How To Choose The Best Gummy Making Machine: The Complete Buying Guide In 2025

How To Choose The Best Gummy Making Machine: The Complete Buying Guide In 2025

Gummy can not only be used as food, but also as a health supplement, which can be seen everywhere. Do you know how this small gummy is made? Of course, it’s a gummy making machine. The birth of every gummy begins with this precise and magical machine.

Faced with so many gummy making machines on the market, do you find it difficult to make a decision? How to choose the best gummy making machine? You need to consider multiple factors, such as type, appearance, quality, etc.

Now, let’s explore how to choose the best gummy making machine together.

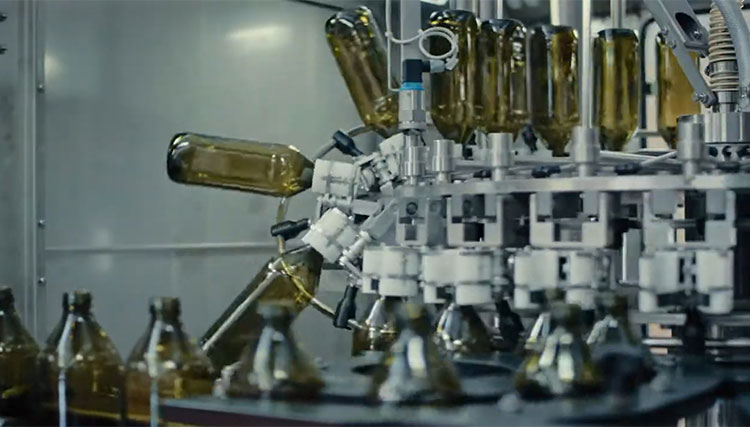

1.What is the Gummy Making Machine?

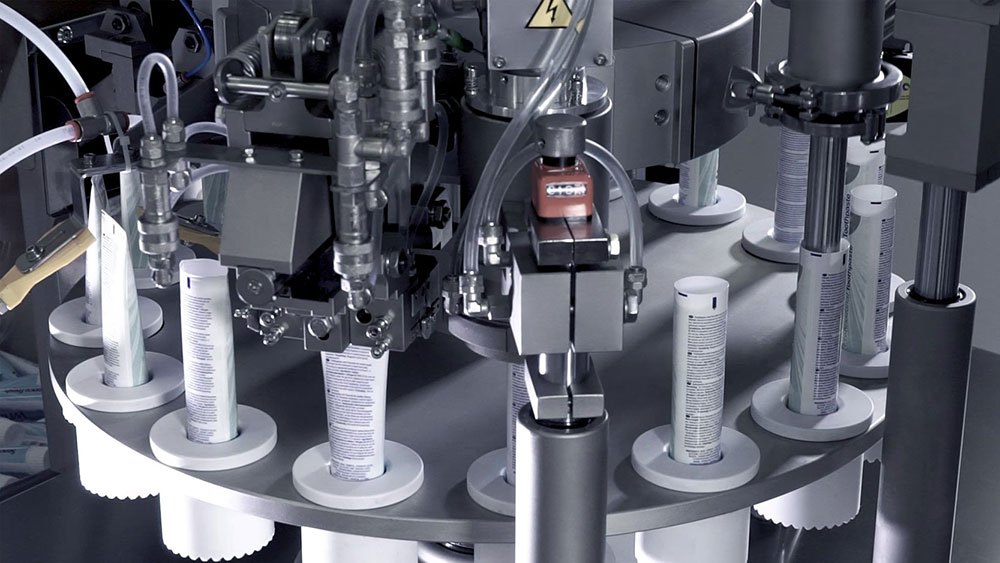

Allpack Gummy Making Machine

The gummy making machine stands as a key equipment in the manufacture of gummy candies, seamlessly integrating diverse functional modules to automate the entire production cycle, from the mixing of raw materials to the final molding stage. This machine enjoys extensive application across the candy-making, pastry production, snack food industry, and beyond.

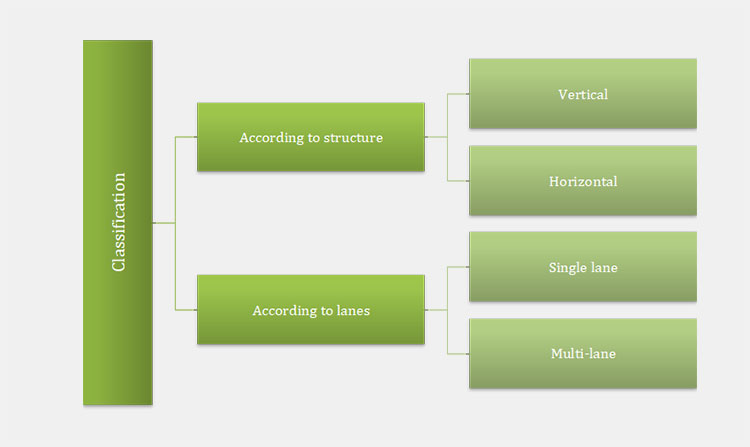

2.What Are the Common Types of Gummy Making Machines?

Upon grasping the essence of a gummy making machine, are you aware of the various types it commonly falls under? Let’s delve into the details to uncover the different types.

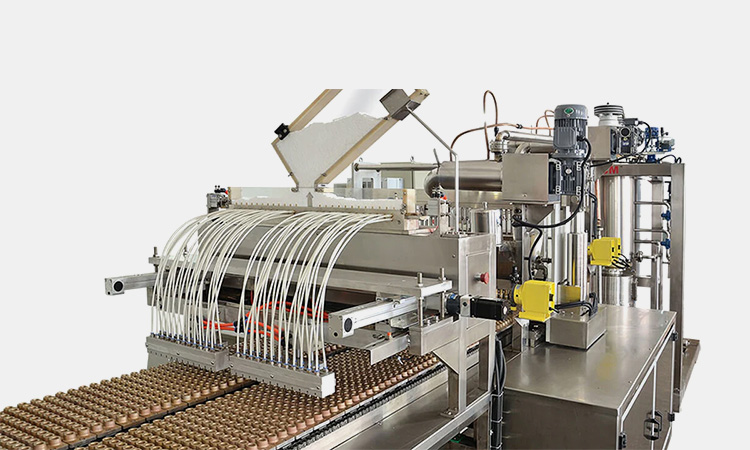

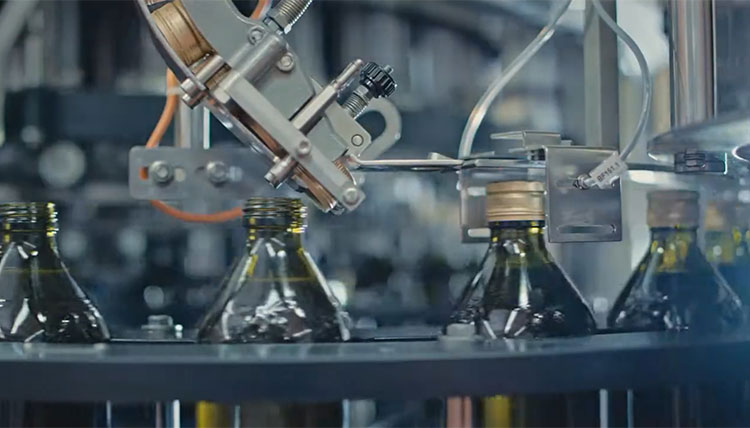

Fully automatic gummy making machine

Allpack Fully Automatic Gummy Making Machine

The fully automatic gummy making machine boasts exceptional automation levels and remarkable production efficiency, rendering it an ideal choice for large-scale operations. Its versatility allows for the production of diverse gummy varieties.

The output capacity varies across models and configurations, with some advanced production lines capable of churning out 150 kilograms or more per hour. However, due to its heightened sophistication, this type of machine commands a higher price tag, thus catering to enterprises with substantial financial capabilities.

Semi-automatic gummy making machine

Semi-automatic Gummy Making Machine - Sourced: huadapharma

In contrast to fully automated production lines, semi-automatic gummy making machines offer a more user-friendly operation experience, making them an attractive option for small and medium-sized enterprises or individual producers.

While incorporating certain automation features, they still necessitate manual intervention in certain stages of the process. Their moderately priced nature makes them a fitting choice for producers operating within tighter budgetary constraints.

Manual gummy making machine

Manual Gummy Making Machine - Sourced: cbdfillingfactory

A manual gummy making machine is a device used for making gummy candies, usually with a relatively simple operation and a relatively small production scale, suitable for use in small candy stores, family workshops, or teaching experiments.

3.How to Choose the Best Gummy Making Machine?

When choosing a gummy making machine, multiple factors need to be considered to ensure that the selected equipment can meet production needs and has good performance and reliability.

Function and performance

Performance - Sourced: gosmallbiz

You need to consider the performance of the gummy making machine, which needs to be able to continuously and accurately produce gummy with stable output.

Furthermore, the machine must be versatile enough to produce a diverse range of soft candies, encompassing traditional gummy candy, fruit juice-infused gummies, gel-like gummies, and other innovative varieties.

Adjustability

The best gummy making machine boasts the ability to adjust temperature, speed, pressure, enabling it to cater to the unique production needs of different gummy candy formulas.

Safety

Safety - Sourced: hazwoper-osha

The material of the best gummy making machine should comply with food safety standards, such as using corrosion-resistant and non-toxic materials such as medical grade stainless steel. It also has necessary safety protection measures, such as anti scalding, anti electric shock, etc., to ensure the safety of operators.

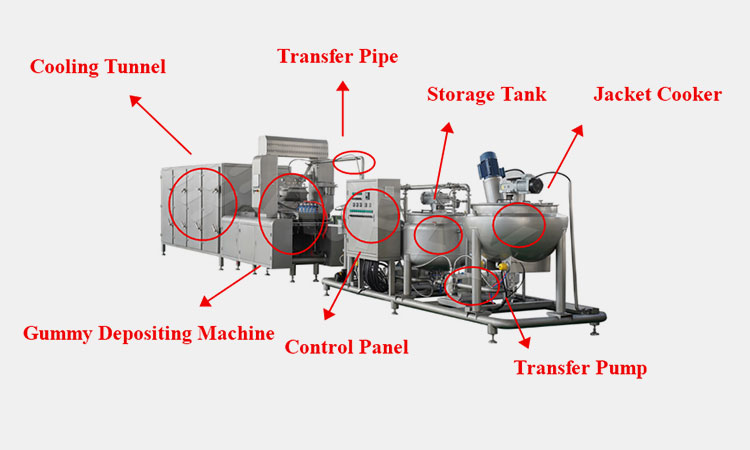

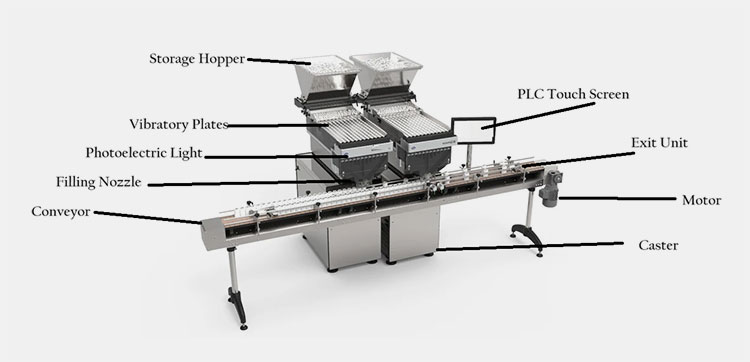

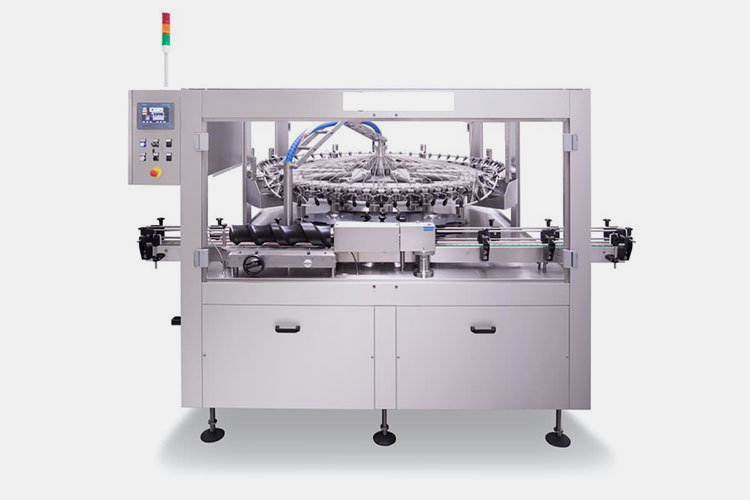

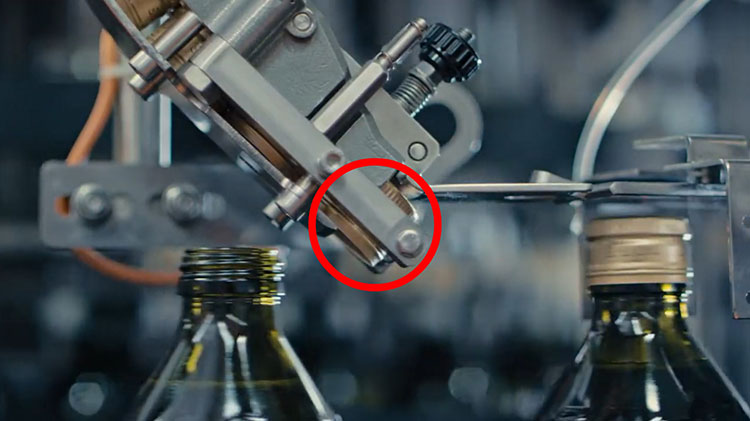

4.What Are the Key Components of Gummy Making Machines?

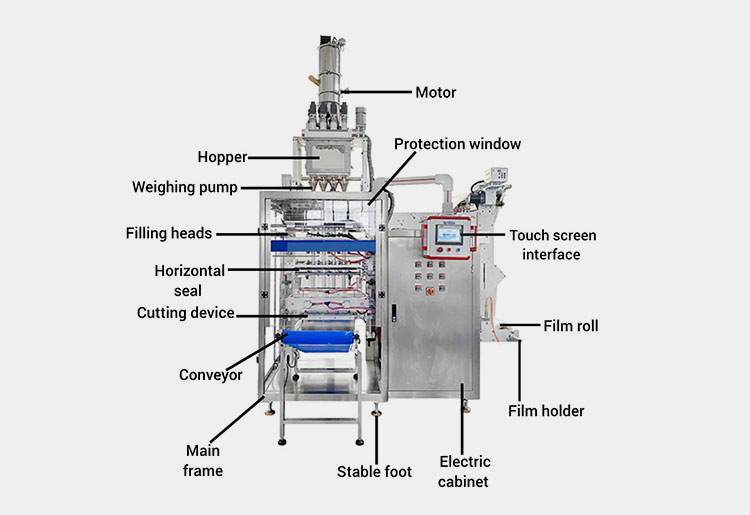

Key Components of Gummy Making Machine

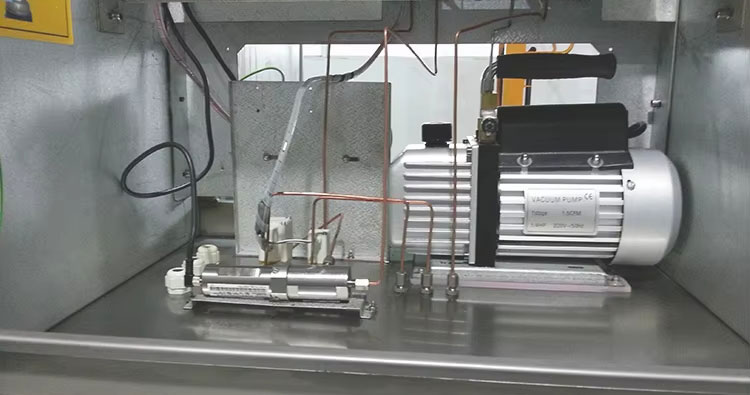

The components of a gummy making machine can differ significantly based on the specific model and production requirements, yet, at a broad level, the core components that typically constitute a gummy production line encompass the following essentials:

| Jacket Cooker

|

It is used to dissolve raw materials such as gel, carrageenan, pectin, etc. in water to form a uniform colloidal solution. This is the first step in the production of gummies and has a significant impact on the subsequent processes. |

| Transfer Pump

|

It delivers the prepared colloidal solution or syrup to subsequent equipment. The selection and use of pumps should ensure stable flow and avoid the generation of bubbles or blockages during transportation. |

| Storage Tank | It is used to store solutions and maintain the appropriate temperature. |

| Mixing Tank | It is used for mixing raw materials to ensure the uniformity and consistency of the ingredients during the gummy candy making process. |

| Transfer Pipe | It is used for transporting solutions. |

| Cooling Tunnel

|

Gummy candies require rapid cooling to solidify their shape. The cooling system can be air-cooled or water-cooled, depending on the configuration and process requirements of the production line. |

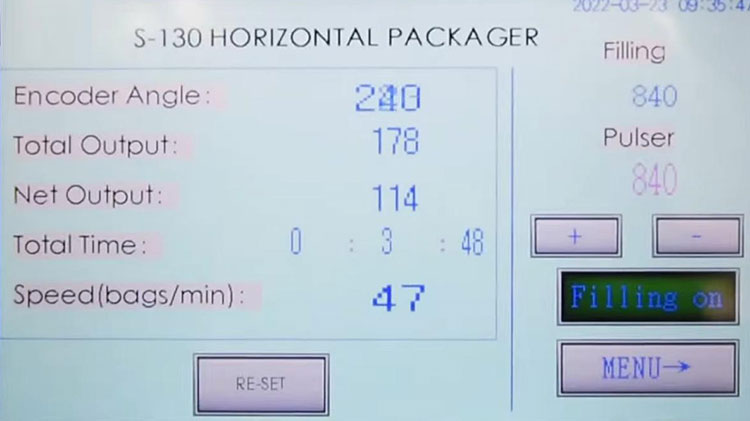

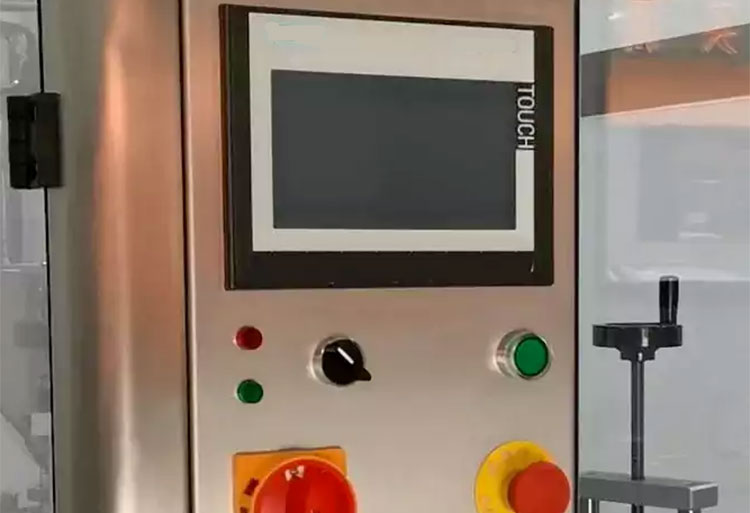

| Control Panel | It is used to monitor and adjust various parameters during the production process, such as temperature, flow rate, speed, etc., to ensure product quality and production efficiency. |

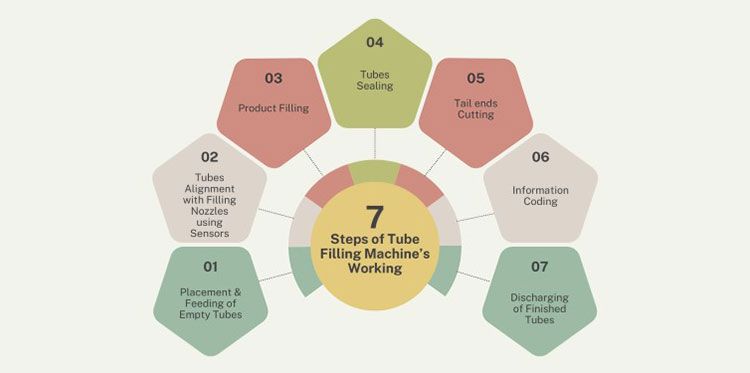

5.What Is the Workflow of Gummy Making Machines?

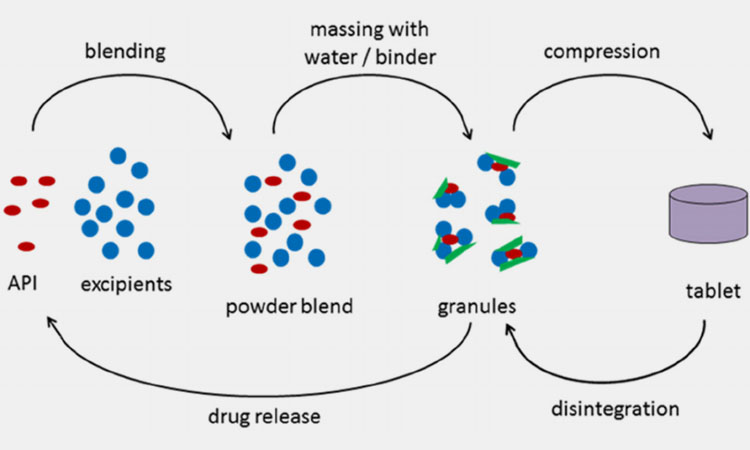

The workflow of a gummy making machine is a complex process involving multiple steps, with the main goal of transforming raw materials into delicious gummy products. The following is an overview of a typical gummy making machine workflow.

Mixing and Depositing

Mixing and cooking

Mixing sugar, starch syrup, fruit and grape juice and other ingredients together, and stir thoroughly until all ingredients are completely dissolved and mixed evenly.

Depositing

Once melted, the sugar solution is temporarily held within the storage tank or the designated container of the gummy making machine, awaiting further processing for sugar injection and production. Throughout this storage period, it is crucial to maintain the optimal temperature and ensure the fluidity of the solution to prevent freezing or degradation.

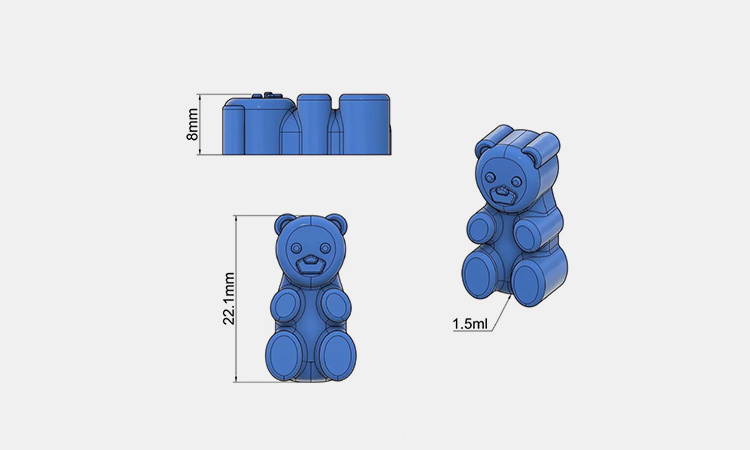

Cooling

The melted sugar solution is then carefully injected into the mold via a precision pouring machine, where it takes on the desired gummy shape. This step necessitates precise control over the pouring speed and flow rate to guarantee uniformity in the shape and size of the gummies. Following the pouring process, the gummies undergo gradual cooling and solidification within the mold.

Demoulding

Demolding

Once the gummies have fully cooled and solidified, they are delicately extracted from the mold. For unique varieties like peeled gummies, an additional step may involve removing a thin layer of oil from the mold’s surface to achieve the desired peeling effect. The demolding process necessitates meticulous handling to prevent any shattering or deformation of the gummies.

6.What Are the Features of the Best Gummy Making Machine?

As a specialized equipment for producing gummies, the best gummy making machines have a series of unique features aimed at improving production efficiency, ensuring product quality, and meeting diverse production needs. Here are some main features of the gummy making machine:

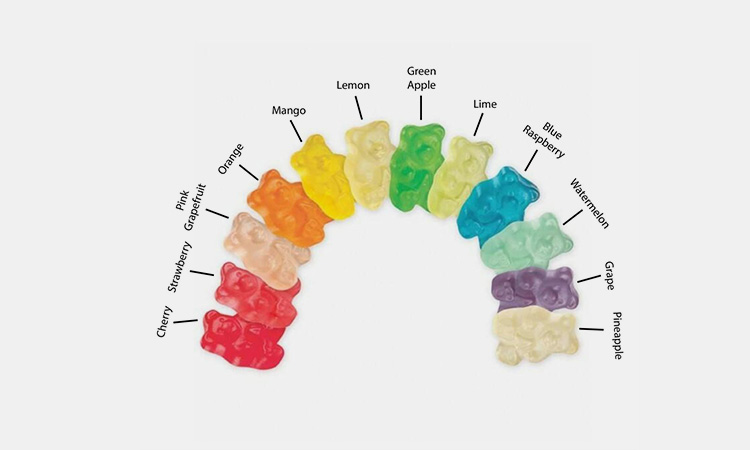

Diversified production

Various Types of Gummies - Sourced: albanesecandy

In order to meet the diverse needs of the market, the best gummy making machines usually have the ability to produce various types of gummies, including gummies of different flavors, colors, shapes, and sizes. By adjusting the formula and process parameters, it is easy to achieve product diversification.

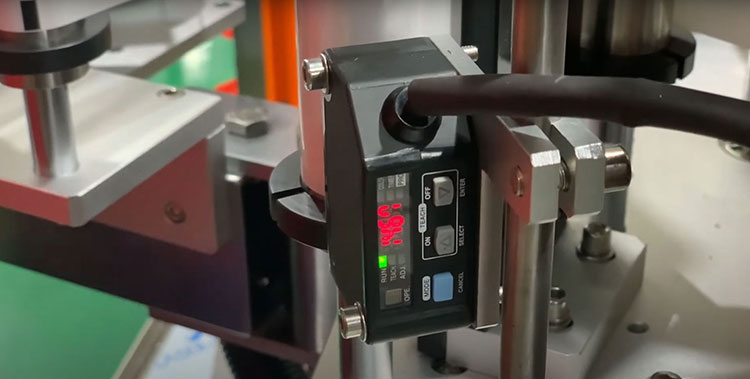

Precise control

The best gummy making machine can accurately control key parameters in the production process, such as temperature, humidity, stirring speed, molding pressure, to ensure stable quality of gummy. This precise control helps to produce gummies with consistent taste, color, and shape.

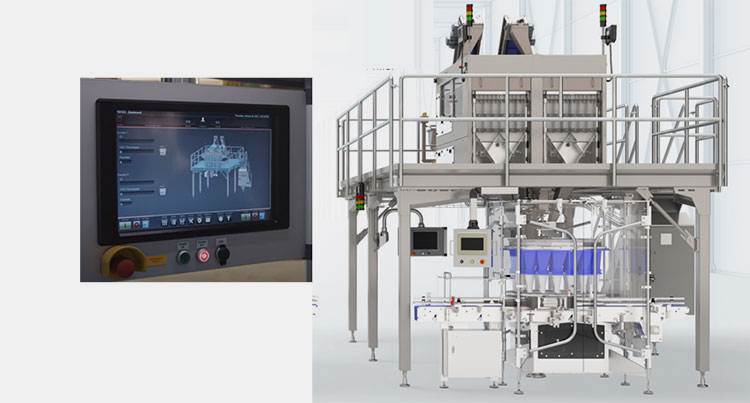

Intelligent control

Touch Screen - Sourced: capplustech

Some high-end gummy making machines are also equipped with intelligent control systems, which enable human-machine interaction and remote monitoring through advanced devices such as touch screens and PLC. This intelligent control not only improves production efficiency, but also facilitates real-time monitoring of equipment status and product quality by operators.

Easy to clean and maintain

The design of the gummy making machine emphasizes easy cleaning and maintenance to reduce hygiene issues and maintenance costs during the production process. The equipment structure is usually simple and clear, easy to disassemble and clean, and made of corrosion-resistant and non-toxic materials to ensure food safety.

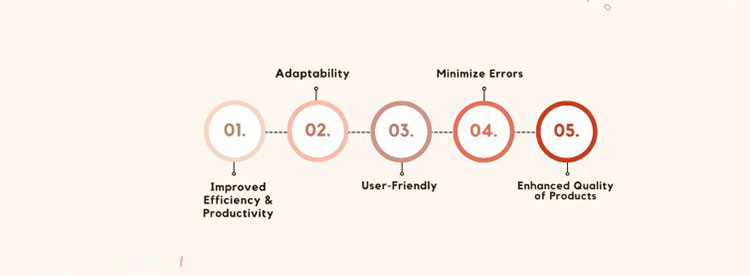

7.Why Is It Important to Choose the Best Gummy Making Machine?

Choosing the best gummy making machine is crucial for gummy candy production enterprises, mainly due to the following reasons:

Lowering production cost

Lower Production Cost - Sourced: katanamrp

Although the best gummy making machines may have relatively high initial investment, their efficient production capacity and low failure rate can significantly reduce production costs in long-term operation. In addition, these machines typically have energy-saving designs that can reduce energy consumption and operating costs.

Improving production efficiency

Improve Production Efficiency - Sourced: bizjournals

The best gummy making machines usually have a higher degree of automation and more precise control systems, which can significantly improve production efficiency. This means that more gummies can be produced in the same amount of time, thereby increasing production and meeting market demand.

Ensuring product quality

A high-quality gummy making machine can precisely control various parameters during the production process to ensure that the produced gummy has consistent and excellent quality. This includes stability in terms of taste, color, shape, and size, which helps to enhance the market competitiveness of the product.

Enhancing corporate image

Enhance Corporate Image - Sourced: Marketing 91

Utilizing the best gummy making machines to produce high-quality gummies can elevate the corporate image and reputation in the eyes of consumers. This positive reinforcement not only attracts a wider customer base but also fosters brand loyalty, driving long-term success for the enterprise.

8.How to Enhance Your Gummy Production Efficiency?

Improving the production efficiency of gummy making machines is an important concern for gummy candy production enterprises. The following are some specific strategies and methods:

Selecting the best gummy making machine

Allpack Gummy Making Machine

Equipped with an advanced control system, the best gummy making machine exerts precise control over various production parameters, ensuring consistent product quality and minimizing the occurrence of defective products.

Optimizing production process flow

You should sort out and optimize the existing production process, remove unnecessary links, simplify operational steps, and improve production efficiency. And you should develop standardized production process operating procedures to ensure that each production process is carried out according to uniform standards, reducing production delays and quality issues caused by improper operations.

Improving equipment utilization

Improve equipment utilization - Sourced: asana

You can reasonably arrange production plans based on market demand and equipment capacity to avoid idle or overloaded equipment operation. Regularly maintain the gummy making machine to ensure that it is in good working condition and reduce production interruptions caused by equipment failures.

9.How to Integrate Auxiliary Equipment for Efficiency?

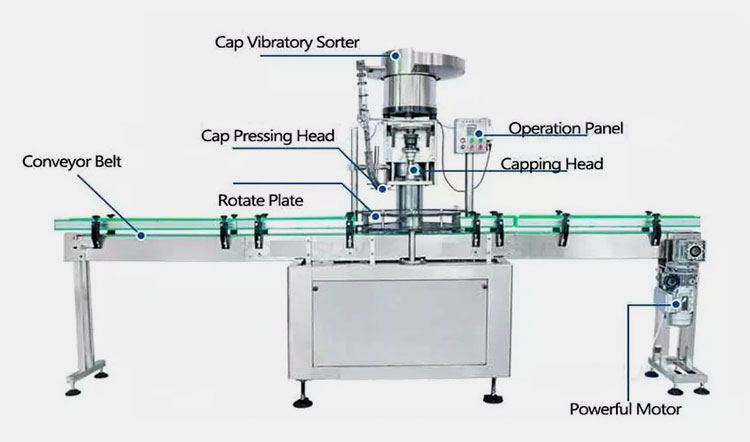

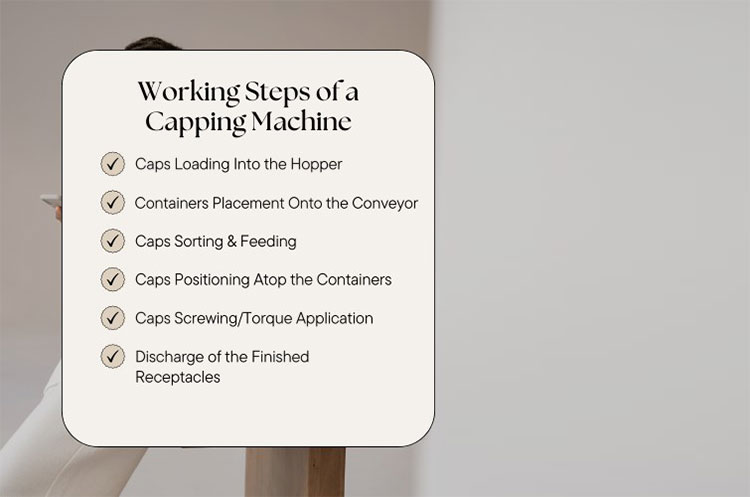

Integrating auxiliary equipment can improve the efficiency of gummy production. Do you know which auxiliary equipment can be used?

Convey system

Convey System - Sourced: pficonveyors

Conveyor system is one of the key equipment on the gummy candy production line, which can transport products among many production processes, achieving automation and continuity of the production process.

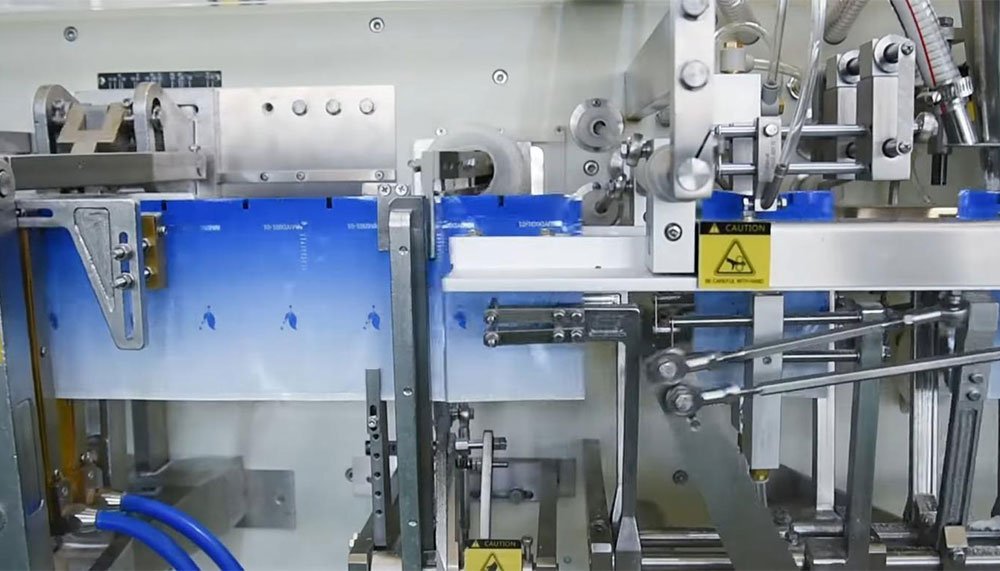

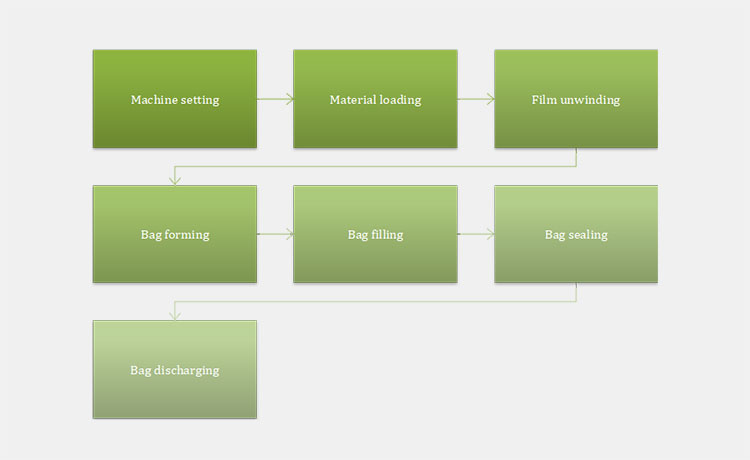

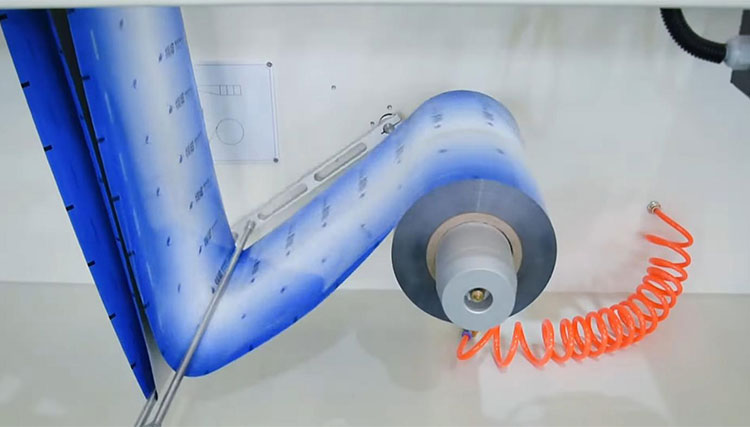

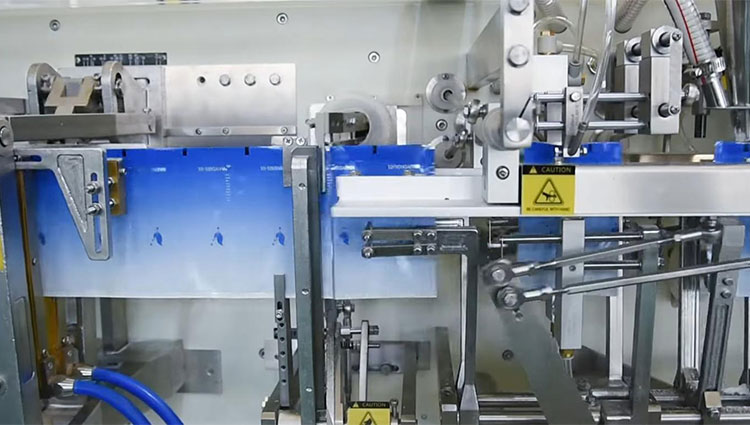

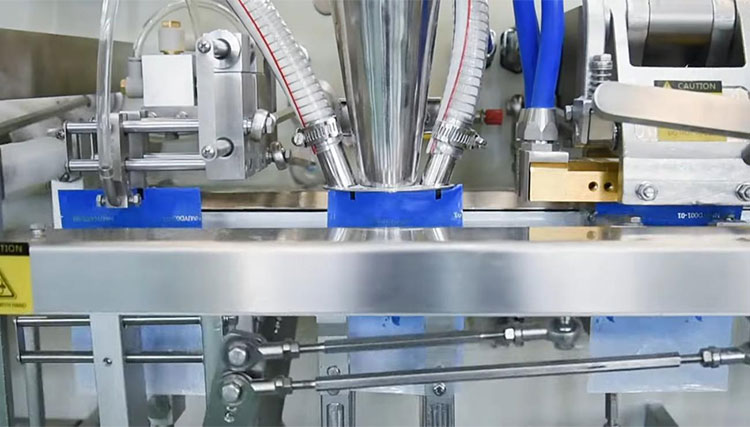

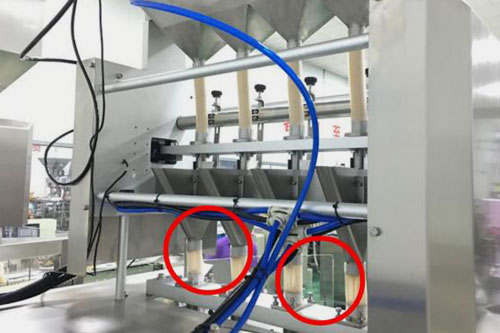

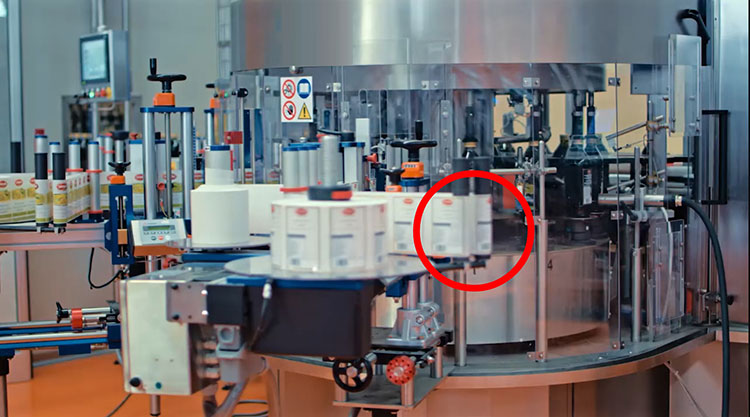

Automatic packaging equipment

It serves the purpose of efficiently filling gummy candies into packaging bags, while guaranteeing a swift and efficient packaging process.

Ingredient mixer

Ingredient Mixer - Sourced: Freepik

The mixer is mainly used to mix sugar, butter, water, and other ingredients evenly to form flavored gummy.

Dehumidifiers and climate control system

These two devices play a pivotal role in maintaining the optimal humidity and temperature levels within production settings, thereby ensuring their essential for smooth operations.

Quality control system

It can constantly check the product standards quality during the production.

10.How to Optimize Your Gummy Production Line?

To optimize the production line of gummy candies, multiple strategies can be taken, including upgrading high-quality equipment, optimizing gummy candy formulas, and conducting regular maintenance.

Upgrading to equipment with higher capacity

Allpack Large-scale Gummy Making Machine

You can invest in purchasing large-scale gummy making machines that can accommodate more raw materials.

Implementing lean manufacturing

It is necessary to clarify the goals of lean manufacturing, including improving production efficiency, reducing production costs, improving product quality, and shortening production cycles. These goals should be aligned with the overall strategy of the enterprise and market demand.

Optimizing the recipe for gummies

Various Gummy - Sourced: My Kitchen Love

According to market demand and consumer taste preferences, adjust the raw material ratio in the gummy candy formula, such as increasing or decreasing the amount of certain ingredients, to improve the taste and quality of the gummy candy.

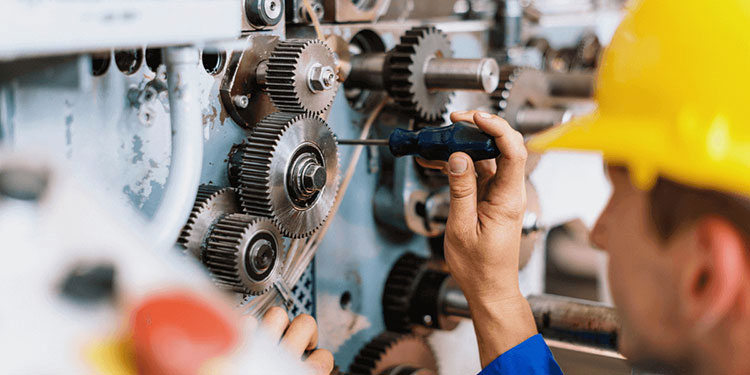

Performing regular maintenance

Regularly inspect the gummy candy production equipment, including equipment cleaning, component wear, electrical circuit connections, etc., to ensure that the equipment is in good working condition.

11.How to Ensure Quality Standards of Gummy Production?

To ensure the quality standards of gummy candy production, implement strict testing standards, the use of high-quality ingredients and automated quality testing serve as key steps.

Implementing a rigorous testing protocols

Quality Management System - Sourced: Arena Solutions

You should develop and improve quality management system to test raw ingredients and products to ensure the effective operation of the quality management system.

Using quality control checks

You should adopt automated detection equipment in the production process of gummy, such as metal detectors, weight detectors to monitor and detect various links in the production process in real time. These devices can quickly and accurately detect foreign objects, weight deviations, and uneven colors in products, ensuring consistency in product quality.

Selecting high-quality ingredients

Ingredients of Gummy - Sourced: Haboba Family

You should strictly inspect each batch of raw materials and ensure that raw materials meet established quality standards, and avoid using inferior or unqualified raw materials.

Continuous staff training

Enable employees to master quality standards and cultivate quality literacy during the production environment.

12.What Quality Standard Should Your Gummy Making Machine Production Comply With?

GMP and HACCP are two important quality standards in the production of gummy making machines. The following are the specific introduction.

GMP (Good Manufacturing Practice)

GMP - Sourced: CCL International

GMP is a regulation for the production and quality management of food, drugs, and medical products, which requires gummy making machine production to meet health and quality requirements in terms of raw materials, production processes, quality control, and other aspects.

HACCP (Hazard Analysis Critical Control Point)

HACCP - Sourced: Food Safety Tech

HACCP is a preventive management system that ensures gummy safety by analyzing potential hazards in the production process, identifying key control points, and taking corresponding control measures to ensure food safety.

13.What Role Does A Manufacturer of Gummy Making Machine Play?

Occupying a pivotal position within the gummy candy production industry, manufacturers of gummy making machines supply the essential equipment that facilitates the efficient and high-quality production of these popular candies. They are not only drivers of technological innovation, but also key forces in improving production efficiency. Choosing the best gummy making machine manufacturer is crucial, here are some top manufacturers:

Top Gummy Making Manufacturers

Tanis

Located in Netherlands, Tanis harbors the ambition to emerge as the premier global manufacturer of jelly and fudge production machine, renowned for consistently delivering reliable, top-quality fudge and jellies through their innovative equipment.

Allpack

Allpack represents an advanced, continuous production line tailored for crafting diverse sizes of gummy candies with exceptional quality. This state-of-the-art equipment excels in both manpower optimization and space efficiency, making it the ideal choice for producing high-quality gummy candies.

Loynds

Loynds was established in 1940, and renowned globally for offering premium-quality gummy making machines and depositors that cater to the industry’s diverse needs.

14.What Should you Consider When Choosing a Gummy Making Machine Manufacturer?

When selecting the best gummy making machine, it is imperative to factor in multiple considerations beyond the machine itself. Notably, assessing the manufacturer’s qualifications and their commitment to after-sales service is crucial for ensuring the equipment’s quality and fostering a positive user experience in the long run.

Manufacturer’s quality management certification

ISO 9001 - Sourced: blog-qhse

You should consider the gummy making machine manufacturers whether has attained quality management system certification, such as ISO 9001. By doing so, it is ensured that the gummy making machines produced by these manufacturers conform to the utmost standards of quality, thereby meeting the expectations of consumers.

Industry experience and reputation

Understanding the industry experience and market reputation of manufacturers is also an important part of the selection process. By examining the manufacturer's historical performance, customer evaluations, and other information, a more comprehensive understanding of their product quality and service level can be obtained.

Technical support

Technical Support - Sourced: tlists

Technical support is an important component of after-sales service. You should consider that gummy making machine manufacturers whether provide comprehensive technical support services, including guidance and assistance in equipment installation and commissioning, operation training, troubleshooting, and other aspects.

Repair service

The timeliness and professionalism of maintenance services are crucial for the normal operation of equipment. Therefore, when choosing a gummy making machine, it is important to understand the manufacturer’s maintenance service network, the technical level of maintenance personnel, and the speed of maintenance response.

15.What Are the Future Development of Gummy Making Machines?

Gummy making machines are gradually developing, and their development trend should not be underestimated. The subsequent discussion primarily delves into the anticipated future development trends of gummy making machines, offering insights into the direction these machines are poised to evolve.

The growing popularity of gummy production

The Market Size of Gummy Market - Sourced: visionresearchreports

According to relevant market research data, the global gummy market continues to expand in size. For example, data shows that the global gummy market size in 2030 will reach USD 52.06 billion, and it is predicted to grow at a high compound annual growth rate in the coming years. This trend provides a broad market space for gummy making machine manufacturers.

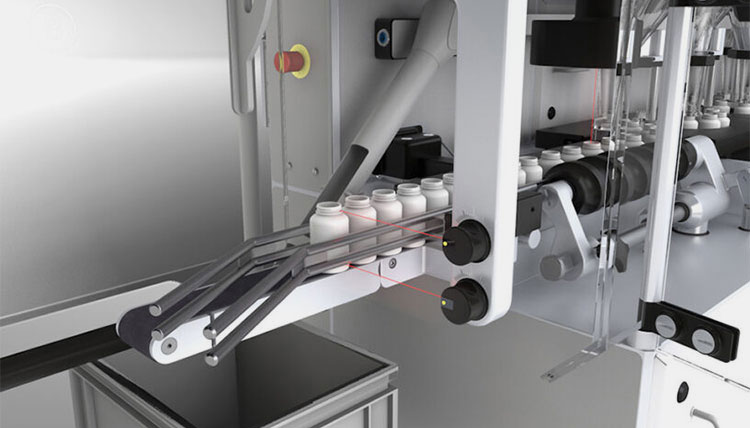

Technological innovation in gummy making machine

Technological Innovation - Sourced: retail

In the future, gummy making machines will prioritize the integration of automated production technology, with a focus on enhancing both production efficiency and the quality of the final product. For example, advanced equipment such as automated control systems, intelligent detection technology, and robots will be widely used in gummy candy production lines.

Market demand changes lead to product upgrades

Market Demand of Gummy - Sourced: verywellfit

As consumers’ interest in health and nutrition intensifies, the focus of future gummy products will shift towards incorporating healthier ingredients and enhancing their nutritional profile. This trend will propel gummy manufacturers to innovate continuously, devising new formulations and refining production processes to cater to the burgeoning demand for healthy gummy options in the market.

Conclusion

Choosing the best gummy making machine is not an easy task. To simplify your decision-making process, this article provides you with a complete buying guide to choosing the best gummy machine. If you have any further questions, please do not hesitate to reach out to Allpack at your convenience. We’re here to help!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

How To Choose The Best Gummy Making Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours