Handheld Tablet Press: The Complete Buying Guide In 2025

Handheld Tablet Press: The Complete Buying Guide In 2025

Are you a business owner that involves usage of a handheld tablet press? Are you interested in buying a high-quality handheld tablet press to improve your productivity? Are you interested in investing in a handheld tablet press? Does your industry involve tablet pressing process? Want to know more regarding a handheld tablet press? This is the forum where you can get all the related information that will support you in selecting the right type of handheld tablet press. Read the complete guide to resolve your queries.

1.What Is A Handheld Tablet Press?

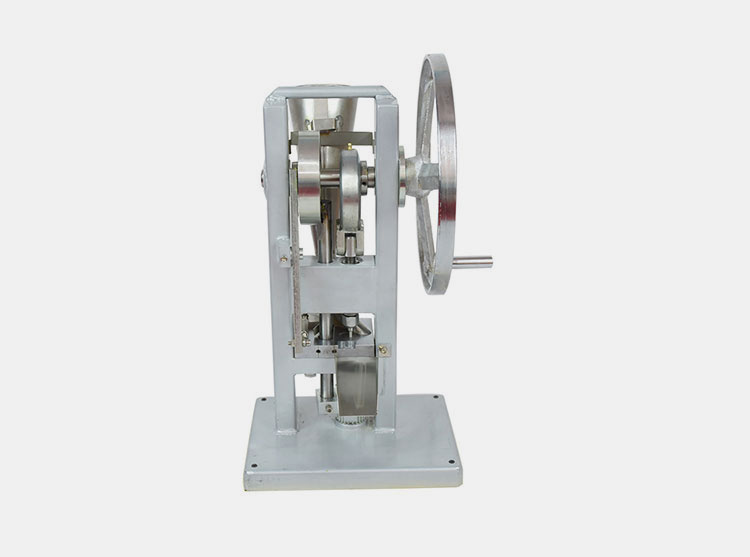

Handheld Tablet Press

A handheld tablet press is a portable equipment used in various industries to manually compress powdered or granular materials into tablets.

It has a press mechanism, die cavity, and a handle for manual operation, making it ideal for small-scale or laboratory applications. These presses provide a simple and cost-effective way to produce tablets with precise dimensions and consistent weight.

2.What Are The Applications Of A Handheld Tablet Press?

Allpack Handheld Tablet Press Applications

Handheld tablet press has numerous uses depending upon the size and shape of tablets. Some of the applications of a handheld tablet press are

Pharmaceutical Industry

Formulating Pharma Tablets - Picture Courtesy: PharmaTech

Pharmaceutical industry widely uses handheld tablet press for its clinical trials and initial testing purpose. Some of the small-scale pharmaceutical industry also applies handheld tablet press to produce efficient and unique type of tablets. Many clinical trials are also carried on using a handheld tablet press as it can be easily adjusted for different formulations and produce accurate samples.

Herbal Industry

Herbal Tablets - Picture Courtesy: Candy Room Sweets

Herbal industry also uses handheld tablet press to make precise and consistent dosage of medicines. This helps in preventing material loss and also standards the productivity with keeping the quality consistent in each tablet.

Nutraceutical Industry

Manufacturing Nutraceutical Tablets - Picture Courtesy: Nutraceutical Business

Formulation of supplements and vitamins produced in nutraceutical industries are mostly carried out using a handheld tablet press. These tablets are produced for testing and research purpose in small scale industries. Press is feasible to use and also efficient in producing nutraceutical tablets.

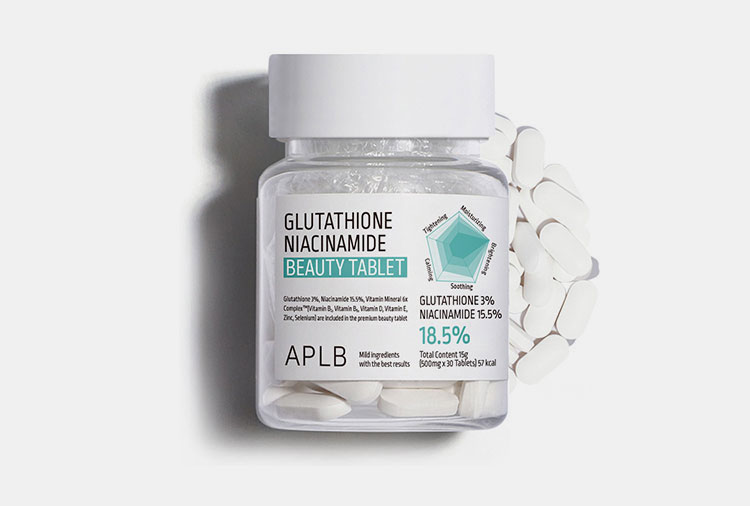

Cosmetics Industry

Glutathione Niacinamide Beauty Tablet - Picture Courtesy: APLB

Most of the skin and health care tablets produced in cosmetics industry are manufactured using a handheld tablet press. These tablets are easily produced by high quality pressing and material mixing capability of a handheld tablet press.

Fertilizer And Agricultural Industry

Tree Grow Fertilizer Tablets- Picture Courtesy: Northwoods Tree Farms

Fertilizers and pesticides that are important for the growth of plants to provide them a controlled growth and to keep insects away are also processed using a handheld tablet press. Agricultural sector uses these handheld tablet presses for formulation of unique types of tablets.

Research And Development Labs

Research & Development - Picture Courtesy: Bora Pharmaceuticals

Handheld tablet press is also used for on field research and development purposes. They are used in field applications or remote places where larger-scale tablet pressing equipment is unavailable or unfeasible.

3.What Benefits You Can From A Handheld Tablet Press?

There are several advantages of a handheld tablet press. Some of them are

Flexibility

Flexible Use Of Handheld Tablet Press

Handheld tablet press is highly efficient when it comes to their mobility and accommodation. These can easily be moved from one place to another and are flexible in handling. Handheld tablet press allows quick changes to formulas and forms. Tablets of any size and shape can easily be produced using a handheld tablet press.

Handling

Handheld Tablet Press - Picture Courtesy: Automatic Rotary Tablet

The press has simple operation that does not requires any expert training. The controls are provided and guided for exact tablet compression.

Customization

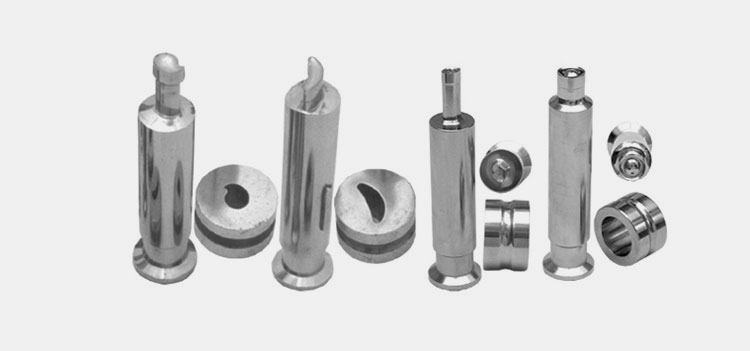

Design Tablet Tooling

Another benefit of a handheld tablet press is that it can be changed easily according to the required shape and size of tablet. The machine is easy to customize by just changing the die cavity of required tablets within a small fraction of time.

Waste Reduction

Several Efficient Medical Tablets Designs

Handheld tablet press ensures that no material of tablet is send on account of wastage and also reduced material spillage. It maintains the composition of tablets and saves a lot of resources.

4.What Types Of Tablets Are Processed In A Handheld Tablet Press?

Some of the types of tablets that are processed in a handheld tablet press are

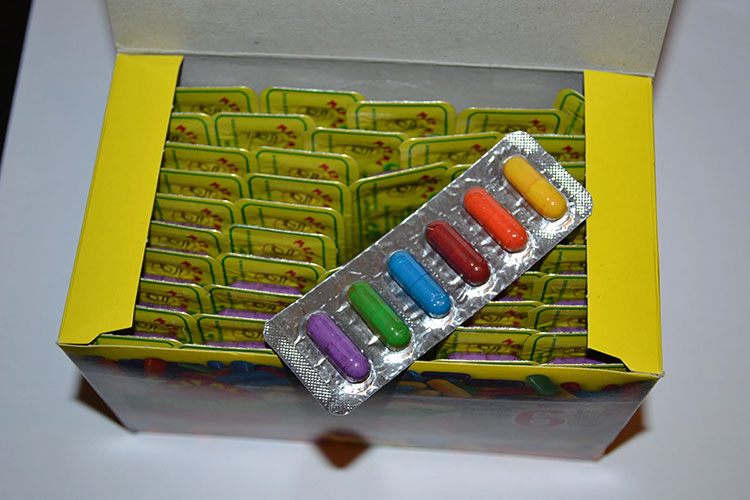

Immediate And Extended Release Tablets

Immediate Release Tablet - Picture Courtesy: XenoFarma

Abundantly, pharmaceutical tablets are processed using a handheld tablet press globally. Immediate and extended release tablets are mostly processed in a handheld tablet press to maintain their effectiveness and quality. The drugs are used for quick and gradual cure of diseases respectively.

Chewable Tablets

Chewable Tablets - Picture Courtesy: PharmaTech

Some of the formulated tablets are difficult of inhale. For this purpose, modern research and development has introduced chewable tablets that are easy to swallow and also have different flavors that can help in their easy intake.

Vitamin Supplements

Vitamax - Picture Courtesy: Nutrifactor

Most of the tablets that contains vitamins or minerals can easily be processed using a handheld tablet press. It ensures their accurate formulation and also helps in saving important material from wastage. Most of the nutraceutical and cosmetics industry use handheld tablet press for processing of vitamins and minerals tablets.

Lozenges

Strepsils Orange With Vitamin C Lozenges - Picture Courtesy: Strepsils

Handheld tablet presses are also compatible with variety of lozenges that are made up of active pharmaceutical ingredients. This equipment can easily produce lozenges medications that are used mostly for throat and mouth diseases that make them easy to swallow or chew.

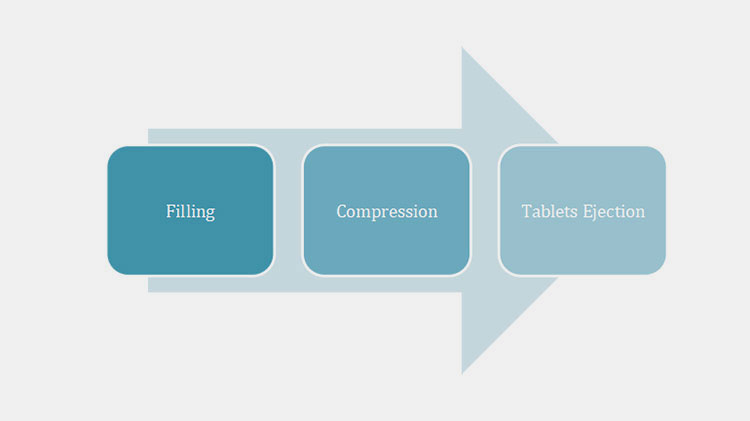

5.What Is The Working Procedure Of A Handheld Tablet Press?

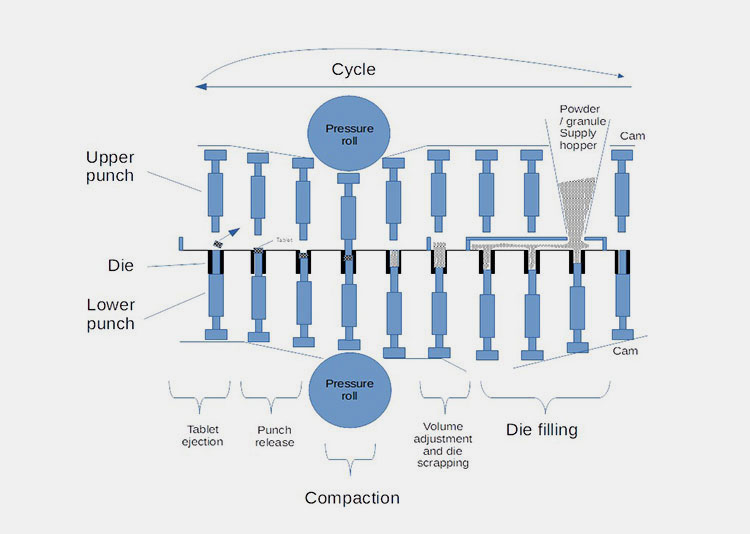

Handheld Tablet Press Working – Picture Courtesy: Powder Process

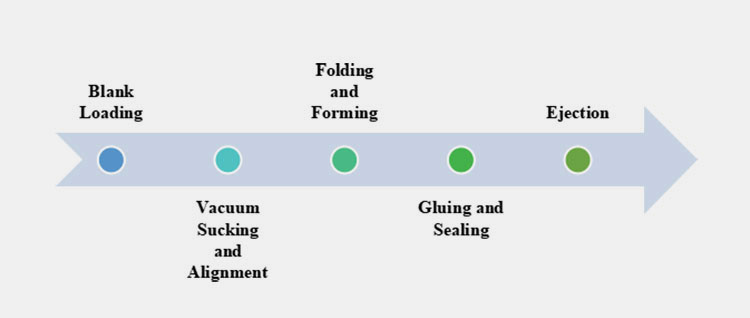

A handheld tablet press typically involves following working steps in its operation

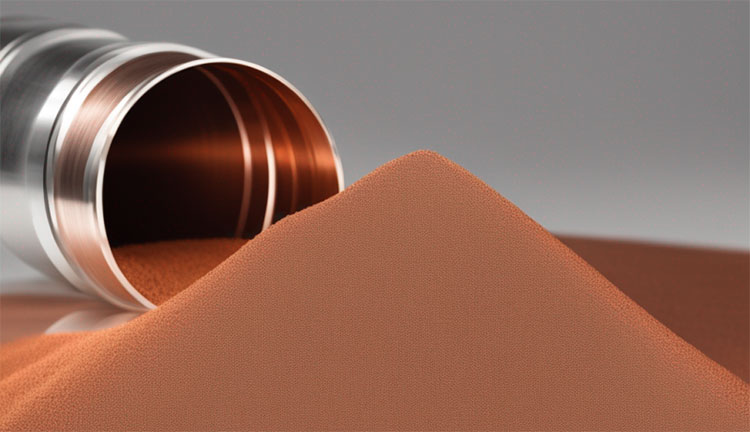

Step 1: Formulation

Initially the powdered or granular components are formulated that are to be used for the preparation of a tablet.

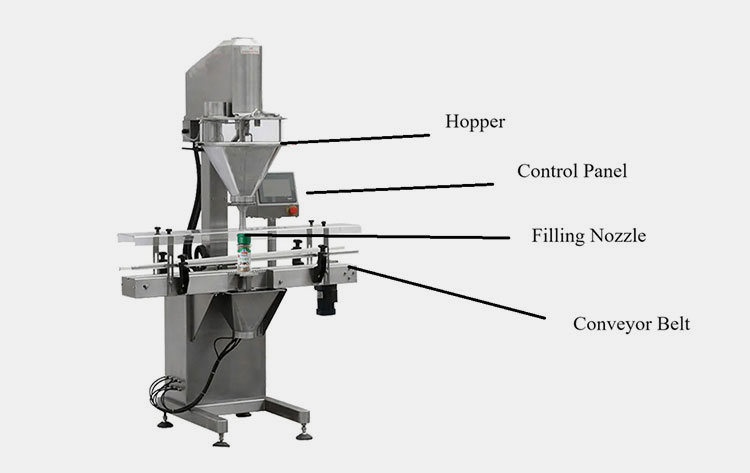

Step 2: Material Filling

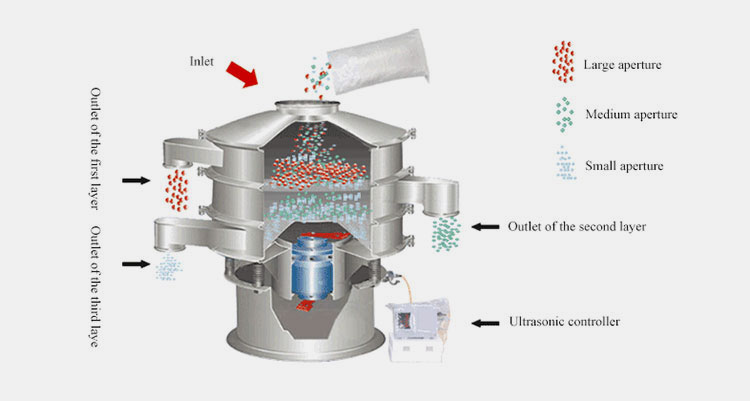

Once the formulation is done the die cavity of a handheld tablet press is filled with evenly distribution of prepared formulation so that the composition remains the same in each tablet.

Step 3: Compaction

Manual pressure is used to condense the formulation into a tablet shape within the die chamber of a handheld tablet press.

As a result of this pressure the tablet is forms within the die cavity and it is then removed from the die cavity with the ejection mechanism.

Step 4: Tablet Ejection

The tablets are collected to ensure their quality which included their size, shape, weight and consistency. The same process is repeated to continue the process.

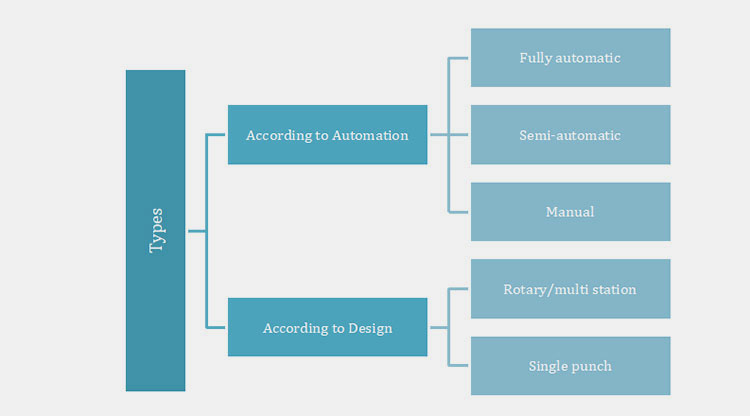

6.What Are The Different Types Of Handheld Tablet Press Available Globally?

Globally there are various types of handheld tablet presses available which are used to produce different types of tablets

Single Punch Handheld Tablet Press

Single Punch Handheld Tablet Press

One of the simplest types of a handheld tablet press that only uses a single punch for tablet formulation is a single punch handheld tablet press. A single punch handheld tablet press is used in small scale industries where low productivity volume is present.

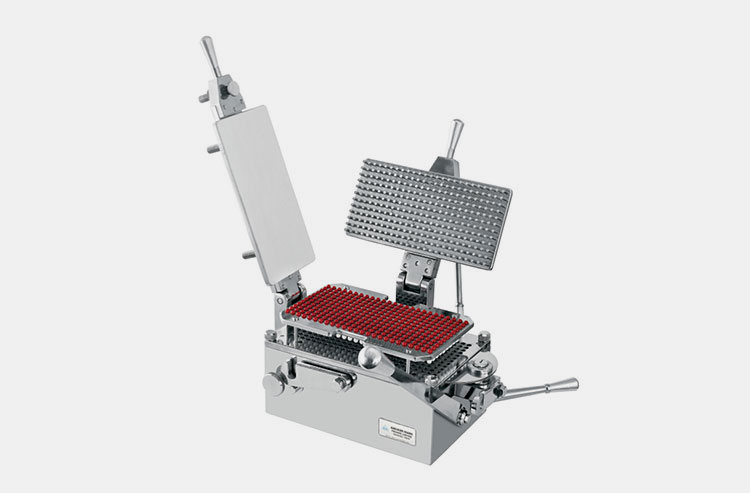

Multi Punch Handheld Tablet Press

Hand Operated Multi Punch Tablet Press

A multi punch handheld tablet press is used to produce more than one tablet at a single punch. The presses have multiple turrets and die cavities that rotate to compress the formulation into tablets. A multi punch handheld tablet press is used in small scale pharmaceutical industry to produce to enhance their productivity.

Manual Cam-Operated Handheld Tablet Press

Manual Cam-Operated Single Punch Handheld Tablet Press

A manual cam-operated handheld tablet press is simple to operate and much user friendly as compare to other types of handheld tablet presses. It is ideal for small-scale or for on field applications.

Hydraulic Handheld Tablet Press

Hydraulic Handheld Tablet Press – Picture Courtesy: Global Pharma

A hydraulic handheld tablet press uses hydraulic pressure to provide fine control tablet formation and is perfect for high-speed and large-scale manufacturing processes. This compact press is ideal for producing single tablets.

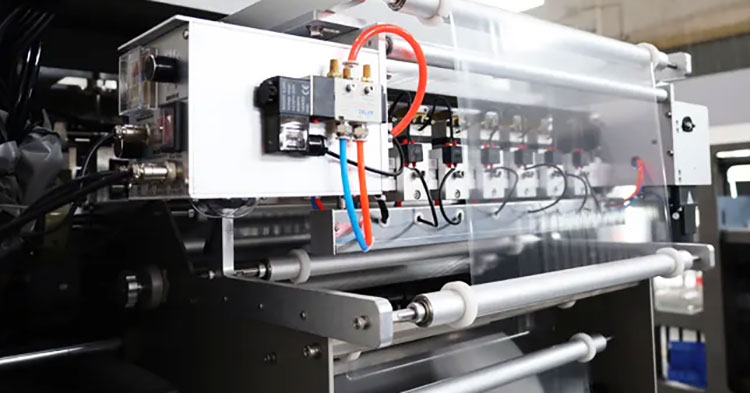

7.What Are The Main Components Of A Handheld Tablet Press?

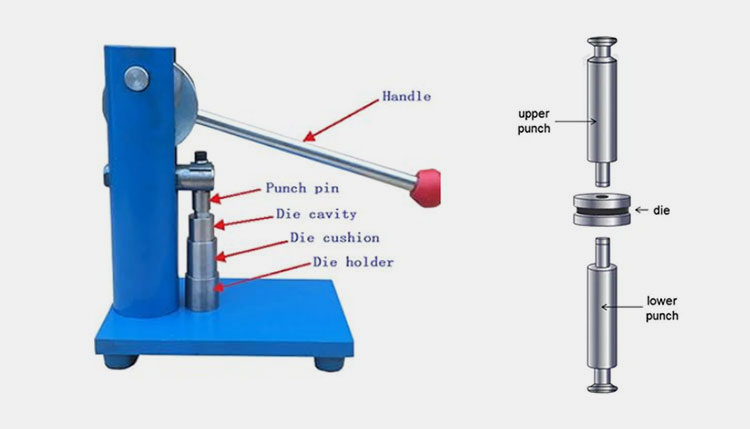

The Main Components Of A Handheld Tablet Press

A handheld tablet press has a simple structure consisting of following parts

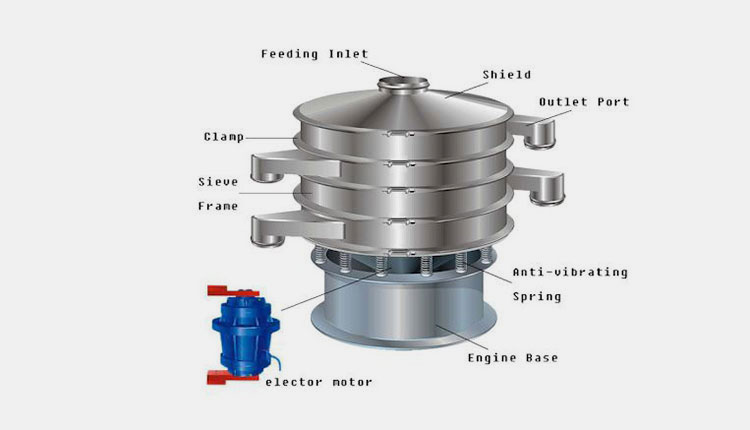

Die Cavity

The die cavity is the area in which the tablet formulation is entered to form a tablet. Here the punches are squeezed to produce tablets of the specified shape and size.

Punch

A handheld tablet press has two types of punches an upper punch and a lower punch. The upper punch is a part that exerts pressure on the formulation within the die chamber. Whereas the lower punch is the section of press that supports the die chamber and aids in tablet compression.

Handle

A handle is used for manually operating the press and applying pressure to compress the tablet formulation.

Die Holder

In the structure a die holder is that holds the tablet press components including the die cushion and die cavity. It offers stability while the operation is performed.

8.What Are The Major Differences Between A Handheld And A Rotary Tablet Press?

Differences Between A Handheld And A Rotary Tablet Press

Both handheld and rotary tablet press is used for tablet formulation and has same basic mechanism. Some of the differences between these two types of tablet press are:

| Description | Handheld Tablet Press | Rotary Tablet Press |

| Operation | A handheld tablet press has mostly single punch for tablet formation. It uses manual intervention to form different types of tablets. The formulation is entered in the die cavity and pressed manually to form tablet. | Whereas a rotary tablet press uses a turret with multiple die pockets that can compresses the powder or granules into tablets as the turret rotates. Automatic and semi-automatic processes are carried out in an efficient manner. |

| Machine Structure | A handheld tablet press has a simple and small structure with a handle and a die cavity to press tablet formulation. Manual process is done by the operator in an easier way. | The structure of rotary tablet press is complex as compare to handheld tablet press as it contains multi layered dies, punches and feeding system. All combine to form large number of tablets in a small fraction of time. |

| Production Capacity | Only 5 to 10 tablets are formed in a minute depending upon the efficiency of the operator. | The rotary tablet press is basically designed in a way that is can fulfill requirement of large-scale industries. Thousands of tablets are produced in a single minute with a greater efficiency and precision. |

9.How Different Die Sizes Are Adjusted In A Single Handheld Tablet Press?

Manual Single Punch Tablet Press - Picture Credit: CECLE Machine

Different sizes and shapes of tablet require different dies and punches for their formation. For these tablets, a single handheld tablet press can be suitable by just changing both the upper and lower punches of die cavity. These punches can easily be removed and are interchangeable with other sets. Each die set has its particular size and shape that makes it appropriate to handle and use when required.

Discuss following points are suitable for adjusting punch die in a tablet press:

Die Replacement

Die replacement- Picture Courtesy: Natoli

This is the first thing that comes in mind when talking about adjusting die. Yes you need to replace the whole die with older one. This is involved with manual removal of die by twisting the mold followed by newer die changeover.

Adjusting Lower Punch

Lower Punch of tablet Press

Many handheld tablets press are featuring adjustable lower punch with variation in thickness and diameter. This is the most flexible way as this is fast and easy.

Turret Rotation

Turret Rotation

By rotating turret, die of different sizes can be adjusted and allows a quick changeover.

Modern tablet presses are featured with tool free adjustments of dies with high working efficiency.

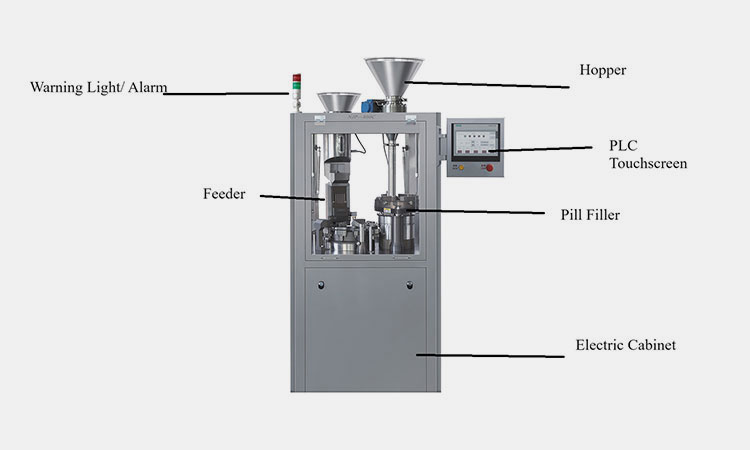

10.What Are the Major Differences Between A Handheld And An Automatic Tablet Press?

Some of the major differences between handheld and automatic tablet press are:

| Parameter | Handheld Tablet Press | Automatic Tablet Press |

| Working Operation | Complete operation in a handheld tablet press required manual intervention that is to perform all tasks. From material loading to ejection of tablet, all of the process is done manually. | In an automatic tablet press, majority of the process steps are performed by the machine itself. The machine gets the material from the hopper or container, presses it in between die cavities and then ejects them out of the system once they are fully prepared. |

| Controlling | From adjustments of die to production of tablets, the operator is responsible for the controlling of a handheld tablet press. | Machine is responsible for the task performing whereas the system parameters like speed, dispensing time, flow and other are feed by the operator that are used in controlling the operation. |

|

Efficiency |

The overall efficiency of a handheld tablet press remains low and completely relies of the expertise of the concern operator. | Where an automatic tablet press has complete automatic processes, the overall efficiency of the system remain top the mark in each of the produced tablet. Completely aligned and synchronized production is carried throughout the operation. |

| Productivity | The productivity of a handheld tablet press remains very low as it depends on the performance of operator that supports small scale industries only. | High level large scale industries prefer automatic tablet press where the production requirement remains high. These machines can produce thousands of tablets in an hour. |

11.How To Maintain A Handheld Tablet Press?

How To Maintain Handheld Tablet Press

Lubrication

To maintain a handheld tablet press it is important to lubricate its moving part with oil or grease that makes it easy to move for a longer period. If lubrication is not done on proper basis it can damage the parts both internally and externally.

Cleaning

One of the most important ways to maintain a handheld tablet press is to clean it properly after every batch or designated duration. As tablet powder can remain left in the die cavity therefore it is necessary to clean it properly and regularly to maintain the efficiency of tablets. Formulation and composition of tablets can also get affect if it is not cleaned properly.

Calibration Of Die Cavities

With certain pressure, die cavities or punches of a handheld tablet press can transform its shape that can be dangerous sometimes. It is always necessary to check the dimension of these punches and die cavity to maintain the quality and shape of any tablet. Otherwise, it can create a greater loss to the manufacturer.

Conclusion

A handheld tablet press gives significant usage when it comes to tablet formation and R&D purpose. It is always important to understand the uses, advantages, and operational methods of a handheld tablet press before buying it. Allpack is always here to provide you complete information related to a handheld tablet press and helps you in buying the best type of press. For any query contact our customer representatives that are available 24/7 for your guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Handheld Tablet Press: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours