Uphill Tablet Deduster: The Complete Buying Guide In 2025

Are you tired of dealing with dusty and inefficient tablet production lines? Look no further than the uphill tablet deduster! This revolutionary machine is the solution to all your tablet dedusting needs.

But before you make your purchase, it’s important to understand what to look for in an uphill tablet deduster. What size should you get? And most importantly, how do you know you’re getting a good deal?

Don’t worry, we’ve got you covered. In this complete buying guide, we’ll answer all your burning questions and equip you with everything you need to know to make an informed decision. So sit back, relax, and let’s get started!

Some important questions we will cover in this guide include:

1.What is an uphill tablet deduster?

An uphill tablet deduster is a pharmaceutical manufacturing machine used to remove excess powder and debris from tablets as they travel along an inclined conveyor belt. This machine plays a crucial role in the production of high-quality tablets that meet the strict standards of the pharmaceutical industry.

The use of an uphill tablet deduster helps ensure that the tablets are free from contaminants, such as dust, which can compromise the effectiveness and safety of the medication.

The process of manufacturing tablets involves compressing a blend of active ingredients and excipients into a solid dosage form. During this process, excess powder and debris can accumulate on the surface of the tablets, which can affect their appearance and quality.

To address this issue, pharmaceutical manufacturers use an uphill tablet deduster, which is designed to remove these unwanted materials as the tablets move up the conveyor belt.

2.What advantages does an uphill tablet deduster offer?

An uphill tablet deduster is a specialized equipment used in pharmaceutical manufacturing that offers several advantages over traditional tablet dedusters. Here are some of the unique benefits of an uphill tablet deduster:

Increased Efficiency:

One of the primary advantages of an uphill tablet deduster is its increased efficiency. The uphill design allows for more tablets to be dedusted in a shorter amount of time, thereby increasing production output. This increased efficiency can be especially beneficial for large-scale manufacturing operations where high volumes of tablets need to be processed quickly.

Improved Quality:

An uphill tablet deduster can also improve the quality of tablets produced. The equipment is designed to remove dust, debris, and other impurities that can affect the quality and appearance of tablets. This can lead to a more consistent product that meets the required standards.

Lower Operating Costs:

Another advantage of an uphill tablet deduster is that it can help lower operating costs. The equipment is designed to be energy-efficient, reducing the amount of electricity needed to operate it. Additionally, the uphill design allows for better use of gravity, which means that fewer moving parts are required to move tablets through the system. This can result in lower maintenance costs and reduced downtime.

Flexibility:

An uphill tablet deduster can also offer greater flexibility in terms of the types of tablets that can be processed. The equipment is designed to handle a variety of tablet shapes and sizes, making it suitable for use in a wide range of pharmaceutical manufacturing applications. This can be particularly beneficial for companies that produce a diverse range of products.

Improved Safety:

Finally, an uphill tablet deduster can offer improved safety for operators. The equipment is designed to be easy to clean and maintain, reducing the risk of contamination and ensuring that the equipment is safe to use. Additionally, the uphill design means that operators can access the equipment from a safer position, reducing the risk of injury.

These benefits can help pharmaceutical manufacturers improve their production processes and deliver high-quality products to customers.

3.In what situations is an uphill tablet deduster typically used?

An uphill tablet deduster is a device used in the pharmaceutical industry to remove excess powder and debris from tablets as they move up a conveyor belt. The device utilizes a combination of vibration and suction to remove unwanted particles from the tablets. While the primary use of an uphill tablet deduster is in the pharmaceutical industry, there are a few other unique applications where it can be utilized:

Nutraceutical Industry:

Nutraceuticals are products derived from food sources that provide health benefits beyond basic nutrition. Many nutraceuticals are in the form of tablets and require similar processing as pharmaceutical tablets. An uphill tablet deduster can be used in nutraceutical production to ensure that the tablets are free from excess powder and debris.

Cosmetics Industry:

Some cosmetic products are also produced in tablet form, such as effervescent tablets for skincare. An uphill tablet deduster can be used to remove excess powder and debris from these tablets, ensuring that they are clean and safe for use.

Agricultural Industry:

Some agricultural products are produced in tablet form for use in animal feed, such as vitamin supplements. An uphill tablet deduster can be used in the production of these tablets to ensure that they are free from excess powder and debris, m

4.Are there other types of tablet dedusters available except the uphill one?

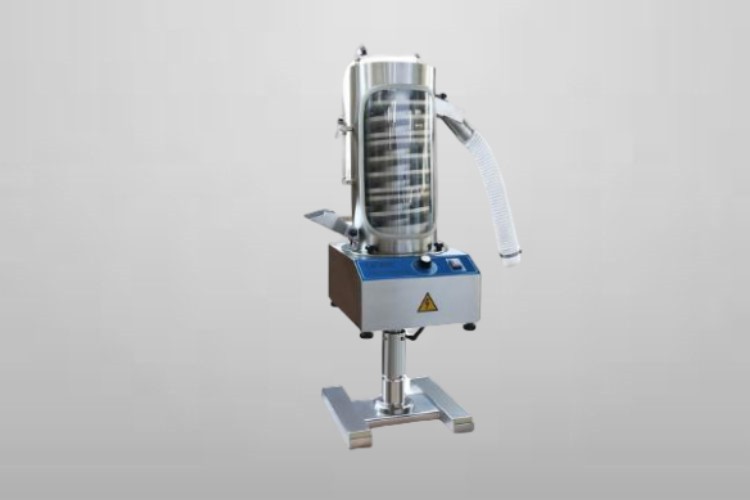

Vertical/Elevating Tablet Deduster

The vertical/elevating tablet deduster is a cutting-edge piece of equipment designed to remove excess powder and debris from pharmaceutical tablets, capsules, and other similar products.

This machine is incredibly versatile and can handle a wide range of products and tablet sizes. It’s easy to use and maintain, making it a cost-effective solution for any pharmaceutical manufacturing facility. Its compact size and efficient design make it an ideal choice for businesses looking to optimize their production processes without sacrificing quality.

Horizontal Tablet Deduster

Introducing the horizontal tablet deduster, a state-of-the-art pharmaceutical equipment designed to effectively remove excess powder and debris from tablets. Thanks to its advanced design and features, the horizontal tablet deduster helps ensure that tablets meet the highest standards of quality and safety. Its automated cleaning system also makes it easy to maintain, reducing downtime and increasing efficiency.

Brush Type Tablet Deduster

Brush Type Tablet Deduster-Photo Credits: CapPlus Technology

Whether you are a pharmaceutical manufacturer, a contract packaging company, or a research laboratory, the brush type tablet deduster is the ideal solution for achieving clean, polished, and ready-to-package tablets with maximum efficiency and reliability.

The brush type dedusting system features a series of soft, flexible brushes that rotate at high speeds, creating a powerful air current that lifts and carries away loose particles. The inclined conveyor belt ensures that the tablets are always moving upwards, against the force of gravity, further improving the efficiency of the dedusting process.

Telescopic Tablet Deduster

Telescopic Tablet Deduster-Photo Credit:Natoli Products

The telescopic tablet deduster is an advanced device specifically designed for removing dust and other unwanted particles from pharmaceutical tablets as they travel up an inclined conveyor belt. It is equipped with a telescopic arm that can be adjusted to match the height of various conveyor belts. Using a high-powered suction mechanism, this dedusting system guarantees top-quality products by eliminating any undesirable contaminants.

Whether it is used as a stand-alone tool or integrated into an existing production line, this dedusting system provides a reliable and efficient method of ensuring optimal tablet cleanliness and consistency.

High Speed Tablet Deduster

High Speed Tablet Deduster-Photo Credit: iPharMachine

One of the standout features of the high speed tablet deduster is its ability to operate at high speeds while still maintaining exceptional accuracy and precision.

The high speed tablet deduster is an innovative and highly efficient machine designed to remove dust, debris, and other unwanted particles from tablets that are produced in pharmaceutical, nutraceutical, and other related industries. With its advanced features, this state-of-the-art tablet deduster can handle a wide range of tablet sizes and shapes, providing reliable and consistent results.

Rotary Vibrating Tablet Deduster

Rotary Vibrating Tablet Deduster-Photo Credit: ProgiTec

The rotary vibrating tablet deduster is a cutting-edge device that is revolutionizing the tablet production industry. Designed with efficiency and precision in mind, this machine features a unique rotary vibration mechanism that ensures the thorough and effective removal of dust and other impurities from tablets.

What sets the rotary vibrating tablet deduster apart is its advanced technology and customizable settings.

5.How does uphill tablet deduster compare with tablet polisher?

Uphill tablet dedusters and tablet polishers are both commonly used in the pharmaceutical industry to remove excess dust and improve the appearance of tablets. While they serve a similar purpose, there are some clear differences between the two machines.

Operating Principle: The operating principle of the uphill tablet deduster involves an inclined vibrating channel where tablets are fed to move up with vibration and filtered with the help of the airflow. Tablet polisher, on the other hand, employs a rotating polishing drum where the tablets are polished through mechanical and chemical processes.

Efficiency: Both machines are efficient in cleaning and improving the appearance of tablets. However, the uphill tablet deduster is more effective in removing dust and other debris from the tablets as it uses an airflow to remove the dust particles. Whereas, the tablet polisher is more effective in improving the tablet’s appearance by polishing it and giving it a shiny surface.

Suitability: The uphill tablet deduster is more suitable for use in industries where dust is a major concern, and the tablets need to be cleaned thoroughly. On the other hand, the tablet polisher is more suitable for use in industries where the tablet’s appearance is a primary concern, such as cosmetics, where the tablets need to have a smooth, polished surface.

Maintenance: Both machines require regular maintenance to keep them in good working condition. However, the tablet polisher is more complex and may require more maintenance than the uphill tablet deduster due to the intricate components and chemical processes involved.

In summary, the uphill tablet deduster is more effective in removing dust and debris from tablets, while the tablet polisher is more effective in improving the appearance of the tablets. Both machines are useful in the pharmaceutical industry, and their suitability will depend on the specific needs of the industry.

6.What are the key components of an uphill tablet deduster?

Tablets Inlet

Tablet Inlet-Photo Credit: Medical EXPO

The tablets inlet is the entry point of the uphill tablet deduster where the tablets are fed into the machine for cleaning and polishing.

Metal Detector

Metal Detector-Photo Credit: Medical EXPO

The metal detector is a device integrated into the uphill tablet deduster that detects and removes any metallic impurities or foreign objects from the tablets.

Vacuum Suction Device

The vacuum suction device is a component of the uphill tablet deduster that sucks in and removes dust and debris from the tablets during the cleaning and polishing process.

Digital Vibration Controller

Digital Vibration Controller-Photo Credit: CroPharm

The digital vibration controller is a component of the uphill tablet deduster that regulates and adjusts the vibration frequency and intensity to ensure effective cleaning and polishing of the tablets.

Perforated Plate

Perforated Plate-Photo Credit: NIMA ERRE.TI PACKAGING

The perforated plate is a component of the uphill tablet deduster that aids in the cleaning and polishing process by allowing for proper distribution of air and vibration to the tablets.

HMI

The HMI (Human-Machine Interface) is the user interface component of the uphill tablet deduster that allows operators to monitor and control the machine’s operation.

Dust Collector

A dust collector is a device used in a tablet deduster to remove dust and debris generated during the tablet cleaning process. It helps to maintain a clean working environment and prevents the release of potentially harmful particles into the air.

Discharge Chute

The discharge chute is the exit point of the uphill tablet deduster where the clean and polished tablets are discharged from the machine.

Auto-Rejector

The auto-rejector is a component of the uphill tablet deduster that automatically removes any defective or misshapen tablets from the production line.

7.How does an uphill tablet deduster operate?

Here’s how it operates step by step:

- Tablets are loaded onto the inlet hopper of the uphill tablet deduster.

- The tablets are then fed onto an inclined conveyor belt that vibrates, causing them to move up the belt.

- As the tablets move up the belt, they pass through a chamber where they are subjected to an upward flow of air.

- This upward flow of air causes any excess powder or debris on the tablets to be lifted off and carried away from the tablets.

- The powder and debris are then collected in a separate chamber, which can be emptied periodically.

- The tablets continue to move up the conveyor belt, passing through additional chambers where they may be further subjected to air flow to remove any remaining powder or debris.

- Finally, the tablets are discharged from the top of the conveyor belt and can be collected for further processing or packaging.

- Overall, the uphill tablet deduster operates by using a combination of vibration and air flow to remove excess powder and debris from tablets as they move up an inclined conveyor belt, resulting in cleaner and more uniform tablets.

8.Is it possible to integrate a uphill tablet deduster with tablet press machine?

Yes, it is possible to integrate an uphill tablet deduster with a tablet press. In fact, this is a common configuration in pharmaceutical manufacturing.

An uphill tablet deduster is a machine that removes dust and other unwanted particles from the surface of tablets as they move up an inclined conveyor.

A tablet press machine, on the other hand, is a machine that compresses powder or granular material into tablets. The tablets are formed within the machine and are then ejected from it onto a chute or conveyor for further processing.

To integrate an uphill tablet deduster with a tablet press machine, the deduster is typically placed behind the tablet press machine in the production line. The tablets are fed into the deduster from a hopper or another conveyor, and the deduster removes any dust or debris from the tablets after they produced the tablet press machine.

Overall, integrating an uphill tablet deduster with a tablet press machine can help to improve the quality and consistency of the tablets, while also reducing the risk of contamination and improving the efficiency of the production process.

9.What are the procedures for addressing issues with an uphill tablet deduster?

If you are experiencing issues with your uphill tablet deduster, here are some procedures and common troubleshooting steps that you can follow:

Tablets are not feeding properly into the machine:

Check the tablet hopper for any obstructions or blockages that may be preventing tablets from flowing freely. Also, ensure that the tablet size and shape are compatible with the machine’s specifications.

Excessive dust is still present on tablets after dedusting:

Check the machine’s brush speed and vibration frequency to ensure they are set correctly for the type of tablets being processed. Also, check the airflow settings to ensure there is adequate ventilation to remove dust and debris.

Machine is making unusual noises or vibrations:

Inspect the machine for any loose or damaged parts, and tighten or replace them as necessary. Also, check the bearings and belts for wear and tear.

Machine is overheating or shutting down:

Check the machine’s temperature and ventilation, and ensure that it is not overloaded or running for extended periods without adequate rest.

Machine is not turning on:

Check the power source and ensure that it is plugged in and switched on. Also, check the machine’s circuit breaker and fuse box for any tripped circuits or blown fuses.

Conclusion

In conclusion, if you’re looking for a reliable and efficient solution to dedusting your tablets, the Uphill tablet deduster is the way to go. With its advanced technology and user-friendly design, it’s sure to make your tablet production process smoother and more efficient than ever before. Plus, with its ability to handle a wide range of tablet shapes and sizes, you can trust that it will meet all of your dedusting needs. So don’t hesitate – invest in the Uphill tablet deduster today and watch as your tablet production process reaches new heights!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide