Tray Sealer Machine: The Complete FAQ Guide In 2025

Tray Sealer Machine: The Complete FAQ Guide In 2025

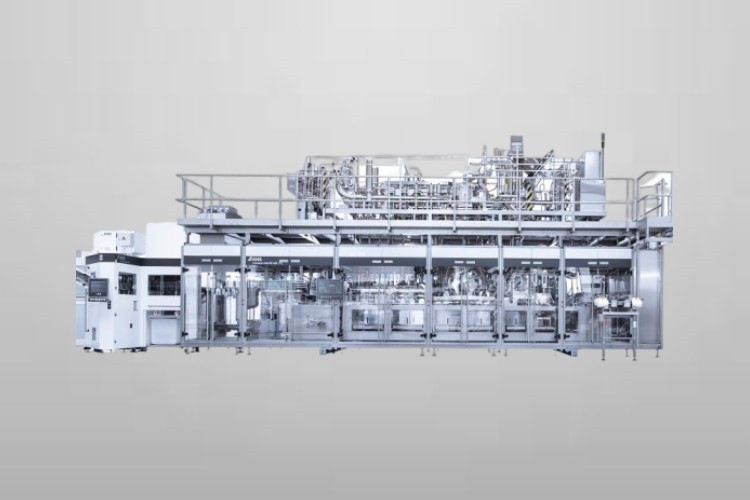

Tray sealing technology is revolutionizing the way we store and transport food and more other products. From providing faster speeds, enhanced performance, and greater flexibility than ever before to achieving perfect seals every time with less waste. These machines are becoming increasingly popular with both commercial and home users alike.

In this blog post, we’ll provide an overview of what tray sealing machines do and how they work so you can make an informed decision on whether such equipment will benefit your operations or not. Let’s get started!

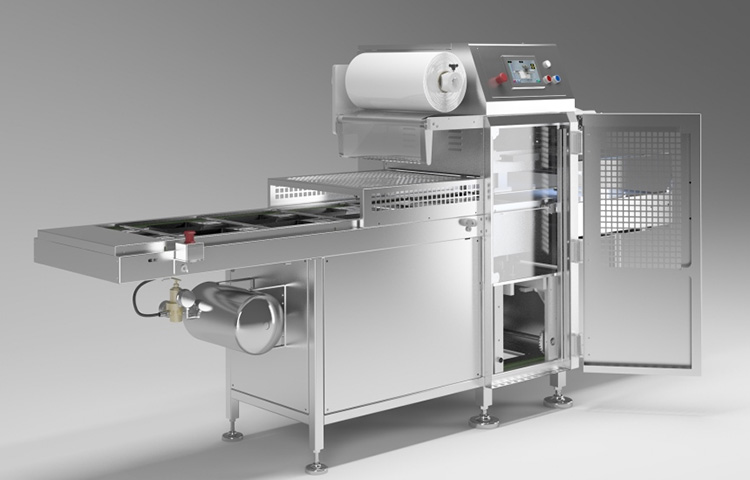

1.What Is A Tray Sealer Machine?

This is an equipment that is used in the many industries to seal products in trays. It typically uses heat, pressure and vacuum to create an airtight seal around the tray, ensuring that the product is kept fresh and sealed until it reaches its destination. The device is ideal for packaging a variety of products such as pre-packaged meals, sandwiches, salads, and other snack items. By using this equipment, the product can be easily packaged with minimal labor needed.

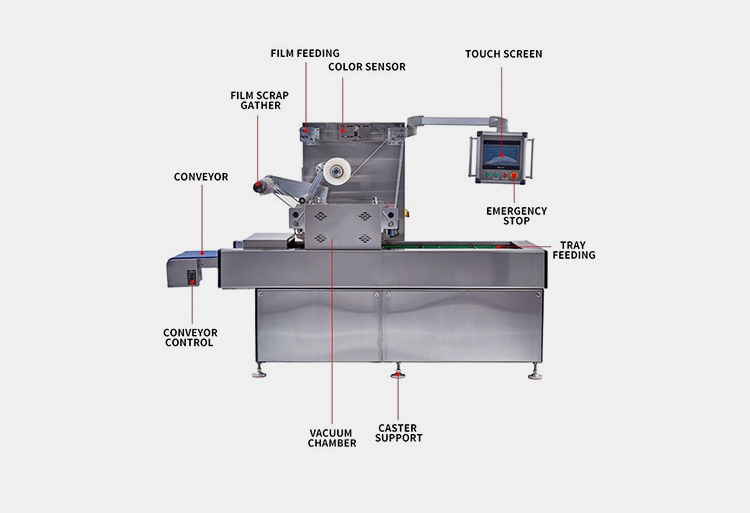

2.What Are The Components Of A Tray Sealer Machine?

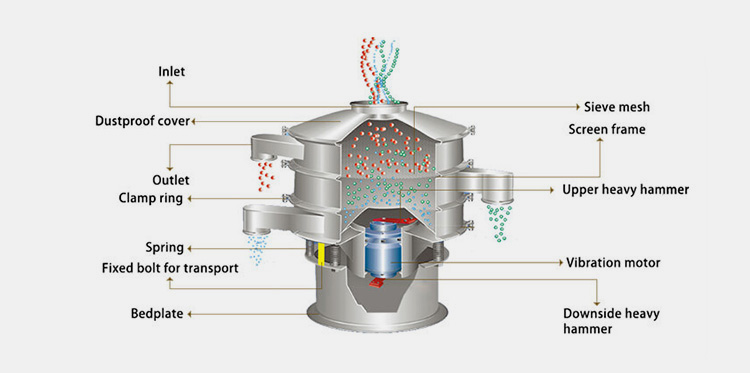

The tray sealer machine is composed of several components that work together to ensure efficient tray sealing. These components include:

Tray Feeding.

This component is responsible for introducing the tray into the tray sealer machine in an orderly fashion.

Caster Support.

The caster support allows the tray sealing system to be moved around the facility easily. This makes it easier to access and maneuver, while also providing support and stability during operation.

Vacuum Chamber.

This component is used to seal the tray with a vacuum. This provides an airtight seal that prevents spoilage and makes it easier to transport products without worrying about leakage or contamination.

Conveyor Control Panel.

This panel allows the user to adjust the speed of the tray transport system and can be programmed with various tray sizes and formats.

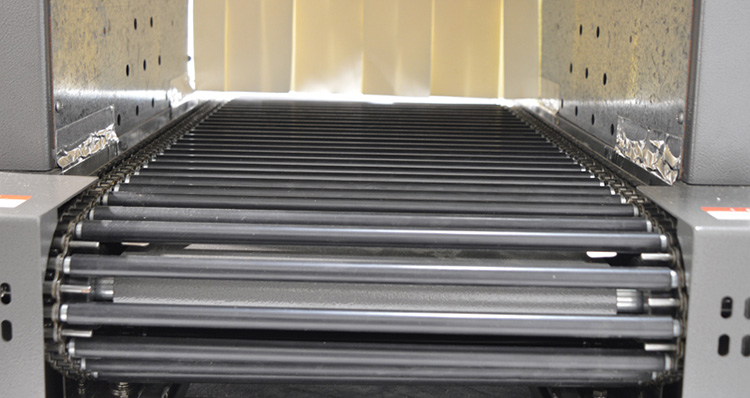

Conveyor Belt.

The conveyor belt moves the tray along the tray sealing system. This ensures that all trays are sealed correctly and efficiently.

Film Scrap Gatherer.

This component is used to collect any excess film that may be created during the tray sealing process. This ensures that no excess material is wasted and that all trays are sealed correctly.

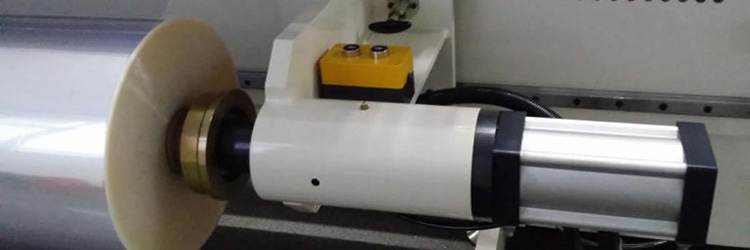

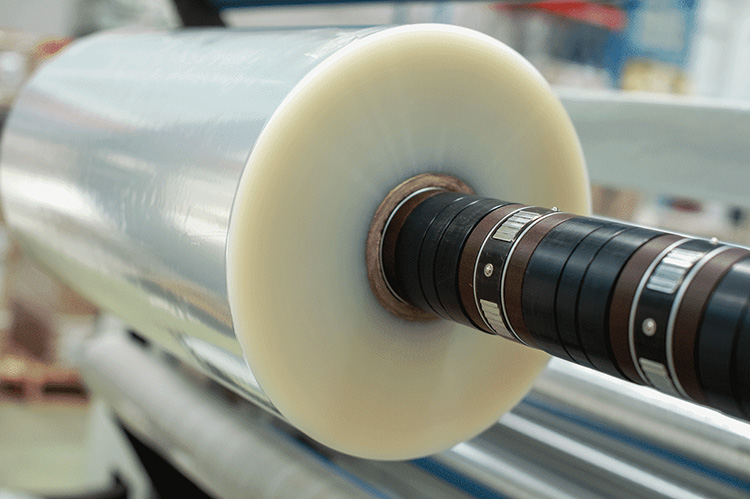

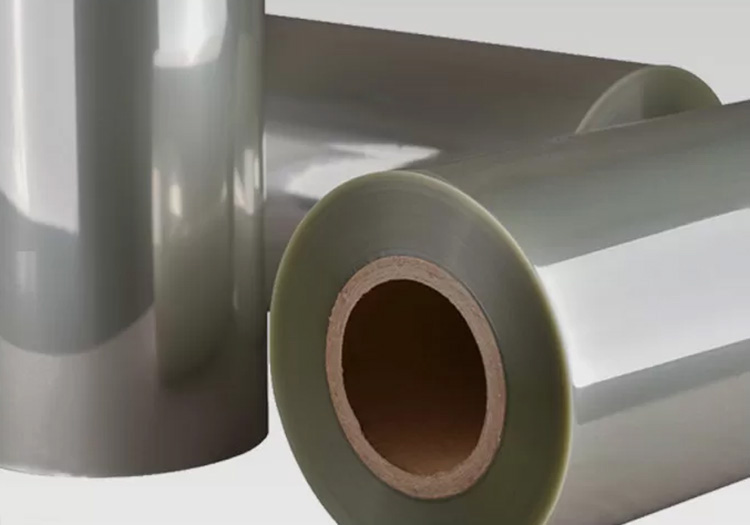

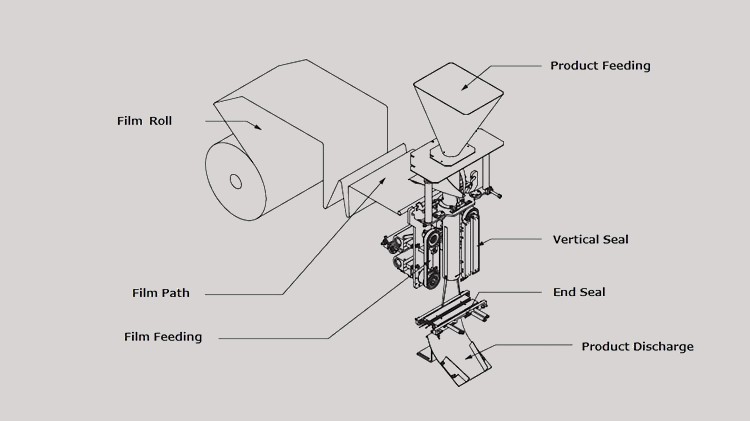

Film Feeding Device.

This part allows the user to easily feed the tray sealing film into the tray sealing system, and helps to ensure that all trays are sealed correctly and efficiently.

Colour Sensor.

Some machines also include a colour sensor that allows the tray sealing system to detect any tray colors, allowing the tray sealing machine to adjust the speed of the tray transport system depending on the tray color.

Touch Screen Display.

These devices also come with a touch screen display. This allows the user to control and monitor the tray sealing system, while providing an easy way to access data and settings related to tray sealing operations.

Emergency Stop Button.

This is an essential component that helps to ensure operator safety and allows the tray sealing system to be stopped should anything go wrong.

3.What Are The Benefits Of A tray Sealer Machine?

A tray sealer machine is an invaluable tool for businesses that need to quickly and efficiently package there products. These machines offer numerous benefits, including:

Increased Hygiene.

Using these machines there is minimal human contact, reducing the risk of contamination and spoilage.

Reduced Labor Costs.

Most of these machines offer higher levels of automation compared to manual packing methods thus allowing for greater efficiency and significantly lower labor costs.

Improved Product Quality.

These machines provide consistent and uniform packaging which leads to improved product quality and presentation.

Reduced Packaging Materials

These machines require less packaging material compared to manual packing methods, resulting in cost savings.

Enhanced Branding.

There is an enabled creation of custom trays with distinct branding for a more attractive and professional product presentation.

Reduced Waste.

There is minimization of waste by eliminating excess air from packages, thus increasing the shelf life of food products.

Increased Productivity.

This is by increasing production speed, resulting in greater output and improved efficiency.

Improved Safety.

Safety is enhanced in that the risk of injuries associated with manual packing methods are reduced, thus ensuring a safer working environment.

4.Where Can The Tray Sealer Machine Be Used?

The tray sealer machine can be used in many industries and applications, including:

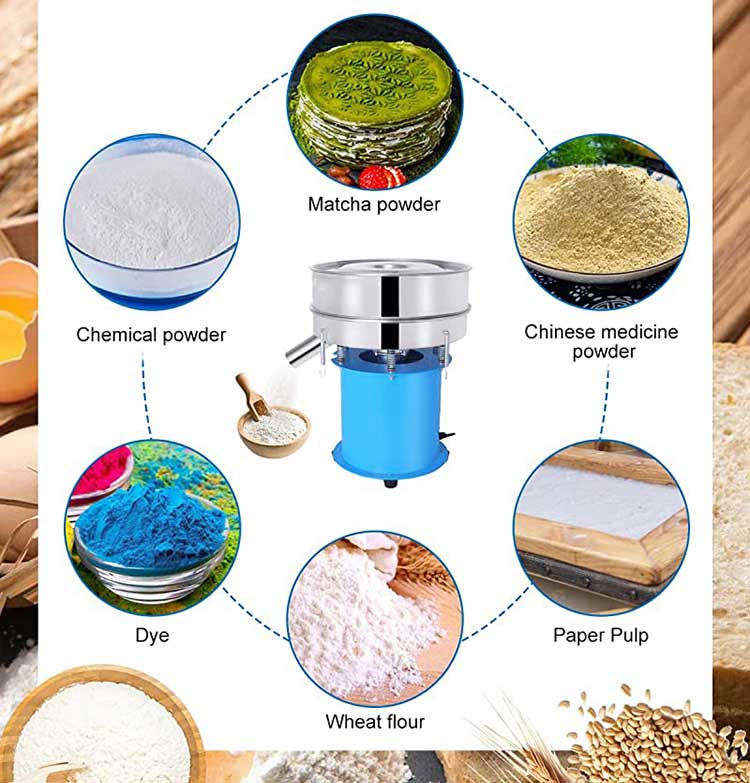

Food Processing

This device is ideal for sealing trays with pre-packaged food items such as fruits, vegetables, meats, dairy products and more. It has the ability to create packages with a tight seal that helps maintain freshness and prevents spoilage.

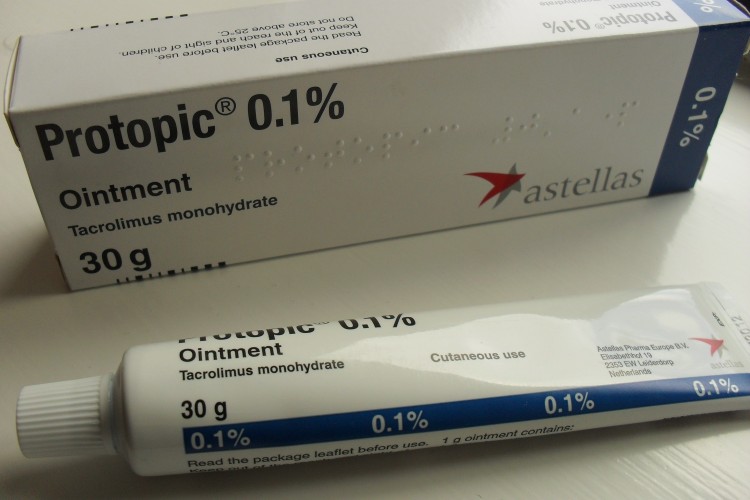

It can also be used to package individual pills, capsules and other medications into trays with a secure seal that helps protect the drugs from moisture and air.

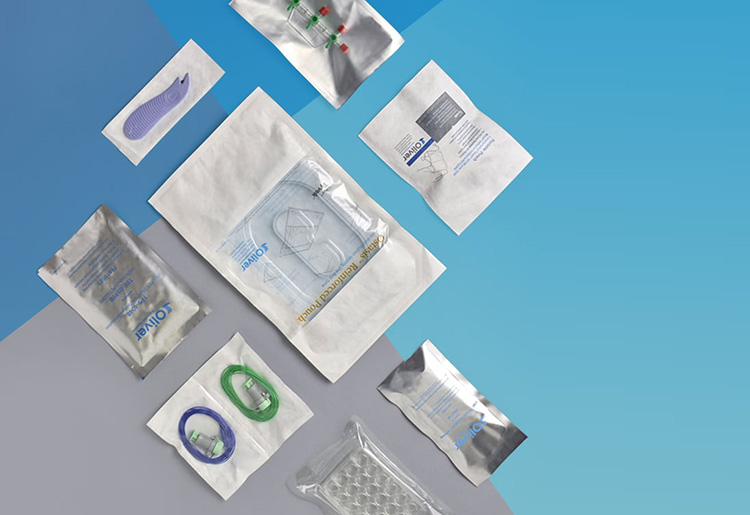

Medical Devices

This equipment is ideal for packaging medical devices such as catheters, syringes and other instruments into sterile tray seals that help protect them from contamination.

Packaging and Shipping

The machine is also useful for packing and shipping items such as books, electronics, tools, toys and more. Its tight seals provide extra protection to keep the items safe during transit.

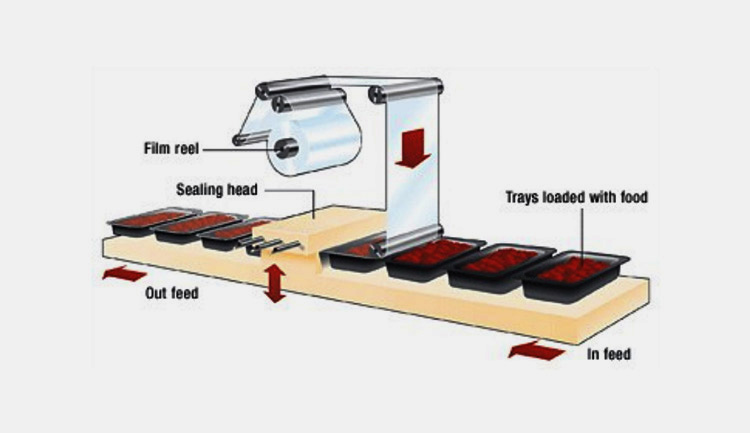

5.How Does A Tray Sealer Machine Work?

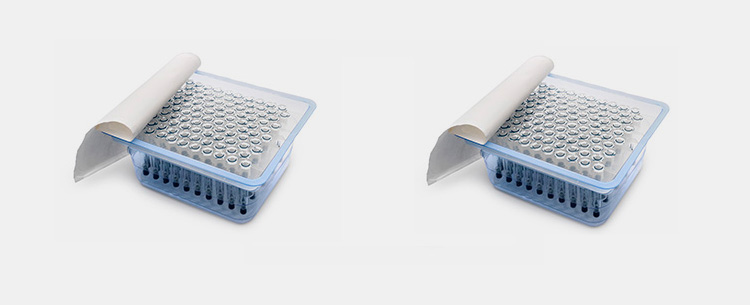

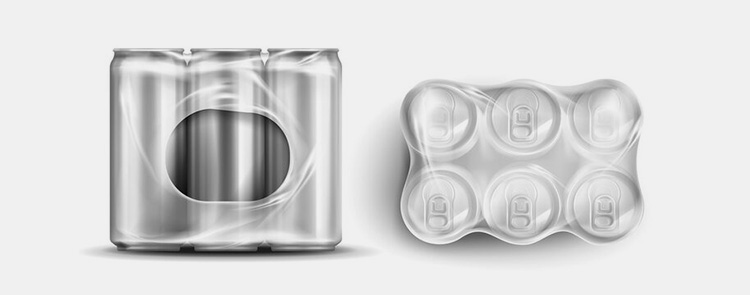

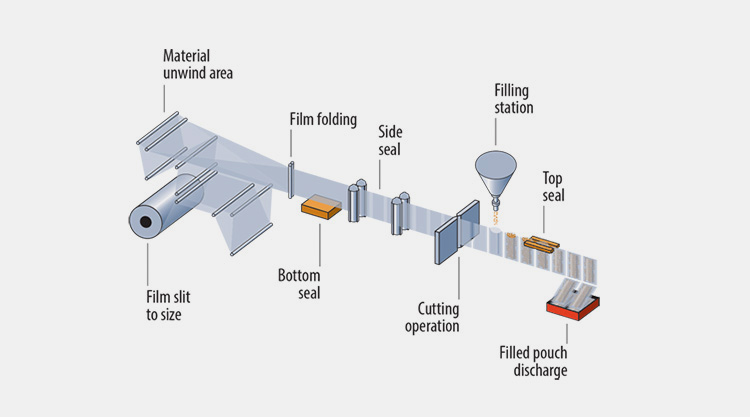

A tray sealer machine is a type of packaging machine typically used to package items. It works by sealing plastic trays with a film lid. This creates an airtight barrier, preserving the freshness and shelf life of the product inside.

This machines have adjustable settings which allow for different tray sizes and shapes, as well as varying tray depths.

They have a flat platform on which a tray is placed. Above the tray, there is a heated sealing bar that applies heat to the plastic film which seals the tray shut. The tray and film then pass through two rollers which press down on the tray to ensure an airtight seal. Once sealed, the tray is ejected off the tray sealer machine and ready for packaging.

In addition to sealing the tray, the machines are typically equipped with other features such as gas flushing, vacuum sealing and modified atmosphere packing (MAP). Gas flushing involves introducing a controlled amount of gas into the tray prior to sealing. This helps to extend the shelf life of the products. Vacuum sealing removes air from within the tray before it is sealed, and MAP changes the atmosphere inside the tray to better preserve and protect the product.

6.What Are The Different Methods Of Sealing Does A Tray Sealer Machine Apply?

Depending on the type of tray sealer and tray material, different methods of sealing can be used.

Heat Sealing.

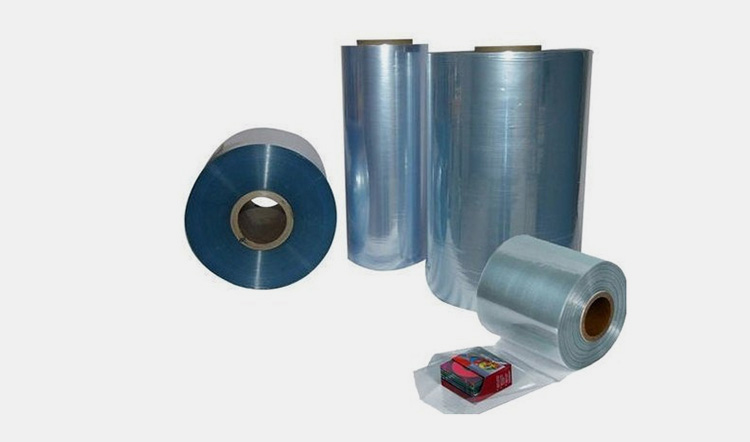

This essential method uses hot bars or wires to melt two pieces of tray material together, effectively creating an air and liquid-proof seal. Heat sealing can be used with tray materials such as aluminum foil, plastic film, paperboard and PVC.

Induction Sealing.

Induction sealing is another special method that utilizes induction heating to create a hermetic seal by creating an electromagnetic field that melts the tray material together. Induction sealing is often used with tray materials such as coated aluminum, plastic and lidding films.

Vacuum Tray Sealing.

Also,is this third method of tray sealing that uses pressure to create an airtight seal. This method is most commonly used with tray materials such as polypropylene, polyethylene and barrier films. Vacuum tray sealing can be combined with gas flushing or tray evacuation to create modified atmosphere packaging (MAP).

7.What Type Of A Tray Sealer Machine Do You Need?

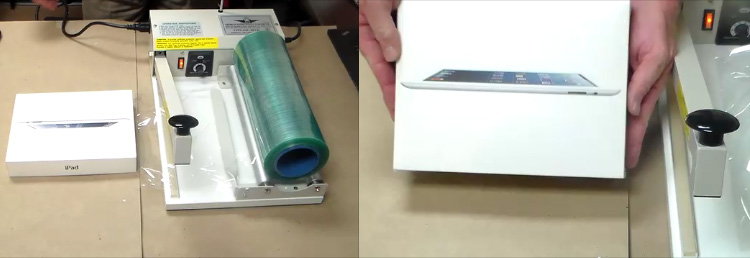

Manual Tray Sealer.

These tray sealing machines are the simplest and most economical tray sealing option. They normally consist of a tray holder, tray support brackets and a tray lid dispenser. The operator manually places the tray onto the machine, then pushes it down onto the tray holder which locks into place. The lidding film is then lowered over the tray and heat sealed to create the tray seal.

Semi-Automatic Tray Sealer

Semi-automatic tray sealers are designed to reduce tray setup time and labour costs compared to manual tray sealing systems.

They feature an in-built conveyor system that moves the tray from station to station during the tray sealing process, meaning all that is required of the operator is to place the tray onto the entrance conveyor and remove the tray from the exit conveyor. The tray is then sealed with a lid, creating an air and watertight seal.

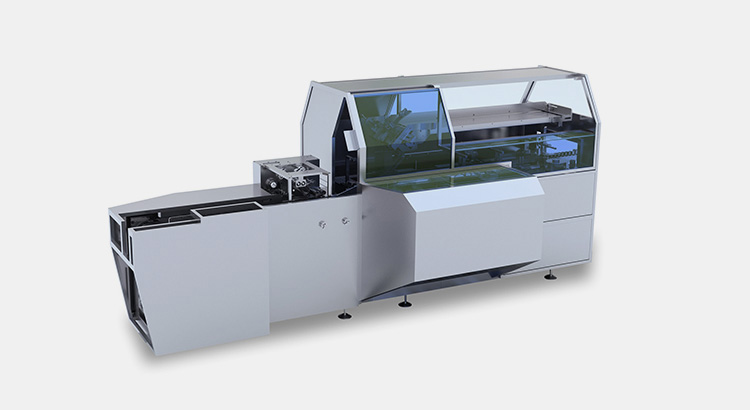

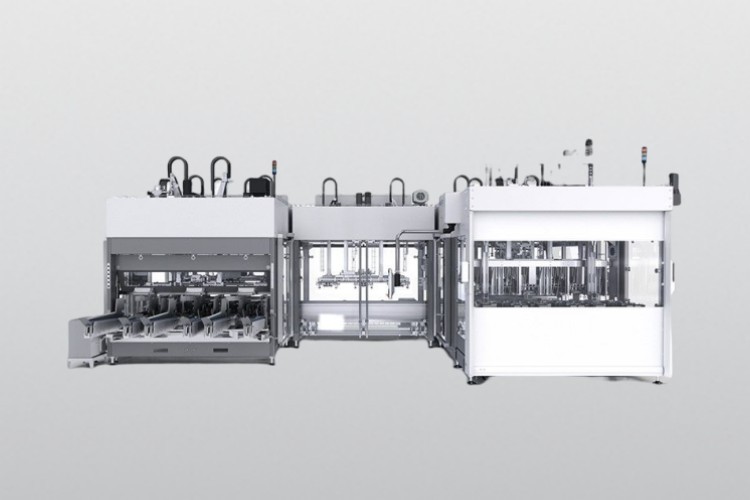

Automatic tray sealer

Automatic tray sealers are designed to offer maximum efficiency in tray sealing process speeds.some models can achieve up to 30 seals per minute depending on tray size and product type.

They typically feature PLC control, automatic tray loading and unloading, adjustable tray feed speeds and a tray sealer that automatically applies lidding film to the tray before heat sealing it in place. The operator can then quickly adjust the tray sealer settings for different tray sizes and types of products, meaning high levels of tray sealing consistency and accuracy.

These machines are suitable for use in a wide range of industries, from food packaging to pharmaceuticals, where an airtight and watertight tray seal is essential for product shelf-life and hygiene purposes.

8.What Is The Difference Between A Tray Sealer Machine And A Pouch Sealer Machine?

A tray sealer machine and a pouch sealer machine are both used for the purposes of sealing and packaging products, but there are key differences between the two that must be noted.

Tray Sealers

These machines are typically used to package food and other items into trays or clamshells. This type of machine uses heat and pressure to create a vacuum seal around the tray and contents, ensuring that it is airtight and tamper-proof. Tray sealers can also be used to fill the tray with products not usually found in tray form, such as fruits or vegetables.

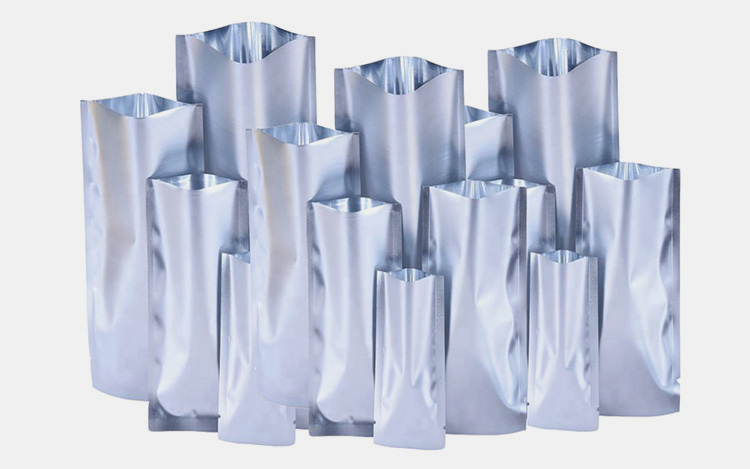

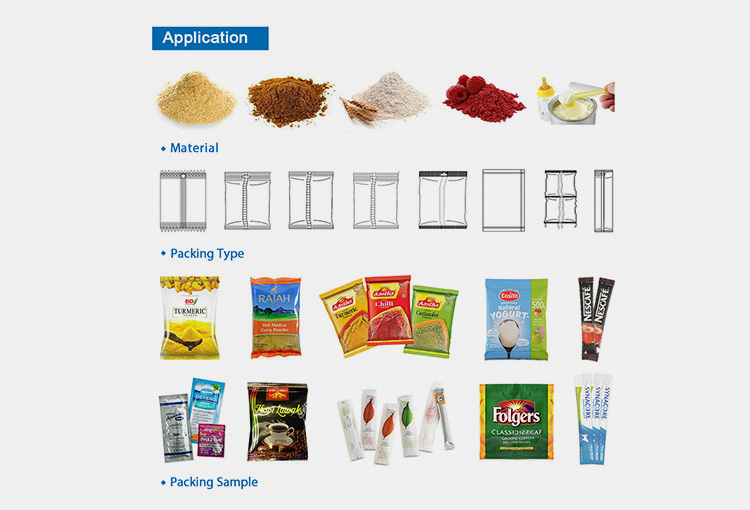

Pouch Sealers.

These essential devices are also used to package various items into pouches or bags. They use heat and pressure to seal the pouch closed, creating an impermeable barrier that keeps the products inside safe from exposure to air or contaminants. The bags can be filled with a variety of items such as dry goods, liquids, powders, or pastes.

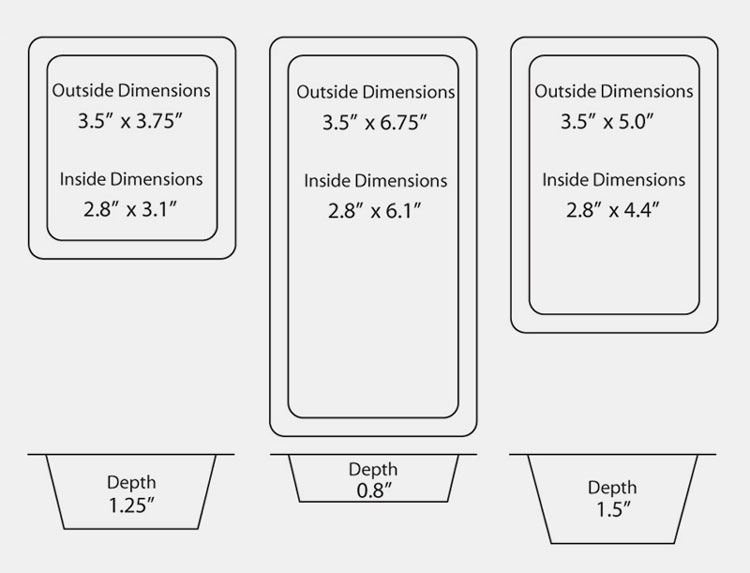

9.What Types Of Trays Can The Tray Sealer Machine Accommodate?

The tray sealer machine is designed to accommodate a wide variety of tray sizes and materials. Trays can range from small snack-sized trays all the way up to large 10 lb. tray sizes, in both rigid and flexible tray varieties.

Common tray materials include plastic, paperboard, aluminum foil, and other coated films. All tray types can be sealed with the tray sealer machine, and the operator can adjust the tray sealer’s sealing parameters to suit the tray material.

10.What Kind Of Tray Material Can The Tray Sealer Machine Handle Effectively?

Plastic Material Tray

Plastic trays are containers used for packaging products. They provide a convenient and safe way to store and transport goods. Most tray designs can be folded or stacked for easy storage and handling.

Aluminum Tray

These trays are stronger and more durable than plastic trays. They are ideal for tray sealing in wet or humid environments as they are resistant to moisture and temperature changes.

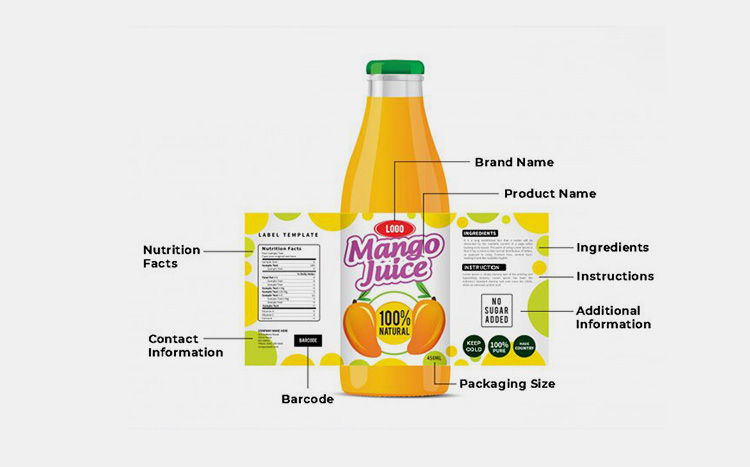

Paper Tray

These trays are a good choice for tray sealing applications because of its flexibility, durability and low cost. It is also very easy to print on paper tray material, making them great for tray sealing applications that require branding or labeling.

Foam Tray

Foam tray is a lightweight, cost-effective tray option. It is an ideal choice for tray sealing of delicate food items as it does not cause damage to the product and helps maintain its freshness for longer periods of time.

These machines can accommodate a wide range of tray materials. Depending on the application, you can choose from plastic, aluminum, paper or foam trays. Each tray type offers different advantages that make it suitable for a particular tray sealing application.

Choose the tray material and tray sealer machine that best fits your needs!

11.What Are Tray Sealer Machine’s Maximum And Minimum Tray Size Specifications?

They have an adjustable tray size range to accommodate different tray sizes, making them perfect for a variety of tray sealing applications. If you need to seal trays with larger or smaller than the maximum and minimum tray size specifications, custom tray sealers are also available.Whichever machine you choose, make sure that the tray size is within its tray size range to ensure proper sealing of your products.

For more specific information on tray sealers and the tray size range they can accommodate, contact the manufacturer for assistance. They can provide you with guidance and recommendations on the machine that will suit your tray sealing needs. By understanding the tray size specifications for these machines, you can make an informed decision to ensure that you have the right machine for your application.

12.Does The Tray Sealer Machine Require Any Additional Equipment Or Accessories To Operate?

The tray sealer machine does not require any additional equipment or accessories to operate. However, depending on the type of machine you are using, there may be some optional accessories and components that can be used to enhance its capabilities.

Common machines come with a trimming tool which is used for cutting excess film from around tray edges. Additional components such as gas flush units, in-line date coders, tray handling systems and conveyors are also available to enhance the tray sealing process.

For optimal tray sealing performance it is always recommended to follow the manufacturer’s operating instructions and use only accessories that are specifically designed for this machine you have purchased. Using non-approved or incompatible parts and components can damage this device and may even void any warranty associated with it.

If you are unsure about which accessories to use for your machine, contact the manufacturer or distributor of the tray sealer machine directly.You will be provided with more information on the type of machine you have and advise you on the best accessories to use.

13.What Maintenance Requirements Are There For Tray Sealer Machines?

Tray sealer machines require regular maintenance in order to ensure that they are running at optimal efficiency. The following are some of the key points of tray sealer machine maintenance:

Cleaning

Regularly cleaning of this machine with a mild detergent and warm water solution is required, as well as keeping it vacuumed inside and out after every use.

Lubrication

This is very essential to prevent wear and tear caused by friction in this machine.

Calibration

These machines should be calibrated periodically to ensure that they are sealing correctly and applying an even amount of pressure.

Replace Parts

Worn out or damaged parts should be replaced as soon as possible to avoid further damage and ensure these machines are functioning properly.

14.What Are The Considerations When Purchasing A Tray Sealer Machine Machine?

When it comes to tray sealer machines, there are several factors to consider before making a purchase:

Type Of Machine

You need to determine what type of tray sealer machine is best suited for your needs – manual or automatic tray sealers can both be used in a variety of different production environments.

Campatibility With Other Accessories

The compatibility of this machine with certain tray materials should be taken into account, as tray sealers typically have a specific tray material and size compatibility.

The Cost

Also, the cost of this device needs to be considered, both in terms of initial purchase price and ongoing maintenance costs.

Requirement Of Other Accessories

It is important also to consider whether you will require any additional accessories or attachments with your machine, such as tray top trimmers or tray lid applicators.

Where To Purchase From

Also, take into consideration purchasing a machine from a reputable supplier with a proven track record in delivering high quality machines.

Warranty

The tray sealer machine should be purchased with a warranty, in case any faults occur after purchase, and it is important to inquire about the post-purchase support that can be expected from the supplier.

Conclusion

The tray sealer machine has completely revolutionized the packaging industry. With faster and automated sealing capabilities, businesses have seen drastic improvements in profitability. With its versatility to handle various materials and packaging shapes, tray sealer machines are set to be a game changer in the industry. Enable continuous production of packages at high speeds with amplified accuracy even when crunching time frames, it eliminates extra labor costs while keeping up product quality. If you’re searching for a reliable sealing solution for your business, look no further than Allpack’s tray sealer machine – designed and built with your needs in mind!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tray Sealer Machine: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

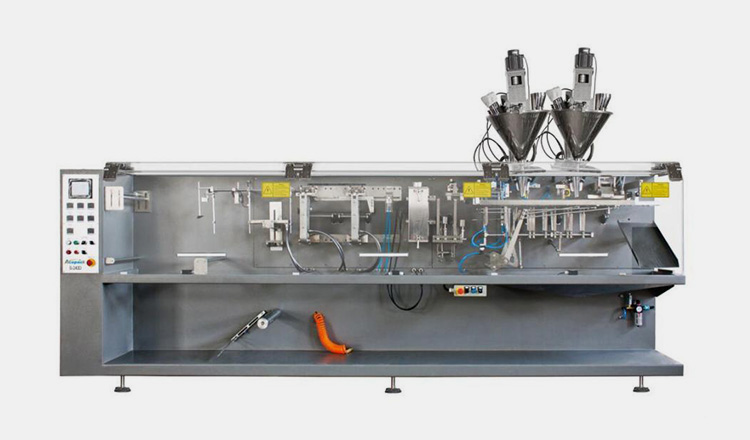

ACF-L Liquid Packaging Machine

ACF-L Liquid Packaging Machine

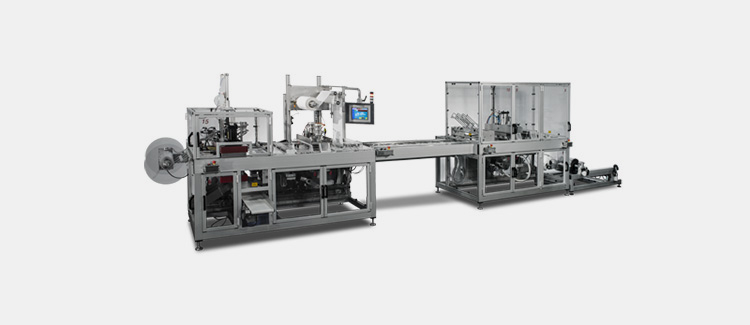

Mercury Liquid Packaging Machine

Mercury Liquid Packaging Machine

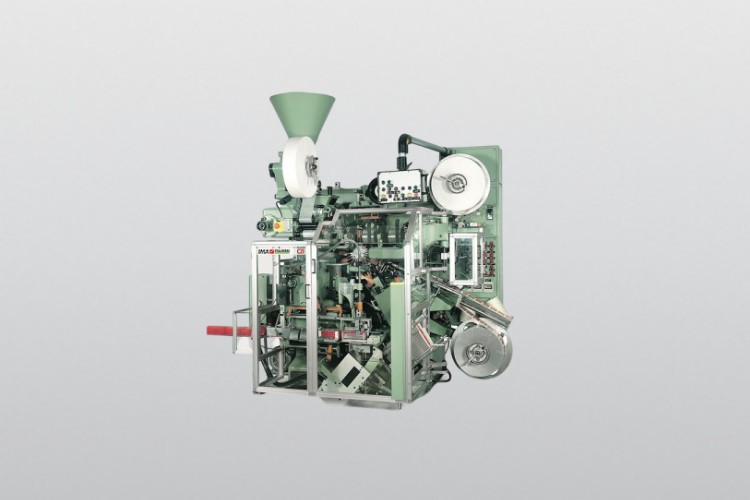

PHS-100 Liquid Packaging Machine

PHS-100 Liquid Packaging Machine

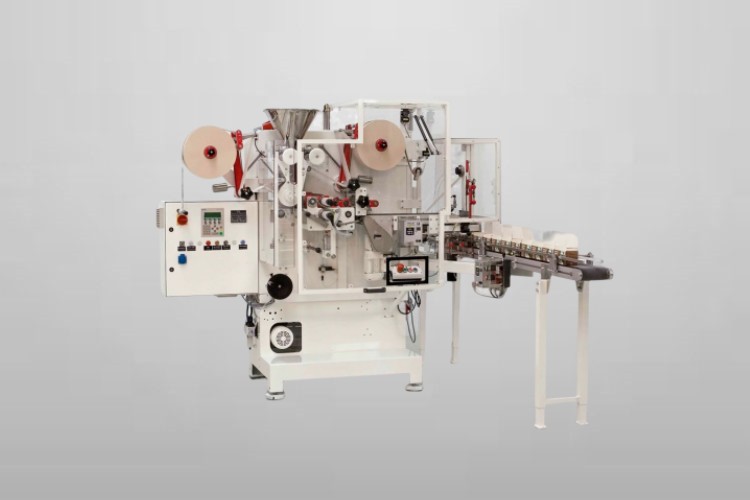

LINEA Liquid Packaging Machine

LINEA Liquid Packaging Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours