Horizontal Flow Wrapper: The Complete Buying Guide in 2025

Are you looking to upgrade your packaging production process? Are you wanting to increase efficiency while also reducing costs? If so, then investing in a horizontal flow wrapper could be the perfect solution for you.

Flow wrappers are an incredibly versatile and efficient form of automated packaging machinery that offer tremendous advantages over traditional manual processes. They provide an effective way to package products quickly, securely, and economically — making them ideal for all types of businesses in the food industry or beyond!

In this blog post, we’ll explore the different features and benefits associated with using a horizontal flow wrapper and how it can ultimately save your business both time and money.

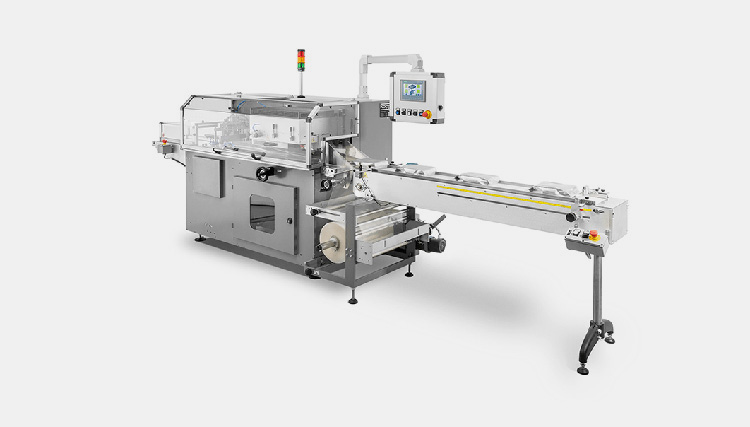

1.What Is A Horizontal Flow Wrapper?

A horizontal flow wrapper is a type of packaging machine that is used to wrap products in plastic film.

This machine works by feeding the product onto a conveyor belt, which then passes through several rollers that shape and seal the film around the product. The end result is a tight and secure package with an attractive appearance.

Horizontal flow wrapping machines are often used by food and beverage companies to package products like chocolate bars, candy bars, and snacks. They can also be used in other industries such as medical and pharmaceutical packaging or even industrial packaging

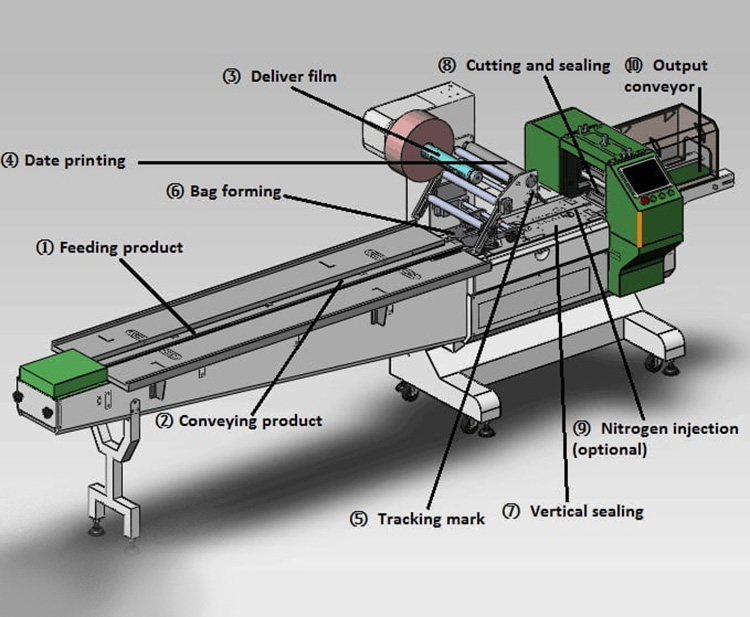

2.What Are The Components Of A Horizontal Flow Wrapper?

Feeding product

The horizontal flow wrapper is equipped with a feeding mechanism that feeds the product into the film, usually by means of horizontal conveyor belts.

Conveying product

Horizontal conveyor belts are used to transport the product from the feeding mechanism to the wrapping process

Deliver film

Horizontal flow wrappers are equipped with a film delivery system which delivers the film to the product and wraps it around it.

Date printing

Horizontal flow wrappers are equipped with a date printing device which prints the expiration or production date on the product.

Tracking mark

The horizontal flow wrapper has a tracking mark system which is used to detect the position of the product. This helps make sure that the horizontal flow wrapper keeps up with its ‘wrapping’ speed, and also avoids potential collisions that could occur if the horizontal flow wrapper gets ahead or behind of the product on its path.

Bag forming

The horizontal flow wrapper has an automatic bag forming mechanism which takes the packaging material and forms it into a neat, sealed package. This is done without any manual intervention, and also helps to ensure that the horizontal flow wrapper maintains its speed on its wrapping path.

Vertical sealing

The horizontal flow wrapper also has a vertical sealing mechanism which seals the horizontal edges of the package in order to ensure that all products are securely packaged.

Cutting and sealing

The horizontal flow wrapper also has a cutting and sealing mechanism which cuts the package in order to make it easy for the consumer to open. The horizontal seal system also seals the end of each package after it is cut, making sure that no air can enter and contaminate the product.

Nitrogen injection(optimal)

This horizontal flow wrapper also has an optional nitrogen injection system which helps to preserve the quality of the product by infusing it with nitrogen. This helps to protect the product from oxidation and other types of contamination.

Output conveyor

The horizontal flow wrapper also has an output conveyor which helps to move the packaged product away from the horizontal flow wrapper quickly and effectively. This helps to make sure that the horizontal flow wrapper can continue on its wrapping path without any delay or interruption and consumers receive a high-quality products every time.

3.How Does A Horizontal Flow Wrapper Work?

A horizontal flow wrapper is a type of packaging machine. The horizontal flow wrapping process begins with the product to be packaged being placed onto a conveyor belt.

This conveyor belt then moves the product through several stages which involves cutting, sealing, and forming the packaging material around the product.

The horizontal flow wrapper uses two horizontal webs of packaging material to form a pouch around the product. One of these horizontal webs is pre-cut and folded into a rectangular shape, while the other horizontal web is welded around its edges.

A vacuum system then holds this horizontal web in place as it moves along with the conveyor belt.

The horizontal flow wrapper also includes several cutting mechanisms which are used to cut and seal the packaging material around the product. The horizontal flow wrapper can be programmed to cut and form different types of packaging shapes, such as bags, pouches, or wrappings.

Once the desired shape is created, a horizontal sealing mechanism then uses heat to create a strong seal which ensures that the product is securely packaged.

4.What Are The Advantages Of A Horizontal Flow Wrapper?

Cost-efficiency: horizontal flow wrappers are much more cost-effective than vertical flow wrappers due to their simpler design and fewer moving parts.

Flexibility: horizontal flow wrappers have adjustable settings, so they can be tailored to different products easily, making them a versatile piece of machinery that can be used to package a variety of goods.

High Speed: horizontal flow wrappers can wrap and seal up to 300 packages per minute, making them one of the fastest wrapping machines on the market.

Easy Operation: horizontal flow wrappers are easy to operate and maintain compared to other types of packaging machinery, which makes them ideal for businesses with limited staff and resources.

Compact Size: horizontal flow wrappers are much smaller than vertical machines, which makes them ideal for businesses working in tight spaces or with limited floor space.

Longer Shelf Life: horizontal flow wrappers create highly secure seals that keep products fresh longer, providing businesses with an additional benefit when it comes to preserving their goods.

Automation: horizontal flow wrappers can be automated, reducing the amount of labor needed and increasing efficiency while ensuring consistent quality.

Safety: horizontal flow wrappers are designed with a variety of safety features, including interlocks and emergency stop functions, to protect both the product and the operators from harm.

5.What Are The Applications Of A Horizontal Flow Wrapper?

Horizontal flow wrappers can be used in a variety of industries and settings, including food production, pharmaceuticals, electronics assembly, medical device assembly, and many more.

Food Industry

In the food industry horizontal flow wrappers are used to package snacks, candy bars, and other items that need to stay fresh for extended periods. These machines wrap products securely using a horizontal film that is heat sealed on both ends. This provides an extra layer of protection from the elements and helps keep products fresh for longer.

Pharmaceutical Industry

In pharmaceuticals, horizontal flow wrappers are used to package tablets, capsules and other dosage forms in airtight pouches or blisters. This form of packaging helps protect drugs from contamination and provides tamperproof protection.

Electronic Industry

In electronics, horizontal flow wrappers are used to package components and boards in protective covers that help prevent damage and keep parts secure for transportation and assembly.

Medical Industry

Finally, medical device assembly uses horizontal flow wrappers to package medical equipment such as catheters and other instruments in sterile packaging. This ensures devices are properly protected and sterilized when they arrive at the medical facility. Horizontal flow wrappers also provide a layer of protection to products against moisture and other contaminants that could affect their performance.

Cosmetic Industry

Horizontal Flow Wrappers are used in the cosmetic industry to provide a secure and efficient wrapping solution for various types of products. The horizontal flow wraps are designed to securely hold and protect items such as lipsticks, lotions, mists, face creams etc., ensuring that each item reaches its destination intact. The horizontal flow wrappers also provide a visually appealing packaging solution with their horizontal wraparound design and clear window for product visibility.

6.What Are The Different Types Of Horizontal Flow Wrappers?

Horizontal flow wrappers come in two main types – semi-automatic horizontal flow wrappers, and automatic horizontal flow wrappers.

Semi-Automatic Horizontal Flow Wrappers

Semi-automatic horizontal flow wrappers are usually manually operated and require an operator to manually place the product onto the infeed conveyor – making them suitable for low volume production runs. Semi-automatic horizontal flow wrappers tend to be less expensive than their automatic counterparts, as they do not require additional investment in automation equipment.

Automatic Horizontal Flow Wrappers

Automatic horizontal flow wrappers are designed to run in high production environments, and allow for continuous product infeed. Automated horizontal flow wrappers can be set up to receive products from an upstream hopper or vibratory feeder, increasing the speed of the wrapping process.

Automatic horizontal flow wrappers also require additional investment in automation equipment, which makes them more expensive than their semi-automatic counterparts.

7.What Is The Difference Between A Horizontal Flow Wrapper And Vertical Flow Wrapper?

Horizontal flow wrappers and vertical flow wrappers are both types of packaging machines used to package a variety of products. The key difference between horizontal and vertical flow wrappers is the orientation of the product and film as they travel through the wrapper.

In horizontal flow wrapping, the product is placed in a horizontal position on the infeed conveyor and flows horizontally into the wrapper. The horizontal film is then passed over the product, which is held in place by horizontal compression plates, before being sealed and cut to form a package.

In contrast, a vertical flow wrapper has the product placed vertically on an infeed chain, with the film wrapped vertically around the products before being sealed and cut. The vertical product orientation allows for greater flexibility in package design.

Horizontal wrappers are often used to pack large or bulky items such as boxes, cartons, cases and bags, while vertical wrappers are often used for smaller products like candy, snacks and baked goods.

Depending on the type of product being packaged, horizontal wrappers tend to be more cost effective for high-volume production, while vertical wrappers are more suitable for short runs and smaller packages.

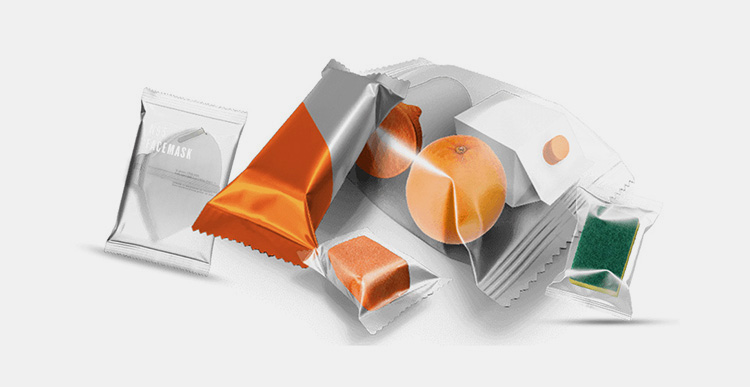

8.What Type Of Products Can Be Packaged By Horizontal Flow Wrappers?

A horizontal flow wrapper is an automated packaging machine used to package a variety of products with flexible or rigid wrapping materials. Products that are typically packaged using horizontal flow wrappers include:

- Candy

- Bakery Goods

- Cheese

- Confectionary Items

- Dietary Supplements and Vitamins

- Fresh Produce

- Medical Supplies

- Pet Food and Treats

- Pharmaceutical Products

- Soap and Detergents

- Snack Foods

The horizontal flow wrapper is one of the most versatile packaging machines, able to accommodate a wide range of product shapes, sizes and wrapping materials. It is an efficient machine, able to package products quickly and accurately without the need for manual labor.

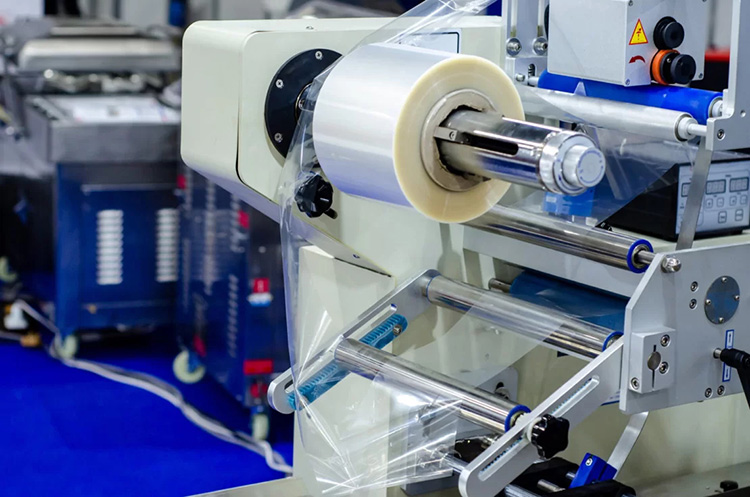

9.What Type Of Materials Can Be Used With Horizontal Flow Wrappers?

Cold Sealing Films

These materials include wax, aluminum foil, paper and other non-thermoformable films. The horizontal flow wrapper seals these materials using pressure instead of heat to create a tight seal.

Composite Film

This material is a combination of two or more films and can be used with horizontal flow wrappers to provide extra strength and durability.

Mono Film

This is a single layer of film that horizontal flow wrappers can seal e.g PE,PP and other thermoplastic materials.

Paper Based Wrap

Horizontal flow wrappers can be used to wrap products with paper-based materials such as wax coated, plastic laminated or multi-layer papers.

These are just some of the materials horizontal flow wrappers can work with. With the use of horizontal flow wrappers, manufacturers are able to package a wide range of materials in an efficient and cost-effective way.

10.How Does A Shrink Wrapper Compare To A Horizontal Flow Wrapper?

A horizontal flow wrapper is an automated packaging machine that utilizes horizontal film material to tightly wrap products. This type of wrapping is ideal for food items, bakery goods and other consumer goods due to its excellent sealing capabilities. The horizontal flow wrapper uses a horizontal film which is applied laterally across the product being wrapped while also forming air tight seals along the edges.

A shrink wrapper on the other hand is a packaging machine that utilizes horizontal and vertical film material to tightly wrap products. This type of wrapping typically requires the product to be placed on some form of support tray or rack before it is sealed with plastic film material.

The horizontal film seals the top and bottom of the product while the vertical film seals the sides of the product. The combination of horizontal and vertical film material creates a tight seal that shrinks around the product’s shape when exposed to heat.

The main difference between horizontal flow wrappers and shrink wrappers is in the type of packaging material used for each application. The horizontal flow wrapper utilizes horizontal film material which form airtight seals around the product, while shrink wrappers use horizontal and vertical film material which shrinks tightly around the product when exposed to heat.

Horizontal flow wrappers are typically used for products that require excellent airtight seals and minimal visible packaging, while shrink wrappers are designed for products that need a tighter fit or more protective packaging.

Both horizontal flow wrappers and shrink wrappers have their advantages, so it is important to understand the differences between each type of packaging machine before making a purchase

11.What Are The Maintenance Procedures For a horizontal Flow Wrapper?

Check if the horizontal flow wrapper is running smoothly and at the right speed.

Inspect the machine for any signs of wear and tear, such as broken or worn parts that need replacing.

Lubricate all moving parts of the horizontal flow wrapper regularly using certified lubricants suitable for this application.

Check the tension of the horizontal flow wrapper’s belts regularly and adjust as necessary.

Clean all parts of the horizontal flow wrapper, including the casing, with a dry cloth or compressed air to ensure there is no dust buildup inside.

Ensure that cables and wires are undamaged, correctly connected and properly routed to prevent any interference.

Test the horizontal flow wrapper’s safety systems regularly, including emergency stops and power-failure protection.

Clean the horizontal flow wrapper after each production run using a mild solvent or cleaning fluid according to the manufacturer’s instructions.

Check all seals for wear and tear regularly and replace as necessary.

Check the horizontal flow wrapper’s film transport system for any sign of wear or damage, including misalignment of the film rollers.

Keeping up with these simple maintenance procedures will help ensure that your horizontal flow wrapper is running at its best performance, while also increasing its lifespan. Regular maintenance will also help prevent any potential problems from arising and ensure a safe working environment.

12.What Are The Common Problems Associated With Horizontal Flow Wrappers With Their Solutions?

Jammed Film

One of the most common issues with horizontal flow wrappers is that the film can become jammed in the system or not feed properly. This can cause problems with product quality and production rate. Solutions to this problem include ensuring that a high-quality, smooth film is being used, regularly maintaining the machine and keeping tension on the film tight.

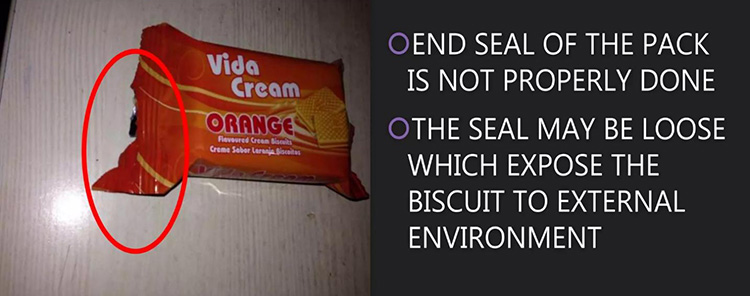

Unreliable Sealing

Another common problem with horizontal flow wrappers is that the seal can be unreliable, meaning it doesn’t always adhere properly or tears easily. This can cause problems with product integrity and shelf life. Solutions to this issue include ensuring good heat settings on the machinery, using quality film and regularly maintaining the equipment.

Product Damage

The horizontal flow wrapping process can cause product damage due to improper loading, incorrect infeed speed or other factors. Solutions to this issue include ensuring that products are properly loaded in the feeder, setting the machine’s infeed speed to an appropriate level and regularly inspecting the machinery for wear and tear.

Unwrapped Products

Horizontal flow wrappers can also have issues with unwrapped products, meaning they don’t make it through the entire wrapping process. Solutions to this include regularly cleaning and maintaining the machine, ensuring that products are correctly loaded in the feeder and checking for any loose or broken parts.

Conclusion

All in all, the horizontal flow wrapper packs a powerful punch when it comes to packaging and productivity. If you need more information on how a horizontal flow wrapper can be beneficial for your business, don’t hesitate to contact Allpack for expert advice. Whether you are considering purchasing or a consultation about sizing options – Allpack will be available to assist you every step of the way. Get in touch with us today to get started on the journey of smoother and efficient packaging processes with the horizontal flow wrapper!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide