Types Of Packaging Cans

Packaging is broad term that carries several titles under its umbrella among which packaging cans is also most popular. The significance of packaging cans are increasing day by day due to the high degree of safety it gives to enormous products.

There are various types of packaging cans utilized for different purposes and items including drinks, sweets and cooked food etc. If you are also in search of getting best packaging cans you should first explore the types of packaging cans, their uses and advantages to better understand their usability. For that, just continue to read the details below!

1.What Are Packaging Cans?

Packaging cans refers to the process of storing products in containers made up of steel, aluminum or tin. It is mostly done for packaging of food items in order to better enhance their lifespan.

The reason behind adoption of packaging cans instead of pouch sealing or other means is the convenient portability and durability of cans. Most importantly, the direct consumption of inner material like beer or beverages make it more appealing for buyers. Today, the developed countries are more used to these packaging cans in their daily life.

2.Describe Different Types Of Packaging Cans?

When it comes to knowing different types of packaging cans, you must not be left with any information regarding material used in these cans. Following are the details about types of packaging cans:

Metal Cans

Metal cans are prepared from steel or aluminum tin with chromium coated steel. It is hard in nature and more durable that it cannot be easily deformed during transportation. Metal cans are having strong barrier against moisture, external gases and most importantly refract ultraviolet radiation thus preventing content decay. Metal cans are mostly used for cooked food, cosmetic products, confectionaries and paint etc.

Aluminum Cans

Aluminum is very thin form of metal which is popularly brought into use by many industrial sectors. It is cheap by nature depending on the volume and is too light by weight. It is corrosion resistant and is suitable for material that needs proper protection for preserving color and flavor. Moreover, the beverage industries, wine industries and food processing firms are highly dependent upon using aluminum cans.

Tin Cans

Like aluminum, tin is also formed by thin metal, however its color and nature is different from aluminum. Tin is cost-effective and light weighted as a result of which its presence can be found in every enterprise that is linked with any sort of producing soft drinks, medications, jam and liquid foods etc.

Paper Cans

You might be surprised after knowing that cans are also created from paper, and they have good consumer preference due to their sustainability and attractive appearance. With reclosable lid you can use paper cans for long time. You may not be unaware of paper cans usage by noticing the packed potato chips, dry fruit, candies and baked goods in them.

Plastic Cans

Plastic is most commonly used for packaging purpose in form of sealing pouches, containers and bottles. But, now it is also undertaken for making cans due to its alluring colors and transparency which remains the same even after colored surface. Furthermore, it reduces the risk of damaging your inner content by rust and ensures full security to your drinks, food, chemicals and cosmetics etc.

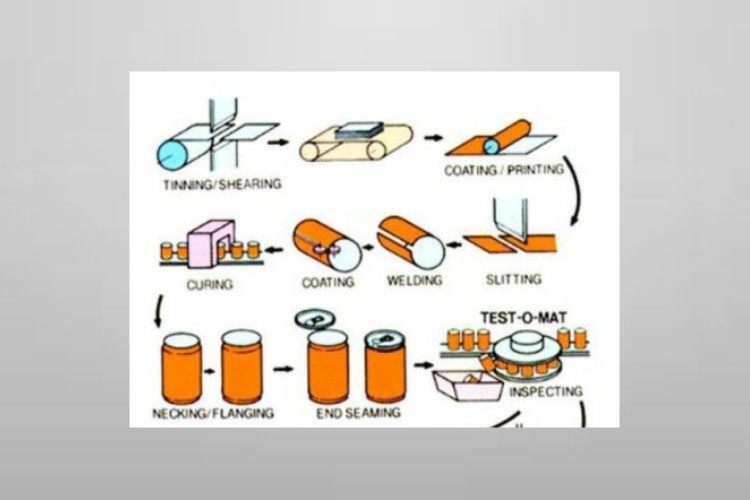

3.How Does Cans Are Prepared And Which Material Is Used For Coating?

The process of making cans is quite interesting and simple to understand which involves following steps:

Cup Formation

In the very initial stage, sheet of aluminum foil is grabbed by the can making machine. Just after entering the aluminum or steel sheet, trimmers cut it down into rectangle shape which are turned into circular cups by welding at the edges.

Bottom Making

This step is optional, as in two-piece cans bottom of the cup is prepared at the time of cup formation. But, in three-piece cans, bottom, body and cap are separately prepared. Here, the base of can is accurately created by the machine and both body and bottom are seamed on.

Trimming

Once the body of can is prepared, trimmer clean up the sharp and unclear edges of cans. These cans are transferred to washing area through conveyor belt in bulk form.

Washing Stage

In this step, washing of cans is occurred. The initial two flushes include hydrofluoric acid reflux. The last four flushes are of deionized water flowing with high pressure at the temperature of 60°C. Here the six stage of washing is done in which start two stages are composed of hydro

Baking

After passing through various washing stations, all these cans are processed under the warm air of oven for drying purpose.

Printing & Varnishing

The conveyor belt further delivers bottles to a rolling drum which quickly holds the bottles in holders and pass them through printer one after another. Five colors are simultaneously printed over the cans. In order to protect the ink, a layer of varnish is applied over it.

Inside Spraying

Before final step, once again the spraying process is taken place, but that is inside the can in order to fix the barrier between content and aluminum.

Baking

Sprayed cans are conveyed to heating station for making sure that printed ink and inner spray are completely dry.

Necking In

Necking are formed with cans, so it would be easy for companies to fit them over filled cans. Necks are produced in such a way, that there necks are reduced towards inside of cups and embossed on upper side.

Testing

At last, finished cans are tested, in case of leakage they are eliminated from the accurate bundle of cans.

4.For Which Purpose Various Types Of Packaging Cans Are Used?

The purpose of using different types of packaging cans is not hidden anymore. The packaging cans have brought much ease both for enterprises who process the filling content and the consumers who prefer using these cans.

The high degree of portability, sustainability and protection of cans have produced the convenience for users especially in those places where use of glass or containers are prohibited like stadium etc. In such areas, a person can enjoy his favorite drink and wine etc.

In addition, companies who want to brand their products are keen to incorporate cans packaging into their manufacturing line for gaining good reputation.

5.What Are The Shapes And Sizes Of Packaging Cans?

The shapes and sizes of packaging cans are distinguished in their respective spheres which are considered below:

Shapes Of Packaging Cans

Shapes of packaging cans are various, but there are certain reasons behind every kind of cans which are expressed as under:

Rectangle & Square

Rectangle and square shape packaging cans are usually of thick metal as it can prevent the walls of cans from damage. Cans with this shape are popularly used for cooked meals, sea-foods and dairy products.

Cylinder

It can be also called round shape which is frequently suitable for beverages, soft drinks and wine etc. The cylindrical cans require no effort for holding and can be directly used for consumption of drinks.

Irregular

Regardless of the standard shapes of packaging cans, you can make irregular cans with customized designs which would better assist you in identifying your brands among others in international market.

Size Of Packaging Cans

Like different shapes, you would also find some specific sizes of packaging cans which are enlisted below:

| No | Size | Capacity |

| 1 | #300 Can | This size of can has the capacity to hold the material with weight up to 15 ounces. |

| 2 | #2 Can | Can of this size having food holding capacity of 20 ounces. |

| 3 | #2.5 Can | This can is equal to the size of 1 pound and 13 ounces. |

| 4 | #10 Can | It can carry 6 pounds along with 6 ounces and suitable for heavy material like paint. |

| 5 | #303 Can | Can of this ratio can hold 2 cups weight that is equivalent to 27 ounces. |

| 6 | #5 Can | It is equal to 56 ounces. |

6.Which Type Of Material Can be Packed In Packaging Cans?

To broaden the circle of your knowledge, we have picked up the most common and prevalent goods that are always ready for conveying into packaging cans as like:

Drinks

Drinks include all those flowing material which is orally taken in liquid form like juices, soft drink and wine etc. These are most likely to be delivered in packaging cans.

Dairy Products

All the products who are originated from milk sources like butter, cheez, yogurt and milk itself can be better preserved in packaging cans.

Seafood

Seafood is among those products which are highly appreciated for their quality packaging in form of cans. You may find fish, tuna and canned shrimps used by many people.

Baked Items

Baked goods are also often available in canned form like cookies, cakes, biscuits and rucks are usually packed in fully closed cans, so they can be keep away from moisture and

Cooked Food

Mixed vegetables, baked beans, brined mushrooms and other prepared food is always to consume or added further into your daily dishes. These pre-made meals are preserved in cans for taking on picnic, travel and hiking etc.

Sweets

Most of the sweets including confectionaries, jam, desserts and traditional sweet cuisine are still used by many people in ready made form.

Snacks

Different snacks like potato chips, crinkle, waffle and pop corns are frequently poured into tin or paper cans for direct consuming during watching movies, live matches and concerts etc.

7.Describe The Advantages Of Using Packaging Cans?

No doubt, the popularity and demand for packaging cans is the result of many advantages. But what are these by nature, can be acknowledged below:

Durable

One of the prominent features of packaging cans is their durability. They are pressure resistant and easily adjustable in less area. For instance, you can stack them on one another without bearing any fear of their damage due to their maintenance of original shape.

Reusable

Cans made of metal or aluminum are also reusable instead most of the companies pay their customers on returning empty cans. Consumers can also bring them in use such as storing food in refrigerator or take them for outing purpose.

Easy to Peel

The opening method of sealed cans is something not unfamiliar to anyone. The integrated holder on upper side of can lid allow you to easily hold it via hole by your finger and simply push it by exerting pressure against can.

Eco-friendly

All types of packaging cans are sustainable and eco-friendly because they can be recycled. In addition, paper based cans are moisture sensitive and quickly decomposed when directly placed in wet temperature.

Extend Shelf-life

The major benefit of using cans is to prolong life of your food products for longer period, so that they can be consumed for long time without facing any type of quality deterioration or change in quality and taste.

Light Weighted

Tin cans are light in weight which eliminate the difficulty of both its handling individually and during transit. It eventually reduces the cost of shipping due to light weight.

Customization

The shape or design of packaging cans are not something static that would be strictly followed and cannot be changed. Instead, there is more availability of customization for drafting your own shapes of cans by making unique designs.

Multipurpose

The term multi-purpose indicates the advantages of packaging cans even after using them. You can use plastic, metal and paper cans for so many other purposes like decoration, food storage or planting.

Hygienic

Packaging cans are prepared from pure aluminum that is processed through predetermined steps. The protective layer inside cans fully assures that there is strong barrier between can material and content filled, eventually preventing any sort of product damage due to rust or corrosion.

8.What Are The Applications Of Packaging Cans?

There are various areas, who are constantly using packaging cans for their products and these are described below:

Beverage Industry

The beverage industry is from long period of time, constantly engaged in packaging of soft drinks, energy drinks and juices in cans. This method for packaging of drinks is quite easy, environmental friendly and cost-effective.

Wine Industry

Wine industry is now more in need of packaging cans, and it prefers using cans over glass bottles due to the highly sterile nature of glass. Now, the industry is more concerned towards distributing wine in cans especially as a result of the safety and reduction of context loss.

Dairy Industry

Like other industries, dairy sector is also involved in producing various products and their exact packaging in form of cans such as cream, condensed milk, butter and cheez etc.

Confectionary Industry

The word confectionary is composed of lots of material, but in its simplest form all the sugar rich food items can be labeled as confectionary as chocolates, fondant, pudding etc. Different famous brands and bakeries used to present their best services of delivering fresh confectionaries in form of packaging cans.

Food Processing Industry

Products like ketchup, ready to eat meal, seafood, vegetables, and fruits are common examples of food items which are provided to consumer in full secure form of packaging cans.

Medical Industry

In medical sector, various nutritional syrups, medicines and storage for various tests, the packaging cans are often admired for being hygienic, rigid and stable.

Cosmetic Industry

You may be amazed that how packaging cans are utilized in cosmetics. The bottles for body spray, perfumes or lotion are mostly of aluminum. They are made in same way as simple cans are prepared.

Paint Industry

Paint is thick decorative color used for covering the surface of walls, door or furniture etc. The thick nature of paint is difficult to keep liquidized and away from air, but this is done by packaging cans.

9.Explain The Disadvantages Of Using Packaging Cans?

Despite lots of benefits, there are still few disadvantages of packaging cans which are displayed to you as under:

Damage Acidic Content

Some products are acidic by nature like chemicals, medicines and even food products. It can lead to can rust and corrosion which will resultantly deteriorate both the content and can.

Expensive

Metal is now expensive, and using it for such large quantity of cans can overburden you, and you would resultantly increase the rate of goods which something unfavorable.

Low Water-resistance

Paper cans are easily get deformed due to low water resistance. That’s why you have to be strict in keeping the surrounding of your paper cans in moisture proof area.

10.How To Choose Best Packaging Cans And Machine For Producing Cans?

To choose packaging cans and machine which are exactly according to your requirements, look into following points:

Nature of Products

What type of products you are desiring to pack in packaging cans? Is it liquid, solid or gas type? What is the thickness ratio? If the products are of liquid like juice, sauces or confectionary, you should use metal or aluminum cans. On the other hand, solid food including snacks, baked goods and dry fruits can be packed in paper cans.

Production Volume

This question is related to the can making machine which requires you to determine the volume of your production. If you are associated with ordinary or medium scale processing, a semi-automatic can making machine will meet your needs. Although, for large manufacturing line you must have to bring automation for high output.

Size of Cans

The size of cans entirely depends upon how much quantity you want to pack in each can. By choosing standard sizes of cans, you can better manage the material that is to be filled in them.

Staff Training

Processing packaging cans is not any game rather it is highly responsible task which enable you to hire an experienced staff or train them with necessary information and precautions. Because, a minor mistake can cause harmful damage.

Conclusion

The packaging cans are generally metal or aluminum based containers which are highly flexible because of the capacity of storing huge number of items. Today, most of the world’s largest companies are solely relying on using different types of packaging cans. If you are also among them or want to be part of them just contact Allpack for cans making machines. Don’t hesitate to contact us for further information.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide