Liquid Beverage Stick Packing Machine: The Complete FAQ Guide In 2025

Liquid Beverage Stick Packing Machine: The Complete FAQ Guide In 2025

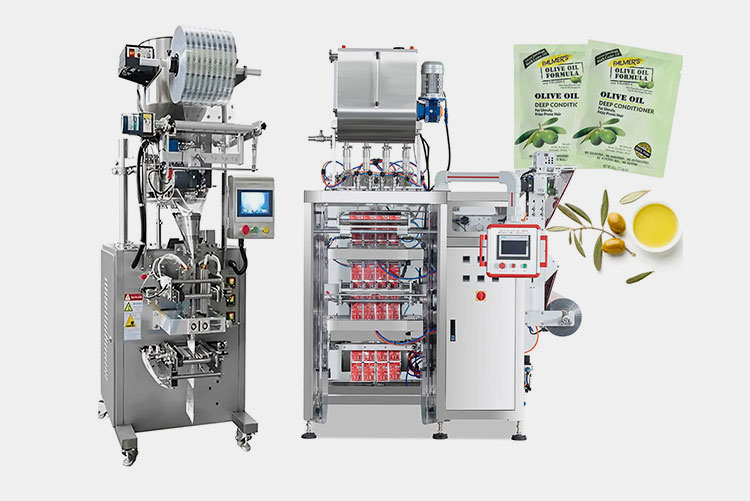

Beverages are a must on hot summer days and for that liquid beverage stick packing machine is a significant option. This machine has revolutionized the packaging field, as it makes stick packs that are convenient when hiking, camping, or hoteling.

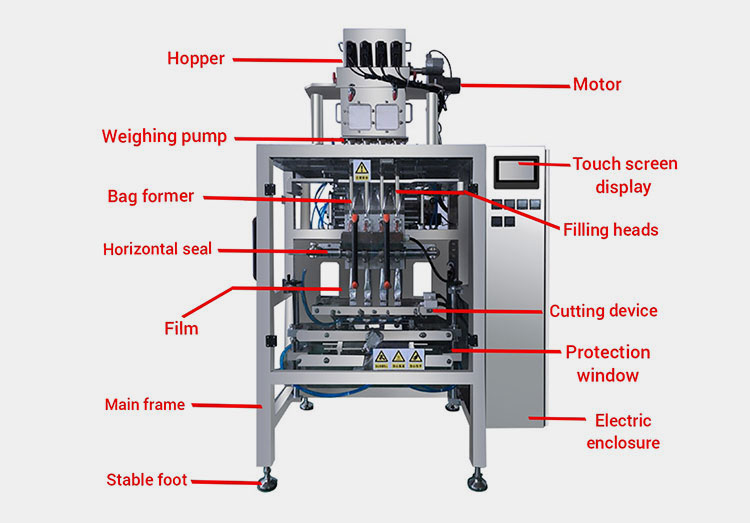

Liquid beverage stick packing machine meets daily production targets with its efficiency and speed. Due to its advanced and state-of-the-art technological parts, it delivers top-notch performance.

Are you an entrepreneur looking for this solution, then Jump On for an informative journey. In this FAQ guide, we will inform you about different packaging aspects of the liquid beverage stick packing machine.

1.What is Meant by the Liquid Beverage Stick Packing Machine?

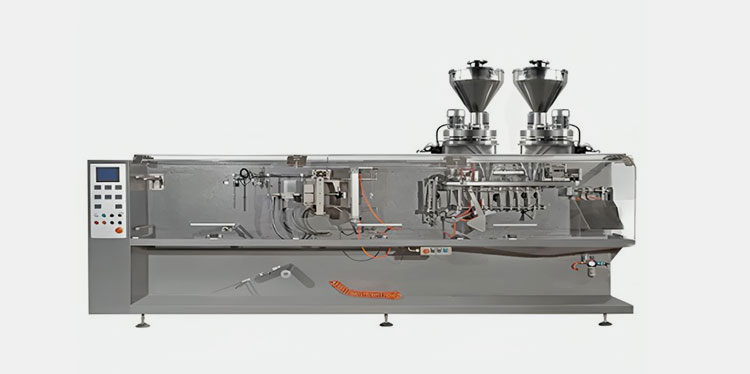

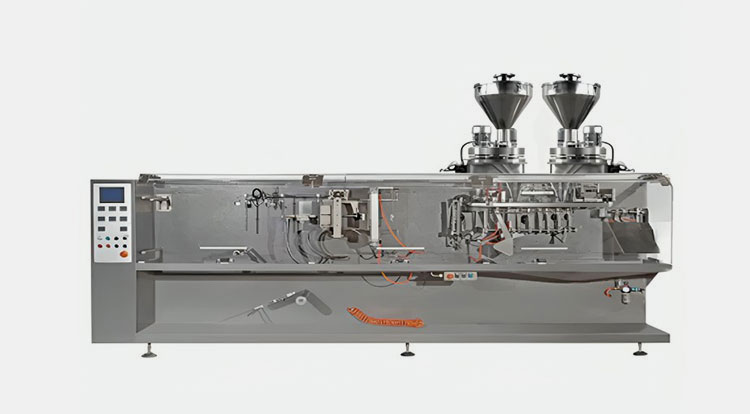

Liquid Beverage Stick Packing Machine

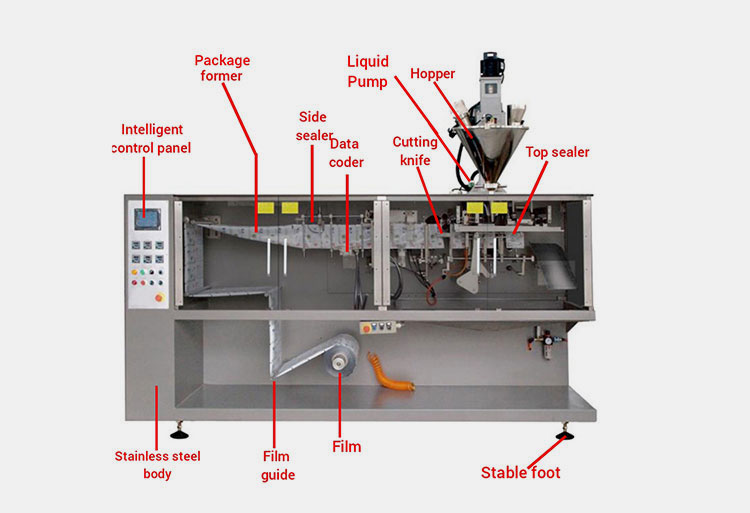

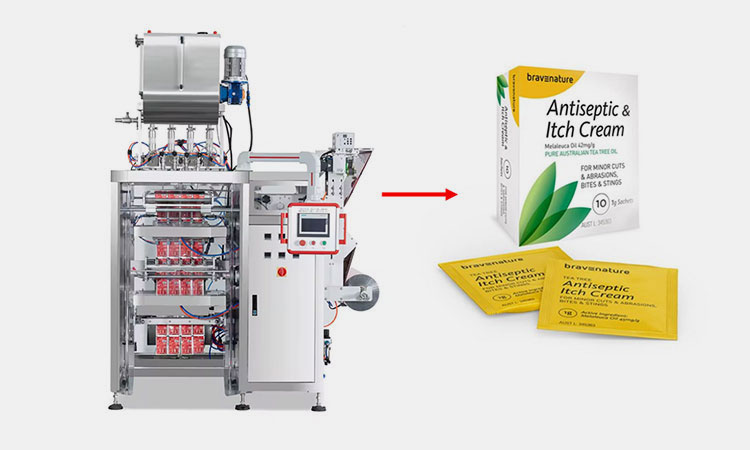

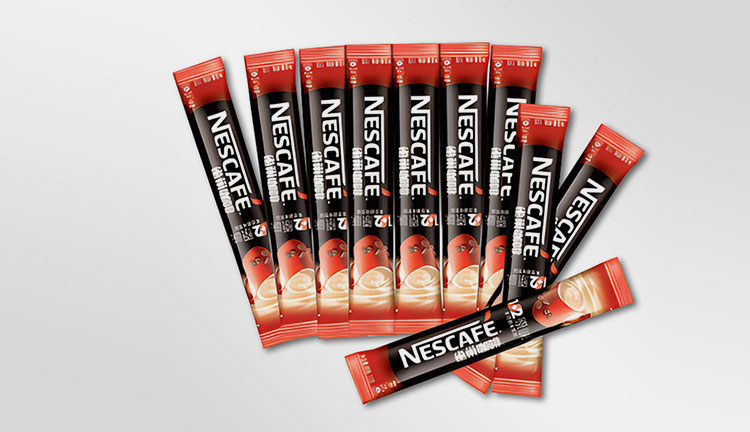

A liquid beverage stick packing machine is a piece of equipment that creates an elongated tubular narrow stick pack, fills it with single-serving of liquid beverage and seals it. It is an automated machine that fully contains liquid beverages in the stick pack for easier retailing, distribution, handling, and, marketing.

One of the main objectives of a liquid beverage stick packing machine is to pack a one-time serving of various liquid beverage for the go-on customers and portion control. This machine also ensures the freshness of liquid beverages by tightly sealing the stick pack.

2.How is Liquid Beverage Stick Packing Machine Important for Businesses?

Liquid beverage stick packing machine is automated and is equipped with advanced features that bring huge deals of benefits to the production like speed, versatility, and accuracy. Some of the useful attributes of this machine are discussed below:

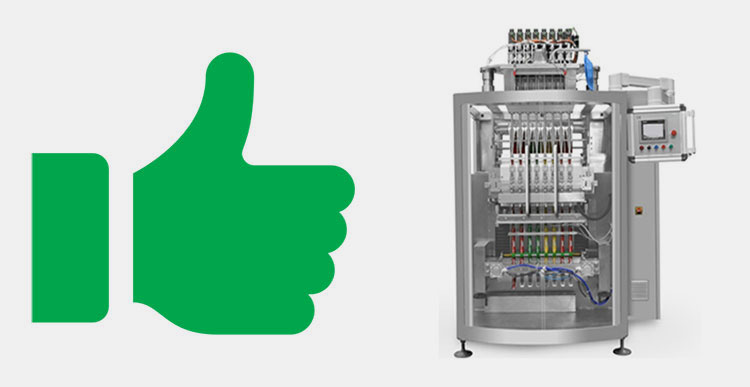

Efficiency and Speed

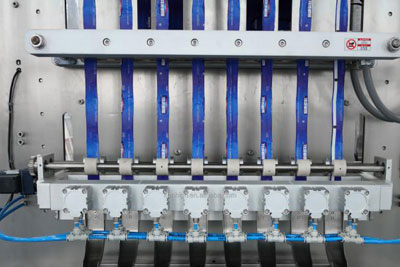

Efficiency with Liquid Beverage Stick Packing Machine- Picture Courtesy: Snapklik.com

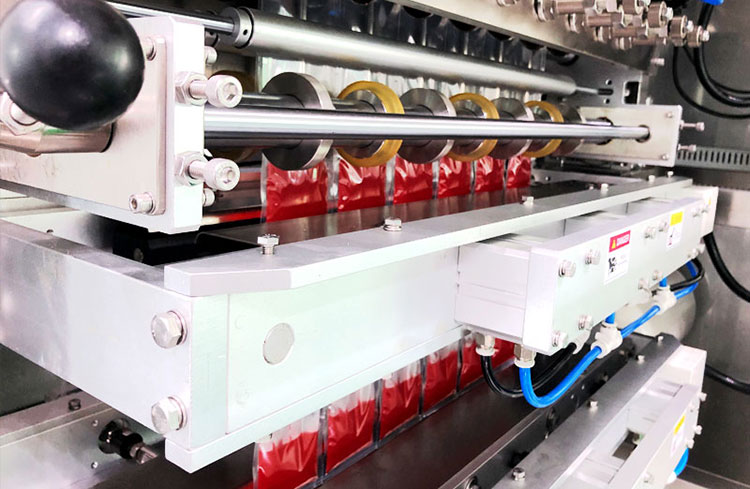

This machine is equipped with multiple lanes and due to these lanes, this machine can form, fill, and seal numerous stick packs in a single run. Various brands prefer this machine due to its advanced speed and high efficiency. Its high speed and extraordinary output rate bring profitable results for businesses.

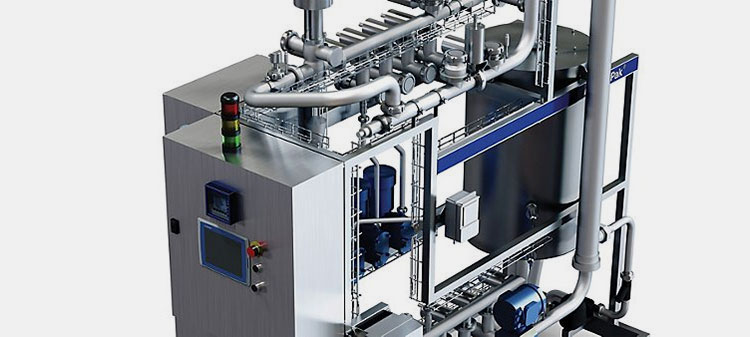

Increased Automation

Increased Automation with Liquid Beverage Stick Packing Machine- Picture Courtesy: Clean Simple Eats

Manual packaging is slow and tiresome, leading to low output. The liquid beverage stick packing machine is fully automated, working and packing liquid beverages independently. With its computerized parts, like the HMI touch screen and PLC unit, it is easier to program and control the packaging processes, ultimately reducing the burden on the workforce.

High Accuracy

High Accuracy with Liquid Beverage Stick Packing Machine

Liquid beverage stick packing machine features high-tech weighing systems and photocell sensors with which it achieves accuracy and precision in the forming, filling, and sealing processes. Different piston, pump, and net weigh systems in the liquid beverage stick packing machine reduce the rate of under-filling and overfilling.

Flexibility and Versatility

Flexibility and Versatility with Liquid Beverage Stick Packing Machine- Picture Courtesy: Vista Concept

This machine is known for its flexibility and versatility as it packs different shapes and sizes of stick packs. Furthermore, due to its changeable parts and filling devices, it can fill liquids with varying viscosities. Hence, it is versatile both in terms of liquid beverage being filled and stick pack being sealed.

Hygienic Processing

Hygienic Processing with Liquid Beverage Stick Pack- Picture Courtesy: Tailwind

The liquid beverage stick packing machine is fitted with easy-to-clean and food-grade materials, thus this machine allows hygienic processing. This hygienic processing is highly demanded in the food and beverage industry. The components of this machine are made with stainless steel that is durable, corrosion resistant, and safe for direct food contact.

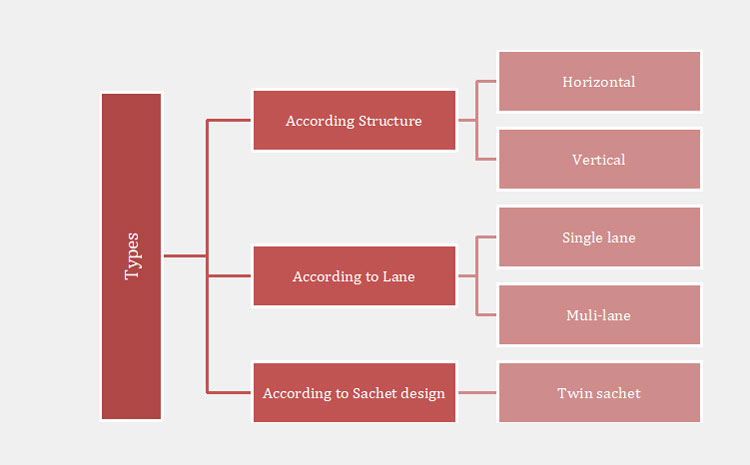

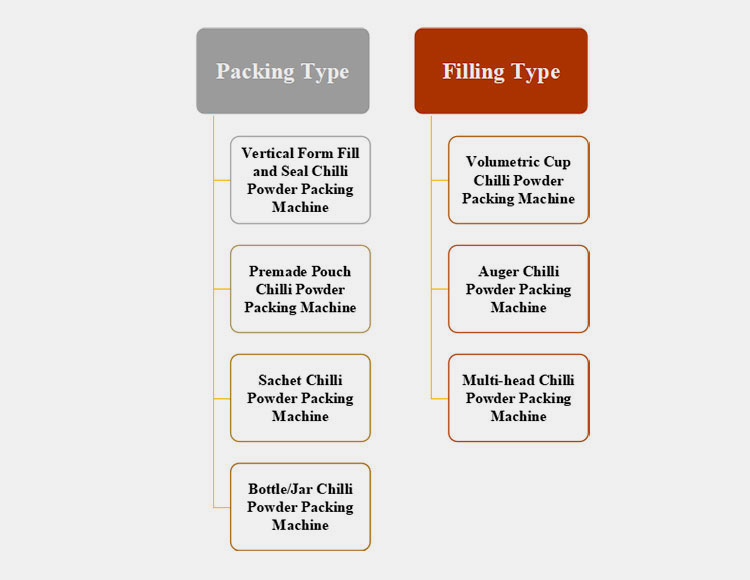

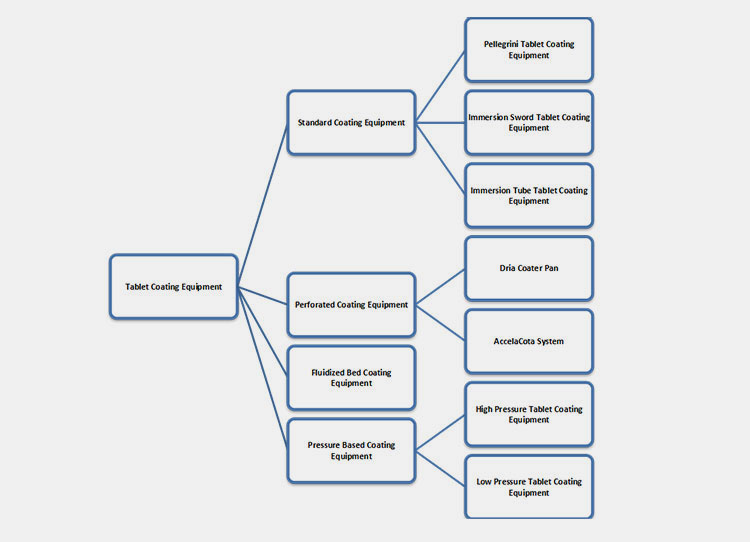

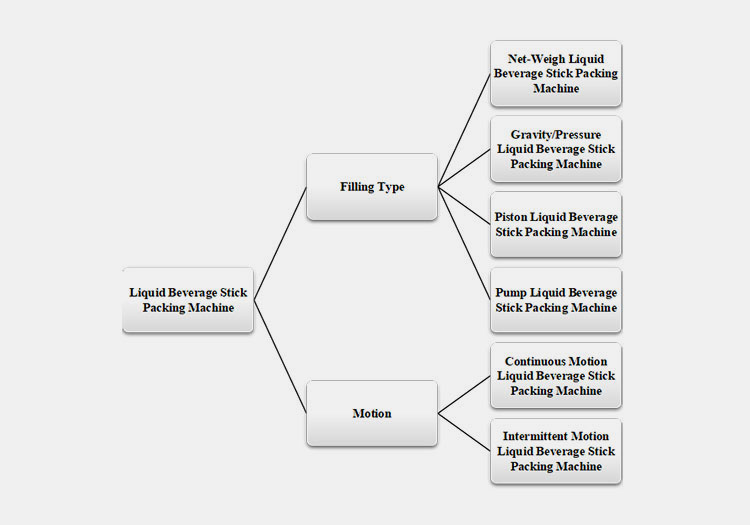

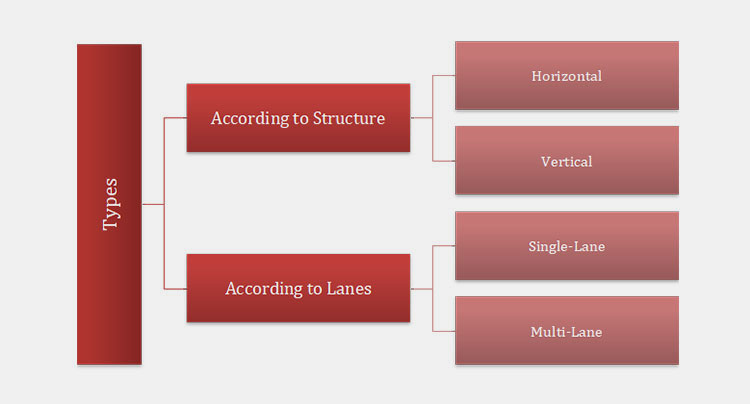

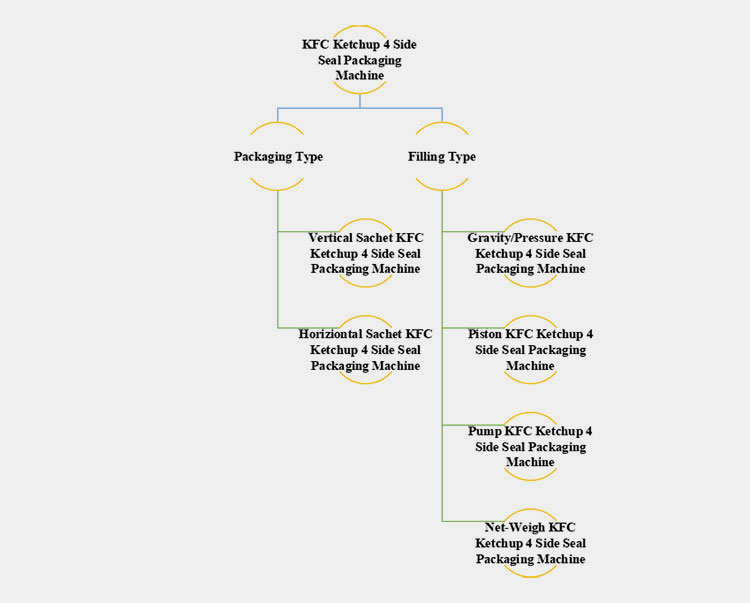

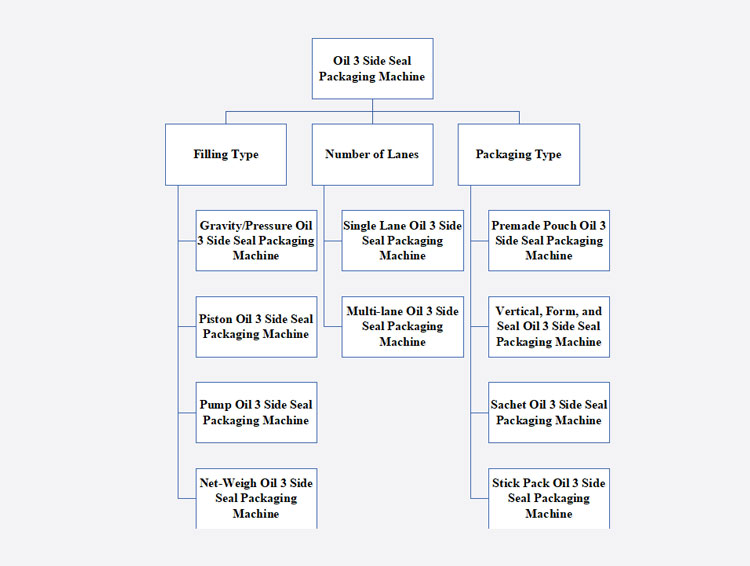

3.What is the Classification of Liquid Beverage Stick Packing Machine?

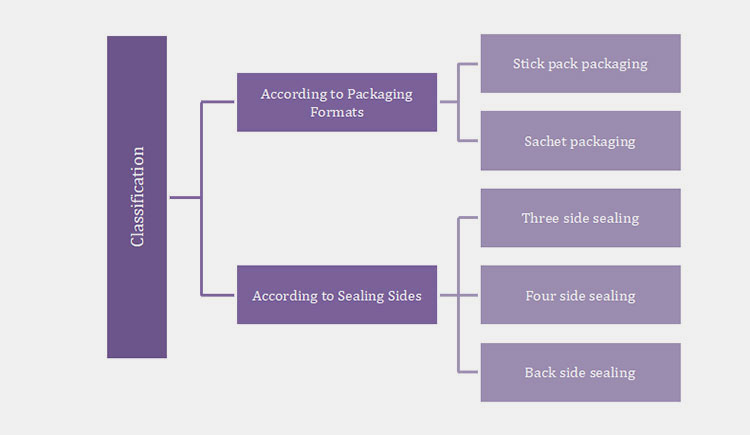

There are different types of liquid beverage stick packing machine based on filling types and motion types.

According to the Filling Type

Net-Weigh Liquid Beverage Stick Packing Machine

Net-Weigh Liquid Beverage Stick Packing Machine

This type of liquid beverage stick packing machine is equipped with a weight scale, load cells, and a PLC unit, with which it can load the liquid beverage in the stick pack by their weight. It is the only machine that loads liquid beverage by weight. This machine is used for filling liquid beverage, in which fill differences affect the product quality.

Gravity/Pressure Liquid Beverage Stick Packing Machine

Gravity/Pressure Liquid Beverage Stick Packing Machine

This machine has a simple construction and convenient design, consisting of a hopper, filling hose, and fill pipes. It fills thinner viscosity liquid beverage because of natural gravitational force and the pressure difference. Due to its simpler filling principle, it consists of a few parts and is a cost-effective machine for small and medium-scale businesses.

Piston Liquid Beverage Stick Packing Machine

Piston Liquid Beverage Stick Packing Machine- Picture Courtesy: jintian pack

The machine is mainly preferred for filling and packing of all types of liquids, like you can fill liquids with thinner as well as thicker flow rate. That’s why a piston liquid beverage packing machine is significantly used in various packaging industries as it features a simple construction and equipped with piston.

A to-and-fro movement helps in the loading and release of formulation into desirable packaging. The purpose of piston is to ensure ease of flow without product spillage or leakage and accurate filling.

Pump Liquid Beverage Stick Packing Machine

Pump Liquid Beverage Stick Packing Machine

This machine consists of a hopper, hose pipes, filling nozzles, and pumps. It is considered a safe machine for filling sterile liquid beverages, as the liquids do not come in contact with the filling devices. Rotation of pumps allows this machine to accurately dispense liquid beverages into the stick packs.

According to Motion

Continuous Motion Liquid Beverage Stick Packing Machine

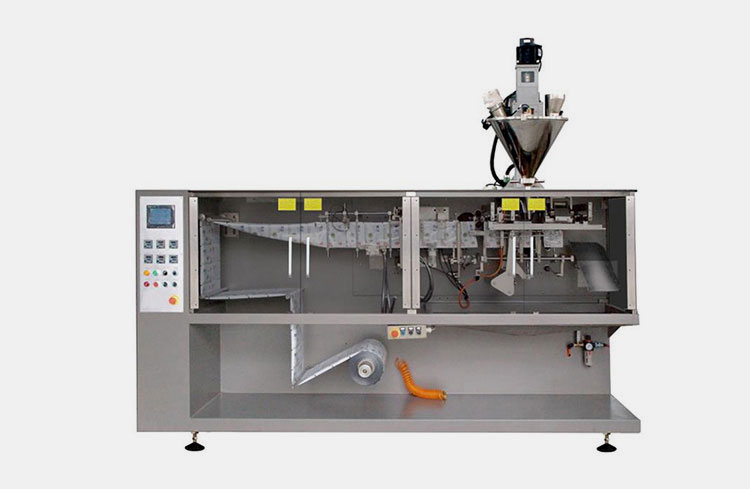

Allpack Continuous Motion Liquid Beverage Stick Packing Machine

This type of liquid beverage stick packing machine works continuously without stopping between the cycles. It is more suited to the higher production settings because it packs liquid beverage at much higher rates. It lowers the downtime and has high efficiency. It is more complicated than the intermittent motion liquid beverage stick packing machine.

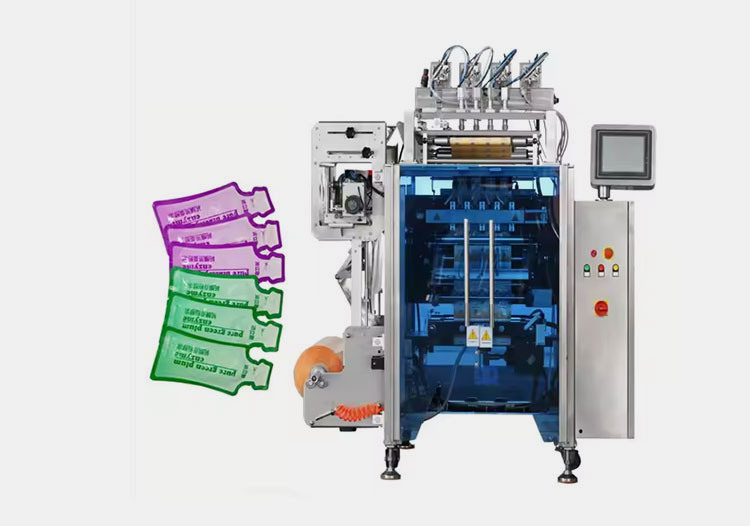

Intermittent Motion Liquid Beverage Stick Packing Machine

Intermittent Motion Liquid Beverage Stick Packing Machine- Picture Courtesy: Ima.it

This machine, as the name indicates, fills and packages stick packs intermittently. The forming process stops while the machine is filling the liquid beverage stick packs. It operates in intervals and has a sequential series of steps. It has less productivity and is used in small and medium-scale productions. It can fill wide range of liquids due to its intermittent motion.

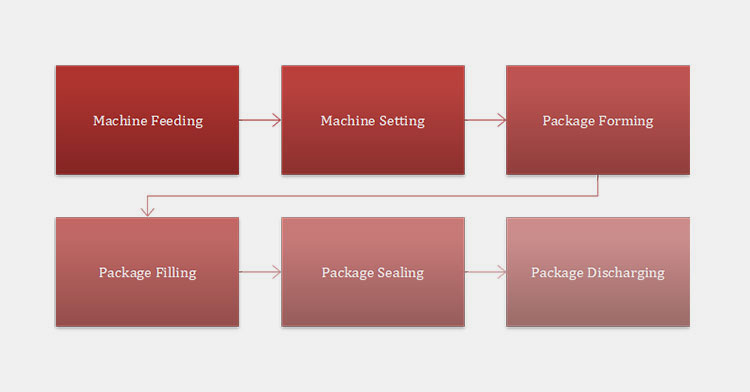

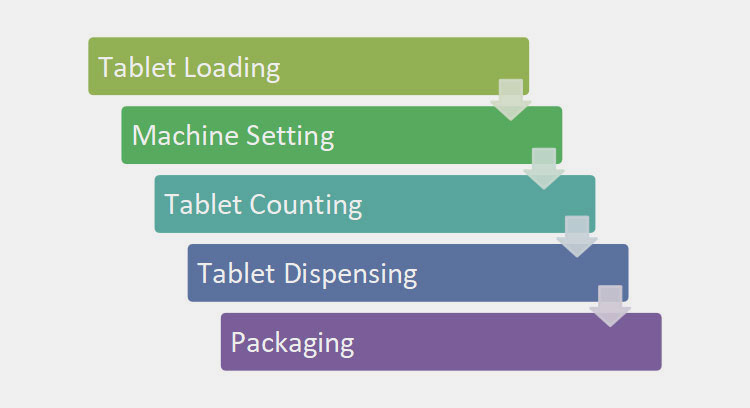

4.How Does Liquid Beverage Stick Packing Machine Work?

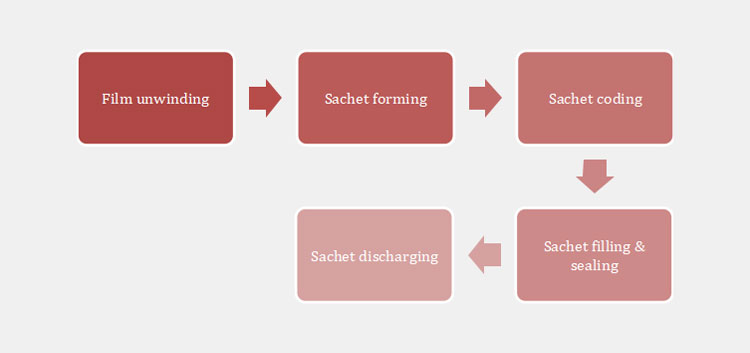

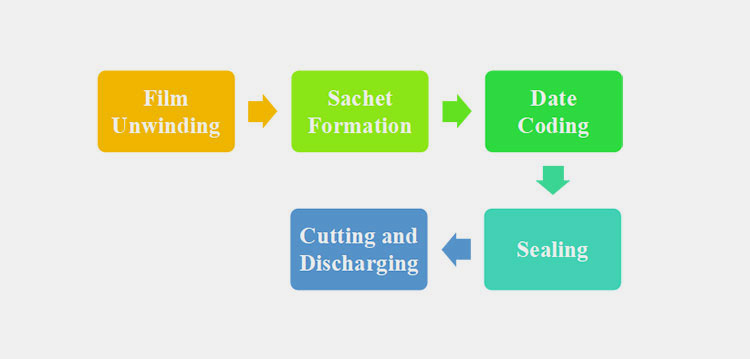

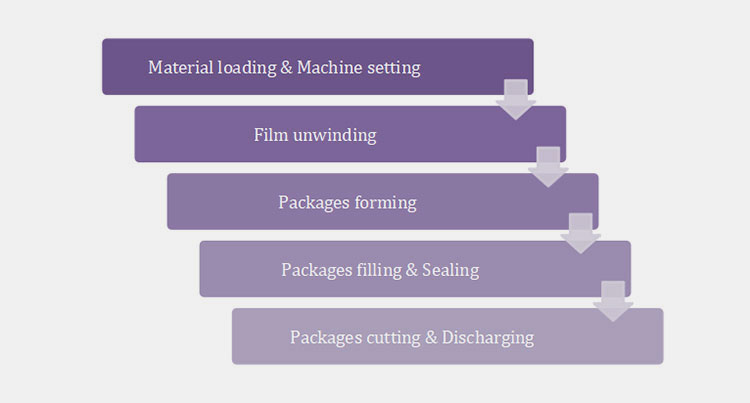

The liquid beverage stick packing machine operates in sequential cycle where forming, filling, and, sealing are the main steps. The complete detail of working of liquid beverage stick packing machine are discussed below:

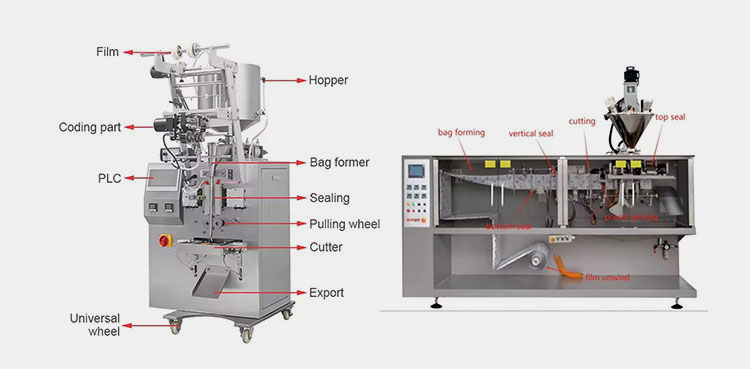

| Liquid Beverage Loading and Film Loading

First, the operators load the large volumes of the liquid beverages in the top hopper that is used for storing bulk quantities of product for non-stop filling operations. A large film roll is put on the film unwinding disk. The operators guide this film over the rollers and the dancer’s arm for smooth operation. This process is essential in keeping the film on track. |

Film Loading |

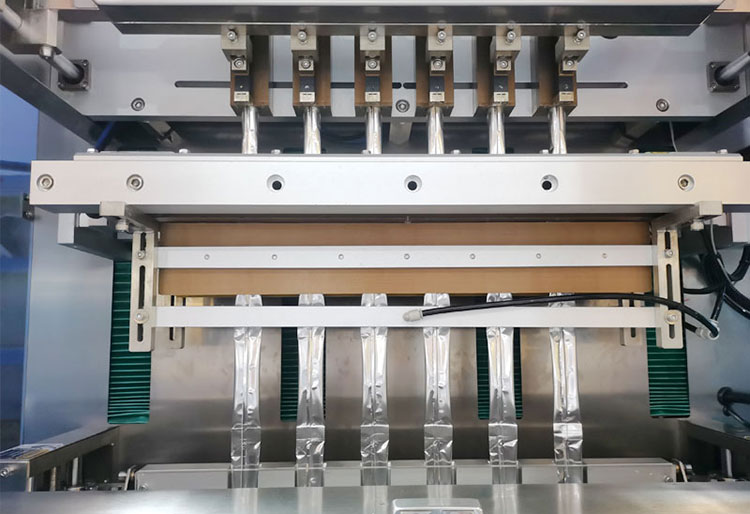

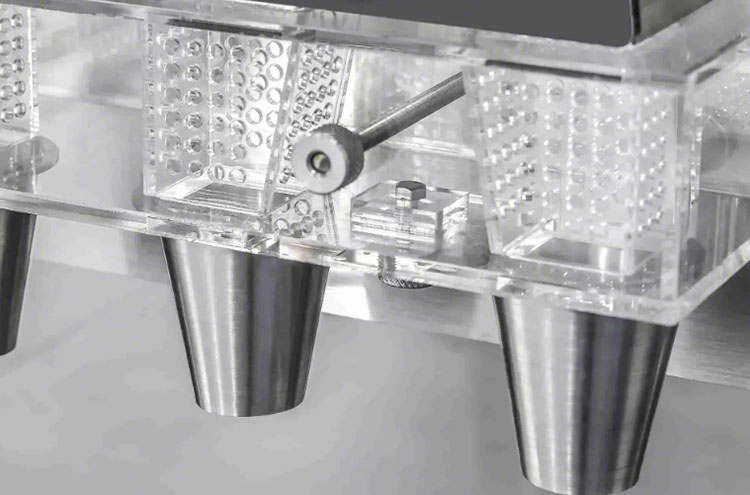

| Cutting, Forming and Filling

This film then goes to the cutting station, where it is cut into smaller strips depending upon the number of lanes. Each individual strip goes to its respective forming station. At the forming tube, the strips are doubled and wrapped around forming collar to create stick packs. A set of vertical jaws seals the back side of the stick pack while the set of horizontal sealing jaws seal the bottom part of the stick pack. Afterwards, the stick pack is filled with the liquid beverage by the filling device. |

Cutting, Forming and Filling |

| Sealing and Cutting

After filling, the top part of the stick pack is sealed hermetically by the sealing jaws. In the last, the joining stick packs are separated with the sharp cutters. |

Sealing and Cutting |

5.Does Liquid Beverage Stick Packing Machine Handle Different Shapes and Cutting Types?

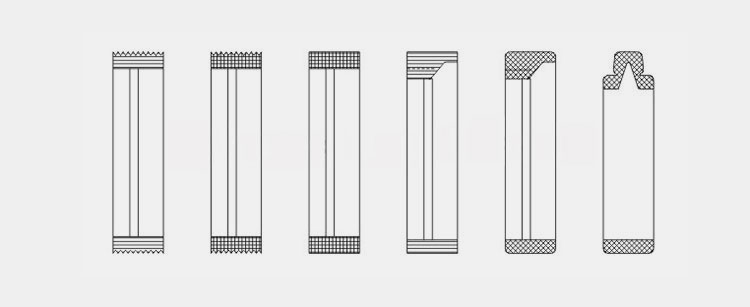

Diversity and uniqueness are two important aspects that make or break the chances of selling. Hence, the liquid beverage stick packing machine processes different shapes and cutting types to increase the product appeal. These shapes and cutting types are mentioned below:

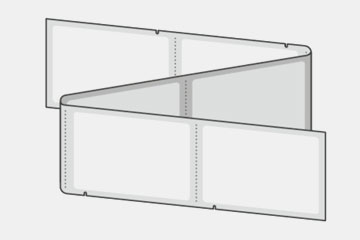

Shapes

Different shapes produced by the liquid beverage stick packing machine are:

Rectangular Shape Stick Pack

Rectangular Shape Stick Pack- Picture Courtesy: Vitalyte

It is traditional shape of stick packs and is commonly used worldwide. It has four sides and four corners. The parallel sides of rectangular-shaped stick packs are equal to each other.

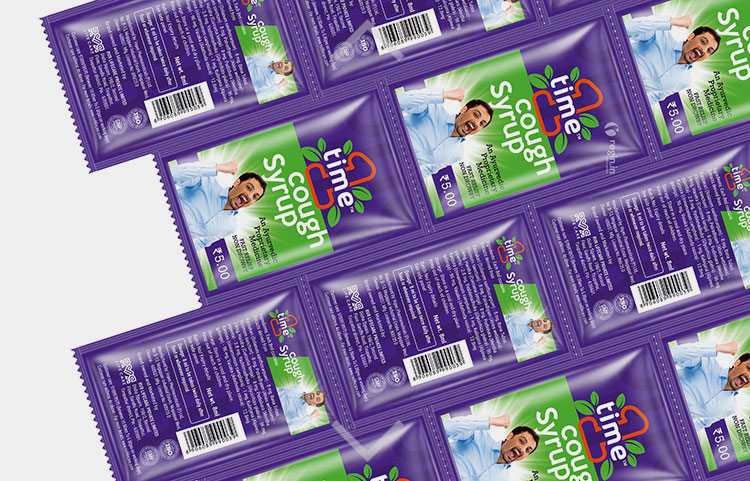

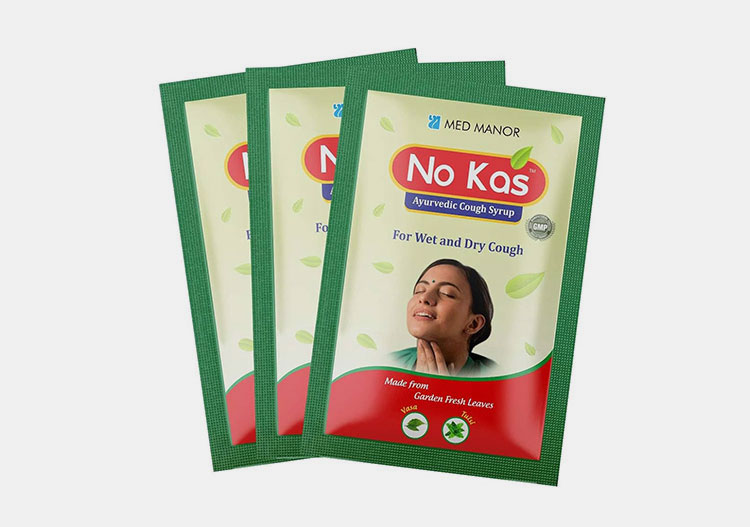

Bottle Shape Stick Pack

Bottle-Shape Stick Pack

It is the second most common shape type of the stick pack produced by the liquid beverage stick packing machine. It has a wide base that tampers off at the top. It has a small top part in the shape of the bottle cap.

Round Corner Stick Pack

Round Corner Stick Pack- Picture Courtesy: Kingvictor Packaging

Instead of typical straight corners, this type of stick pack has round edges. These stick packs are easier to handle and reduce the risk of cutting, which is possible with the straight corner stick pack.

Cutting Types

Different cutting types produced by the liquid beverage stick packing machine are:

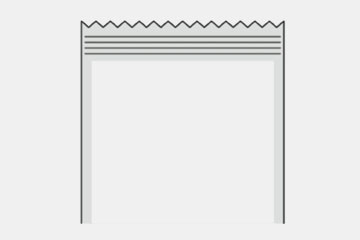

Zigzag Cut Stick Pack

Zigzag Cut Stick Pack- Picture Courtesy: Skratch Labs

This cut type of the stick pack has alternate left and right turns and is variation of typical straight cuts. A specialized type of cutting blade in the liquid beverage stick packing machine is used for forming this pattern on the stick packs.

Flat Cut Stick Pack

Flat Cut Stick Pack- Picture Courtesy: ePac Flexible Packaging

This stick pack has typical straight ends and is the most common cut type of the stick pack. It is produced by regular cutting knives in the liquid beverage stick packing machine. Flat cut stick pack has tear-notch seals that provide convenience in opening the stick pack.

Round Cut Stick Pack

Round Cut Stick Pack- Picture Courtesy: ePac Flexible Packaging

It is another different type of stick pack. This type of cut offers round cornered stick pack. Round cut improves aesthetics of the stick pack and makes the latter more appealing for the customers.

Shaped Cut Stick Pack

Shaped Cut Stick Pack- Picture Courtesy: Oh la laqua

It is a unique type of cut stick pack that comes in a variety of shapes that are beyond regular zigzag and round cuts. These types of stick packs are typically employed on the special occasions to increase the chances of sales.

6.What Beverages are Packed by Liquid Beverage Stick Packing Machine?

Liquid beverage stick packing machine is an incredibly flexible and adaptable manufacturing unit, packing diverse liquid in small single-serve stick packs. The list of these liquid beverages are discussed below:

| Coffee Concentrate

This machine can pack a one-serve of liquid coffee like espresso and instant coffee in the stick pack. These stick packs are highly popular among go-on coffee lovers. |

Coffee Concentrate- Picture Courtesy: NextDayCoffee |

| Tea Concentrate

Not only coffee, this machine can pack tea concentrate such as herbal and fruit tea in the stick pack. These tea concentrates are enjoyed in every season without preparing and boiling the tea. |

Tea Concentrate |

| Juices

Different kinds of juices like fruit juice and vegetable juice are go-to drinks in hot summers. These drinks are favoured by health-conscious people. |

Juices |

| Energy Drinks

Liquid energy drinks are easily consume and are dispensed in portable stick pack. It gives instant energy boost. |

Energy Drinks- Picture Courtesy: Bucked Up |

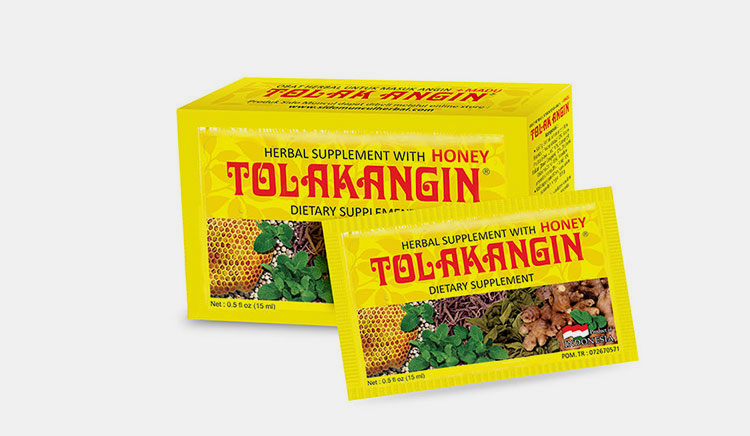

| Nutritional Supplements

Liquid nutritional supplement is simple and easy way to consume nutrients. These supplements include liquid vitamins, protein shakes, and meal replacements. |

Nutritional Supplements- Picture Courtesy: Condition Supplement |

| Dairy

Yes, dairy products like milk, creams, and, ice lollies are conveniently loaded into the stick packs by the liquid beverage stick packing machine. These milk and other dairy products are consumed anytime and anywhere. |

Dairy |

| Water

Flavored water is a delicious substitute for the simple water. It is an way to increase hydration while enjoying different flavors. |

Water |

7.What Packaging Materials are Compatible with Liquid Beverage Stick Packing Machine?

Liquid beverage stick packing machine can easily accommodate different materials to fabricate different styles stick pack. Use of diverse materials bestows uniqueness to the stick pack. Here is the list of materials used by the liquid beverage stick packing machine.

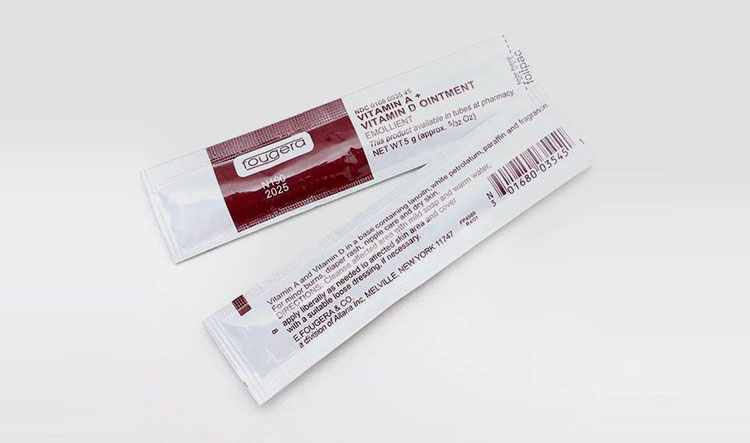

Metalized Film

Metalized Film Stick Pack- Picture Courtesy: Unjury

These metalized films include pure aluminum that is quite easy to mold and bend for forming stick pack. It offers utmost protection to the inner liquid beverage contents against sunlight, air, water, and high temperature.

Food-Grade Plastics Films

Food-grade Plastic Film Stick Pack- Picture Courtesy: Halo Hydration

Different kinds of plastic films are included in food-grade plastics, for instance, polyethylene (PE), polypropylene (PP), and polyester(PET). These different kinds of plastics have their specific characteristics. However, they provide the highest tensile strength, heat resistant, and impermeability to elements. Food-grade plastic films are commonly used for making liquid beverage stick packs because these materials are commonly available.

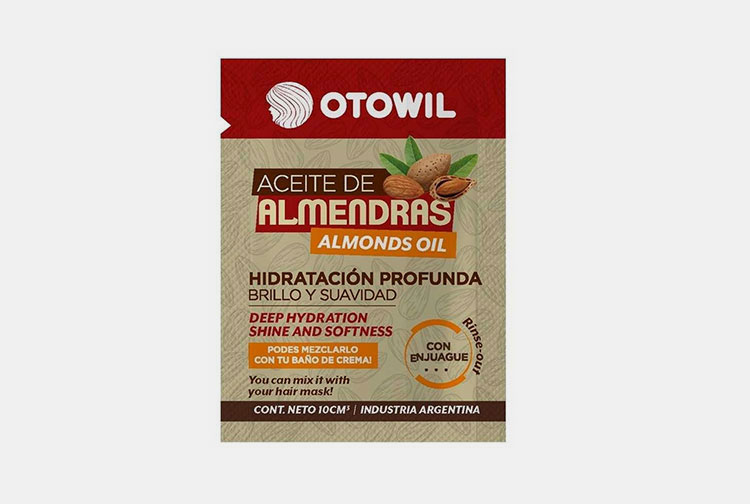

Laminated Films

Laminated Film Stick Pack- Picture Courtesy: Just Ingredients

These films are frequently used for forming liquid beverage stick pack because they combine the best properties of both aluminum and plastics. They have increased weather resistance, shiny metallic appearance, and toughness.

Biodegradable Films

Biodegradable Film Stick Pack- Picture Courtesy: Just Ingredients

Now with the increase in sustainability efforts, brands are switching to biodegradable and sustainable films for making their stick pack. These films are easily decomposed and recycled, positively impacting the earth's resources.

8.Does the Liquid Beverage Stick Packing Machine have any Safety Features?

To ensure the safety of the operator and the workforce, there are different safety features present in the liquid beverage stick packing machine. The details of these safety features are discussed below:

Emergency Stop Button

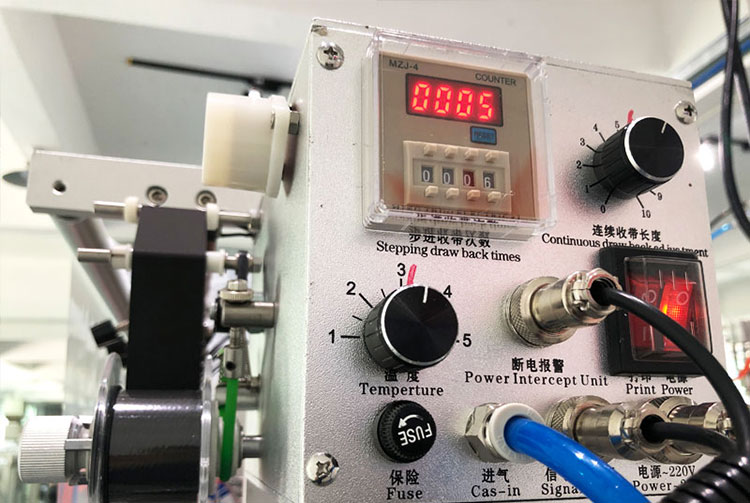

Emergency Stop Button- Picture Courtesy: omag - Pack

A conspicuous emergency stop button is present on the control panel. This button is immediately pressed to quickly shut down the machine to avoid any hazardous situation. Moreover, in case of machine malfunction, it is pressed without waiting for normal machine shutdown.

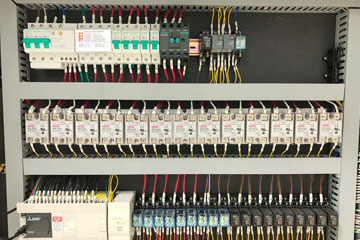

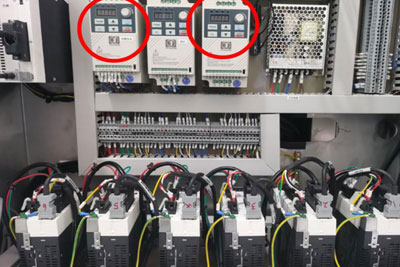

Overload Protection Switches

Overload Protection Switches- Picture Courtesy: Plan In Packaging

An overload protection switches are built-in the machine to check for electrical overload or high pressure. These switches quickly shut down the machine inn case of electric or pressure overload to prevent further damage.

Safety Sensors and Alarms

Safety Sensors and Alarms- Picture Courtesy: Gelgoog

Different types of safety sensors like proximity sensors are present in the machine that monitors the presence of operator or an object in the immediate area of the machine and turn off the machine to prevent injury or collision. Alarm systems are also fitted in liquid beverage stick packing machine that notifies the operators about the defect in the machine by lightening up and sounding alarm.

Safety Guards

Safety Guards

Transparent and stainless steel safety guards and enclosures are fitted around the mobile parts of the machine to decrease accidental machine contact during its packaging process.

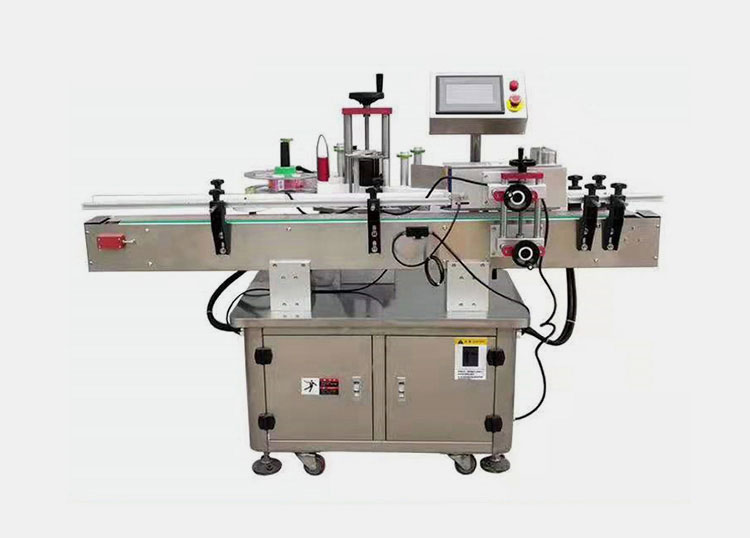

9.What is the Maintenance Schedule of Liquid Beverage Stick Packing Machine?

Maintenance of Liquid Beverage Stick Packing Machine

Regular maintenance increases the efficiency of iquid beverage stick packing machine and boosts its operational life. The maintenance schedule of liquid beverage stick packing machine is penned below:

| Daily Maintenance | Clean the exterior like frame as well as forming, filling, and sealing devices to get rid of dust, debris, and product buildup.

Check the leakage in the liquid beverage filling lines. Check the working condition of gasket seals and other joints and ensure that they are properly tightened. Make sure sensors and other safety instruments are properly clean. |

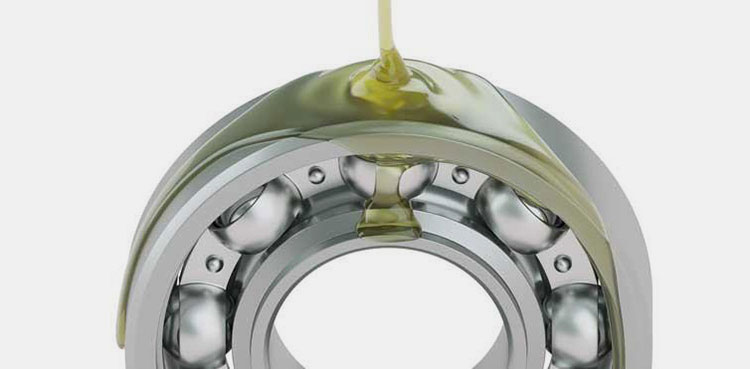

| Weekly Maintenance | Use food-grade lubricants to lubricate different mobile parts of the machine to reduce frictional buildup.

To decrease the clogging of air and liquid filter, clean them weekly. Inspect the sealing jaws and cutting blades for damage and defect. |

| Monthly Maintenance | Perform deep and complete cleaning of all the machine parts especially interior of the filling devices and fill nozzles.

Inspect the tension in the drive belts and chain conveyors. Examine the working condition of the electric components and if needed then replace them. |

| Quarterly Maintenance | Check and replace all the defective parts for instance, seals gaskets, and cutting blades.

Re-calibrate the filling and sealing devices of the machine. Conduct detail examination of the safety components to reduce chances of hazardous conditions. |

| Yearly Maintenance | Update machine software if available.

Conduct a thorough examination of all the machine parts and if required then replace them. |

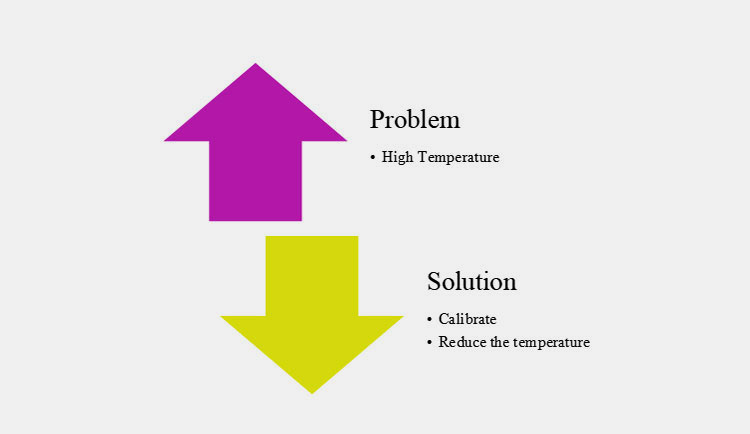

10.How To Detect and Troubleshoot Liquid Beverage Stick Packing Machine?

Unanticipated problems can lengthen the production and can cause problems down the line. However, a systematic approach is used to detect and troubleshoot such problems. The solution and troubleshooting of this machine are discussed below:

Inadequate Print Quality on Stick Packs

Inadequate Print Quality on Stick Packs- Picture Courtesy: Perk Energy

Sometimes, the information printed on the stick packs is faded or misprinted. This issue is due to poor printer alignment. Sometimes, inks levels are low and printers heads are dirty.

Troubleshooting

This issue is resolved by properly aligning the printer components with the film. Checking and ensuring proper ink levels also resolved this problem. Cleaning printer heads also solves the problem of misprinting.

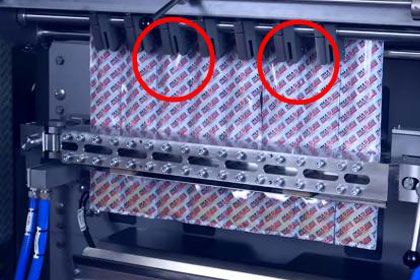

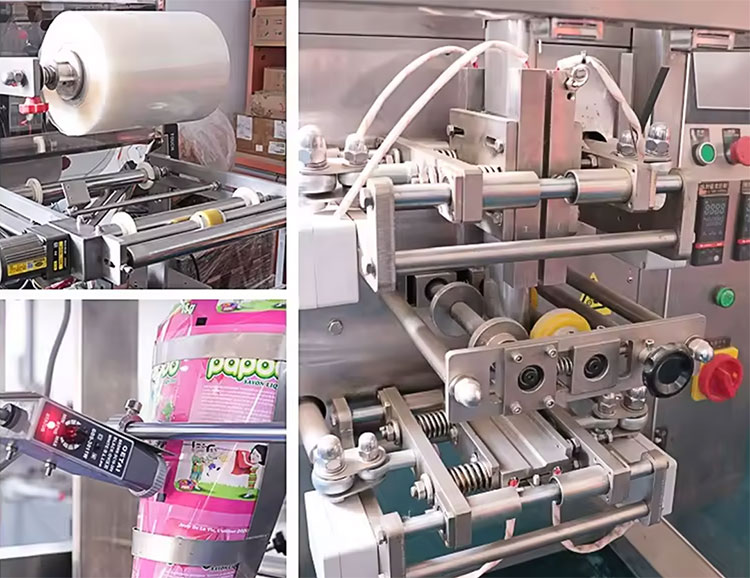

Mis-feeding of Packaging Film

Mis-feeding of Packaging Film

The packaging film is not properly tracking to forming, filling, or sealing components. It is due to improper film tension, blockage or jamming in the path of packaging film. Improper alignment of guides and sensors also causes this problem.

Troubleshooting

Check the film tension and ensure the film has adequate tension; it is not very tight or loose. Clearing the blockage in the film path also solve this problem. Rightly align the sensors and guides in accordance with the width of the film.

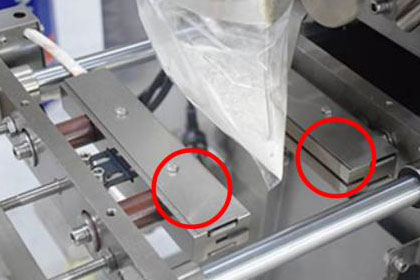

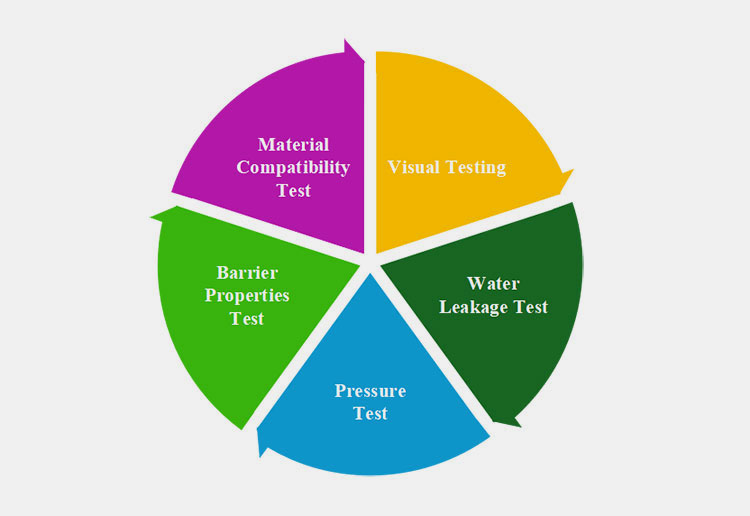

Poor, Weak, or Inconsistent Sealing

Poor, Weak or Inconsistent Sealing

The sealing of the stick packs lacks proper bonding between the two film layers. This problem is usually due to improper temperature and pressure. This improper sealing issue is also due to unclean or worn-out sealing elements.

Troubleshooting

This issue is easily solved by maintaining proper temperature and pressure. The sealing temperature and pressure should be not either too high and too low. Replacing old sealing bars and properly cleaning them also solve this defect.

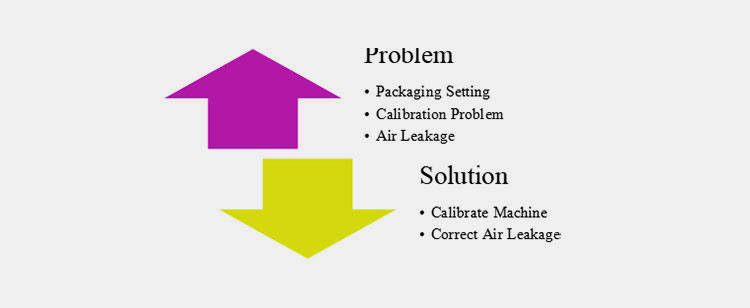

Inconsistent Fill Quality

Inconsistent Fill Quality

Sometime, there is variation in the filling volume or weight. This issue is because of out-of-calibration filling systems, air leaks in the system could also cause this problem. Sometime, incorrect settings of pump devices is the reason of incorrect fill quality.

Troubleshooting

This problem is resolved by calibrating the filling devices which then accurately dispense liquid beverage in the stick packs. Checking for air leaks and fixing them also resolve this issue. Resetting the pump parameters solve this problem.

Conclusion

Now, its time to concluded this FAQ guide about liquid beverage stick packing machine. Hopefully, you have found this guide interesting and informative. The liquid beverage stick packing machine is a great addition to the packaging line, it smoothly and effectively carries out different packaging jobs without the need for human involvement. It brings optimized and cost-effective results. Now, are you tempted to integrate this machine into the production, then without further delay contact Allpack customer care for the best-quality solutions.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Liquid Beverage Stick Packing Machine: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours