Continuous Induction Sealing Machine: The Complete Buying Guide In 2025

Are you looking for an efficient and effective way to seal packaging materials? Consider investing in a continuous induction sealing machine. These machines have been used by businesses throughout the packaging industry to provide reliable seal integrity that can help protect products while ensuring they look great on retail shelves.

Not only do continuous induction sealing machines create highly secure seals, but with modern technology advancements such as advanced user interfaces, automated features, visual alarms, and fast changeover times, these machines are becoming even more attractive for buyers seeking high-quality equipment for their business operations.

In this blog post we will explore the benefits offered by continuous induction sealers, enabling buyers like you to make an informed decision when investing in this type of machinery. Ready to learn more? Let’s dive right in

1.What Is A Continuous Induction Sealing Machine?

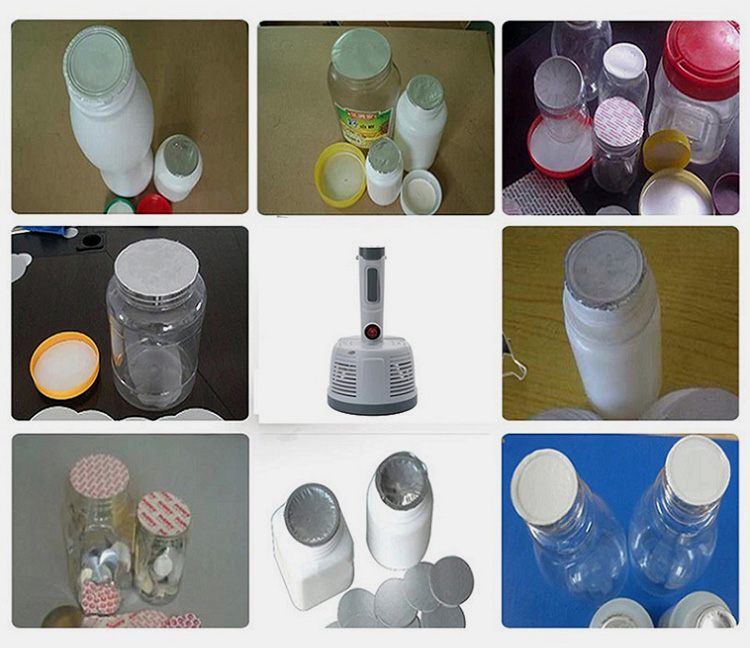

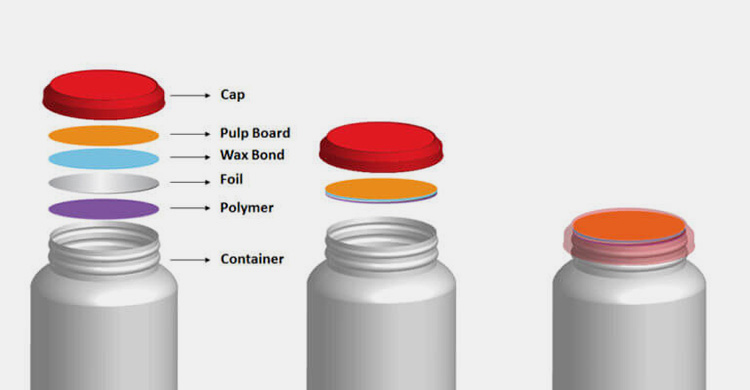

A continuous induction sealing machine is a packaging machinery that uses electromagnetic induction to seal containers, typically made of plastic or glass. This process creates a tight seal by inducing heat into a foil liner which melts and bonds the lid to the container.

Also, continuous induction sealing machines offer increased efficiency compared to manual sealing methods as they require little human input while still providing consistent results with each pass through the system. Moreover, these machines are cost-effective due to their low maintenance needs and relatively long lifespan.

In addition, continuous induction sealing machines are highly versatile and can produce seals of various sizes and shapes, making them suitable for a wide range of applications. This machine is frequently used in food, beverage, cosmetic, pharmaceutical, chemical, and agricultural industries.

2.What Is An Aluminum Induction Sealing Liner?

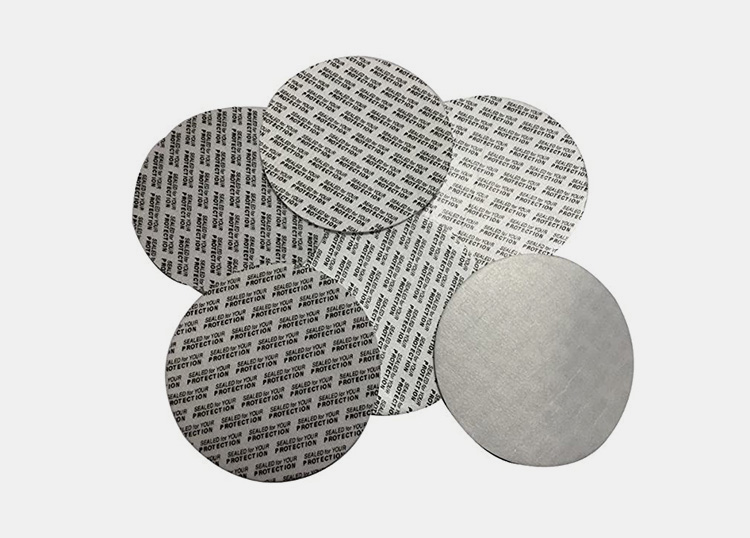

An aluminum induction sealing liner is a type of closure that combines aluminum foil with a paperboard or plastic backing. It seals the opening of containers, such as bottles and jars, to protect contents from contamination and maintain freshness.

The aluminum foil provides an effective barrier against moisture and oxygen, while the backing adds strength for easy application and removal. Induction sealing liners are often used in industries such as pharmaceuticals, beverages, chemicals, and cosmetics.

The aluminum foil can be printed with branding or product information for a professional look. Induction sealing liners provide a cost-effective and efficient way to protect products from contamination.

Also, these liners help preserve freshness and extend shelf life, making them a great option for businesses looking to improve their packaging. Additionally, aluminum induction sealing liners can help reduce product waste due to spoilage.

3.What Are The Components Of A Continuous Induction Sealing Machine?

A continuous induction sealing machine is composed of several components that work together to ensure accurate and efficient sealing operations. These components are:

Induction Generator

This component produces the high-frequency current necessary for heating the foil seal material. It also regulates the output power and can be adjusted depending on different applications.

Capacitor

The capacitor helps store energy, so it can be released as a continuous stream of electricity at a higher voltage than originally supplied by the generator. This is used to create heat in order to properly seal the product container’s lid with foil material.

Sealing Head

The sealing head contains two parts – an upper part (seal head) and lower part (sealer). The sealing head is responsible for containing the induction field and directing it towards the foil.

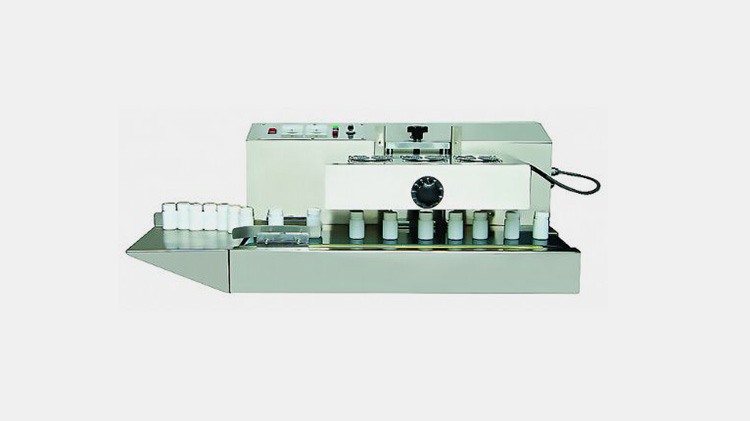

Conveyor System

The continuous conveyor system ensures that the containers are moved through the machine in a continuous flow, allowing each one to pass under the sealing head to be sealed with foil material.

Cooling System

Finally, a cooling system is necessary to prevent overheating of the components during continuous operation of the machine. This helps keep all parts working optimally and prevents any damage from occurring due to excessive heat.

4.What Are The Advantages Of A Continuous Induction Sealing Machine?

Tamper Proof

Continuous induction sealing machines create an airtight and secure seal that clearly shows any tampering with the product. This gives customers peace of mind when purchasing goods as they know they are receiving a safe, unopened product.

Prevents Contamination

Continuous induction sealing machines are designed to provide an airtight seal to bottles and containers, which helps protect the product inside from contaminants, such as dust, dirt, and moisture thus extending its shelf life.

Versatility

Continuous induction sealers are highly versatile and can be used with a range of containers including aluminum foil lids, plastic bottles, glass jars, and more. Additionally, continuous induction sealers can be used with various types of packaging materials such as polypropylene, polyethylene, and PVC.

Extends Shelf Life

Continuous induction sealing machines are designed to create a tight seal that ensures product freshness and extends the shelf life of packaged goods. Continuous induction sealers also help protect sensitive products from moisture, oxygen, and other contaminants that can cause spoilage

5.What Are The Application Of A Continuous Induction Sealing Machine?

Beverage Industry

Continuous induction sealing machines are used to seal the tops of beverage containers such as cans, bottles, and jars. This prevents contamination and tampering. The continuous nature of the machine ensures that each product is sealed quickly and efficiently with minimal waste or downtime.

Pharmaceutical Industry

In the pharmaceutical industry, continuous induction sealing machines provide an efficient way to package tablets and capsules in blister packs or strip packaging without compromising their integrity. The continuous nature of the machine seals each individual package quickly and uniformly, ensuring a high-quality product every time.

Chemical Industry

Continuous induction sealing machines can also be used for chemical products such as detergents, cleaners, fertilizers, pesticides, and lubricants. The continuous nature of the machine ensures that each container is sealed properly and securely, ensuring that the product does not leak or evaporate.

Cosmetic Industry

In the cosmetic industry, continuous induction sealing machines are used to seal items such as lip balms, hand creams, lotions and gels in containers. This prevents contamination and tampering while allowing products to be packaged quickly and efficiently.

Food Industry

Continuous induction sealing machines can also be used for food items such as condiments, peanut butter, sauces and jams. The continuous nature of the machine ensures a quick and uniform seal every time which helps preserve the integrity of the product while preventing spoilage or contamination.

6.What Are The Working Principles Of A Continuous Induction Sealing Machine?

A continuous induction sealing machine works by generating high-frequency electric currents which heat up the foil liner in the container lid and cause it to melt and adhere to the container rim. This creates a tight seal that keeps contents fresh, protects against leakage and contamination, and increases product shelf life.

The continuous induction sealing process begins when a row of sealed containers passes underneath the continuous induction sealing machine’s coil. As soon as the container lids pass underneath the coil, an alternating current is generated which produces an oscillating magnetic field that penetrates through both sides of the lid material.

The heat produced melts the foil liner so that it bonds with the container rim. The continuous induction sealing machine then turns off as soon as the container leaves the coil’s range, and a continuous airtight seal is created.

7.What Are The Different Types Of Continuous Induction Sealing Machines Available On The Market?

Continuous induction sealing machines are specialized tools used to seal containers with a tight and secure fit. There are several different types of continuous induction sealing machines available on the market today, each designed for specific applications:

Automatic Aluminum Continuous Induction Sealer

This type of Continuous Induction Sealer is designed for high speed and large-scale production. It uses a programmable microprocessor with adjustable parameters, allowing for adjustability and accuracy in sealing containers.

Components

The Automatic Aluminum Continuous Induction Sealer consists of the following components:

Automatic Control System

The automatic control system regulates and monitors the entire sealing process. It is designed to ensure that the sealing temperature, conveyor speed, container position and other factors are accurately controlled throughout the process.

Automatic Feeder Unit

The automatic feeder unit automatically feeds aluminum foil or plastic film onto a continuous belt conveyor. This allows the automatic aluminum continuous induction sealer to continuously apply aluminum seals to containers without interruption.

Automatic Foil/Plastic Film Cutting Unit

The automatic foil/plastic film cutting unit automatically cuts pre-determined lengths of foil or plastic film from a roll and feeds it into the automatic feeder unit. This ensures that the automatic aluminum continuous induction sealer can apply aluminum seals to containers with seamless efficiency.

Automatic Heat Sealing Device

The automatic heat sealing device is designed to generate and maintain a specified temperature for sealing foil or plastic film onto the container lid. This ensures that the automatic aluminum continuous induction sealer can apply aluminum seals to containers with complete accuracy.

Automatic Conveyor System

The automatic conveyor system is designed to transport containers through the automatic aluminum continuous induction sealer at a specified speed and in a predetermined order. This ensures that the automatic aluminum continuous induction sealer can accurately apply aluminum seals to containers with precision.

Automatic Adjustment Device

The automatic adjustment device is designed to adjust the automatic aluminum continuous induction sealer in order to accommodate different containers and lids. This ensures that the automatic aluminum continuous induction sealer can accurately apply aluminum seals to a variety of container sizes and types with ease.

Automatic Rejection System

The automatic rejection system is designed to detect and reject containers which have not been properly sealed. This ensures that the automatic aluminum continuous induction sealer can accurately apply aluminum seals to containers with complete accuracy.

Working Principles

An automatic aluminum continuous induction sealer works by producing an electromagnetic field that binds itself to the aluminum foil of the seal. This creates a heat-sealing effect, which can be used to close and secure packages. In order for this process to work correctly, there must be adequate contact between the aluminum foil and the inductor coil.

The automatic aluminum continuous induction sealer utilizes a self-contained power supply, which produces a high frequency alternating current. This current then causes an induction field to be generated in the sealer head through its inductor coil, which is typically wound around an iron core.

When the aluminum foil passes through this electromagnetic field, it induces eddy currents in the material, which causes resistance heating. This heat is used to seal the aluminum foil and create a secure package.

Applications

Automatic aluminum continuous induction sealers are widely used in the food, beverage, pharmaceutical and chemical industries. These machines are also used in industries such cosmetics and personal care products.

Plastic Continuous Induction Sealer

Plastic continuous induction sealer is an essential tool for businesses who need a reliable sealer for plastic containers. This type of sealing machine typically operates by passing plastic containers along a conveyor belt, where they are exposed to an electromagnetic field. This seals the plastic container with a tight band that creates an air and watertight seal.

The plastic continuous induction sealer creates a reliable, tamper-proof seal that keeps plastic products safe and secure during transportation and storage. The plastic continuous induction sealer is also incredibly easy to operate.

Additionally, plastic continuous induction sealers are designed to be durable and require minimal maintenance, providing businesses with a long-lasting sealing solution. With its reliable performance and low maintenance requirements, plastic continuous induction sealers are an ideal choice for businesses who need a reliable and efficient plastic container sealing machine.

Components

Sealing Head

The sealing head is responsible for the proper functioning of plastic continuous induction sealer machines. It has a heating element that generates an electromagnetic field, which will be used to create the heat necessary to melt plastic sealing materials such as polypropylene or polyethylene.

Sealing Roll

The sealing roll is the part of a plastic continuous induction sealer that takes plastic foil and wraps it around containers such as plastic bottles or plastic jars. It has a pair of rotating wheels that ensure the plastic film is placed correctly on the container, and then an electric current is sent through the plastic film, heating it up and allowing it to adhere to the container.

Film Feeder

The plastic film feeder is responsible for feeding plastic foil into the sealing roll of plastic continuous induction sealers. This component consists of a motor-driven roller that slowly brings plastic film from its storage area and feeds it into the plastic sealer.

Control System

The plastic continuous induction sealer’s control system is responsible for regulating the sealing speed, temperature, and pressure of plastic containers. This component consists of a display panel with a timer, temperature regulator, and digital controller that can be adjusted to ensure the plastic sealer is set to the correct parameters for each plastic container.

Cooling Mechanism

This component of plastic continuous induction sealers helps maintain plastic sealing temperature after the plastic containers have been sealed. A cooling fan blows air over plastic containers and seals to reduce heat, ensuring plastic materials remain soft and pliable after they are sealed

Exhaust system

The exhaust system of plastic continuous induction sealers helps remove any fumes that may be created when plastic containers are heated up and sealed. This component consists of a fan, filter, and exhaust pipe which helps disperse fumes away from plastic sealers, ensuring a safe and clean working environment.

Electronic Components

Electronic components such as relays, switches, sensors, and circuit boards are necessary for managing the flow of electric current through plastic film materials and help control plastic sealing parameters. The electronic components also monitor plastic sealers and alert operators if plastic sealers need to be serviced or repaired.

Working Principles

The plastic continuous induction sealer works by using an induction generator to transfer heat to the plastic material within a plastic tube. An electrical current is passed through the plastic tube, which generates a magnetic field around it.

When plastic material is placed in this field, it induces an eddy current that causes the plastic molecules to vibrate and generate heat. This heat is then transferred to the plastic material, which melts it and adheres it to the plastic tube.

The plastic continuous induction sealer also utilizes a plastic application head that applies pressure on the plastic material while it cools, producing a tight seal around the plastic tube. This helps ensure that any liquids or gases contained within remain safely sealed and protected from outside contamination.

Applications

The plastic continuous induction sealer is widely used across a variety of industries, including pharmaceuticals, cosmetics, food and beverage, and chemicals due to its ability to ensure product integrity by providing tamper-evident seals.

c)Table Top Continuous Induction Sealer

A table top continuous induction sealer is a type of machine that applies a heat-sealable foil to the top of an open container, creating a secure and tamper-proof seal. This sealing process is used on containers filled with liquids or powders and provides several benefits over traditional methods. It is fast, efficient, and requires minimal manual labor.

Components

Sealing Head

This is the physical part of the table top continuous induction sealer that actually seals the product. It consists of an electromagnetic field generator and a silicone pad that’s placed on top of the cap to conduct heat.

Control Box

This contains all of the electrical circuitry needed to operate the table top continuous induction sealer. It also contains various settings to adjust the sealing parameters as needed, such as current level and time duration.

Cap Feed System

The table top continuous induction sealer must have a cap feed system to continuously supply it with caps to be sealed. This can be manual or automated depending on the needs of the user.

Sealing Table

This table is used to hold the product to be sealed and guide it under the sealing head. It can also be inclined or adjustable so that different products can be accommodated.

Product Support Table

If a product needs additional support while being sealed, such as a bottle with a long neck, then a product support table can be used to ensure that the seal is applied properly.

Cooling System

After the sealing process has been completed, the product needs to cool down before it can be moved or handled. The table top continuous induction sealer machine has an integrated cooling system for this purpose.

Conveyor System

This is an optional component that can be used to feed a continuous stream of products through the table top continuous induction sealer machine. It is especially useful if large quantities of products need to be sealed quickly and efficiently.

Safety Guards

All table top continuous induction sealers come with safety guards to protect the user from the electrical components and hot surfaces. These guards must be in place before the machine is operated.

Working Principles

Table top continuous induction sealers use electromagnetic induction to create heat and bond a foil laminate inner seal to the lip of containers. The technology works by supplying an alternating current through a coil in the sealing head.

This creates an oscillating magnetic field which induces eddy currents into the metallic foil of the closure, creating heat by resistive losses. This heat bonds the closure to the container lip and forms a tight seal.

Applications

Table top continuous induction sealers are commonly used in the food and beverage industry to preserve freshness and taste of packaged foods. Additionally, table top continuous induction sealers are used in the pharmaceutical industry to ensure product integrity and quality control.

8.What Are The Differences Between Continuous Induction Sealing Methods And Manual Sealing Methods?

a) Continuous Induction Sealing Methods

b) Manual Sealing Methods

Continuous induction sealing is a continuous process that quickly and effectively seals multiple products at once. This method utilizes an electromagnetic field to bond the lid to the container, creating a tight seal. It is faster than manual sealing methods and produces consistent high-quality results.

Additionally, continuous induction sealing does not require any type of heat or power source for operation and is able to work with various materials such as plastic, glass, Polypropylene (PP) and more.

In contrast, manual sealing methods involve manually applying pressure onto lids in order to create a seal on containers. This method requires precision and skill as well as human labor which can make it expensive over time due to its relatively slow nature.

Manual sealing also has limited uses as it can only work with certain types of materials, such as metal and plastic. Furthermore, manual sealing is susceptible to human error which can lead to products being damaged or the seal not being airtight.

9.What Type Of Containers Can Be Sealed Using A Continuous Induction Sealing Machine?

A Continuous Induction Sealing Machine can be used to seal a variety of containers, including:

Plastic Containers

Continuous induction sealing machines are designed to seal plastic containers such as bottles, jars and cups.

Glass Containers

Continuous induction sealing machines can also be used to seal glass containers like jars and bottles.

PET Containers

Continuous induction sealing machines are commonly used for sealing PET containers, as the material is ideal for creating a hermetic seal.

Metal Containers

Continuous induction sealing machines can be used to seal metal containers, such as tin cans and aluminum cans, although care needs to be taken with thinner metals which may be damaged by the machine’s heat.

10.How Can You Increase Efficiency When Using A Continuous Induction Sealing Machine?

By following these tips, you will be able to maximize the efficiency of your Continuous Induction Sealer and get the most out of it for years to come.

Optimize Sealing Performance

Continuous induction sealing machines can be optimized in terms of frequency, current, voltage, pulse length, etc., to achieve optimal performance. This can be done by adjusting the settings on the machine or through specialized programming software.

Use The Right Components

Continuous induction sealing machines require specialized components such as seals made from aluminum foil with an acrylic based adhesive coating on one side. Using appropriate components ensures that the seals created by the machine will adhere well and have a long life.

Regular Maintenance

Continuous induction sealing machines should be serviced and maintained regularly to ensure optimal performance. This includes cleaning and lubricating the machine and inspecting all electrical components for wear or damage.

11.What Are The Common Problems Associated With Continuous Induction Sealing Machines And Their Possible Solutions?

Leakages from the Sealing Area

Continuous induction sealing machines rely on an electromagnetic field to create a seal between the container and the foil. If this field is not created properly, then leaks can occur in the seal area.

Possible Solution

Make sure that all parts of the machine are correctly adjusted so that the electromagnetic field is created correctly.

Overheating

Continuous induction sealing machines rely on the use of an electromagnetic field, and this can cause components to overheat if they are used for too long.

Possible Solution

Install a cooling system to help keep the machine running at a comfortable temperature.

Contamination

Contamination of the continuous induction sealing machine can be due to dust, moisture or other foreign particles being carried into the system by air currents, which can result in poor seal quality and reduce production efficiency

Possible Solution

Regular maintenance of equipment, using filters and enclosures to keep the area clean, and using high-quality induction sealing materials.

Jamming

Continuous induction sealing machines can sometimes become jammed due to a variety of reasons, including incorrect setup, using unsuitable materials or foreign objects entering the machine.

Possible Solutions

Making sure that all components are correctly set up and functioning properly, avoiding the use of unsuitable materials, and keeping foreign objects out of the machine.

CONCLUSION

Continuous induction sealing machine is becoming increasingly popular solution for businesses looking to secure their products with efficient sealing. With its protective and airtight seals, it guarantees product freshness and quality over a longer period of time. Additionally, these machines are easy to install and operate, giving traditionally manual operations more power and precision than ever before. The advantages of using a continuous induction sealing machine to protect your products really can’t be overstated. If you’d like to learn more about this versatile tool, please don’t hesitate to get in touch with Allpack today. Our experienced professionals can help you make the right choice for your business needs so that you can start enjoying all the benefits associated with this incredible technology!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide