10 Best Case Sealer Manufacturers In The World:The Definite Guide In 2025

10 Best Case Sealer Manufacturers In The World:The Definite Guide In 2025

Do you know case sealer has been more and more popular in industries?The machine can help you tape and seal your boxes automatically and realize flow line production.No matter you are in food packaging industry,express industry or other industries which need many boxes,you will have a need for case sealer.

However,when you have a plan to buy a case sealer and begin to look through case sealer manufacturers,you will find that there are too many,you have difficulty choosing one of them.Don’t worry!This article will help you,the 10 global best case sealer manufacturers are listed to the below,and each one of them is worthy to trust.

| Rank | Manufacturers | Headquarter |

| 1 | Lantech | USA |

| 2 | INSITE | USA |

| 3 | Crown Packaging | USA |

| 4 | Massman | USA |

| 5 | Allpack | China |

| 6 | Combi | USA |

| 7 | Pearson Packaging | USA |

| 8 | Rapid Packaging | USA |

| 9 | Hamrick | USA |

| 10 | BeskPack | USA |

1.Lantech

Company Background & Information

Lantech was established in 1972,until the development of 50 years,it has become a reputed leading manufacturer of case sealer.It mainly manufacture stretch wrapping machine and case equipment.

This company takes providing packaging solutions and reduce customers’ loss as its mission,therefore,it keeps providing durable and stable packaging machines to customers.

Key Products

CS Random Case Sealer

CS1000 Case Sealer

Lantech case sealers can fit different types of cases,and can seal them at a high speed which up to 30 cases per minute.These machines are convenient to operate,and easy to control and adjust,and cases which are sealed by these machines have neat 90 degree angled corners and beautiful appearance.

Recommend Reason

- Lantech has offices which coverfour continentsand two manufacturing facilities,and it also has sales and technical support all over the world,which means you can enjoy its service no matter where you are.

- Lantech has a team of skilled,professional and experienced staffs,which can effectively help you resolve your packaging problems and demands.

- Lantech has focus on manufacturing of case sealers from its beginning,and it has done many researches and innovations on these machine,so you can totally trust the quality of these machines.

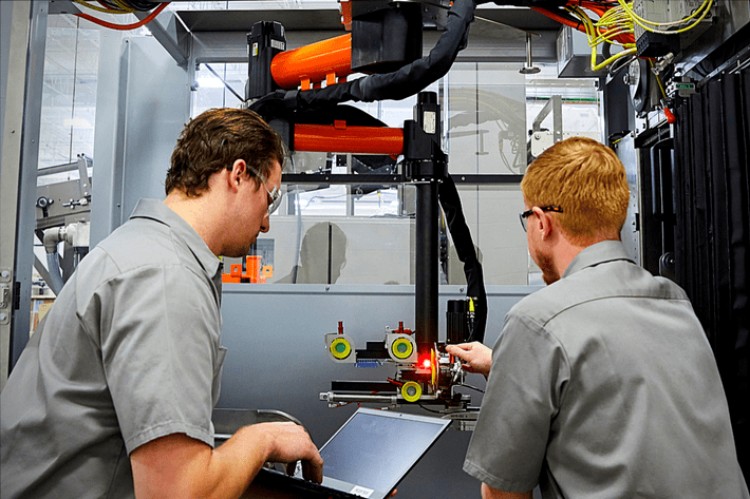

2. INSITE

Company Background & Information

INSITE has a history which is reach 55 years,its purpose is to resolve troubles for customers,for this purpose,the company has constantly searching for methods to improve the quality of its machines.It provides customers reliable,smart machines which have reasonable prices.

Key Products

INSITE Case Sealer

As the picture shows,the machine is equipped with advanced touch screen,spring-loaded side belts and full-length guard doors.Therefore,the case sealers which are made by INSITE have many strengths such as reliable performance,easily control,safe operation,running smoothly and efficiently,etc.

Recommend Reason

- If you buy case sealers from INSITE,the company can ensure the punctuality and safety during the delivering period.

- INSITE provides excellent customer service,for instance,it provides you with 24/7 technical support,in addition,it also offers three years warranty,which can perfectly protect your right.

- INSITE focuses on case erectors and case sealers,which means that it has high degree of professionalism in this field,and due to the 55 years’history,the company has accumulated much experience,so you can totally trust the quality of its products.

- INSITE insists of innovating,exploring and developing its technologies,aims to improve the quality of its machines and gives customers more comfortable using experience.

3.Crown

Company Background & Information

Crown Packaging was established in 1969,it is one of the leading case sealer manufacturers of industrial packaging products and equipment.The company takes help industries improve their business by providing the most proper packaging solutions as its mission.

During the past decades of years since the company’s foundation,Crown Packaging has constantly expanded its scale,has provided machines for thousands of customers in over 50 locations around the world.

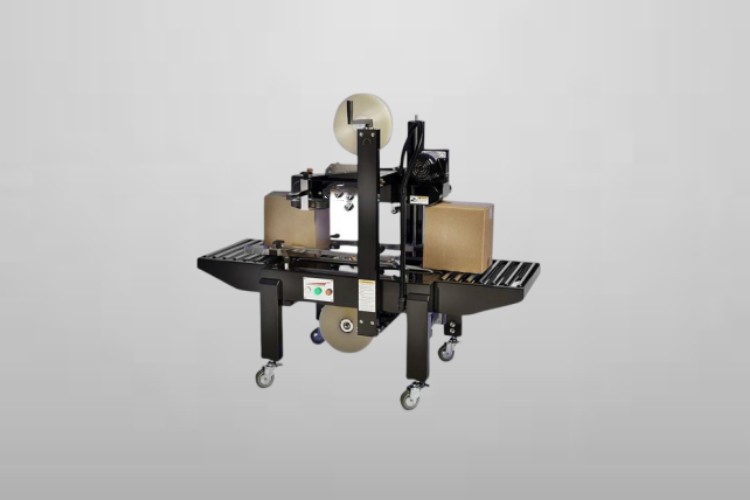

Key Products

Crown Packaging Case Sealer

Crown Packaging Random Semi Automatic Case Sealer

The case sealers of Crown Packaging have compact structures,they will occupy less space than other machines.These machines have high volume that they can pack a large number of boxes which are in uniform size or random size.What’s more?These machines also have advantages such as high speed and simple operation.

Recommend Reason

- Crown Packaging does not only provide case sealers,but also provides other packaging machines as as stretch wrapping machines,strapping machines and labeling machines,besides,it provides packaging materials such as plastic film,boxes,bags and tapes,which can meet all kinds of packaging demands.

- Crown Packaging has established cooperation with many international companies,which means it has good reputation in the packaging industry.

- Crown Packaging has ateam of experts,technicians and engineers who have passions inhelping your business,with the help of this professional team,you can get perfect packaging solutions.

4. Massman

Company Background & Information

Massman is located in the heart of Minnesota,it is a company which was founded in 1978,until now it has been 45 years.The company takes be the preferred long-term partner for automated solutions as its vision and keeps on hard-working for this aim,and the staffs of this company always try their best to serve customers.

Key Products

Elliott MS-30T Case Sealer Machine

HMT-Mini Case Sealer Machine

The case sealers of Massman can seal quantities of cases in limited space and time,they can be adjusted to adapt to different sized cases,the speed of these machines is quite quick which can up to 30 cases/minute.

Recommend Reason

5.Allpack

Company Background & Information

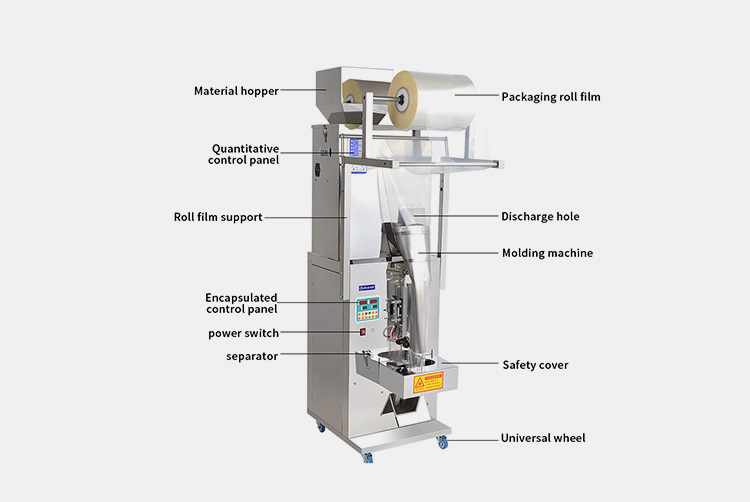

Allpack is a manufacturer of all kinds of packaging machines,it has a history of 12 years,it aims to provide perfect packaging solutions and services to customers.The range of its products is quite wide,which includes strapping machines,labeling machines,all kinds of sealing machines and so on.

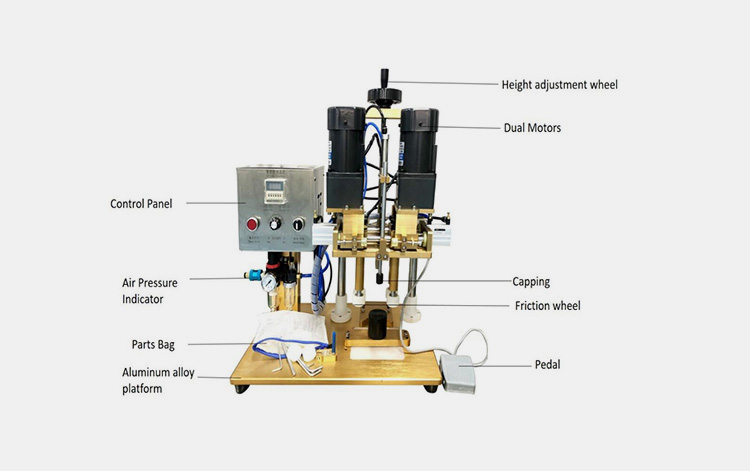

Key Products

Allpack case sealers are suitable for all kinds of cases and have high degree of automation,the machines are easy to operate and durable,and they also have high sealing speed.These machines conform to ISO certification,and have a wide range of applications.

Recommend Reason

- Allpack tries its best to research and develop world top class packaging machines,aims to provide good packaging solutions which can catch customers’satisfactions.

- Allpack possesses a team of professional engineers and technicians,and it also has complete infrastructure,so it can ensure the perfect production process of machines.

- Allpack is one of the leading manufacturer in the world,it has strict test system and extensive logistics network,the machine will be tested before delivery,which can ensure the quality of it,and the company can deliver the machine to you no matter where you are.

6. Combi

Combi is a worldwide packaging equipment manufacturer which was started in 1979,it provides customized and flexible packaging solutions to customers to increase their production.The company has established strategic cooperation relations with world class companies,which makes it stronger.

Key Products

Combi Semi Automatic And Automatic TBS Case Sealer

Combi Heavy Duty Case Sealer

Combi case sealers are sanitary and have high level modern appearances,they adopt high end and advanced technologies and components,which makes them have high quality.And meanwhile,the machines are versatile,they can seal a variety of cases semi automatically or fully automatically.

Recommend Reason

- As a leading packaging equipment manufacturer around the world,Combi provides packaging machines to a diverse of industries to make their productions more convenient.

- Combi has its special customization service,you can get the most suitable packaging equipment after discussing with the engineers of this company.

- The machines produced by Combi will not be too expensive,the price is the the range which most of people can afford,the company will offer you good packaging machines in the range of your budget.

- Combi engineersand manufacturespackaging equipment such as case erectors, tray formers, case sealers,robotic packaging systems and ergonomic hand-packing stations.,which can totally meet your changing demand.

7. Pearson

Company Background & Information

Pearson Packaging was founded in 1955,it has a long history,until now,the company has sold over 21,000 packaging machines all over the world,it’s no doubt that Pearson Packaging is at the top status in the packaging filed.As a leader of this industry,Pearson Packaging has cooperated with many companies to expand its scale.

Key Products

Pearson Packaging CE25-G Random Case Sealer

Pearson Packaging CE35T Case Sealer

The case sealers which are produced by Pearson Packaging can help you largely increase your output cause they can seal 25-42 cases per minute.As the picture shows,they are equipped with touch screen,which can help you easily operate them,and the four-side guard system can guarantee the safety of operator.

Recommend Reason

- The machines of Pearson Packaging adopt the most advanced technologies,to ensure the high automation of them,which can better help customers in their business.

- Pearson Packaging has a history which is over 65 years,it has abundant experience in this area,so you can trust the quality of the machines which are provided by this company.

- Pearson Packaging provides complete and practical technical services such as tune-up,service and run support,remote service support and training.The company will dispatch technicians and engineers regularly to help customers with installation, commissioning, servicing and troubleshooting.

8.Rapid

Company Background & Information

Rapid Packaging was established in 1976,from the beginning,the business was in a farm,and over the past 47 years,the founder has constantly developed its company scale,and acquired other companies,until it has today’s scale.

Now,Rapid Packaging is a large manufacturer of end-of-line equipment and cooperates with world class companies.

Key Products

Rapid Packaging Side Belt Case Sealer

Rapid Packaging Top and Bottom Case Sealer

The case sealers made by Rapid Packaging have high stability,can seal cases smoothly and quickly,and the operation of these machines can be simple and flexible.The machines are made of high level materials that they are durable,have long service life.Besides,these machines are versatile that they are suitable for various cases.

Recommend Reason

- Rapid Packaging possesses mature managements,professional and skilled engineers,experienced marketing specialist and many other good staffs,they are all serve for customers.

- Rapid Packaging insists that it should resolve customers problems at once,it can guarantee to offer customer with quick and useful packaging solutions.

- Rapid Packaging has good credit in the packaging industry since it always establish good and long-term cooperation with customers,it is a trustworthy partner.

- Rapid Packaging provides a variety of packaging machines of different models,these machines have their own advantages and features,which can help you in all aspects in your business.

9.Hamrick

Company Background & Information

As a manufacturer and supplier of end-of-line packaging equipment,Hamrick was started in 1975.Hamrick has high market competitiveness because it provides packaging machines which are durable and have reasonable prices.The machines of Hamrick are very suitable for industries which need flow line production.

Key Products

Rapid Packaging CS30 Hot Melt Case Sealer

Rapid Packaging TT25 Case Sealer

The case sealers produced by Rapid Packaging can be used as independent packaging machine,and they can also be used as a part of packaging production line.These machines are of different models,the speed of them is in the range of 25-50 cases per minute.

Recommend Reason

- Rapid Packaging offers perfect customer service and technical support,can give you good cooperation experience.

- Rapid Packaging has professional and complete infrastructure,which can ensure the machines are produced quickly and safely,meanwhile,the machines are high quality.

- Rapid Packaging has experienced engineers,who will test the quality of machines strictly,to ensure the machines have no problem before they are delivered to customers.

- Rapid Packaging has constantly innovated and improved its machines,aims to grow new designs to meet the changing trend of the market.

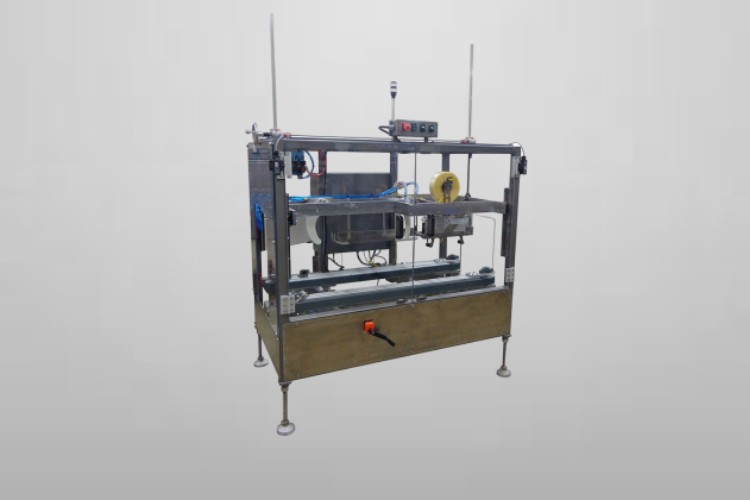

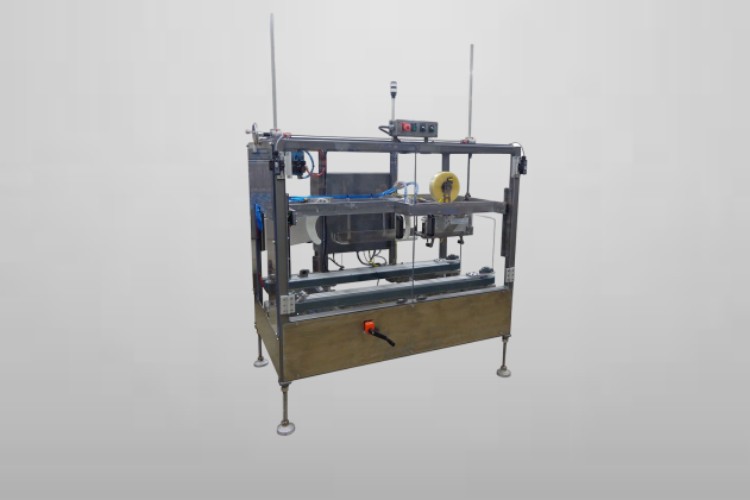

10.BeskPack

Company Background & Information

BestPack was founded in America in 1984,it is an expert in the packaging and sealing industry,it has focused on this filed for almost 40 years.BestPack provides cost effective and high quality packaging machines,the machines produced by this company are sold in over 48 countries.

Key Products

BestPack AQ Case Sealer

BestPack CSF Case Sealer

BestPack have various series case sealers,although these machines have different appearances,they have the same advantages,such as high speed,high accuracy,high automation and low consumption.Moreover,these machines are made of 304 stainless steel,so they are quite sanitary.

Recommend Reason

- BestPack provides complete technical support,for instance,it provides maintenance service for machines.

- The packaging machines provided by BestPack have long service life,their average lifetime is over 20 years,so the cost effective of these machine is pretty high.

- BestPack always applies the newest technologies in its machines,to ensure the machines can adapt to people’s demands in different periods.

- BestPack offers customization service,if you can not find your satisfied machine among the existing series,you can customize one according to your requirements.

Conclusion

In summary,this article gives a detailed background and product introduction to the above 10 best case sealer manufacturers in the world,and it is believe that you already have a primary realization about them.You can choose one of them according to your real requirements,and if you have any other problems,welcome to contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

10 Best Case Sealer Manufacturers In The World:The Definite Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours