Small Capping Machine: The Complete Buying Guide In 2025

Do you have a small production facility or are you considering expanding your current operations? If so, investing in a small capping machine might be the perfect solution for you! This versatile piece of machinery can easily and quickly cap all kinds of containers ranging from beverage bottles, jars to food cans. With a wide range of features available from various companies, there’s sure to be one that suits your needs perfectly.

In this blog post, we will explore on how a small capping machine works, benefits of investing in a small capping machine, different types available on the market today as well as offer tips for deciding which type is best for your applications. Read on for some key information about these machines so that you can make an informed decision when selecting the best option for your particular application.

1.What Is A Small Capping Machine?

A small capping machine is a device that is used to fasten lids or caps onto containers. It is a popular choice for small production runs and low-volume applications, such as small-scale food processing or small craft breweries.

Small capping machines are typically hand-held and manually operated, making them easy to move around the production floor and easy to adjust for different types of caps and containers. Also, these machines offer an economical solution for small-scale production, as they require relatively little space, energy, and maintenance compared to larger models.

Additionally, small capping machines can be configured to fit various bottle sizes and cap shapes thus offering a versatile option for small businesses. Small capping machines are often used in food and beverage production, small medical facilities, small-scale manufacturing operations, or any other industry where small packaging runs are the norm.

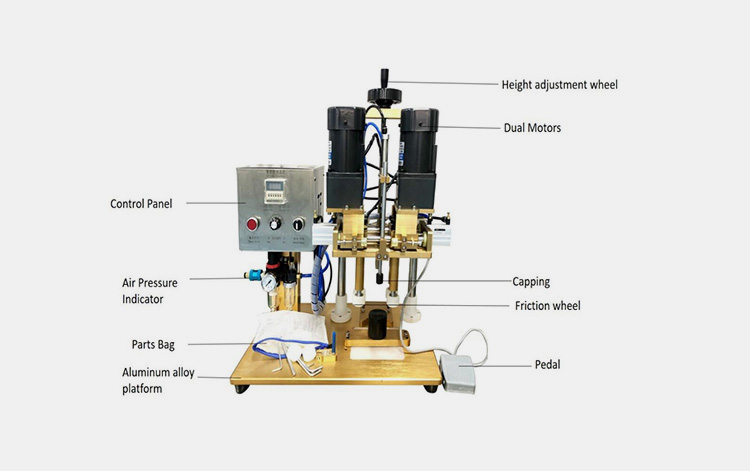

2.What Are The Components Of A Small Capping Machine?

Capping Head

The capping head is the part of the small capping machine that actually applies the cap to the container. It typically consists of a plate with several pins or “fingers” that will grab a cap and press it onto a container as it passes through.

Cap Sorter

The cap sorter is the part of the small capping machine that sorts and feeds caps to the capping head. It typically consists of a hopper or bowl where caps can be placed, a vibrating mechanism to sort them, and a wheel that will feed a single cap at a time for application by the capping head.

Conveyor Belt

The small capping machine has a conveyor belt that brings containers to the capping head for cap application. The conveyor belt is adjustable so that it can be set to move at different speeds and bring bottles of different sizes through the small capping machine.

Safety Guards

Small capping machines typically come with safety guards to protect operators from the moving parts of the small capping machine. The guards are usually made of plastic or metal, and they can be adjusted to fit different sizes of small capping machines.

Control Panel

The small capping machine has a control panel that allows operators to adjust settings, start and stop the small capping machine, and monitor its operation. This panel typically consists of a display screen, push-buttons, and knobs that allow operators to make adjustments as needed.

Motor

The small capping machine is powered by an electric motor which drives the conveyor belt and the other moving parts of the small capping machine. The motor is typically housed in a separate casing which keeps it safe and provides easy access for maintenance.

Sensor

Sensors are used to detect when containers have passed through the small capping machine and the cap has been applied correctly. This helps ensure that all containers are properly capped before they move on to the next part of the production process.

3.What Are The Benefits Of A Small Capping Machine?

Ensures Product Integrity

Small capping machines provide greater control to ensure the integrity of the product. This includes accurate and consistent placement of caps, as well as a secure fit that prevents leakage or tampering.

Improves Product Quality

Small capping machines allow for a more efficient and precise process which results in better-looking products with improved quality and consistency.

Prevents Leakages

Small capping machines are designed with small seals, which can fit precisely around small necks of bottles and containers. Therefore, small capping machines provide an airtight seal that prevents any leakage of liquid from the bottle or container.

Increased Efficiency

Small capping machines are designed to be compact and efficient. They generally require less manpower, are faster than manual capping processes, and can handle small batches of products quickly with ease.

Tamper Evidence

Small capping machines can be used to provide tamper-evident seals for small containers, helping to deter tampering and protect against counterfeiting. This is particularly important in industries that require strict quality control regulations.

Quality Control

Small capping machines help ensure quality control during the capping process by consistently applying caps of uniform size, shape, and pressure. This helps ensure that the product has been securely sealed and will not leak during transportation or storage.

4.What Are The Applications Of A Small Capping Machine?

Food Industry

Small capping machines are used in the food industry to seal bottles and jars with metal, plastic or aluminum caps. This ensures that the product remains fresh for longer periods of time and is securely contained.

Pharmaceutical Industry

Small capping machines are widely used in the pharmaceutical industry to accurately apply tamper-evident seals to medicine bottles. This ensures that the products remain secure and unaltered until they reach the consumer.

Cosmetic Industry

Small capping machines are used in cosmetics manufacturing to securely cap small containers, such as lipstick tubes and mascara wands. This helps to ensure the product is safely contained and tamper-proof for consumers.

Chemical Industry

Small capping machines are used in the chemical industry to precisely apply caps to small containers, such as bottles and vials containing hazardous chemicals or laboratory samples. This helps to ensure that these items remain securely sealed and free from contamination.

Beverage Industry

Small capping machines are used in the beverage industry to securely seal small bottles and cans with metal, plastic or aluminum caps. This helps to ensure that the beverages remain fresh and unaltered until consumed.

5.How Does A Small Capping Machine Work?

The small capping machine operates by first loading the caps into a hopper. The small caps are then fed through a chute and into a spinning wheel that aligns them in position for application.

From there, the small caps are delivered to a chuck or mandrel where they are held in place with adjustable jaws. The cap is then moved by a carriage and placed onto the container’s opening.

As soon as the capping operation is complete, the retainer grabs hold of the cap and keeps it securely in place until it is unscrewed.

6.What Are The Different Types Of A Small Capping Machine?

a) Automatic Small Capping Machine

These small capping machines are fully automatic and require no manual labor or supervision. They can be used to clamp, unscrew and reseal any type of caps at a consistent speed. This machine is suitable for large production lines and can handle high volumes of small caps quickly and efficiently.

Components

Automatic small capping machines are typically composed of the following components:

Bottle Handling System

This system is responsible for transporting bottles from the filling station to the capping station. It uses belts, wheels, and other mechanical elements to move them quickly and accurately.

Cap Sorting System

In order to ensure that the right size and type of cap are used, automatic small capping machines have a dedicated sorting system. This allows them to quickly identify and sort caps into their proper categories.

Feeder System

Automatic small capping machines also feature a feeder system which can dispense multiple types of caps at once, allowing for faster production rates.

Capping Head

The capping head is the part of automatic small capping machines that physically applies the cap onto the bottle. This part is usually equipped with a motor and gear system to provide enough torque to securely apply caps.

Safety System

Automatic small capping machines also have safety systems in place to ensure that operators do not come into contact with the moving parts of the machine. These systems typically use sensors and light curtains to detect any potential hazards.

Control System

Automatic small capping machines are usually equipped with a control system that allows for easy operation and maintenance. This system can be used to set parameters such as speed, torque, and other settings.

Working Principles

The automatic capping machine first positions the containers properly for lidding or capping. This is done by using an automatic feeder system that ensures each container is properly aligned and in place.

The automatic small capping machine then applies a cap onto the container, using a specialized clamping device that firmly seals it in place.

After the capping is complete, the automatic small capping machine inspects the container to ensure that it has been sealed properly. If any defects are detected, the machine will reject and discard the faulty containers.

Finally, after inspection is complete, the automatic small capping machine dispenses a label onto each container. This label includes product information and other details, such as price and bar coding.

Applications

Automatic small capping machines are commonly used in the food industry to seal jars or bottles with condiments such as ketchup, mustard, mayonnaise, and salad dressings. They can also be used to seal cans containing food items such as fruit, vegetables, and grains.

In addition to the food industry, automatic small capping machines are also used in the pharmaceutical and cosmetics industries to securely seal bottles with medication or creams.

Moreover, automatic small capping machines are often used for industrial applications such as sealing containers that contain chemicals, oils, or other hazardous liquids and materials.

Finally, automatic small capping machines can also be used for packaging and shipping applications, ensuring products are tightly sealed for protection during transit.

b) Semi-Automatic Small Capping Machine

These small capping machines are designed to be operated manually and require the operator to clamp, unscrew and reseal any type of caps with one hand. This machine is suitable for small or medium-sized production lines.

Components

The components of semi-automatic small capping machines include:

Automated Feeder

This is a device that is used to feed empty bottles into the machine, which are then filled and capped with appropriate lids.

Dispensing Nozzle

A dispensing nozzle is responsible for providing accurate dosages of the liquid being packaged.

Lid Placing Unit

This component places lids on the bottles before they are sealed with a cap to ensure no leakage occurs.

Sealing Device

The sealing device is responsible for crimping the caps onto the bottles tightly and securely to prevent leakage.

Automated Conveyor

The automated conveyor is used to move the filled and capped bottles from one end of the machine to the other, where they can be collected.

Control Panel

This part of semi-automatic small capping machines is responsible for providing the user interface to control the operations of the machine, such as setting parameters and speeds.

Safety Guards

This part of semi-automatic small capping machines helps to ensure that all parts are safe from harm during operation by preventing any fingers or hands from getting caught in moving components.

Emergency Stop Button

This part of semi-automatic small capping machines is designed to immediately stop the machine in the event of an emergency.

Working Principles

The semi-automatic process begins by placing an empty bottle into the machine, where it will be held in place before the insertion of the cap. A motor then drives the head of the capping machine, screwing the cap onto the container. When properly sealed, the bottle is released and can be sent to the next stage of production.

Applications

Semi-automatic small capping machines can be used in the food and beverage industry to seal products such as sauces, condiments, syrups, oils and juices.

Semi-automatic small capping machines are also used in the pharmaceutical, cosmetics and chemical industries to apply caps on bottles, jars and containers.

Additionally, semi-automatic small capping machines are used to seal cans for storing products such as paints, insecticides and lubricants.

c)Manual Small Capping Machines

Manual small capping machines are manual devices used to accurately seal a variety of containers with tight-fitting caps. These manual machines can be used for both plastic and metal containers, allowing users to easily and quickly secure materials without having to manually screw on each cap.

Manual small capping machines are also capable of applying different types of caps with various shapes, such as tamper evident caps and flip-top caps. Furthermore, manual small capping machines often feature adjustable torque settings for the perfect tight fit.

Components

Tabletop Surface

A manual small capping machine must have a stable tabletop surface to place the containers onto and allow for manual rotation of the cap. This flat, horizontal surface is usually made from stainless steel or aluminum and should have enough room to accommodate large diameter bottles or jars.

Bottle Feeder

The manual small capping machine must have a bottle feeder to ensure efficient manual cap insertion. The manual bottle feeder should be adjustable and capable of accommodating various cap sizes and shapes.

Capping Wheel

This part of the manual small capping machine is responsible for tightening caps on containers. It consists of two concentric wheels and must be able to secure caps of different diameters and shapes.

Cap Dispenser

The manual capping machine must have a cap dispenser that can deliver the correct type and size of cap onto the container for manual insertion by the operator. It should also be adjustable to accommodate various types of caps.

Chute/Rejecter

The manual capping machine must also have a chute or rejecter to separate properly capped containers from those with improperly secured caps. This ensures that only properly sealed containers are sent for further processing.

Control System

The control system is responsible for monitoring all of the manual capping machine’s operations, such as cap supply, manual rotation, and proper cap placement.

Working Principles

Generally, the process of manual small capping machines applies two main principles: compression and torque. The first principle involves compressing the cap tightly against the neck of the container with manual pressure. This helps ensure that the cap is properly sealed and will not come off during transport.

The second principle involves applying the proper amount of torque to secure the cap in place. This is usually done with manual wheel-style tightening devices, which can be adjusted to provide different levels of torque depending on the container’s size and the type of cap being used.

Together, these two principles ensure that manual small capping machines can securely and reliably cap bottles and containers of various sizes.

Applications

Manual small capping machines are suitable for many industries such as food, beverage, chemical, pharmaceutical and cosmetic industries as they provide an efficient way to securely close containers.

d)Pneumatic Small Capping Machine

These small capping machines use compressed air to power their motors. They can be used to clamp, unscrew and reseal any type of caps at a consistent speed. This machine is suitable for large production lines and can handle high volumes of small caps quickly and efficiently.

Components

Compressor

The pneumatic small capping machine contains a compressor to generate pneumatic power for the caps being applied. This can be either an electric or air compressor depending on the model of machine.

Pressure Regulator

A pressure regulator is used to control the pneumatic pressure produced by the compressor. This helps to ensure the pneumatic force applied to the cap is consistent and within tolerance of the requirement.

Cap Tightening Unit

The pneumatic small capping machine contains a cap tightening unit that applies pneumatic pressure on the cap to secure it in place.

Control Panel

A control panel is used to control the pneumatic small capping machine. This allows users to program parameters such as tightening force and cycle time.

Vacuum Chuck

A vacuum chuck is used in pneumatic small capping machines to grip the containers for precise placement of the cap on the bottle or container.

Bottle Turner

A bottle turner is used to rotate the containers and ensure that all sides of the cap are tightened securely.

Sensor

Sensors are used in pneumatic small capping machines to detect the presence of a container, position it correctly for cap application, and check if the cap has been properly applied.

Counter

A counter is used to detect the number of containers that have been processed and can be used for quality control or production tracking purposes.

Motors

The pneumatic small capping machine also contains motors which power components such as the cap tightening unit, vacuum chuck, bottle turner and sensor.

Conveyor

A conveyor is used to move containers through the pneumatic small capping machine and ensure the caps are applied consistently.

Actuator

An actuator is used in pneumatic small capping machines to apply pneumatic force on the cap to secure it in place.

Safety Guard

A safety guard is used to protect users from the pneumatic small capping machine’s moving parts and ensure that it is operated safely.

Electrical Panel

An electrical panel is used in pneumatic small capping machines to control components such as the motors, sensors and actuator.

Control System

The pneumatic small capping machine contains a control system to monitor and manage the system’s operation. This includes parameters such as tightening force, cycle time and total production quantity.

Emergency Stop Button

An emergency stop button is used in pneumatic small capping machines to quickly shut down the system in case of an emergency. This helps to ensure that users are safe while operating the pneumatic small capping machine.

Working Principles

Pneumatic small capping machines are powered by pneumatic pressure, which means they use compressed air to drive their operation.

The pneumatic pressure is generated from an air compressor, and this pressure is used to power pneumatic cylinders, solenoid valves and other pneumatic components that are part of the machine.

These pneumatic components work together to apply force and torque to the caps, enabling them to be securely tightened onto the containers.

Applications

Pneumatic small capping machines are used in a variety of industries for a variety of applications. In the food and beverage industry, pneumatic small capping machines help to package products quickly and efficiently. They are also commonly used in pharmaceuticals, cosmetics, and other industries where precise sealing is needed.

7.What Is The Difference Between Automatic Small Capping Machines And Semi-Automatic Small Capping Machines?

a) Automatic Small Capping Machine

b) Semi-Automatic Small Capping Machine

The main difference between automatic and semi-automatic small capping machines is the amount of human input required. Automatic machines require no manual intervention in the capping process, using sensors to detect the size of bottle caps, adjusting the speed and pressure accordingly. Conversely, semi-automatic machines rely on an operator to feed bottles into the machine and adjust the pressure settings.

In addition, automatic machines are typically faster than semi-automatic machines and can handle a larger quantity of bottles at one time. This makes them ideal for high production applications where speed is essential. Semi-automatic machines on the other hand, are more suitable for smaller production runs or when a greater degree of control is needed.

In terms of price, automatic machines tend to be more expensive than semi-automatic machines as they require more advanced technology and additional components. However, the cost savings gained from automatic machines often offset the initial investment due to their higher speed and efficiency.

8.Are There Any Alternatives To Small Capping Machines That Small Businesses Can Use?

The small capping machine is a popular choice for small businesses, as it is an affordable and easy-to-use solution to apply labels or caps onto bottles or containers. However, there are also other solutions that small businesses can consider when looking for alternatives to small capping machines.

For example, manual cappers are a cost-effective and easy-to-use alternative to small capping machines. Manual cappers are small tools that can be used to quickly and accurately apply caps onto bottles or containers. They are often more cost effective than small capping machines, and they also require less maintenance.

Another option is to use a hand-held electromechanical capper. These machines are small and portable, but they provide a powerful capping solution for small businesses. They use an electromagnetic field to apply caps onto bottles or containers quickly and accurately, making them an ideal alternative to small capping machines.

Finally, automated cappers can also be used as an alternative to small capping machines. Automated cappers are more expensive than small capping machines, but they can be used to apply labels or caps onto bottles or containers quickly and accurately. They are also usually easier to maintain and require less maintenance than small capping machines.

9.What Are The Differences Between Small Capping Machines And Traditional Packaging Machines?

The main difference between small capping machines and traditional packaging machines is in their size and features. Small capping machines are small and lightweight, making them easier to handle and transport than traditional packaging machines.

Additionally, small capping machines are more efficient than their larger counterparts; they can process small batches much faster than large-scale packaging machines, allowing for greater flexibility and shorter lead times.

Furthermore, small capping machines offer increased safety features; they are designed to limit the risk of injury and protect operators from potential hazards. Ultimately, small capping machines provide a convenient and cost-effective solution for small-scale packaging needs.

10.What Type Of Containers Can Be Sealed Using A Small Capping Machine?

Plastic Containers

Small capping machines can be used to seal small plastic containers including jars, tubs, and pouches. The type of cap that is used will depend on the material of the container and its size.

Metal Containers

Small capping machines can also seal small metal containers such as cans and tins with lids or caps.

Glass Containers

Small capping machines are capable of sealing small glass bottles with a variety of caps such as screw, pushdown, and snap on.

Aluminum Containers

Small capping machines can also be used to seal small aluminum cans with a variety of caps as well.

11.How Can Small Capping Machine Production Be Optimized?

Increase Small Capping Machine Speed

Make sure the small capping machines are running at optimal speeds to maximize output while minimizing errors and waste.

Employ Quality Control Measures

Quality control measures such as inspections should be put in place to ensure small capping machines are producing the best quality product with minimal defects.

Invest in Quality Components and Materials

Investing in high-quality components and materials can help small capping machines operate more efficiently and increase the speed of production. Quality components also last longer, reducing the need for frequent repairs and maintenance which can lead to costly downtime.

Ensure Regular Maintenance

To keep small capping machines running in top form, it is important to perform regular maintenance checks and tune-ups. This should include checking all components for wear and tear, lubricating moving parts, and replacing any worn out or damaged components.

Adjust Speed Settings

By adjusting small capping machine speed settings to the appropriate output rate, manufacturers can achieve higher output rates without compromising on quality of production.

12.What Trends And Innovations Should Small Businesses Look Out For In Small Capping Machines?

Automation

Small capping machines can be automated to reduce manual labor and increase production speed. Automated small capping machines are more efficient, require fewer personnel, and result in higher-quality products.

Digitalization

Many small capping machines now come equipped with digital interfaces that allow operators to quickly change settings, monitor production efficiency, and access real-time data. This helps small businesses maximize their resources and stay competitive in a rapidly changing market.

Connectivity

Small capping machines can now be connected to the internet, enabling small businesses to easily communicate with their suppliers, customers, and other stakeholders. This connectivity can help small businesses better manage inventory and provide faster customer service.

Safety

Many small capping machines are now designed with safety features that help protect workers from potential risks. Such features include emergency stop buttons, noise reduction systems, and intuitive design that helps operators more easily understand how to use the small capping machine safely.

13.What Are The Maintenance Procedures For A Small Capping Machine?

Follow these maintenance procedures to keep your small capping machine running smoothly and with minimal issues.

Testing

Test the small capping machine to ensure it is working correctly prior to use. Adjust any small settings or tweaks as necessary.

Cleaning

With a soft cloth and mild detergent, wipe down all of the small capping machine’s components to remove any dirt or dust.

Inspection

Check for any structural damage to the small capping machine, such as cracks or dents in the body, and repair them accordingly.

Lubrication

Lubricate any small capping machine components that move or rotate, such as screws and bolts, to reduce wear on them and ensure smooth operation of the small capping machine.

CONCLUSION

A capping machine is a device that helps in the packaging process of various products by putting caps on them. Allpack is one of the leading suppliers and manufacturer of small capping machines. Therefore, if you are looking for a high-quality and durable capping machine, then you should definitely get in touch with Allpack. We have a wide selection of small capping machines that will meet your needs. Contact us today for more information. Our team of experts will be more than happy to assist you in choosing the right machine for your needs.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide