Milk Sachet Packing Machine: The Complete Buying Guide In 2025

Milk pasteurizing and packaging sector has witnessed a commendable surge after pandemic, when about half of the world was dependent on packaged milk. Now, people have reestablished their proclivities for aseptic packaged milk. In the same manner, manufacturers are also trying to satisfy the growing needs. Hence, the use of a Milk Sachet Packing Machine become inevitable.

Are you among one of them? Probably yes! Then no need to worry, as this buying guide is designed to help you in best possible way. It will be showcasing the unparalleled resilience, high level automation, and enhanced precision of a milk Sachet Packing Machine. So, be prepare to embark on a thorough journey to this guide!

1.What Is A Milk Sachet Packing Machine?

APK-130 Automatic Horizontal Milk Powder Sachet Machine

Milk sachet packing machine is a type of flexible packaging machine purposefully tailored to pack the milk in both its powder and liquid form into sachets. The machine is equipped with smart control touch screen interface, therefore, uses automatic technology to perform its functions.

It is a type of form, fill, and seal packing machine which forms the sachet by using a film, fill it with precise milk powder or liquid, and seal the sachet by creating stringent sealing. In this way, it is crucial in extending the shelf life of milk and is widely used in this sector followed by other food and non-food industries.

2.Enumerate Some Benefits Of A Milk Sachet Packing Machine?

Milk sachet packing machine offers numerous benefits for your business in form of boosting production, ensuring packaging accuracy, and providing the opportunity of customization. Some of these are as follows:

Enhanced Productivity

Productivity icon- Picture Courtesy: empmonitor.com

The very first benefit of using a milk sachet packing machine is its high level of efficiency that is attained by its automation. The low interference of labor leads to reduction in downtime, thereby enhancing production growth.

Multi Functioning

The machine comes up with multiple tasking capabilities of sachet forming, data coding, filling, sealing, and cutting. Ergo, you find all in one milk sachet packing machine.

Precision

Milk powder sachet with precise sealing & cutting- Picture Courtesy: chengyipacking.com

Milk sachet packing machine display up to-the-mark precision level when it comes to form sachets and filling them with exact volume of milk. Therefore, it ensures that each sachet is of uniform size with material of same weight to give your packages a professional look.

Versatility

Different types of powders with their sachet packaging- Picture Courtesy: landpack.com

With growing competition in the field, manufacturers aim to cater the vary needs of market. In this way, milk sachet packing machine can handle variety of products, packaging materials, and providing eclectic designs for sealing and cutting.

Cost-effectiveness

Milk sachet packing machine is a cost-effective solution that can reduce, to a larger extent, the labor cost, material waste, and packaging inaccuracies caused by manual packaging.

3.What Types Of Milk Are Packed By A Milk Sachet Packing Machine?

As we are familiar with the fact that with the use of technology, now milk is available in all the possible forms encompassing dry powder to daily use liquid milk and thick condensed milk. So, a brief description about each kind of milk that a milk sachet packing machine is capable to pack is given below:

Powdered Milk

Dry milk powder in bowl- Picture Courtesy: znaturalfood.com

Powdered milk is the most common type of milk delivered in sachets. It is derived from the liquid milk after its dehydration. The common milk powders packed by a milk sachet packing machine include skim milk powder, whole milk powder, and buttermilk powder etc.

Liquid Milk

Liquid milk- Picture Courtesy: nourishedkitchen.com

Another type of milk which is packed by a milk sachet packing machine is liquid milk. It is available in free-flowing and viscous form. The popular liquid milk includes fortified milk, skimmed milk, pasteurized milk, and condensed milk.

Granulated Milk

Sachet of granulated milk- Picture Courtesy: pro.regilait.con

Through the process of dehydration and evaporation liquid milk is turned into granules. Hence, this machine is capable of packing granulated milk in sachets of different shapes and sizes.

4.What Bag Types Can Be Made By Milk Sachet Packing Machine?

Well, a milk sachet packing machine can offer you astonishing bag types with appealing seals more than you have ever thought. So, let's move forward to know what these types actually look like!

3 Side Seal Sachet

3 side seal coffee powder sachets- Picture Courtesy: chengyipacking.com

This type of convenient sachet comes with 3 side sealing. It is best suitable for delivering single serving milk powder as well as liquid milk in small quantity.

4 Side Seal Sachet

4 side sealed milk sachet- Picture Courtesy: deeski.com

Here, the sachet is characterized by its 4-side stringent sealing which is best option for liquid milk and condensed milk. It is also a kind of single serving sachet used for milk to enhance its protection against spillage.

Back/ Center Seal Sachet

Pillow milk powder sachet- Picture Courtesy: qne.com.pk

In this type of packaging style, the film layer is turned into a sachet by meeting the edges of film at the center of sachet on back side. Hence, it gives a look of pillow sachet.

Shaped Sachets

Shaped bags are type of sachets with irregular shapes. A milk sachet packing machine is capable of customizing sachets shapes to meet your individual needs.

5.How Do A Milk Sachet Packing Machine Work?

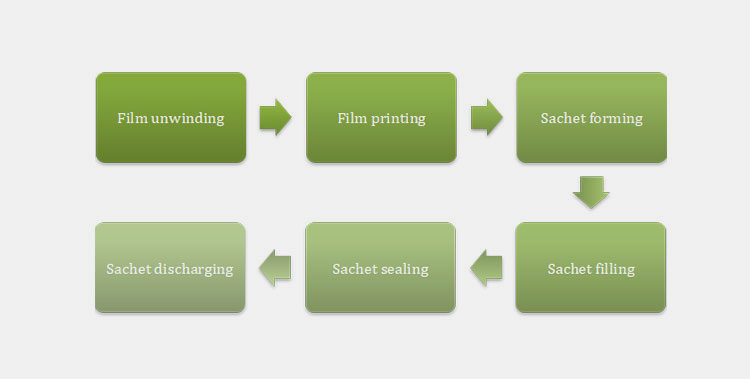

A milk sachet packing machine works in an extremely straight forward way once it is loaded with sufficient volume of material and packaging film in form of film roll. It follows few sequential steps to carry out the sachet packaging. These steps are explained below for your clear understanding:

Film Unwinding

Film unwinding- Picture Courtesy: landpack.com

When the machine is turned on, the very first thing that takes place is the film unwinding. The film rolled over the stock is unwinded by the transport belt pullers and is rightly positioned on rollers. During this phase, the film moves towards dancer's arm which gives the film tension against drifting.

Film Printing

This step is an optional yet important one, where unwinded film is passed through the printer which print batch no, expiration date, and registration mark etc., on it. Afterwards, it is moved forward for sachet forming.

Sachet Forming

Sachets forming- Picture Courtesy: landpack.com

As the printed film reaches sachet forming tube, its edges are overlapped, and it is sealed on longitudinal and bottom side to create a sachet.

Sachet Filling

Milk powder filling into sachets- Picture Courtesy: landpack.com

Once the sachet is formed, it is filled with precisely weighed volume of milk or any other substance. When material is filled into sachet, the filling head will be stopped, and the sachet will be ready for sealing.

Sachet Sealing

Powder sachets sealing- Picture Courtesy: landpack.com

In this step, filled sachet is sealed from the top horizontal side while using heated sealing jaws. Simultaneously, the sealed sachet is separated from continuous film through cutting.

Sachet Discharging

Sachets discharging from machine into carton- Picture Courtesy: landpack.com

At last, when the cutting knife get open, finished sachets fall over the conveyor and is discharged from the machine for further packaging.

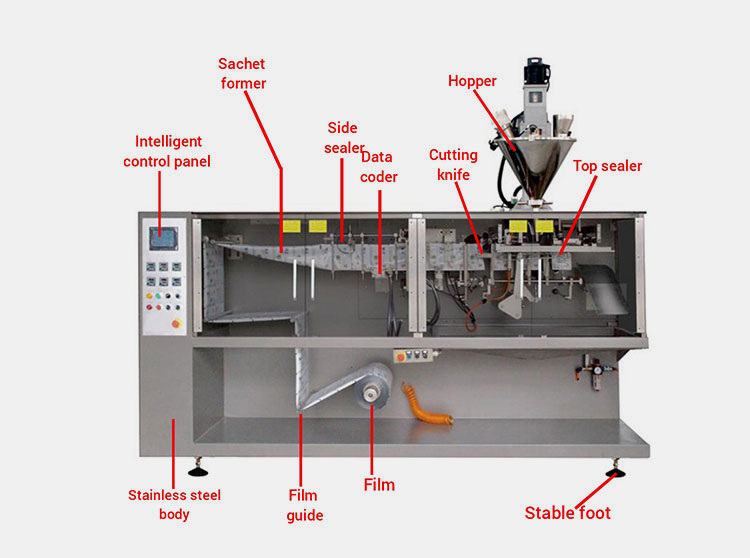

6.Describe The Structure Of A Milk Sachet Packing Machine?

It is significant to have proper knowledge about each component of a sachet packing machine as it helps in operating the machine in a right way and in case of issue, you will be able to tackle it easily. Some of the major components are explained below:

Components of Allpack APK-130 Milk Powder Sachet Machine

| No | Components | Function |

| 1 | Intelligent control panel | Intelligent control panel is one of the core components of a milk sachet packing machine located on the front of machine. It provides the operator with multiple options to set commands and control the machine. |

| 2 | Sachet former | Sachet former refers to the tool that turns the flat layer of film into one-fold film to form sachet. |

| 3 | Side sealer | Side sealer is a vertical sealer employed to seal the longitudinal sides of sachet during sachet formation. |

| 4 | Data coder | It is an optional unit of milk sachet packing machine, but it plays a primary role in printing information like batch no and expiration date on sachets. |

| 5 | Cutting knife | Cutting knife is also known as cutting blade which is responsible to split the finished sachet from continuous film through precise cutting. |

| 6 | Hopper | It is the feeding tank of a milk sachet packing machine made from stainless steel. Inside this hollow container, bulk of material either in liquid or powder form is poured before starting operation. It is helpful in providing the machine with material for smooth functioning. |

| 7 | Top sealer | Top sealer is a horizontal seal which is located after the filling head. It seals the sachet from top after its filling get completed. |

| 8 | Stable foot | Four stable feet are attached to the main body of a milk sachet packing machine. |

| 8 | Film | Film is a thin layer of plastic, aluminum, or laminated paper from which different types of sachets are formed. It is placed in the base of machine in form of a rollstock. |

| 10 | Film guide | Film guide include multiple film pulling rollers which help in the accurate unwinding of film from roll towards forming station. |

| 11 | Stainless steel body | The body of a milk sachet packing machine is made from 304 stainless steel, keeping in view the GMP's regulations, which is fully protected against bacterial presence and is corrosion resistant. |

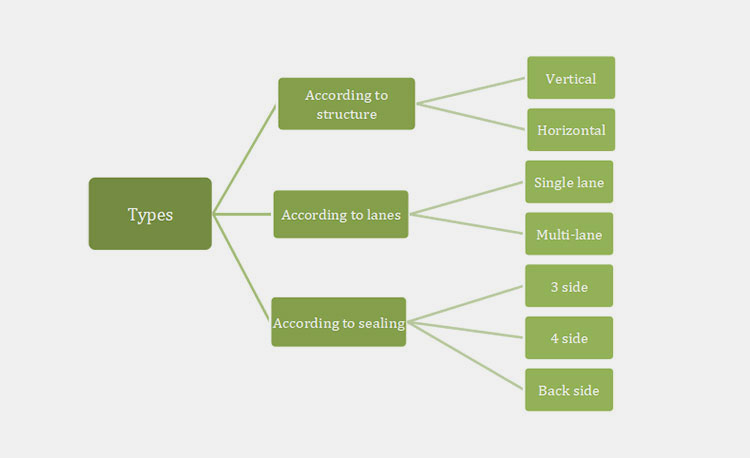

7.Classify The Types Of Milk Sachet Packing Machine?

There are multiple types of milk sachet packing machine available in market today. Each machine has its unique features which distinguishes it from the rest of machines. So, let's have a look towards these all!

According to Structure

Vertical Milk Sachet Packing Machine

LMUHP-5S High Speed Continuous Motion VFFS Packaging Machine- Picture Courtesy: LENIS

Vertical milk sachet packing machine is characterized by its vertical body. It is cost-effective and reliable for small to medium industries.

Structure

Vertical milk sachet packing machine has a long body in a vertical longitudinal position. Therefore, it occupies less space and is easy to mobilize from one place to another. The machine uses forming tubes for sachet formation.

Working Principles

Its working principles are simple where film travel across the different packaging stations in a vertical direction from upside down manner. These sachets are produced on the top of the machine. Once, the formation and filling are accomplished, the finished sachets are sealed and discharged from the machine.

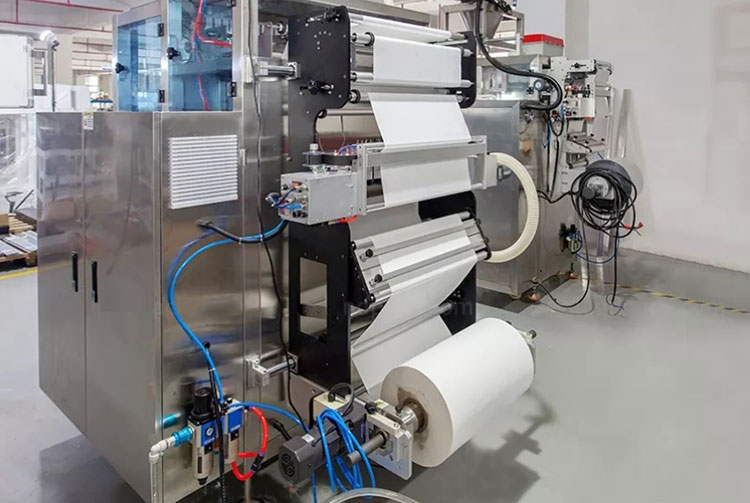

Horizontal Milk Sachet Packing Machine

APK-130 Automatic Horizontal Milk Powder Sachet Machine

This horizontal milk sachet packing machine by Allpack is an extensively used machine designed to pack milk into various types of sachets. It can give you most satisfying results in terms of production.

Structure

It has a large horizontal structure compared to vertical milk sachet packing machine. Therefore, it covers more space.

Working Principles

In this type of milk sachet packing machine, film travel horizontally through different stations and get finished after undergoing sachet forming, filling, and sealing.

According to Lanes

Single Lane Milk Sachet Packaging Machine

LMSTS-450SA Single Lane Stick Pack/Sachet Packaging Machine- Picture Courtesy: LENIS

Single lane milk sachet packaging machine is an economical machine that comes with single lane system for forming, filling, and sealing sachets. It can perfectly meet the existing needs of mediocre milk packaging business. The machine can be attached with any kind of filling mechanism for powder as well as liquid milk packaging.

Structure

It has a small footprint with easy to move body that is comprised of few components including a single filling head, a sachet forming tube, sealing jaws, and a cutting mechanism.

Working Principles

The working process of single lane milk sachet packing machine is simple which starts from loading the film stock into frame and feeding material in hopper. Afterwards, the film is unwinded, moved around a forming tube, turned into a sachet, filled with milk and then sealed for cutting and ultimately discharging.

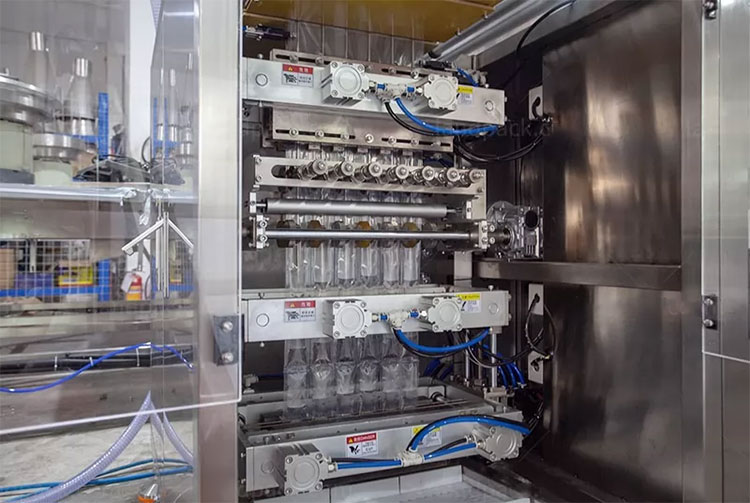

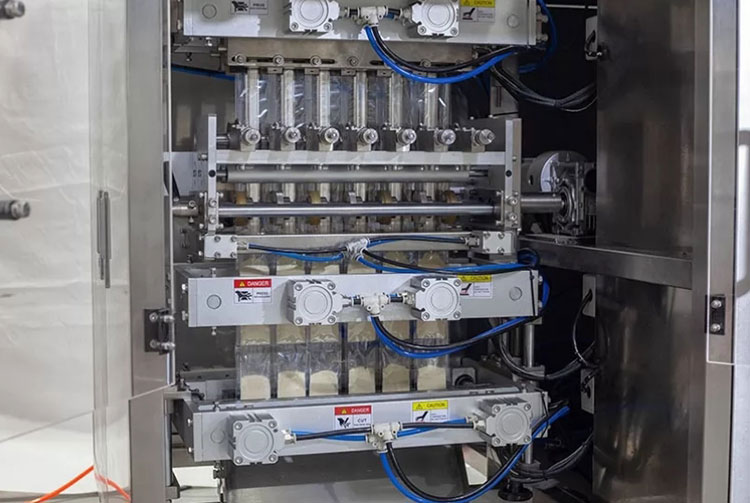

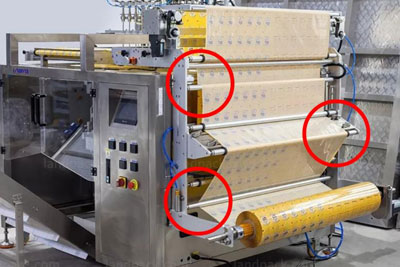

Multi-lane Milk Sachet Packing Machine

Allpack- APK 6-480 Multilane stick packing machine for granule

Multi-lane milk sachet packing machine is a wonderful machine designed with cutting-edge technology to assist you in producing upto 240 sachets in a minute.

Structure

This machine adopts modular design with multiple interchangeable components, electrical system, bag forming, printing, filling, sealing, and cutting stations etc.

Working Principles

It forms and fill multiple sachets simultaneously in each cycle. The process starts from machine unwinding the film, splitting it into different sections and turning them into sachets. Similarly, each sachet is filled with accurate milk volume and all the sachets are collectively sealed at once and discharged out of the machine.

According to Sealing

3 Side Seal Milk Sachet Packing Machine

Multi row 3 side sealing particle packaging machine- Picture Courtesy: chengyipacking.com

As the title demonstrates, this type of milk sachet packing machine is suitable for creating sachets with 3 side sealing. Hence, you can process all kinds of packaging materials by this machine including plastic film, laminated paper, and aluminum film etc.

Structure

The structure of machine is characterized by its unique design bag formers which are tilted toward the single side of machine.

Working Principles

It functions by pulling film from roll and traversing it around the bag former. Firstly, the sachet is sealed from bottom and side. Secondly, the sachet is filled with milk. Thirdly, the filled sachet is sealed from top and ejected from the machine.

4 Side Seal Milk Sachet Packing Machine

Multi row 4 side sealing granule packaging machine- Picture Courtesy: chengyipacking.com

This machine is specialized in making 4 side seal sachets for packing milk. It can be applied for all kinds of single serving milk whether in powder, liquid, or granules depending upon the type of filling mechanism.

Structure

The structure of machine is different from other types of machines due to its sachet forming unit which is flat compared to other types of conical sachet formers.

Working Principles

It carries out the milk sachet packing by first sealing the sachet from bottom and longitudinal sides. After this, the pre-weighed amount of milk is dispensed into it and the sealing of top side turn it into 4 side seal sachets.

Back Side Seal Milk Sachet Packing Machine

Multi row back sealed powder packaging machine- Picture Courtesy: chengyipacking.com

This type of milk sachet packing machine is particularly designed to form and pack sachets with a longitudinal seal on the back side. The common examples include pillow type sachet and stick pack sachet.

Structure

It consists of different hardware and software components with conical sachet formers as primary parts for which the machine is well-known.

Working Principles

The working process start from film being unfurls from roll and moving towards sachet former. Here, the film is traversed around the sachet forming tube and a back sealing is created at the center of sachet along with bottom sealing. Hence, milk is dispensed from upward side and at the end, sachet it sealed from top

8.Differentiate Between Liquid Milk Sachet Packing Machine And Powder Milk Sachet Packing Machine?

There are certain differences between a liquid milk sachet packing machine and a powder milk sachet packing machine which can be better understand by looking into the table below:

| No | Aspects | Liquid Milk Sachet Packing Machine | Powder Milk Sachet Packing Machine |

| 1 | Definition | Liquid milk sachet packing machine is used to pack liquid milk in single serving sachets. | On the other hand, powder milk sachet packing machine is designed to pack dry milk powder in sachets. |

| 2 | Nature of material | Free flowing and viscous liquid milk. | Free-flowing and adhesive dry milk powder. |

| 3 | Filling system | Filling system such as net weigh filling, piston filling, and volumetric filling are used according to the flow properties. | Auger filling system is preferred for dry milk powders. |

| 4 | Preferred sachet sealing | Mostly, 4 side and 3 side sachet sealing is adopted for liquid milk due to its flowing nature. | Dry powder milk is suitable to be packed in all the three kinds of sachets including 3, 4, and back side seal. |

| 5 | Flow ratio | High flow properties. | Comparably poor fluidity. |

| 6 | Picture |

Liquid sachet packing machine |

Single Lane Powder Sachet Filling Machine- Picture Courtesy: bojupacking.com |

9.What Are The Applications Of A Milk Sachet Packing Machine?

The use of a milk sachet packing machine is not only confined to dairy food industry rather it can be utilized in many other food and non-food sectors. Following is the glimpse of these applications:

Dairy Food Industry

Various dairy products- Picture Courtesy: prevention.com

Milk sachet packing machine is widely used in dairy food industry for products like liquid milk, butter, cheese, yogurt, condensed milk, milk shakes, curd, cream, and clarified butter etc.

Daily Food Industry

Various coffee powder sachets- Picture Courtesy: designhooks.com

Food products which are used on daily basis are also commonly delivered in sachets through the help of a milk sachet packing machine. These include coffee powder, tea powder, chocolate, custard powder, juices, sugar, and oil etc.

Condiments Industry

Condiment or seasoning industry is the most notable area where the use of a milk sachet packing machine is undeniable both for dry condiment powders and free flowing to viscous seasonings. The common examples include ketchup, mayonnaise, soy sauce, chilli powder, salt, and pepper.

Pharmaceutical Industry

Various pharmaceutical products in sachets- Picture Courtesy: makwell.com

Milk sachet packing machine is also applicable for products being manufactured in pharmaceutical industry. In this way, ointments, syrups, calcium powder, protein powder, herbal powder, and different kinds of drugs and medicines are packed by this machine.

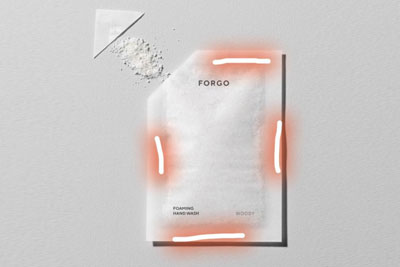

Cosmetic Industry

Multiple shampoo sachets

Cosmetic industry is now also focusing on delivering their products in single serving sachets. Therefore, shampoo, conditioner, hair color, hair oil, lotion, foundations, and hand washing gel are often packed in sachets by using a milk sachet packing machine.

Chemical Industry

Women washing clothes- Picture Courtesy: Nital Detergent

Another most significant application of a milk sachet packing machine is the chemical industry where large volume of pesticides, herbicides, silica gel, detergents, and cleaning agents are packed in sachets.

10.How To Maintain A Milk Sachet Packing Machine?

Maintenance is the key to keep your milk sachet packing machine at optimal condition. It is inevitable for the longevity of your machine, so, make sure you are properly taking essential measures for the machine maintenance. In this way, underlying tips can be helpful:

Operator maintaining the sachet packing machine through HMI- Picture Courtesy: mindmybusinessnyc.com

Cleaning

While running your milk sachet packing machine, you need to ensure the cleaning of machine on daily basis, otherwise, the dust, debris, and residues will accumulate in various parts of machine and will obstruct the way for proper functioning. It can be cleaned by using:

- Clean water for hopper and nozzles.

- Compressed air to blow out dirt from hard-to-reach parts.

- Neat cloth dampened in non-acidic cleaning solution for wiping down surfaces.

Lubrication

Lubrication of the movable parts of milk sachet packing machine not only reduce the friction but also dissipate excessive heat generated by the constant working. Moreover, it is helpful in reducing parts wear and tear. Few crucial tips for lubrication include:

- Using only recommended type of lubrication for your machine.

- Apply lubrication to all required parts like gears, chains, and bearings.

- Do not over lubricate the components, or it will lead to problems.

Inspection & Parts Changeover

Regular inspection of your machine is greatly helpful in detecting issues and taking relevant actions. For this, it is significant to:

- Observe the noise during operation and find its location.

- Pay attention to parts such as belts, rollers, and bearings.

- Check for the possible wear and tear and replace the damaged parts timely.

11.Explain The Troubleshooting Of A Milk Sachet Packing Machine?

While operating a milk sachet packing machine, any spontaneous malfunction can hinder the machine's way of effective packaging and causes unplanned down time. This result in halting the efficiency of machine. Hence, to avoid such problems, promptness is necessary. So, be ready to gain it!

| i. The film eye mark is not registered during operation | ||

Highlighted film pullers- Picture Courtesy: landpack.com |

Cause:

Too shiny or reflective film Bad contrast of eye mark and film background Film is spliced Slipping of film pulling belts |

Solution:

Polluted eye mark registration sensor lens Use film with totally different colors of background and eye mark for quick identification Check if the film splitter is in wrong place. Tight and if needed replace the pulling belts |

| ii. Film feeding issue | ||

Film feeding- Picture Courtesy: landpack.com |

Cause:

The packaging film is finished Error in registration photo-eye sensor Film pulling rollers slipping |

Solution:

Feed the machine with new film Clean the registration photo-eye sensor to see the mark on film Check and adjust the pulling rollers and adjoined belts |

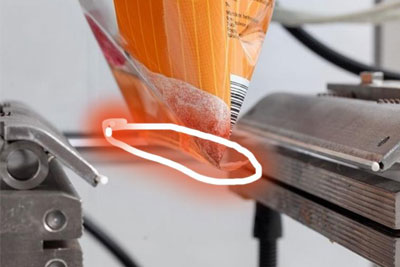

| iii. Bad sealing- vertical and horizontal | ||

Marked vertical and horizontal sealed sides of powder sachet- Picture Courtesy: landpack.com |

Cause:

Misaligned seal bars Inadequate or excessive seal bar temperature Dirty or damaged sealing jaws Incorrectly webbed up film |

Solution:

Adjust the seal bars parallel to each other Reset the seal bars temperature to suitable level Clean the surface of sealing jaws and replace if damaged Web the film rightly |

| iv. Product getting caught in seal | ||

Marked sealed edge of sachet- Picture Courtesy: vikingmasek.com |

Cause:

Inadequate time for product settling in sachet Overfilling of material |

Solution:

Increase the time for sealing intervals to get the material properly settled in sachet Adjust the fill volume of material to avoid overfilling |

| v. Machine downtime | ||

Highlighting missing sachet- Picture Courtesy: landpack.com |

Cause:

The only culprit is lack of preventive maintenance which leads the machine to show inefficiency and intermittent breakdowns |

Solution:

Adopt and maintain regular maintenance of the machine including its cleaning, lubrication, and parts replacement to avoid potential downtime |

12.Factors Essential For Considering A Sophisticated Milk Sachet Packing Machine?

When working in manufacturing and packaging industry, it is always necessary to opt for the machine that suits your requirements. How will you know about these requirements is what we have explained below:

Type of Sachet

Different types of sachets- Picture Courtesy: landpack.com

As we have mentioned earlier, sachet can be further categorized into pillow pouch, stick bag, and standard sachet along with myriad of sealing and cutting designs. Therefore, it is crucial to determine the type of sachet and then search for the compatible machine.

Filling System

Auger filling system- Picture Courtesy: ivs-engineering.com

Another most critical thing is to know about the nature of your product. For instance, whether the milk you want to pack is in liquid form, powder form, viscous form, or granulated form. Answering these questions will help you go for the relevant filling system for your milk sachet packing machine.

Customization

Customized energy gel sachet- Picture Courtesy: muirenergy.com

There are few types of milk sachet packing machine which are not restricted to only single style of sachets rather it offers you wide variety and support multiple packaging formats. So, it you want to market your products, then the machine with automatic parts changeover during operation is best suitable.

Production Volume

What is your current production level? Are you a new businessperson in manufacturing field with small production volume or having a large-scale business? This is another important factor which will surely assist you in deciding whether the single or multi-lane milk sachet packing machine is good for your needs.

Conclusion

To put in a nutshell, milk sachet packing machine is a top-notch machine with advanced features which better fulfill your varying needs regarding milk packaging. It can help you raise your production value as well as growth by prioritizing customer on large scale through delivering the precise amount of milk. Moreover, the flexibility and adaptability of the machine enable you to use the single machine for liquid, powder, and granulated milk by just changing the filling system. If benefits are so many then what are you waiting for? Just click on our website and become our valuable customer!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide