Industrial Sifter Machine: The Complete Buying Guide In 2025

Industrial Sifter Machine: The Complete Buying Guide In 2025

Whether is it a pharmaceutical industry, food sector, or chemical processing field the adherence to strict quality control of goods is always the first choice of manufacturers. This quality control encompasses several steps among which sifting or sieving is the primary one. Do you know about it? Or aspiring An Industrial Sifter Machine but caught in a dilemma about its features, uses, and types?

No worries! As this buying guide is brought for your help. An Industrial sifter machine is an advanced sophisticated machine used on small to large scale industries to carry out the separation of desired solid particles from liquid or from solid. Since, the machine has broad application, a complex body, and multitasking nature, this article will get you through this information. So, be ready to discover these all!

1.What Is An Industrial Sifter Machine?

Allpack- ZS Series High Efficient Screening Machine

Industrial sifter machine is an advanced equipment designed for the processing of granulated liquid and solid application in pharmaceutical, food, and chemical industry. It is also known as screening machine, grading machine, or a sieving machine due to its multifunctional nature. This effective machine is tailored with astonishing features and is the most economical where all functions are performed in a single unit.

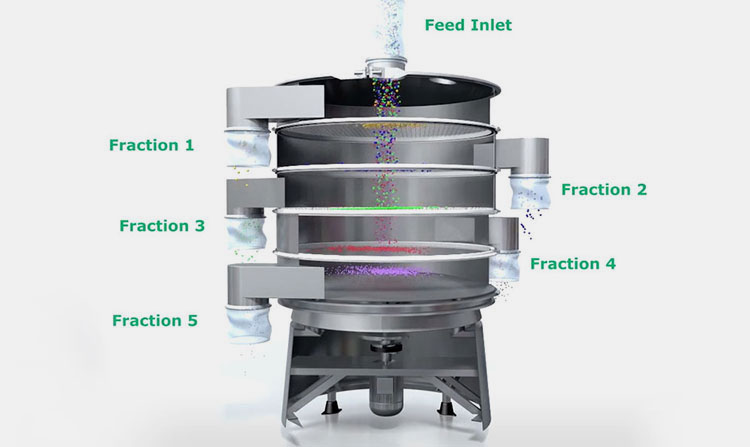

It works on the principle of vibration or centrifugal force where bulk particles are passed through different perforated screens. Each screen has an attached outlet through which similar size objects are collected in individual containers. Hence, the machine is extremely beneficial for maintaining the quality, hygiene, and safety of your valuable materials.

2.Enlist The Features And Benefits Of An Industrial Sifter Machine?

An industrial sifter machine comes with multitude of features which ultimately give you enormous benefits. So, let's know some of the prominent ones!

Multi-Functioning

Different functions of industrial sifter machine- Picture Courtesy: urmachinery.com

Industrial sifter machine offers an extremely versatile way to process particles. For instance, it performs the sieving, grading, scalping, and shifting of separated particles. Therefore, by using the same machine you can get done with so many tasks.

Hygienic

Hygienic operation of an industrial sifter machine m- Picture Courtesy: galaxysivtek.com

As an industrial sifter machine is made up of food grade quality stainless steel to make sure the safety of materials processed, no matter how sensitive your particles are you can sift it through using this machine. Along with that, the enclosed top layer keeps the inside material away from pollution and dirt.

Homogeneity

Homogeneous coriander seeds & powder- Picture Courtesy: thevegcompany.food.blog

The machine has excellent screening system with uniform holes that offers you the utmost precision and consistency during sieving. In addition, by accurately sieving, screening, and then shifting, it provides you with separate but homogeneous mixtures.

Compact

Allpack- Compact ZS Series Vibrating Screen Sifter Machine

The machine has a compact structured body with multiple screens and control system tools integrated together in a way that it can be easily mobilized. Moreover, its precise body make the machine handier to use and clean while requiring little maintenance.

Economical

Economical icon- Picture Courtesy: staebler.com

The cost and maintenance of any machine are what all the manufacturers often concerned about. However, in case of an industrial sifter machine, you will not be bothered to take this luggage rather the machine come in quite low price, with little maintenance, and no additional labor and trained staff required.

3.What Products Are Processed By An Industrial Sifter Machine?

Well, you will be tired if introduced to the never-ending list of the materials being processed by an industrial sifter machine. So, let's have a look towards the few major ones! So, that you will have a general idea about these materials!

Powders

Coco powder- Picture Courtesy; delightfuladventures.com

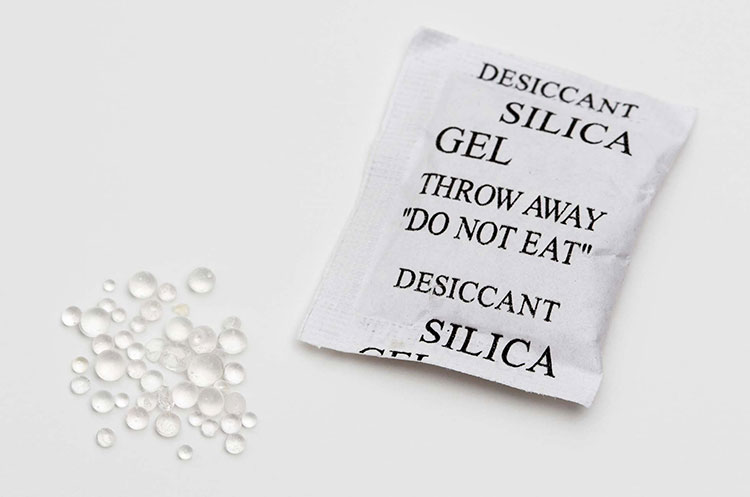

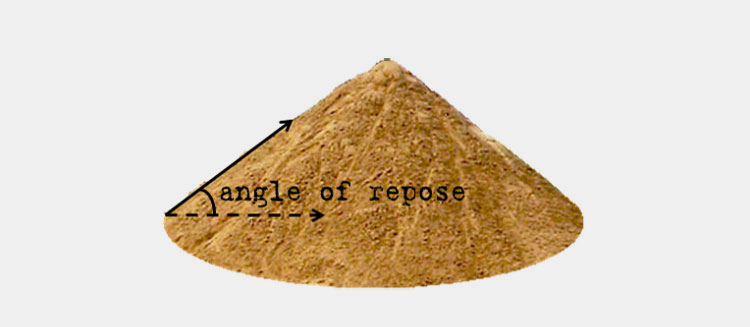

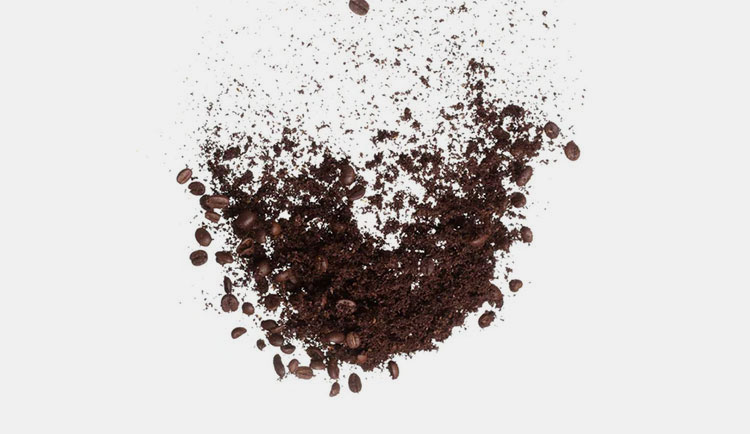

An industrial sifter machine supports all kinds of free flowing and adhesive powders for sifting such as flour, salt, coco powder, condiments, milk powder, medicine powders, facial powder, dyes, and herbal powder etc.

Granules

Orange sanding sugar- Picture Courtesy: WebstaurantStore

All the granulated particles whether in small or large size are perfectly screened by this machine. The common examples include grains, pulses, plastic granules, sugar, coffee beans, and tablets etc.

Pellets

Fish feeding pellets- Picture Courtesy: Adobe Stock

Pellets are small, compressed particulates with cylindrical shape. These are often produced to feed sea animals like fish, ground animals like rabbit, and also made for different purposes. So, what matters here is their eligibility to be processed by an industrial sifter machine.

Snacks

Various fried snacks- Picture Courtesy: photodune.net

You might have a question how can snacks like crackers, potato chips, dried fruits, and peanuts be processed by an industrial sifter machine. But it's not surprising, as the machine has broad range of screening encompassing small size 5 microns to large size 28 microns. Hence, for removing the broken or unwanted pieces of snacks, you can employ the machine.

4.What Functions Are Performed By An Industrial Sifter Machine?

An industrial sifter machine performs wide range of functions despite being a single body machine. That's why, its use is inevitable in every other field. Let's have a look towards these functions one by one:

Sieving

Powder sieving- Picture Courtesy: Elcan Industries

This is one of the primary functions of an industrial sifter machine which aims at removing all the bugs, agglomerates, and wastes from your desired materials which are caused by the long storage. For instance, in case of powders, it carries out this function, by leaving the impurities in upper frame of the machine and flow the fine powders downward.

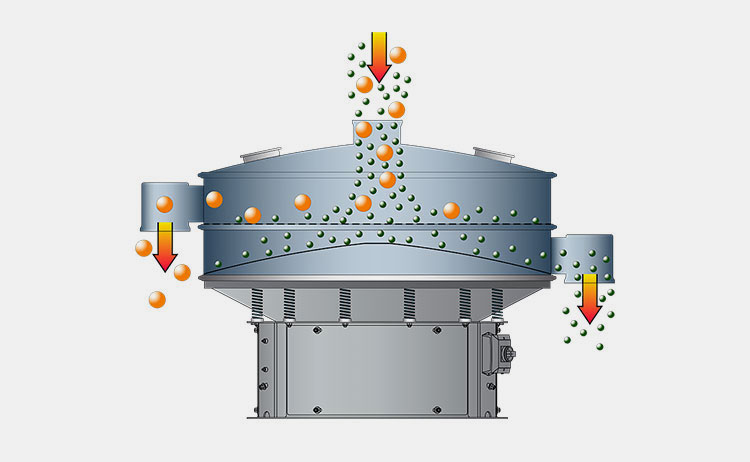

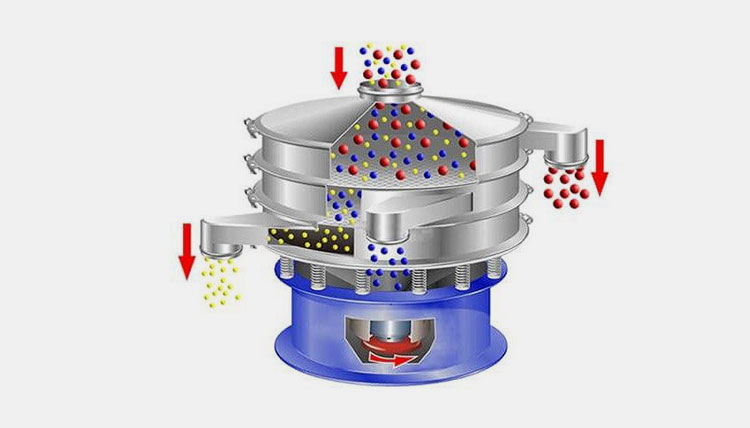

Grading/ Screening

The second notable function of an industrial sifter machine is grading or screening where components are separated according to their size. The larger particules remain in the upper frame and the smaller particles follow a descending order for separation in the middle and bottom frame.

Scalping

Scalping process- Picture Courtesy: amkco.com

Scalping refers to the removal of unwanted foreign objects such as twigs, strings, and sticks found in powders or granules. This step involves using a scalper to restrict these objects from passing through the pores of perforated screens.

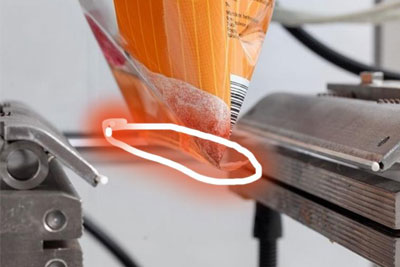

Solid-Liquid Separation

Solid-liquid separation- Picture Courtesy: bulkinside.com

An industrial sifter machine can also perform the separation of granules or solid objects from that of liquids. This is one of the crucial uses of this machine which is praised in many industries.

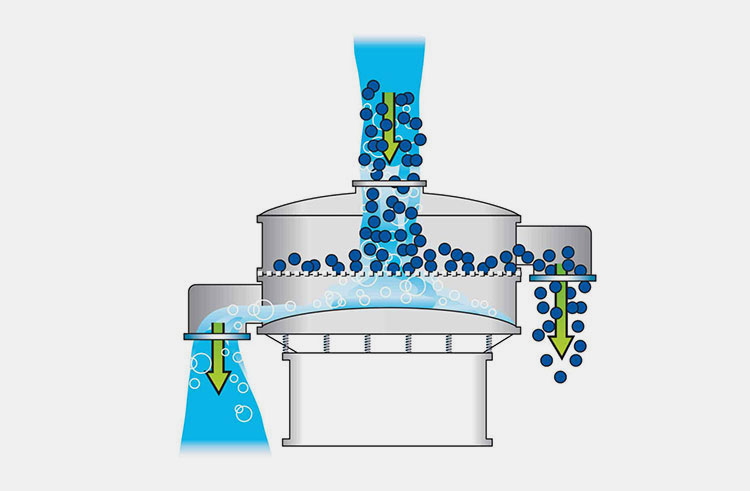

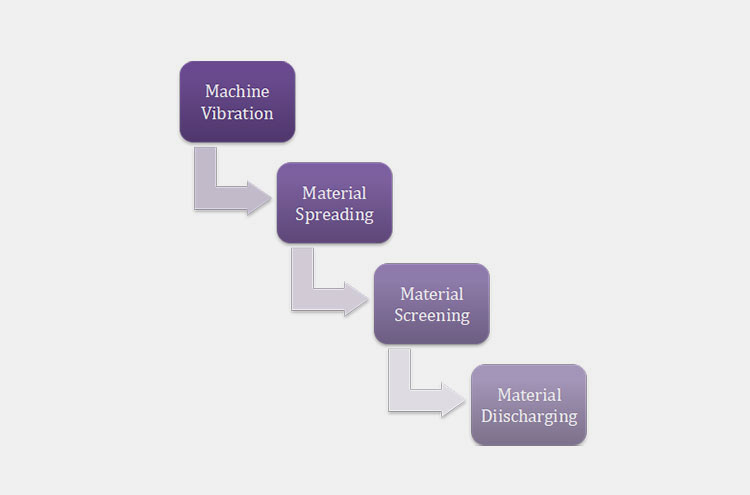

5.What Are The Working Principles Of An Industrial Sifter Machine?

The working principles of an industrial sifter machine are unconventional yet easy to understand. First, you need to set the machine including its structural adjustment and the lead angle etc. Afterwards, pour the material in machine and turn it on. The machine will then follow underlying principles:

Working principles of an industrial sifter machine- Picture Courtesy: ipharmachine.com

Machine Vibration

As the machine is powered on, the vibratory motor of machine start energizing the multiple sifting frames of machine by producing a vibratory motion through springs and lead angle. Consequently, the interconnected multiple frames start continuous vibration.

Material Spreading

The vibration of machine results in the shattering of the material laying over the screens. Similarly, the small particles pass through the pours of screens and flow downward, while as, the larger components remain in upper frame.

Material Screening

Moving forward, the processed particles undergo the same step of spreading over second screen, leaving larger particles inside the frame, and passing smaller ones. Depending upon the number of frames in industrial sifter machine, the process will be continued.

Material Discharging

At last, when sieving and screening get completed, the same size particles will be discharged from the concerned frames through outlets and collected in containers. For instance, the coarse components will be gathered in upper frame outlet and fine particles will be collected in lower frame outlet.

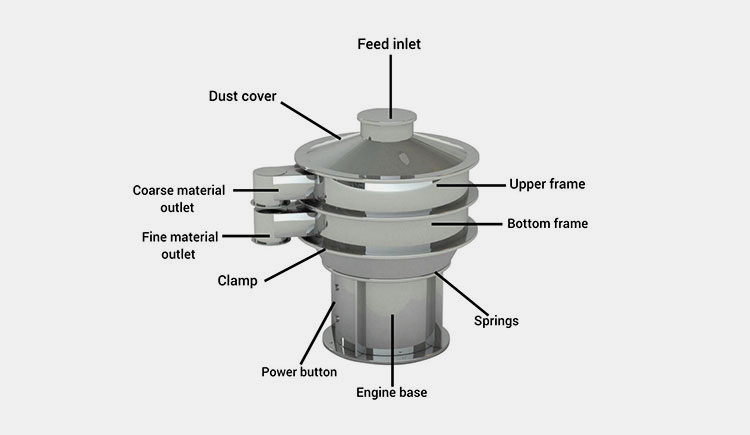

6.Describe The Major Parts Of An Industrial Sifter Machine?

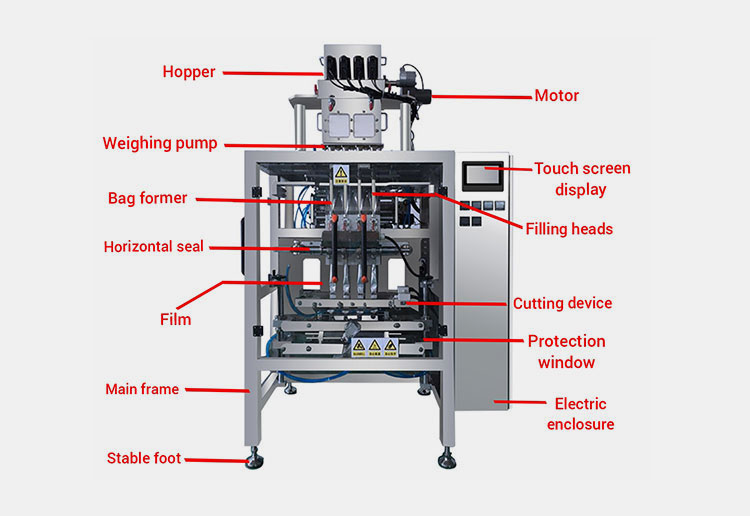

An industrial sifter machine is composed of several components each performing particular task for sifting various materials. Below, you can see an example of vibration sifter machine along with its functions:

Components of Allpack's- ZS Series High Efficient Screening Machine

Feed Inlet

Feed inlet is a hole located on the top of lid hopper through which an industrial sifter machine is supplied with material during operation.

Dust Cover

Dust cover is a durable metallic lid often known as hopper lid or shield cover. It protects the internal materials being processed in machine by redistricting their wastage that might cause during vibration. On the other hand, it also helps in preventing the particles from dust and contamination by keeping them intact.

Upper Frame

Upper frame refers to the upper sifting chamber which consists of a screen that is connected to it through a clamp ring. The screen is made using mesh wire with a fine surface to support uniform and quick screening. While as, the clamp ring is a round shaped tool used to join the screen inside upper frame.

Bottom Frame

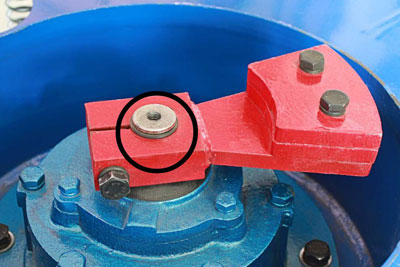

Bottom frame is located under the upper frame which is composed of the same components. In addition to these, multiple ball retaining rings along with bouncing balls are also placed inside the bottom frame for improving sifting accuracy and productivity and avoiding material sticking.

Coarse Material Outlet

This is an important component attached to the upper frame for discharging the well sieved and screened particles from the machine towards an attached pouch or container.

Fine Material Outlet

As the name indicates, fine material outlet is another discharge chute connected with a bottom sieve deck. From here the finest size particulates are transported from machine.

Clamp Ring

Clamp ring is a round shape device employed to hold together the sieve deck and perforated wire mesh. Hence, it is crucial to maintain the integrity of an industrial sifter machine by using this device for quick changeovers.

Springs

Springs are an integral part of the vibro industrial sifter machine which enable the machine to produce vibratory effects, so, that the material will be sieved accurately. At the same time, these springs are responsible to keep the vibration under controlled condition to avoid damage to the material as well as to the machine.

Power Button

Power button is located on the front or back side of engine base. By using it, the operator one and off the processing of machine.

Engine Base

Another crucial parts of an industrial sifter machine are the engine base inside which a motor is fitted. From here, energy is supplied to the machine for efficient working.

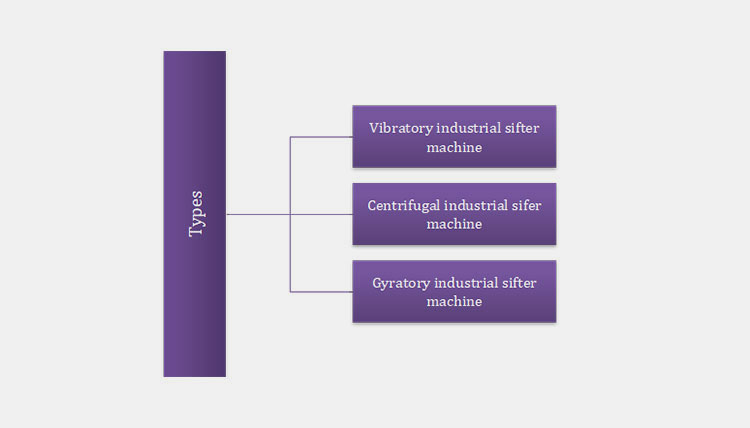

7.Explain The Different Types Of Industrial Sifter Machine?

Range of industrial sifter machines are available in market today pertaining to the growing demands of manufacturers. In this question, we will make sure to give you a detailed but easy-to-understand overview of these machines. These include:

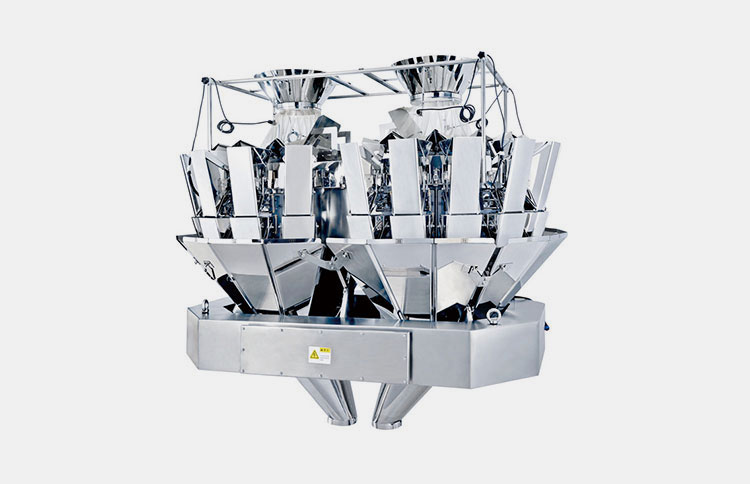

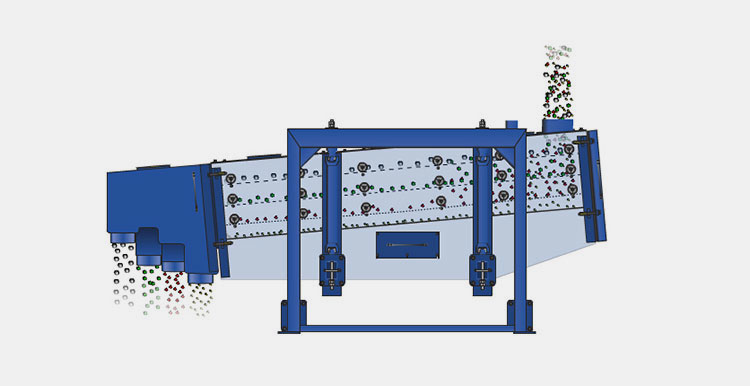

Vibratory Industrial Sifter Machine

Allpack- ZS Series High Efficient Vibratory Screening Machine

Vibratory industrial sifter machine is one of the most popular machines you will ever need in agricultural, medicine, and chemical processing industries. The reasons are many, but most notable is its compact structure and multifunctional nature. The machine is available in 1-5 layers frame. Moreover, it can be used for multilayer grading of inhomogeneous substances.

Structure

The machine has extremely small footprint which if upgraded to 5 layers, will still cover the same place as covered with a single layer frame. It mainly consists of a feet inlet, hopper lid, sieve frame, outlet port, clamp, springs, electric motor, and engine base.

Working Principles

By following the principle of vertical vibratory motion, the machine start vibration which lead the loaded material to spread over screen. Similarly, the material is passed through number of screens until it reaches the desired level state. Afterwards, same size particles are collected into the attached outlets of each sieve frame.

Application

The machine is suitable for powders, granules, pellets, and solid-liquid substances.

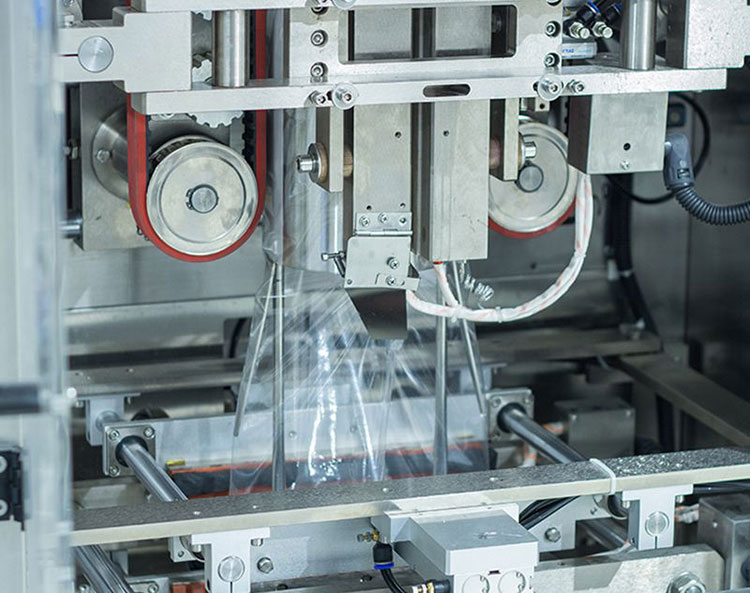

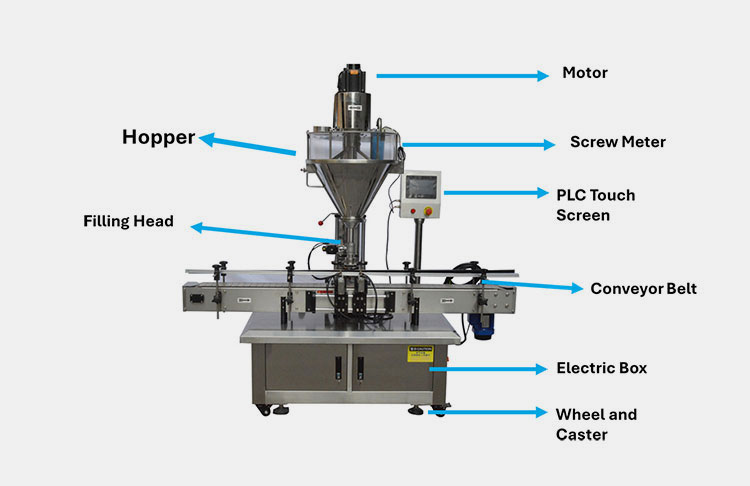

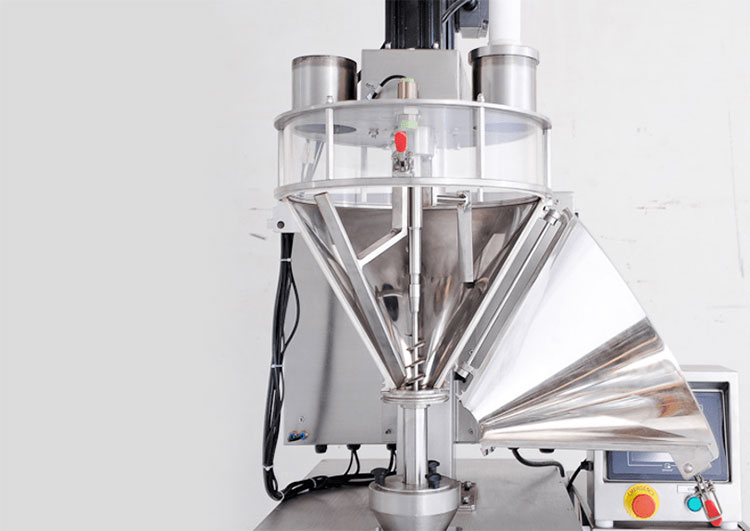

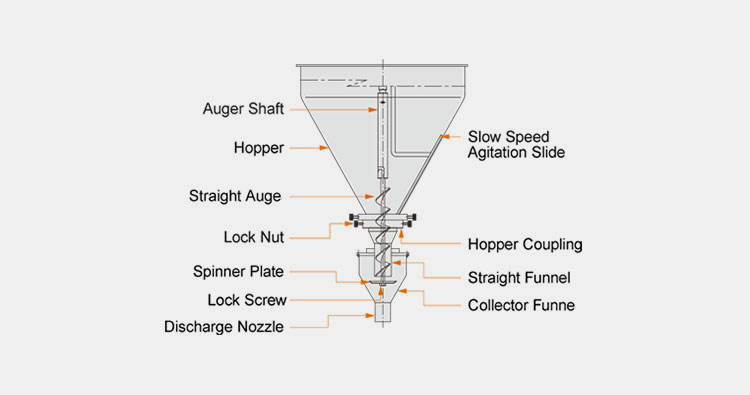

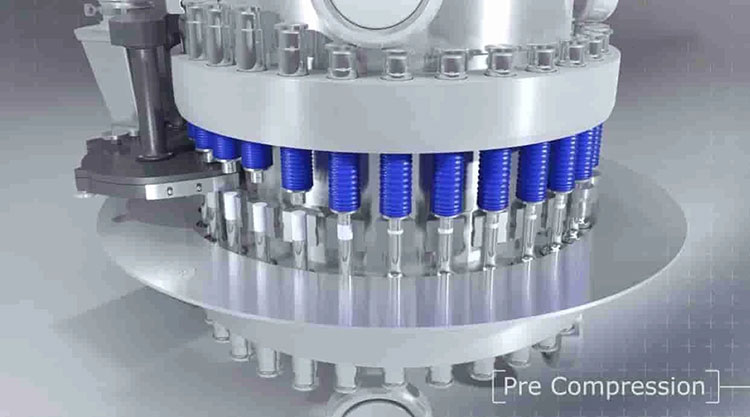

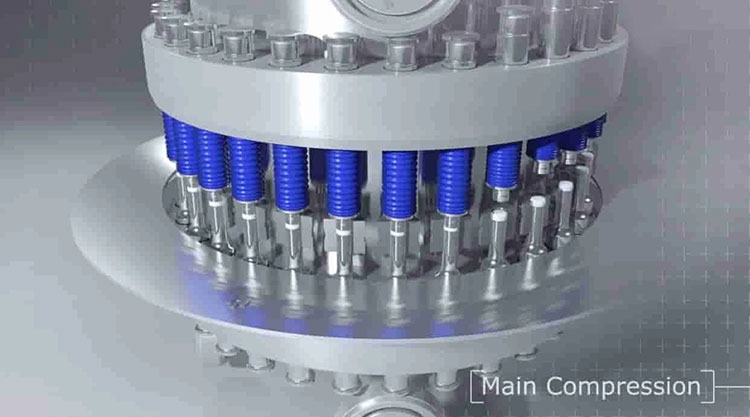

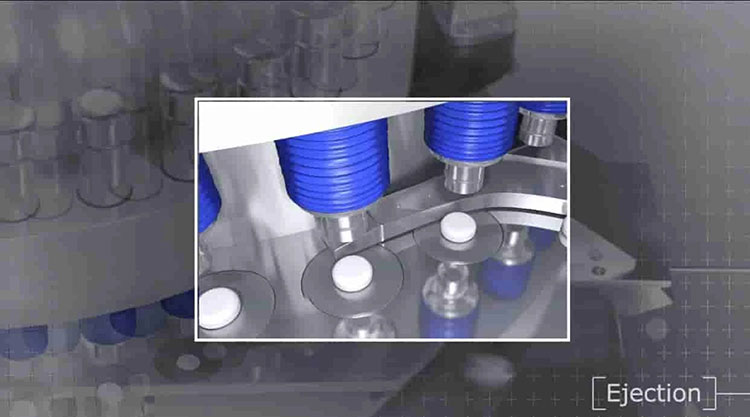

Centrifugal Industrial Sifter Machine

Allpack- LXS Series Centrifugal Screen Sifter Machine

This industrial sifter machine by Allpack is an ideal equipment especially designed to meet the industrial needs of processing hard and electrostatic objects through centrifugal force. The machine is available in 1-4 layers with 1-5 discharging outlets. Hence, it can give you an outstanding range to select the best one for your eclectic needs.

Structure

The basic functioning structure of machine is round with square main frame. Other components include a hopper, screw conveyor, coarse particle outlet, fine particles outlet, inspection window, air purged seal assembly, rolling sieve, control board, and a motor.

Working Principles

It follows simple working procedure where product is poured in the hopper which is then entered into a sieve through screw conveyor and continuous air purging. The rotation of rolling sieve results in the release of fine particles towards fine particles outlet and the coarse particulates are transported through coarse particle outlet.

Application

It is best suitable for highly viscous, electrostatic, fibrous, and high humidity products.

Gyratory Industrial Sifter Machine

Gyratory sifter- Picture Courtesy: HENG YU

Gyratory industrial sifter machine refers to the machine which, unlike the vertical motion of vibratory industrial sifter machine, uses horizontal gyratory action. It is best for large scale industries who wish for efficient, hygienic, and quality processing of their numerous powders. With improved capture of contaminants, it fully assures the safety of your products.

Structure

It is an assembly of different components including an inlet, observation hole, dust cover, gyratory motor, multi-channel screens, and outlet etc.

Working Principles

When product is loaded, it begins moving it in a horizontal rotary direction with no agitation. Moving forward, the reciprocating movement of the machine spread, stratify, and separate the particles according to their sizes. After which, each group of particles are discharged from the machine through outlets.

Application

The machine is ideally recommended for free-flowing sensitive powders being processed in pharmaceutical, chemical, nuclear, and food sector.

8.Highlight The Applications Of An Industrial Sifter Machine?

Following are the major uses and applications of an industrial sifter machine:

Foodstuff Industry

Various dry seasonings- Picture Courtesy: jackedonthebeanstock.com

The very first area which comes in our minds when talking about the applications of an industrial sifter machine is foodstuff industry. It is because immeasurable volume of goods and products are manufactured and packed every day. Therefore, for their safe processing, the machine is used. The common examples include coffee powder, milk powder, spices, sugar, beans, dry fruits, and snacks etc.

Medical Industry

Nutraceutical drugs presentation idea- Picture Courtesy: spain-4life.com

Maintaining hygiene is the top prerequisite of medical industry. machine. Since, an industrial sifter machine offers an enclosed environment for the protection of processed materials, it is used for retaining the integrity and quality of pharmaceutical formulations by segregating different components for products like medicine powders, solid formulations, and solid-liquid formulations etc.

Chemical Industry

Detergent liquid and powder- Picture Courtesy: Reader's Digest

Along with other industries, chemical industry is also growing rapidly and following strict principles for the maintenance of uniformity in products formulations. This is the reason, why an industrial sifter machine is becoming the part of every chemical plant for performing the sifting operation of products like detergent powders, chemical powders, and pesticides, and gun powder etc.

Beauty Care Industry

Lady sketching with cosmetic powders

How can it be possible to leave behind beauty care industry when the ongoing discussion is about powder sifting! The sector is highly dependent upon the use of an industrial sifter machine which greatly helps in removing lumps and agglomerates of face powder, eyeshade powder, and hair dye etc.

Agricultural Industry

Ripen wheat crops- Picture Courtesy: Wallpaper Flare

Wheat and grains are among the top staples all over the world. Their clean processing is as important as increasing their production. So, whenever the crops are harvested, they are to be free from all stones, wastes, and debris before their further processing. Ergo, an industrial sifter machine can perfectly carry out this function.

Hardware Industry

Multicolor plastic pellets- Picture Courtesy: WordPress

Hardware products like nuts, screws, and plastic pellets etc., which are processed in hardware industries can also be screened by using an industrial sifter machine.

9.Can Industrial Sifter Machine Be Directly Integrated With Other Machines?

Displaying integration- Picture Courtesy: Neomind

It is a matter of common fact, that manufacturing industries especially those of large and extra-large scale used to automate their processing in order to get efficiency and precision at once. Similarly, they integrate different essential machines to get their desired output level.

Hence, the answer to your question is yes! You can directly integrate an industrial sifter machine with other machines in your production line. For instance, you can integrate an industrial sifter machine with spice grinding machine, wheat grinding machine, or pellets making machine.

10.How To Examine The Quality Of An Industrial Sifter Machine?

Examining the quality of an industrial sifter machine is a top priority of the manufacturers who value their goods and customers. It is no exception that every producer concerns the latter for which the former is inevitable. That's why, there are some quality standard organizations who work across the globe to meet this end. These include:

Quality inspection icon- Picture Courtesy: Behance

GMP

Good Manufacturing Practices is a global organization which establishes primary rules worldwide like the construction material for different machines. Henceforth, an industrial sifter machine complying GMP regulations is made up of high-quality material.

ISO

International Organization for Standardization is another platform through which the quality of machine can be assessed. In addition, it is a local certification of international level that must be provided to the eligible aspirants.

FDA

As an industrial sifter machine is used both for edible food and drugs, or nonedible chemicals and plastics. Therefore, if a machine is certified by Food and Drug Administration, it will be of top quality.

CE

It is for all the European Union countries, if someone wants to purchase an industrial sifter machine, then the machine must be certified by CE.

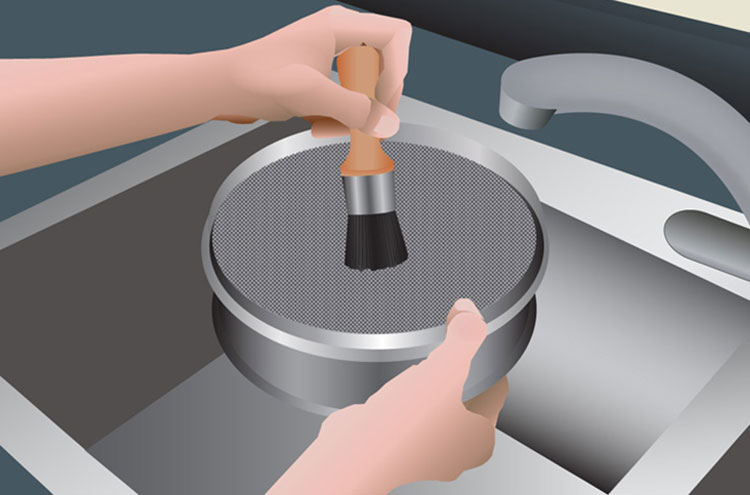

11.How To Maintain And Clean An Industrial Sifter Machine?

If you leave your industrial sifter machine to work continuously without caring for its maintenance and cleaning, it will lose its significance and will start functioning insufficiently. To avoid such condition and extend the working life of your machine with enhanced efficiency, it is crucial to follow certain steps regarding its cleaning and maintenance:

User washing sifter screen- Picture Courtesy: globalgilson.com

Cleaning

Clean your industrial sifter machine on regular basis by disassembling its parts. It can be simply done by removing the clamps, upper and lower frames and attached screens. Wash these parts with non-acidic clean water and wipe these parts with tidy clothes. This will help you keep your machine at stable condition and will avoid frequent damaging of screens.

Maintenance

Maintenance covers both the structural and functional parameters of machine. It includes placing the different components of machine on their exact place before starting operation and fixing the speed of vibration and frequency of temperature in accordance with the requirement of materials. Moreover, greasing vibratory motor and inspecting the parts for wear and tear are other important factors to be looked for.

12.What Are The Possible Causes And Solutions To Diagnose An Industrial Sifter Machine?

What if your industrial sifter machine suddenly starts malfunctioning? If so, there are chances that it will adversely affect the product being processed as well as damage the machine itself. So, you need to be cautious when operating the machine and in case of any mishap, just follow the underlying solutions for their troubleshooting:

| i. The amplitude of machine is small | ||

Damaged motor- Picture Courtesy: ipharmachine.com |

Cause:

The motor is damaged Excessive material loaded over the screen Condensation of the vibrator's grease |

Solution:

Replace the motor Reduce the amount of material to avoid accumulation Clean the old grease from vibrator and supply it with new lubrication |

| ii. Abnormal movement of material | ||

Abnormal movement of coco powder- Picture Courtesy: Eversun Machinery |

Cause:

False placement of screen box The screen may be damaged Too much material feeding on single side |

Solution:

Accurately place the screen box and make sure it is flat Replace the screen and use the one that can withstand the heat processed by the machine Pour material on screen evenly |

| iii. Poor quality grading of materials | ||

Excessive feeding of powder over screen- Picture Courtesy: galaxysivetek.com |

Cause:

The spaces of screens are blocked by foreign objects or waste particles Too low or too fast vibrating speed |

Solution:

Clean the screen and remove out the trapped object Adjust the speed of vibration to suitable level by using the lead angle |

| iv. Screen Blocking | ||

Antiblocking balls for industrial sifter machine- Picture Courtesy: urmachinery.com |

Cause:

High feed rate at once Unsuitable screening Use of electrostatic, cohesive, and sticky substances |

Solution:

Feed moderately Select the right type of screen while keeping in mind the type of material and temperature frequency Use antiblocking devices for free flowing of materials |

13.Factors to Consider When Buying An Industrial Sifter Machine?

When buying an industrial sifter machine, several factors need consideration to ensure you select the most suitable one for your specific needs. Following are some important factors to consider:

Capacity

Industrial sifter machines with 1-3 layers- Picture Courtesy: LinkedIn

Determine the required throughput capacity of the industrial sifter machine based on your production needs. For this, you are required to make sure the machine can handle the volume of material you plan to process efficiently.

Durability and Build Quality

Choose a machine constructed from durable materials that can withstand the demands of industrial use. For instance, a well-built industrial sifter machine will have a longer lifespan with minimal downtime and low maintenance requirement.

Customization Options

Various types of powders, granules, and liquids

Consider whether the industrial sifter machine offers customization options such as interchangeable screens, adjustable settings, or additional features to meet your specific requirements. It will help you opt for a more versatile and adaptable machine.

Supplier Reputation and Support

Significance of reputable supplier- Picture Courtesy: mesinc.net

Purchasing an industrial sifter machine means you are incorporating in your production a new machine which will bring with it certain obligations whose timely fulfilment is inevitable. Hence, you need to look for the reputation of the supplier, and consider factors such as warranty policy, technical support, and after-sales service.

Conclusion

The bottom line of the buying guide about an Industrial Sifter Machine is that the need of this machine has recorded growth. No matter what the background of industry is, its use will be considered to excel quality control and hygienic processing. Not only that, but the variations available in industrial sifter machine has compelled the small to large scale entrepreneurs to come forward and select the best compatible one. It seems like you are also standing there. If yes! Then no need to think more, just click on the given link to reach us out!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Industrial Sifter Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours