Tablet Coater: The Complete Buying Guide In 2025

Tablet Coater: The Complete Buying Guide In 2025

If you are in the pharmaceutical or medical industry, then you understand how important it is to have a reliable and efficient production process. One way to ensure an effective production process is to use a tablet coater. Tablet coaters provide manufacturers with improved efficiency as well as increased accuracy when it comes to accurately applying coatings onto tablets or pills.

Also, coating tablets can help protect them from external factors such as moisture or oxygen which makes them last longer and helps decrease degradation of the drugs within them before reaching consumers. So if you are looking for an efficient and accurate way to coat your products, look no further than purchasing a tablet coater!

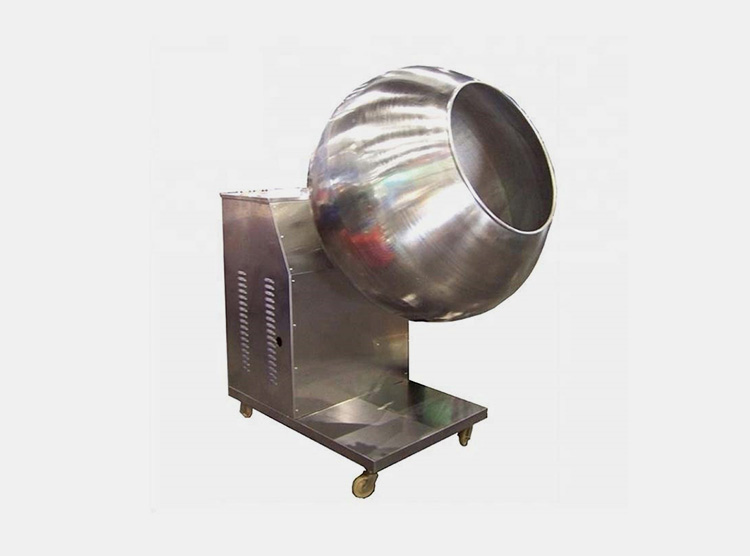

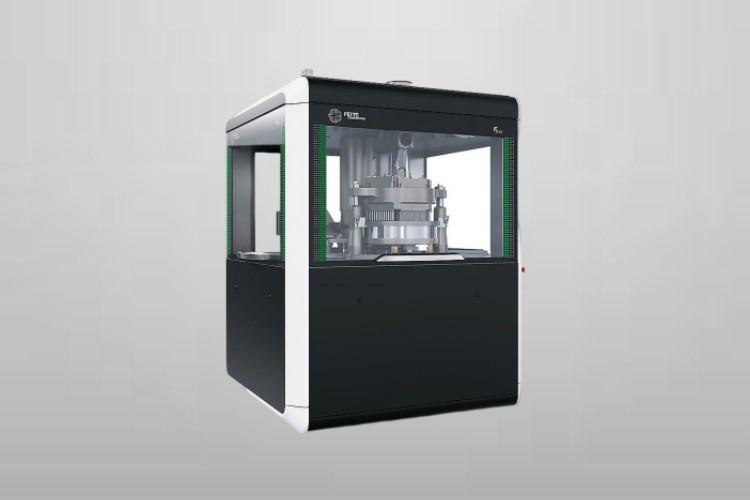

1.What Is A Tablet Coater?

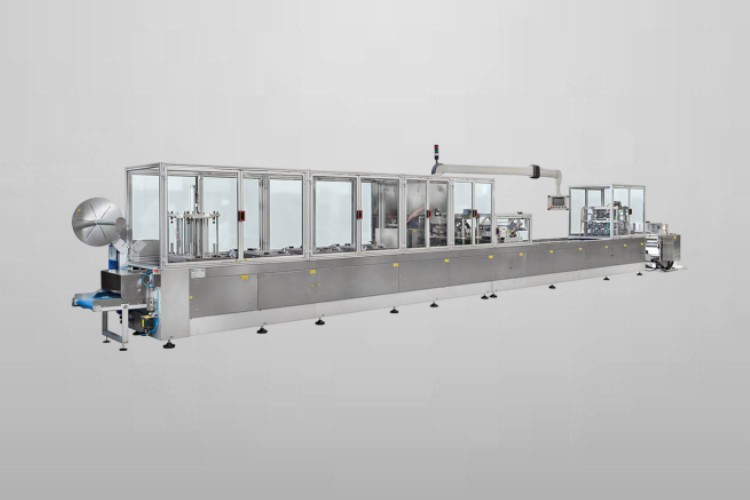

A tablet coater is a device used to coat tablet surfaces with a thin film of material. It is a specialized machine that uses mechanical, thermal, or chemical processes to disperse active ingredients on tablet surfaces.

Tablet coaters create coatings that are essential for protecting medications from environmental conditions such as moisture and oxygen, or to mask unpleasant tastes or smells. Tablet coatings also help to improve tablet appearance, create unique tablet designs, and add extended-release properties.

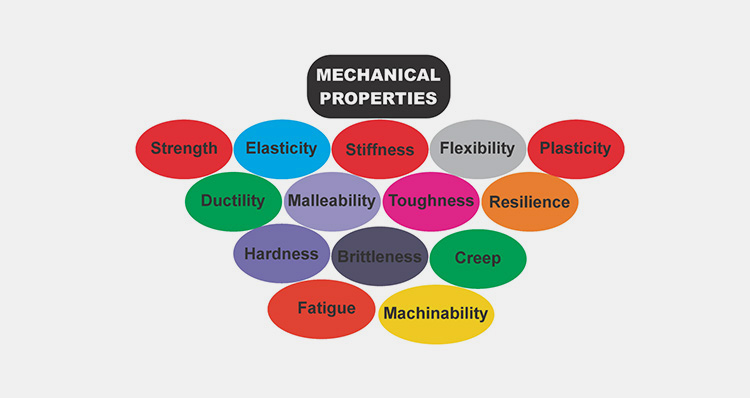

2.What Tablet Properties Can Be Modified Using A Tablet Coater?

Solubility

Tablet coatings can be used to modify the solubility of tablets, allowing them to dissolve faster or slower in certain solutions.

Stability

Tablet coatings can also be used to modify tablet stability, helping protect tablet active ingredients from degradation or oxidation.

Taste

Tablet coatings can be used to mask the taste of certain tablet ingredients, making them more palatable for patients who have difficulty swallowing tablets.

Appearance

Tablet coatings can also be used to improve tablet appearance, helping to create a more aesthetically pleasing tablet.

Palatability

Tablet coatings can also be used to improve tablet palatability, making them easier to swallow and reducing the risk of choking.

Release Rate

Tablet coatings can also be used to control the release rate of tablet active ingredients, ensuring that the patient receives the correct dose.

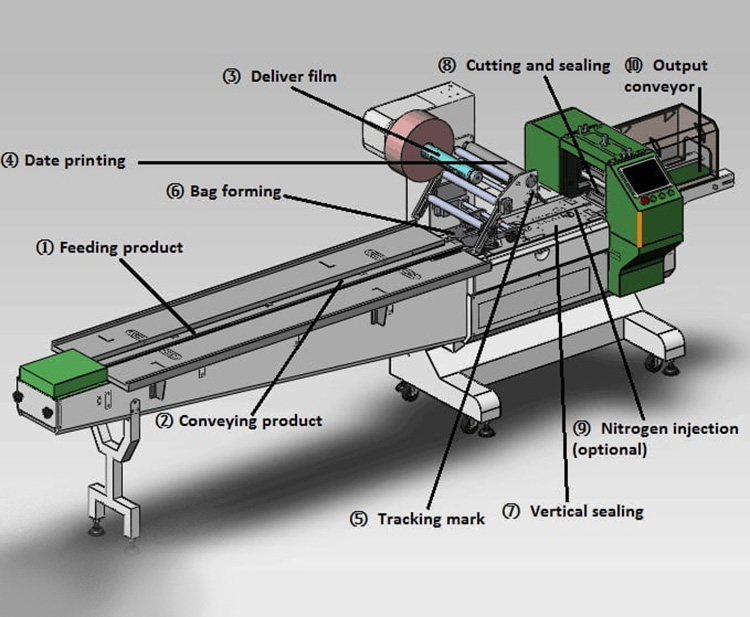

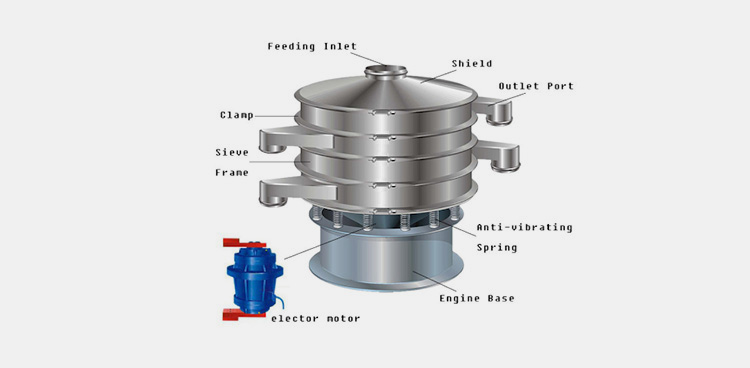

3.What Are The Components Of A Tablet Coater?

Tablet Hopper

This component is used to hold the tablet while they’re being coated and can come in many different shapes and sizes depending on the size of tablet.

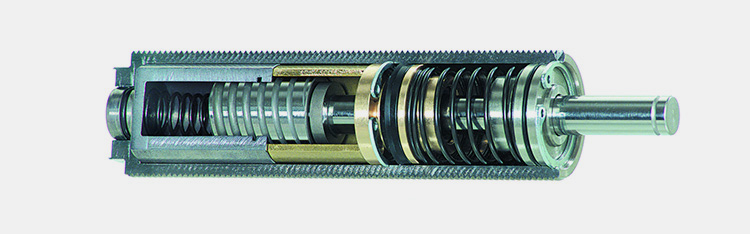

Spray Gun

This component is responsible for spraying a fine mist of coating solution onto the tablet, which helps give it an even coat.

Coating Solution Reservoir

This is where the coating solution is stored so that it can be used to coat the tablet.

Air Compressor

This component helps to provide pressure for the spray gun, which helps create a finer mist of coating solution to be applied onto the tablet.

Vacuum Pump

This part is used to remove excess moisture and air from the tablet coater, which helps ensure an even coating.

Heating System

This system helps to provide a consistent temperature for the tablet coater, which ensures that the tablet is coated evenly.

Exhaust System

This component helps to vent out any fumes or vapors from the tablet coater, which helps ensure a safe working environment.

Control Panel

This constituent is where all the controls are located on the tablet coater and can be used to adjust various settings and monitor performance. It also typically includes an alarm system to alert operators of any problems that may arise during operation.

4.What Are The Advantages Of A Tablet Coater?

Reduced tablet production time

Tablet coaters are designed to coat tablets quickly and efficiently so that tablet production can be completed at a much faster rate than with manual coating methods.

Improved tablet quality

Tablet coaters reduce the amount of human contact, which in turn reduces the chances of contamination or tablet damage due to mishandling. This results in a tablet with improved consistency and overall quality.

Increased tablet uniformity

Tablet coaters are also designed to ensure tablet coating is uniform, meaning every tablet produced will have the same amount of tablet coating. This reduces tablet contamination and ensures the tablets are consistent in quality.

Enhanced tablet durability

Tablet coaters help to protect the tablet from physical damage and environmental factors, making it more durable when stored for longer periods of time. This helps to extend the shelf life of the tablet, allowing it to remain potent for longer periods.

Increased tablet solubility

Tablet coaters are also designed to improve tablet solubility, meaning they will be easier to dissolve in water or other liquids when taken orally. This improves the effectiveness and absorption of the tablet, making it more effective.

5.Are There Any Disadvantages For Tablet Coaters?

Tablet coaters can be an effective way to apply coatings and finishes to tablet surfaces, but there are several potential drawbacks.

One of the main disadvantages is that tablet coaters often require a significant upfront investment in equipment, which can be quite expensive. Additionally, tablet coaters must be cleaned and maintained regularly to ensure optimal performance. This extra maintenance can add to the cost and complexity of tablet coating operations.

Lastly, tablet coaters are limited by their size, meaning they may not be able to accommodate large tablet sizes or shapes. For these reasons, tablet coaters may not always be the best choice for tablet coating operations.

6.What Are The Applications Of A Tablet Coater?

Tablet coaters provide a range of applications in a variety of industries that require coating tablets for different purposes. They include:

Food Industry

Tablet coaters are commonly used in the food industry for coating sugar, chocolate or other flavors onto candy, snacks and cereals. This can help to improve the taste of the product as well as provide a more attractive appearance.

Pharmaceutical Industry

Tablet coaters are also used extensively in the pharmaceutical industry for film coating tablets and capsules, which helps to improve the tablet’s stability as well as create a more pleasant taste.

Cosmetic Industry

Tablet coaters can also be used in the cosmetics industry for coating powders, waxes and other ingredients onto facial creams, ointments and lotions. This helps to ensure that the product’s active ingredients are evenly distributed and provides a better user experience.

Agriculture Industry

Tablet coaters can also be used in the agriculture industry for coating fertilizers, pesticides and other products onto tablet forms. This helps to improve the product’s efficiency and effectiveness when applied to crops.

Chemical Industry

Tablet coaters can be used in the chemical industry to coat materials such as catalysts, pigments and dyes onto tablets or other substrates. This helps to ensure that these active ingredients are consistently distributed and makes them easier to work with.

7.How Does A Tablet Coater Work?

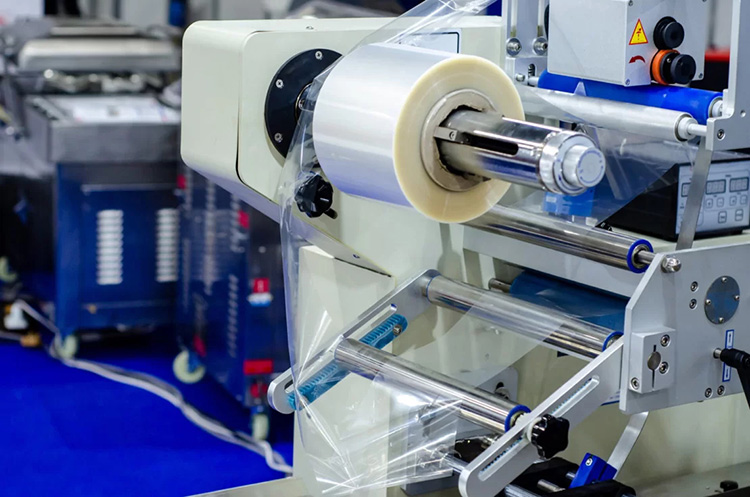

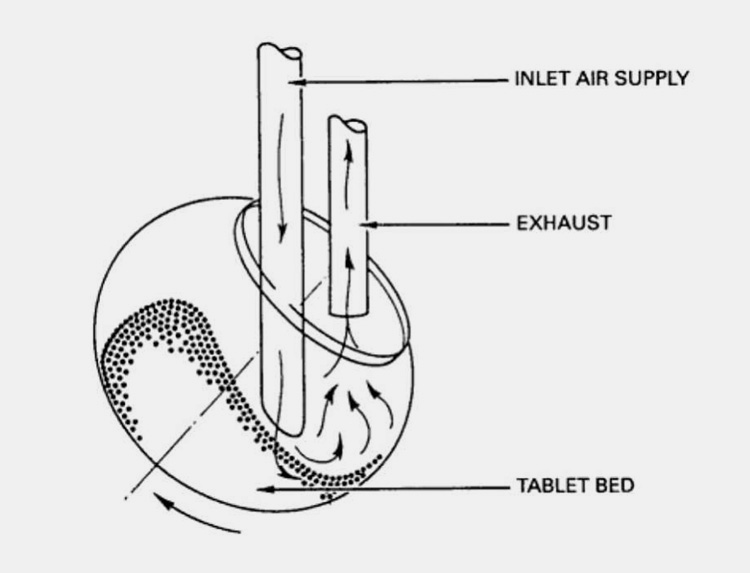

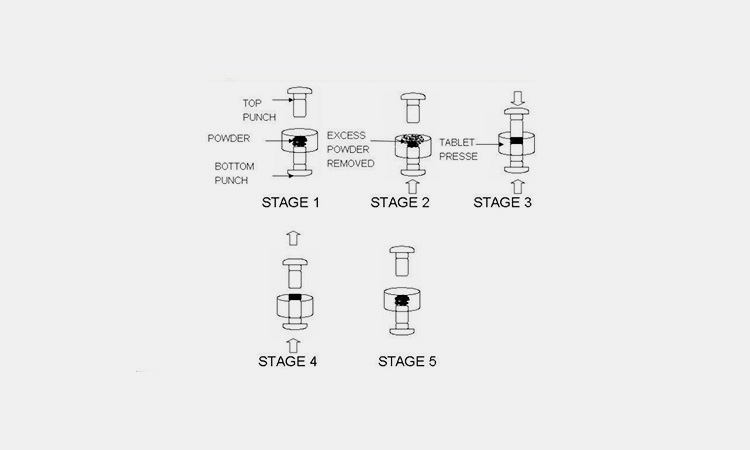

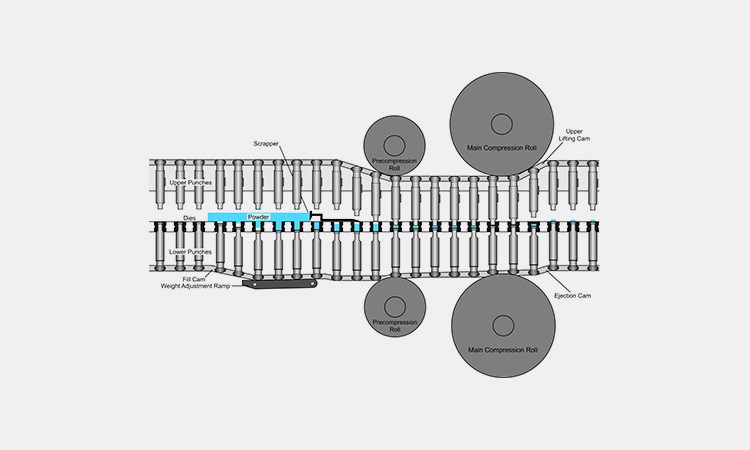

A tablet coater operates by using centrifugal force and air pressure to evenly apply the coating material over the tablet. The tablet is placed in the machine’s hopper, which then rotates at high speeds, causing the tablet to spin in the air.

This spinning action creates a centrifugal force, which evenly spreads the tablet coating material across the tablet’s surface. After the tablet has been coated, it then passes through an air passageway that helps to dry and set the tablet coating.

8.Are There Any Specialized Tablet Coaters Available For Specific Applications?

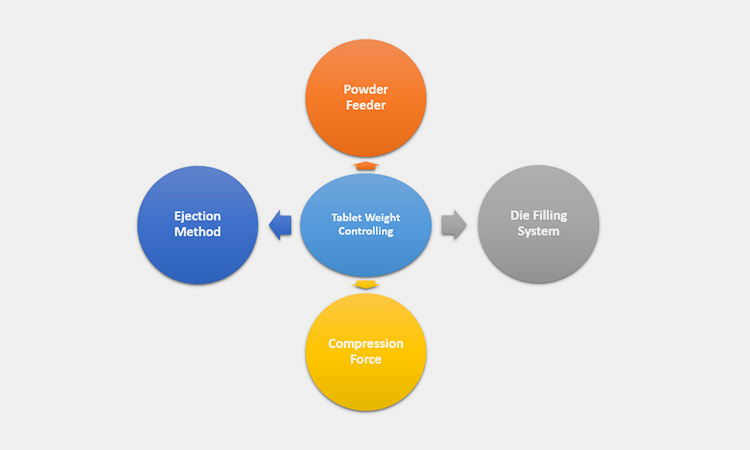

The answer is yes; tablet coaters are available for many specific applications. Tablet coaters come in different sizes and can be used to coat tablets with a variety of materials such as waxes, shellacs, resins, and powders. They also come with various features such as automatic tablet weight control and an adjustable speed setting which makes it easy to coat tablets with an even material thickness.

Tablet coaters are ideal for tablet applications in the pharmaceutical, nutraceutical, confectionery, and food industries. They are highly efficient and can be used to achieve consistent tablet coating results without the use of hazardous solvents or other chemicals.

With a specialized tablet coater, tablet production processes can be streamlined and tablet coatings can be applied more efficiently. This makes tablet coaters an ideal choice for applications that require uniform tablet coating results.

9.What Are The Different Types Of Tablet Coaters?

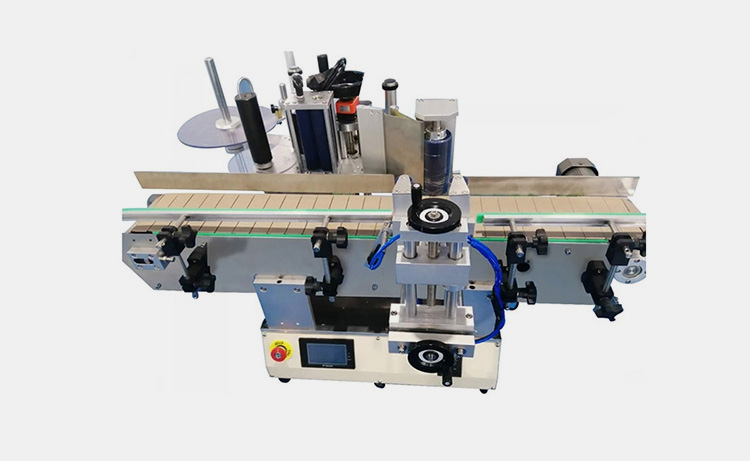

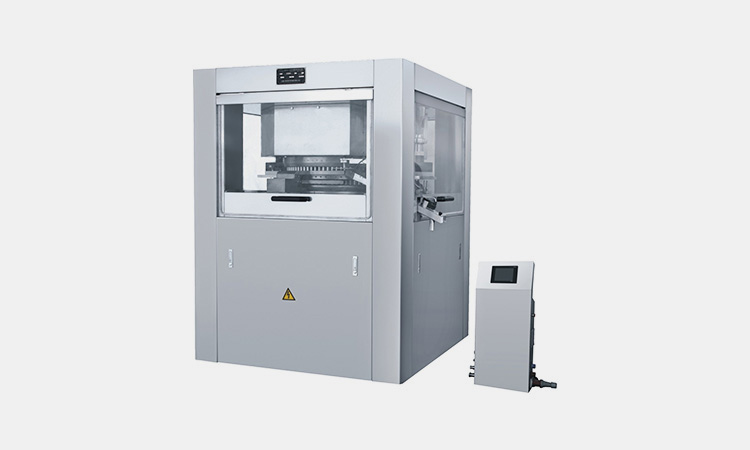

a) Automatic Tablet Coaters

Automatic tablet coaters provide higher levels of control and accuracy. These tablet coaters are operated by a computer-controlled system and can be programmed to coat tablets with different thicknesses, colors, and textures. They also have the ability to adjust air flow and temperature in order to ensure maximum efficiency.

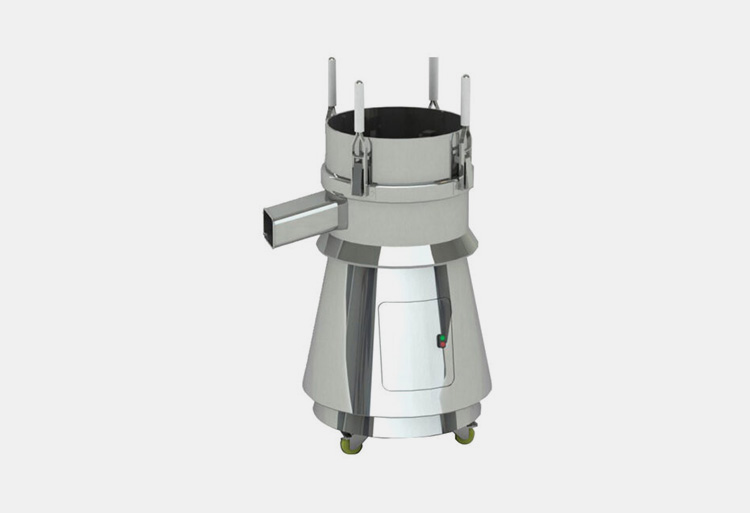

b) Fluid Bed Coater

A fluid bed coater is a machine that uses hot air to suspend and coat tablet particles. It works by introducing tablet particles and a coating solution into a chamber, then subjecting both to hot air which causes the tablet particles to be suspended in mid-air while the coating is applied. This type of tablet coater is ideal for high efficiency coating with uniform coverage.

c) Spray Coaters

Spray tablet coaters are similar to fluid bed tablet coaters but they use a spray head to apply coating material onto tablet surfaces. This type of tablet coater is commonly used to coat tablets with wax, varnish, or other materials. It can also be used to apply a thin layer of water-based resins.

d) Hot Melt Tablet Coaters

Hot melt tablet coaters are used to apply hot-melt coatings onto tablet surfaces. This type of tablet coater uses heat and pressure to melt the coating material and then spray it onto tablet surfaces.

10.How Can You Choose A Solvent For Your Tablet Coater?

Choosing the right solvent for your tablet coater is essential as it helps to ensure consistent tablet coating results. When selecting a solvent for the tablet coater, it is important to consider factors such as compatibility with coating materials and release agents, performance in terms of viscosity and volatility, cost-effectiveness, and environmental impact.

Compatibility is essential for tablet coatings as it affects not only the quality of the tablet’s finish but also its durability. The solvent must be compatible with both the coating material and release agents used in the tablet coater process to ensure a uniform application of the coating.

Performance is another factor to consider when choosing a tablet coater solvent. The viscosity of the solvent should be low enough so that it can readily dissolve and spread coating materials, while also allowing for efficient tablet release from the tablet coater.Also, the volatility of the solvent should be low enough to avoid rapid evaporation and thus ensure uniform tablet coating.

The cost-effectiveness of the solvent must also be taken into consideration. Ideally, you want a tablet coater solvent that is not only effective but also cost-efficient in order to reduce production costs.

Additionally, environmental impact is also an important factor to consider when selecting a tablet coater solvent. Choose a solvent that is non-toxic and biodegradable, so as to minimize its environmental impact.

11.Which Factors Affect The Tablet Coater Efficiency?

Temperature: The tablet coater must be operating at the right temperature, otherwise it can affect the tablet coating process. If the tablet coater is too cold, then the tablets may not coat evenly or completely. On the other hand, if it is too hot, this could cause clumping of tablet material and uneven coating of the tablet.

Spray Pattern: The tablet coater must be set up correctly in order to ensure the tablet coating process is as efficient as possible. This includes setting the tablet coater’s spray pattern to match the tablet profile, so that all areas of the tablet are evenly coated.

Rotation speed: The tablet coater must rotate at the right speed in order to coat the tablet evenly. If it is operating too slowly, then there is a risk that some tablet material may be left behind on the tablet surface. On the other hand, if it is rotating too quickly, this can cause clumping and uneven tablet coating.

Air velocity: The tablet coater must operate with the correct air velocity to ensure tablet coating efficiency is maximized. If the air velocity is too low, tablet material may not be coated evenly or completely. On the other hand, if it is too high, tablet material may be blown away from the tablet surface resulting in an uneven coating.

12.What Are The Most Common Problems Associated With Tablet Coaters?

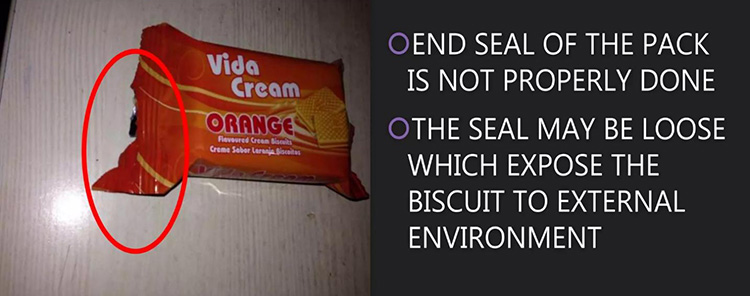

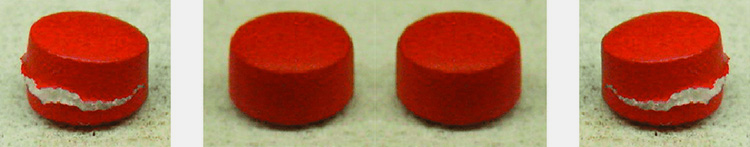

Poor Film Integrity

Lack of uniformity can also lead to poor film integrity and tablet breakage. Poor film integrity can occur when tablet coating material is not properly applied and/or dried, resulting in a weak tablet coating that does not adhere to the tablet surface.

Inaccurate Coating Uniformity

Tablet coaters can fail to evenly distribute the coating material, resulting in uneven tablet surfaces that may cause batch-to-batch differences or even tablet breakage during processing.

Contamination

Tablet coaters may be prone to contamination from dust or other particles which can result in flaws on tablet surfaces or cause tablet breakage during processing.

Heat Damage

Tablet coaters can also be susceptible to heat damage, which can lead to tablet breakage or poor tablet coating integrity. Overheating of tablet coatings can cause them to dry too quickly and fail to adhere properly or crack after drying.

Operational Difficulties

Tablet coaters may also require frequent adjustments and maintenance due to operational difficulties. This can lead to increased downtime and potential tablet coating defects.

Airflow Problems

Poor airflow through the tablet coater can cause tablet coatings to not properly set or dry, resulting in tablet breakage or poor tablet integrity. In addition, poor airflow can contribute to tablet coating defects such as streaks or uneven tablet surfaces.

Material Variations

Tablet coaters may also be subject to material variations, which can cause tablet coatings to set improperly and lead to tablet breakage or poor tablet integrity. This is especially true when tablets are coated with different materials or in batches of varying sizes.

13.What Quality Standards Should Tablet Coaters Meet?

Accurate tablet coating weight – Tablet coaters must be able to accurately apply the desired amount of coating to each tablet. This is important for ensuring that tablets contain the proper dose of active ingredients, and that batches are uniform in quality.

Uniform tablet coating thickness – Tablet coatings should be applied evenly so that there is no variation across the tablet batch. This ensures that each tablet will have consistent release characteristics and potency.

Proper tablet coating adhesion – Tablet coatings should adhere well to tablet surfaces, so that they are not easily removed or damaged during storage or handling. Coating adhesion is also important for maintaining proper tablet shelf life.

Tablet coating uniformity – Tablet coatings should be applied uniformly and consistently so that there are no variations from tablet to tablet within the same batch. This helps to ensure that each tablet will have the same release characteristics as well as potency.

Safe tablet coating ingredients – All tablet coatings must be safe for human consumption. This means tablet coaters must use only approved and tested ingredients that have been thoroughly evaluated for safety.

Compliance with GMP requirements – Tablet coaters must comply with all relevant good manufacturing practices (gmp) requirements in order to ensure tablet safety, efficacy and quality. This includes maintaining proper cleanliness, documenting processes and conducting regular inspections.

Adherence to tablet coating specifications – Tablet coatings should be applied in accordance with the tablet formulation specifications. This helps to ensure that each tablet batch has the same release characteristics and potency.

Compliance with regulatory requirements – Tablet coaters must comply with all relevant regulatory requirements, such as those mandated by FDA or other government bodies. This helps to ensure tablet safety and efficacy.

14. What Factors Should Be Taken Into Account When Choosing A Tablet Coater?

Here are some of the factors to consider before making a purchase of a tablet counter

Price

Tablet coaters come in a range of prices, from budget-friendly models to high-end commercial machines. Consider your budget and the features you need before making a purchase.

Compatibility

Tablet coaters are designed to work with specific tablet sizes, shapes and materials. Ensure that the tablet coater you select is compatible with the tablet sizes and materials you plan to use.

Coating Speed

Tablet coaters vary in coating speed and should be chosen based on your specific needs. If you require higher speed production, opt for a tablet coater that can handle the workload.

Ease of Use

Tablet coaters can be complex machines with multiple settings and controls. Ensure that the tablet coater you select is simple to operate and understand, this will reduce downtime and increase efficiency in tablet coating.

Warranty

Ensure that your tablet coater has a good warranty, as tablet coating can be a delicate process and problems can arise.

Brand

Tablet coaters come from many different manufacturers, so do some research into each one before making a purchase. Look into the company’s reputation and customer service record to ensure you select a tablet coater from a reliable brand.

CONCLUSION

To summarize, a tablet coater can be an excellent option for increasing the effectiveness of your medications. It is an efficient and cost-effective way to help ensure that your tablets have the desired effect. A tablet coater also helps to improve the shelf life of tablets by creating a protective film on their surface. Moreover, tablet coaters are suitable for various formulations, making them a versatile and valuable add-on to your drug development processes. If you’re interested in purchasing a high-quality tablet coater, look no further than Allpack. With competitive prices and quality products, they have everything you need to make sure your tablets are effective and properly protected. Reach out today to take the first step towards getting the right tablet coating equipment for your needs.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tablet Coater: The Complete Buying Guide In 2025 Read More »

FlexaLAB Capsule Filling Machine

FlexaLAB Capsule Filling Machine

Automatic Capsule Filling Machine

Automatic Capsule Filling Machine

TES 1200A Automatic Capsule Filling Machine

TES 1200A Automatic Capsule Filling Machine

Syntegon GKF 2500 Capsule Filling Machine

Syntegon GKF 2500 Capsule Filling Machine

FEC20 Capsule Filling Machine

FEC20 Capsule Filling Machine

Automatic IN-CAP Capsule Filling Machine

Automatic IN-CAP Capsule Filling Machine

aking them more palatable and easier for animals to consume.

aking them more palatable and easier for animals to consume.

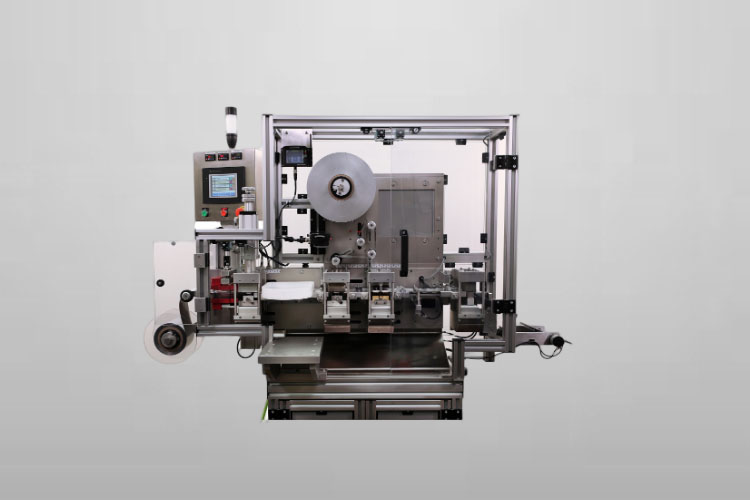

SEPHA EZ Blister Tabletop Blister Packaging Machine

SEPHA EZ Blister Tabletop Blister Packaging Machine

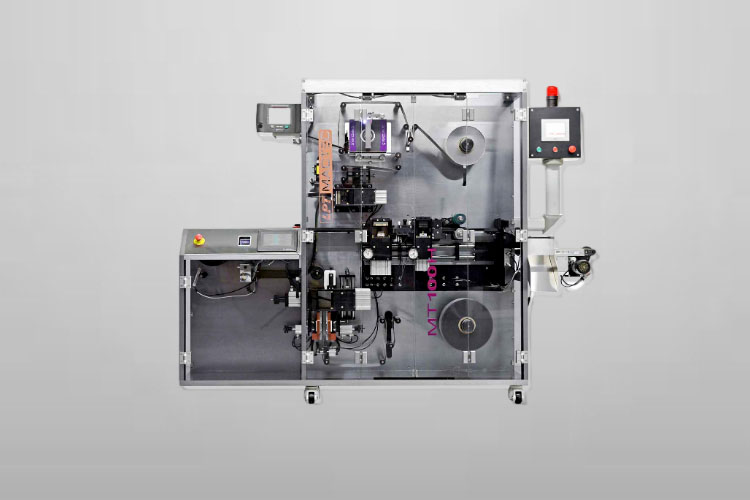

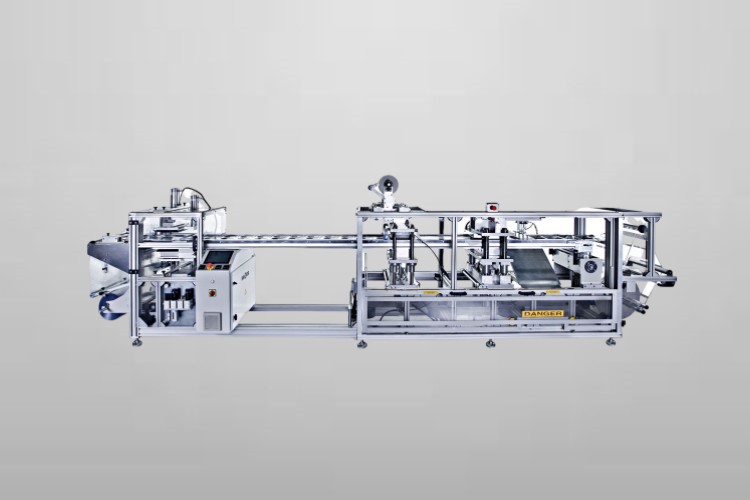

MT-100 Blister Packaging Machine

MT-100 Blister Packaging Machine

BPC 23 Blister Packaging Machine

BPC 23 Blister Packaging Machine

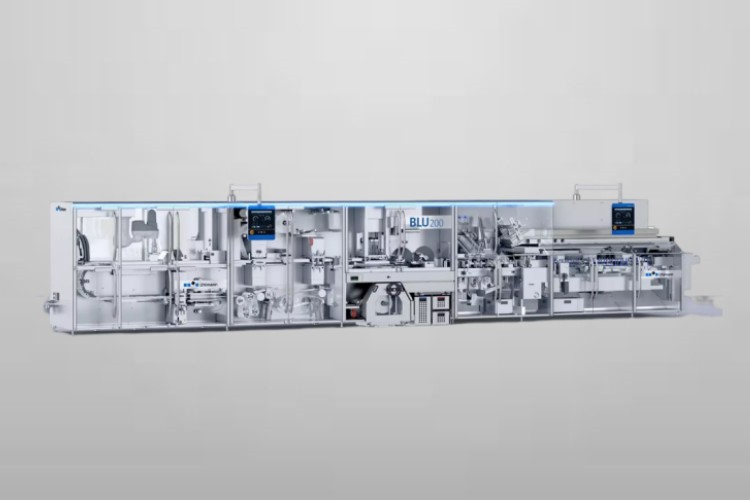

BLU200 Blister Packaging Machine

BLU200 Blister Packaging Machine

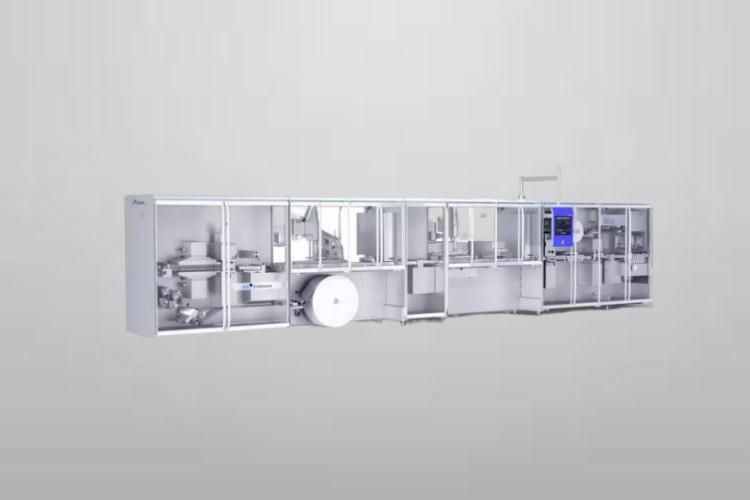

BLIMAR® 3050 AITT Blister Packaging Machine

BLIMAR® 3050 AITT Blister Packaging Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours