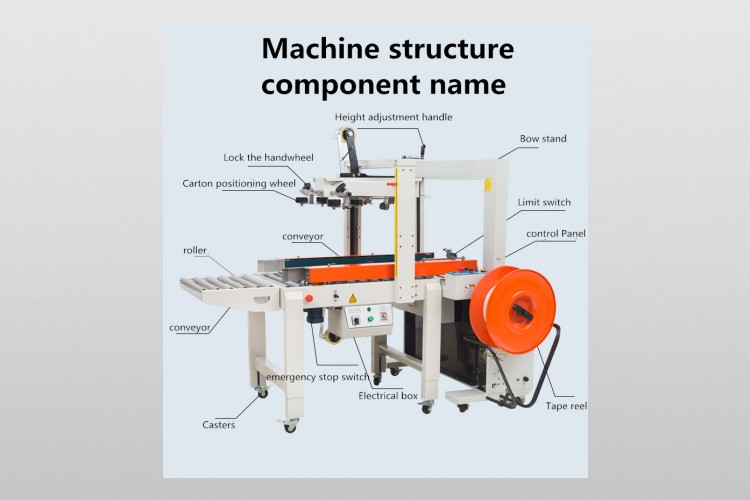

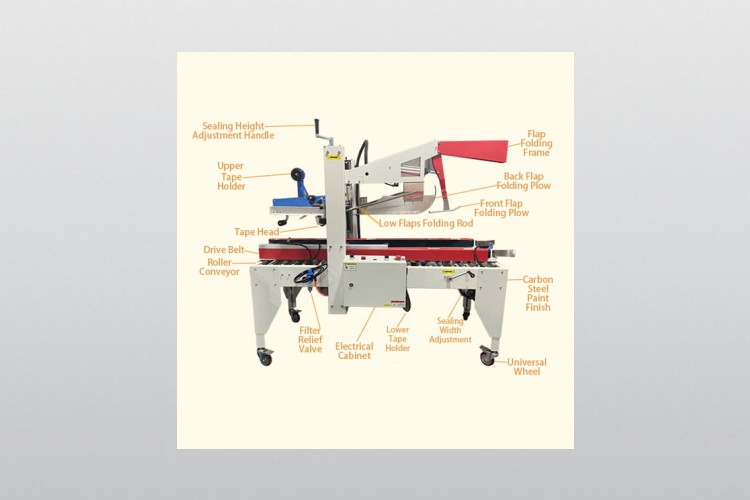

5.What are the components of a plastic wrapping machine?

Plastic wrapping machines are the game changers for domestic businesses to large product output enterprises. Since huge plastic wrapping machines are a lifetime investment, it is vital to understand the design and systems that makeup this machine.

a)Frame & Exterior

The skeleton of the plastic wrapping machines is a significant feature that makes or breaks its performance and life-longevity. The best durable plastic wrapping machines come in metal sheets or welded steel alloys. Also, the plastic wrapping machines are coated in a weather-proof paint or polish as nobody wants their expensive purchase to turn rusty and dirty in no time.

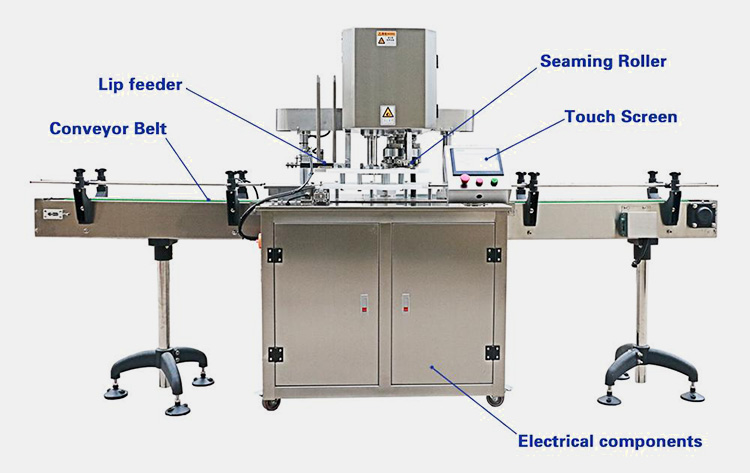

b)Product Handling System

The process of product packaging involves consistent movement from one section to another requiring proper handling mechanism. The conveying system in certain plastic wrapping machines is limited to certain product types. Since these machines handle ready-to-patch-off materials, the collation process, and conveyor mechanisms in plastic wrapping machines is top-notch.

c)Central Control System

Several electrical and software-built features are incorporated into the plastic wrapping machines. It ensures prompt response to received information and task execution. Plus, the control systems such as Programmable Logic Controller (PLC) and Human Machine Interface (HMI) control movement of components, electrical activities, and role efficiency.

d)Safeguard System

An ideal design for plastic wrapping machines is incomplete until and unless there are proper trouble-shoot mechanisms in place. The plastic wrapping machines have physical safety measures such as welded metal frame conveyors and insulators placed around the heated strip. More so, emergency shutdown and fail-safe shutdown options ensure maximum task execution and least mishaps.

e)Film storage System

Film handling is the core mechanism of plastic wrapping machine designs. The regulated delivery of films around the edge is all the game of a master program. The best film storage system will allow film run out alerts, calculated film outflow, and smooth-running accumulator. An excellent film delivery system has the power to turn a two-star machine to a huge four star one.

f)Sealing System

Every plastic wrapping machine has a different sealing system. Getting hang of your plastic wrapping machine’s sealing system is most important when it comes to packing thousands and more packages a day. Sealing quality depends on sealing knife performance, and active temperature control. Also, if you have a higher budget, there are great partially and completely automatic plastic wrapping machine designs to spruce up your product output.

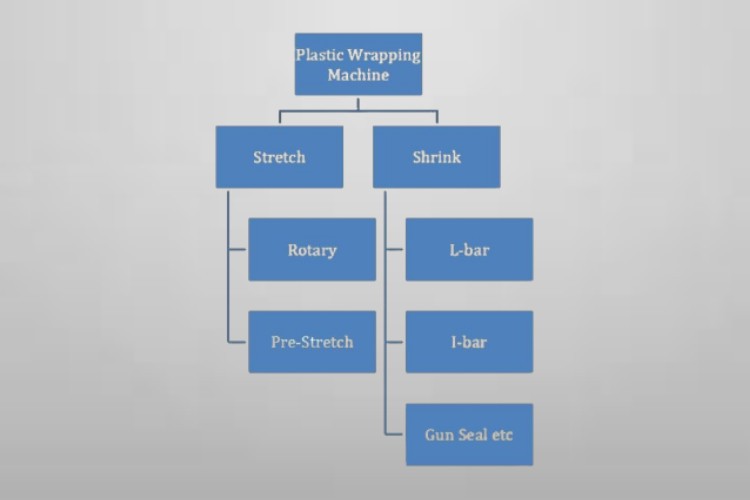

6.What are the types of plastic wrapping machines?

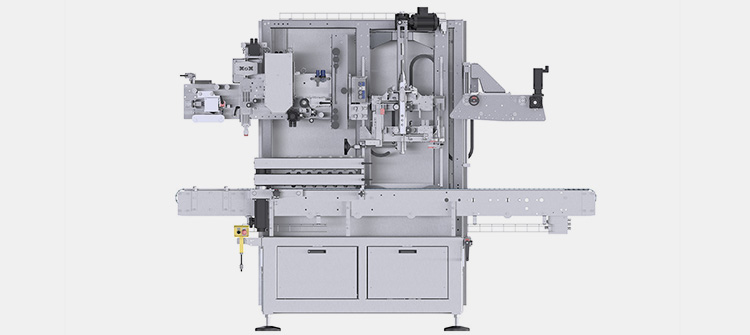

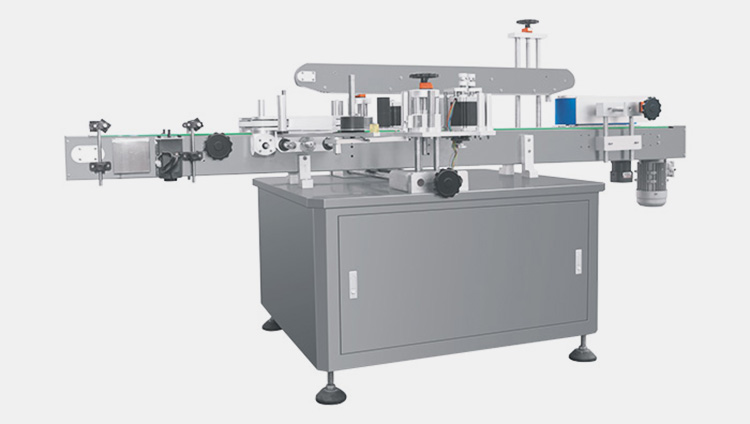

Plastic wrapping machines are the go-to solutions for businesses seeking optimum product packaging. Plus, they are available in different varieties to suit your business’s unique needs. The plastic film laid out by plastic wrapping machines has a thin, flimsy outlook, and their quality of taut and secure packaging is unparalleled.

To choose the best plastic wrapping machines for your product here’s all you need to know about the famous types of plastic wrapping machines.

Stretch Wrapping Machine

Stretch wrapping is a method of wrapping hefty goods in plastic film making full use of its elastic potential. You’ve probably already seen one of these machines at airports and cargo stations.

Types of Stretch Wrapping Machine

● Rotary Arm Stretch Wrapping Machine

These rotary arm stretch wrapping machines throw plastic films right at the product and work their way up. This plastic wrap machine allows seamless tight packaging with no manpower required. If you need hefty loads securely packed for easy transport and protection, then turntable plastic-pallet wrap is the best way around it.

Main Parts OF Rotary Arm Stretch Wrapping Machine

1.Rotary Arm

This is a one of the main parts of rotary arm stretch wrapping machine,by the rotating of rotary arm,the products can be tightly wrapped by plastic film.

2.Control Panel

The function of control panel is to control the working process of the machine,set up all kinds of parameters during the working process.

3.Stretch Wrap Holder

This part is to hold the plastic film which is used to wrap products,the film is fixed on the holder,which can ensure the smooth and precise wrapping process.

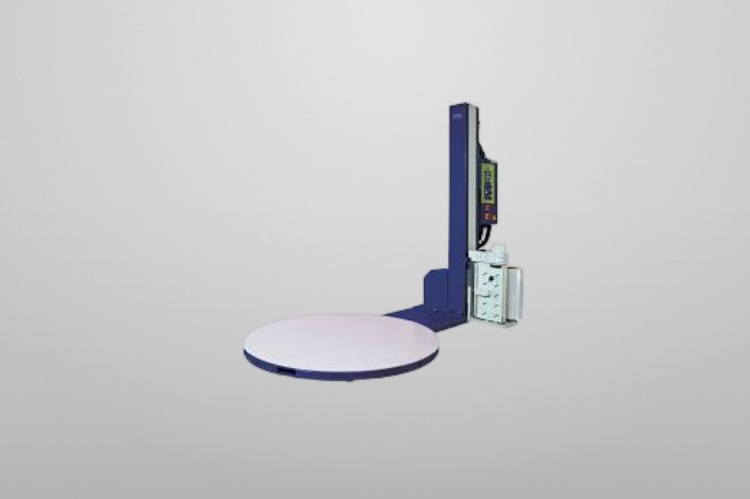

- Pre-stretch Pallet Wrapping Machine

The pallet wrapping machines have plastic films wrapped into a roll in a pre-stretched state. This type of wrapper machine requires less energy investment in stretching the film to build up elastic pressure. More so, a pre-stretch film is double the amount of plastic film present in conventional pallet-wrapping machines.

Main Parts of Pre-stretch Pallet Wrapping Machine

1.Automatic Programs

Modern plastic wrapping machines have up to 7 and more programs to ensure basic safe and precise pallet wrapping. These programs function to adjust height of the film dispenser, manage layers of wrapping, ensure appropriate film tension, and error-free task execution.

2.Extensive Control Panel

For automatic machines such as pre-stretch plastic wrapping machines, the control panel is the summary of all adjustable functions. The easier the control panel, the better will be the operators command over the process.

3.Security Blocking Code

Since automatic machines are liable to uncontrolled mishaps, erroneous code blockage and instant action stop options are made possible by the security codes.

4.Turntable

A characteristic of pre-stretch pallet wrapping machine is that is has a turntable,put the products on it,and the turntable begins rotating,then the film will be wrapped on the products.

5.Stretch Wrap Holder

The same as the rotary arm stretch wrapping machine,this types of stretch wrapping machine also has a stretch wrap holder,to hold the plastic film.

Shrink Plastic Wrapping Machine

The shrink wrap method is a heat-inclusive wrapping process in which plastic film is made to contract to the size of the product under heat. It is by far the best wrapping method to pack up small, singular objects alongside various edible items.

Types of Shrink Wrapping Machine

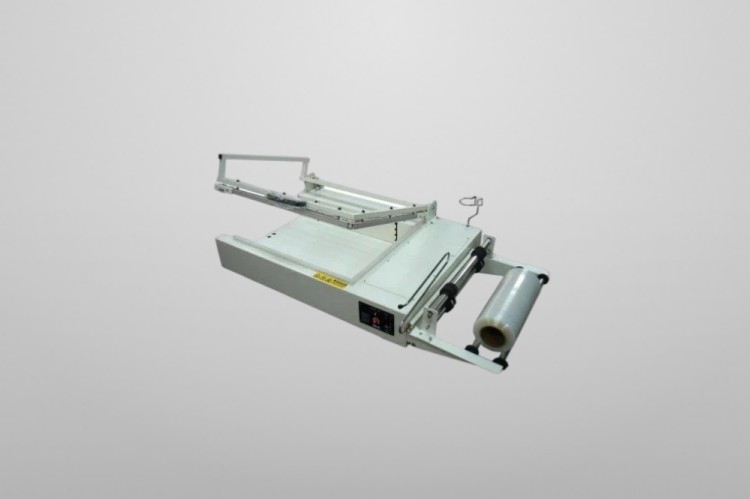

- I-Bar sealer

These single, elongated bar sealers are the best shrink-wrap options for low-output businesses. With variable temperature settings, the I-bar sealer easily seals up wraps at blind ends like that of tubes, and transverse ends like in bags. Using this machine, you can easily pack up to 200 and 300 medium-sized packages per day.

Also, the incorporation of plastic film rolls close to the silicone bar in this plastic wrap machine turned out to be of great help with sizing and sealing.

● L-Bar sealer

This one is the most efficient heat sealer for wrapping up small to medium-sized products. This machine is basically a heated L bar that seals shut the two sides of a plastic wrap. Later the sealed package undergoes a heated chamber where the entire plastic film shrinks to the product’s size. L-sealers are not only time saving but also easy to assemble and function.

- Shrink Tunnel

Shrink tunnel takes a use of hot-wind to shrink wrapping products,it is a types of common plastic wrapping machine,the temperature,height of the tunnel are both be adjustable.shrink tunnels are most suitable for heat shrinkable film such as PVC, POF, PP etc.

Main Parts of Shrink Tunnel

1.Heater Bank

This is the most important part of shrink tunnel,the function of it is to provide heat,it is equipped with standard heating elements,when the machine is powered on,the heater bank also begins its work,the heat will be distributed to the whole tunnel evenly.

2.Blower motors

Blower motors is to provide wind to the tunnel,let the air in the tunnel be circled,the purpose is to let the heat evenly distributed to the tunnel,but,if the motors blow too much air to the product,there is a risk of burning of the shrink film.

3.Conveyor

It is obvious that the function of conveyor is to deliver products,from the entrance to the exit,it will move the product at a uniform speed, so that the product is evenly heated, so as to achieve a better shrinking and wrapping effect,and the speed of the conveyor is adjustable.

4.Control Panel

The control panel is to control the parameters of the shrink tunnel,it is mainly used to control the temperature and the speed of conveyor.

● Heat Shrink wrap gun

Heat shrink wrap guns are the handiest tool for industrial labor packing up to 100 goods each day. These easy-to-carry shrink-wrap guns are designed to ensure a heat-controlled fast seal in a matter of minutes. The heat shrink wrap guns are electricity-powered or gas-powered, and both variants make excellent domestic-grade sealers for small to medium-sized packages.

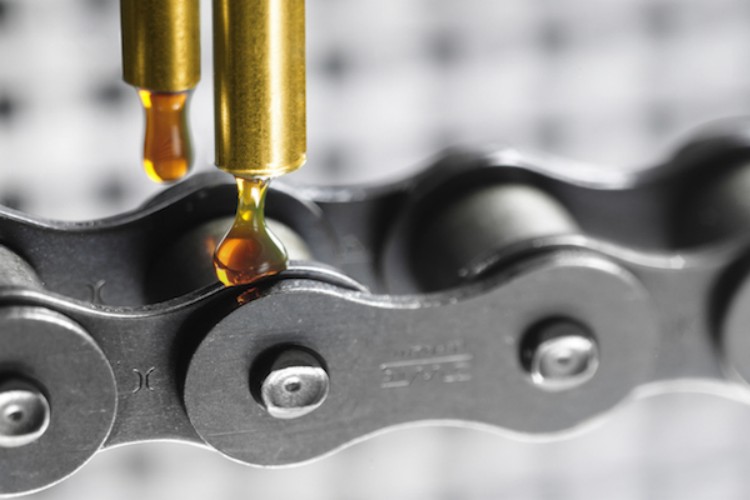

7.How to maintain plastic wrapping machine?

This machine is quite easy to maintain and doesn’t require a complex method for its cleansing. Let us discuss some of the points which would help us understand how this machine can be maintained.

- Lubricate the components of the machine with oil. This will prevent friction, improve their efficiency and increase their life.

- The machine should be regularly inspected. Each part should be checked to see if they are working as efficiently as they can.

- For cleaning, wire brushes are used to clean blades and peeling agent. They can also be cleaned with a fabric cloth to remove any dust on the machine.

- The machine should not be kept in a place where the room temperature or the humidity is too high.

- The machine should be kept on a stable ground at an appropriate angle to prevent it from getting damaged.

- The room in which the machine is kept should be properly ventilated to ensure the safety of the machine and the people working around it.

8.What is the marketing strategy of plastic wrapping machine?

Plastic wrapping machine would be an excellent choice to install it in your industry due to its unique features and benefits it offers. This machine offers safe packaging for your products, protecting them from any harm. This ensures that the customer does not have to worry about paying for the damages, providing huge profit returns to the industry. Moreover this machine also gives the industry to promote its brand by printing the logo of the company on the plastic wrap. As a result they can easily promote their brand, without investing huge sums of money into marketing their brand.

The machine has the ability to package not just one, but hundreds of different kinds of products. This eliminates the need to buy other machines for packaging, making the whole wrapping process cost effective.

9.What quality standards should plastic wrapping machine conform to?

There are a number of quality standards issued by certain organizations around the world which ensure that the machine is carrying out the wrapping process in a safe and organized way and would not pose any harm to the environment and the people. These quality standards are as follows.

Current Good Manufacturing Practices Quality Standards (cGMP)

This ensures that the production of the good is of high quality standard and the industry is using raw materials of good quality. Plus it also meets the current standards needed to pass the criteria which is issued by this organization.

International standard organization quality standard (ISO)

This gives the guidelines for quality control and ensure that the product which is being packaged meets the criteria.

Electronic quality standard (CE)

This ensures that the product being satisfy the needs and is safe for public health and environment.

Food and drug admin quality standard (FDA)

This organization gives guidelines for public health protection.

10.What are the factors which need to be considered before buying the plastic wrapping machine?

Plastic wrapping machine has different types which are suitable for certain kind of products. Thus before buying this machine, there are a few points one needs to consider to ensure proper investment.

Which type of plastic wrapping machine is suitable for a particular industry

This machine has a various types like manual, automatic or semi-automatic plastic wrapping machine. Each of this type has its own unique features, efficiency, speed and cost price. Thus the customer needs to check which type of plastic wrapping machine would be best suitable for his industry.

Production capacity

Since different types of plastic wrapping machine have different production capacities, the customer needs to check which type would be the most efficient for his industry. If he has a large scale industry, automatic plastic wrapping machine would be the best option whereas a manual plastic wrapping machine or a semi-automatic plastic wrapping machine would be suitable for small scale businesses.

Authenticity of the manufacturer

The customer needs to check that the manufacturer he’s buying the machine from is authentic and approved by the government.

Space requirements

Different types of plastic wrapping machine have different space requirements. Automatic plastic wrapping machine takes considerable space whereas semi-automatic and manual plastic wrapping machine take comparatively low space. Thus the customer needs to know which type would be able to fit in his production line.

Budget limitations

Since each type of this machine has its own cost price, the customer has to decide how much investment he’s willing to make and buy accordingly.

Conclusion

After discussing all the points above, we can deduce that plastic wrapping machine is one of the most efficient, convenient and easy to use machine to wrap manufactured goods.This machine is the perfect choice for anyone who wants his products to be packaged in a safe and hygienic way and ship them to their final destination without any worries!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Plastic Wrapping Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours