Induction Foil Sealing Machine: The Complete Buying Guide In 2025

Recently, due to the rapid development of science and technology in the packaging industry, an induction foil sealing machine has become a necessity for many businesses. Not only does this machine help to achieve efficient container sealing’s faster than ever before, but also provides clean and reliable seals that greatly reduce chances of contamination.

In today’s blog post, we will discuss what an induction foil sealing machine is, how it works as well as the numerous advantages it comes with for industries using it for their production process. So let’s get to learn more about this amazing equipment.

1.What Is An Induction Foil Sealing Machine?

An induction foil sealing machine is a device used to seal the tops of containers with induction-sensitive materials such as aluminum foil. This equipment heats the material thus creating a hermetic seal that prevents leakage and contamination.

This type of sealing is commonly used in food packaging and pharmaceutical products, as well as cosmetic products. Also, induction foil sealing machines offer a reliable and secure method of creating an airtight seal that ensures the product’s freshness and purity.

Additionally, these devices can be customized to meet the specific needs of any application. With these equipment, manufacturers can easily create a secure seal that meets all industry standards and requirements.

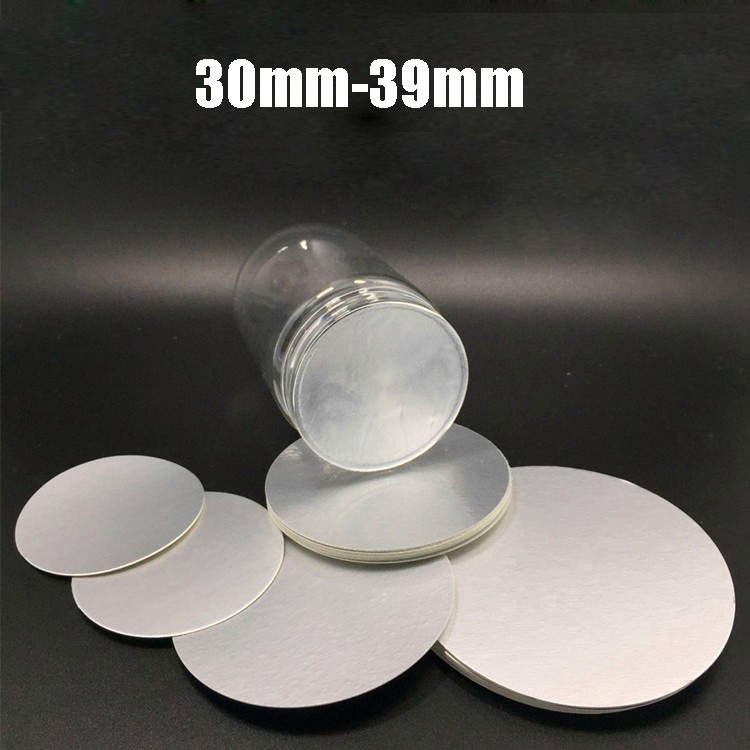

2.What Is An Induction Foil?

An induction foil is a type of seal that is applied to the top of a container using an induction foil sealing machine. It has a special inner-liner that melts when exposed to induction heat, creating an airtight seal and locking in freshness and flavor.

In addition, induction foils can also be used to extend product shelf-life and act as tamper-evident seals. These foils come in a variety of sizes, colors, and materials to suit any application. This makes induction foils a great choice for food, beverage, pharmaceutical, chemical, and cosmetic containers.

Induction foil packaging provides consumers with an extra layer of security and peace of mind, knowing the product is safe and unaltered. With induction sealing, you can be sure that your products are sealed safely and securely for optimal freshness.

3.What Type Of Induction Foils Can Be Used With An Induction Foil Sealing Machine?

Using induction foil sealing machines with the appropriate induction foils can help maximize efficiency and reduce costs associated with packaging operations. Here are some of the induction foils that can be used with induction foil sealing machines:

Aluminum Foil

This is the most widely used induction foil and provides a strong, airtight seal. It also offers great protection against moisture, light, oxygen and other contaminants.

Copper Foil

Copper induction foil provides excellent electrical conductivity making it ideal for induction sealing applications that need electrical contact between the induction foil and the container.

Tin Plated Steel Foil

This induction foil is suitable for high speed induction sealing operations due to its strong adhesion properties. It also provides a barrier against oxygen, water vapor and other contaminants.

Polyester Foil

Induction foil made of polyester provides a strong seal with excellent chemical resistance. It also offers superior protection against light and oxygen, making it an ideal choice for food packaging applications.

Polypropylene Foil

This type of foil is suitable for induction sealing operations that require high temperature stability or electrical insulation. It also has good chemical resistance, making it suitable for induction sealing operations in a wide range of industries.

4.What Are The Components Of An Induction Foil Sealing Machine?

Vacuum Chamber

The induction foil sealing machine is equipped with a vacuum chamber which creates an airtight environment, allowing for precise induction heating of the materials being sealed.

Heating Element

This induction heating element creates an electromagnetic field that generates heat to melt and seal the induction film to the package or container.

Sealing Die

This component is responsible for forming the induction film into a secure, airtight seal. It can be changed to accommodate different induction foil sizes and shapes.

Foil Feeder

The induction foil sealing machine is equipped with a foil feeder which pulls induction film from a roll and feeds it into the machine in an orderly manner.

Foil Cutter

This component is responsible for cutting induction foil to size before it enters the induction chamber. It is usually adjustable and can be used for different induction foil sizes and shapes.

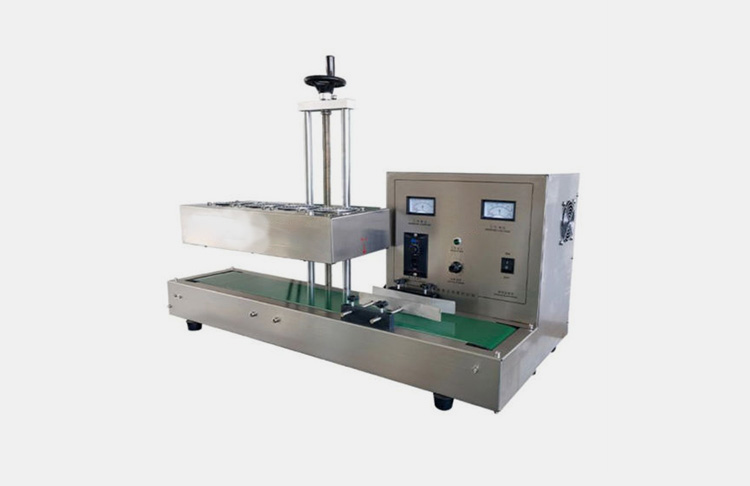

Control Panel

The induction foil sealing machine also has a control panel which acts as the nerve center of the machine. It allows you to easily adjust and monitor parameters such as induction time and temperature, thus ensuring a consistent seal quality.

Conveyor Belt

This component helps to transports containers or packages through the induction chamber, allowing for quick and efficient induction heating and sealing. Also, this part can be adjusted to accommodate different induction foil sizes and shapes.

5.What Are The Advantages Of An Induction Foil Sealing Machine?

Tamper Proof Seals

Induction foil sealing machines provide seals that are resistant to tampering, making them ideal for use in the packaging of pharmaceuticals, food products and other sensitive items.

Versatility

Induction foil sealing machines can be used for a variety of applications, from food and beverage packaging to cosmetic and medical products. This makes them suitable for many industries and ensures that businesses can find the right induction foil sealing machine for their needs.

Prevents Leakages

Induction foil sealing machines provide a strong airtight seal which prevents leakage of the product.

Cost-Effectiveness

Induction foil sealing machines are relatively cost-effective compared to other types of packaging equipment, making them an attractive option for businesses looking to save money on their production costs.

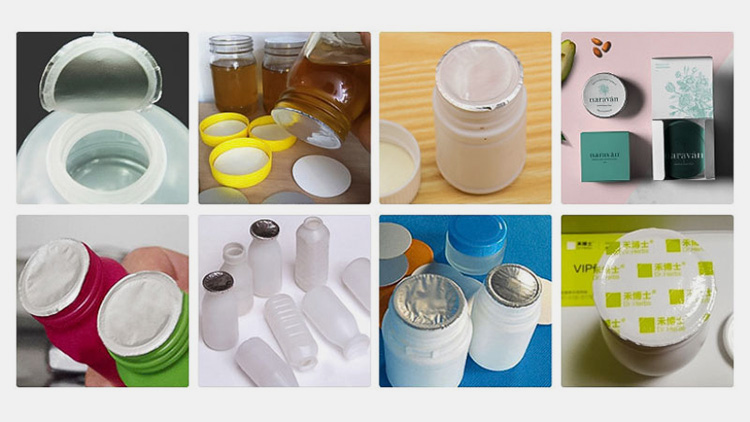

6.What Are The Applications An Induction Foil Sealing Machine?

An induction foil sealing machine is a versatile and cost-effective solution for many industries. Common uses include:

Food Industry

Induction foil sealing machines are widely used in the food industry to seal food products such as sauces, condiments, and other canned or jarred foods. This helps preserve the taste, aroma, and freshness of products.

Pharmaceutical Industry

In the pharmaceutical industry, induction foil sealing machines are used to securely seal pharmaceutical products such as tablets, capsules, syrups, creams, gels, solutions, and suspensions. This helps protect these products from moisture, oxygen and other contaminants.

Cosmetics Industry

Also, induction foil sealing machines can be used to seal cosmetics such as lotions and creams in packed in bottles or jars.

Beverage Industry

Induction foil sealing machines are used in the beverage industry to seal bottles and cans of beer, wine, and other beverages.

Chemical Industry

In the chemical industry, induction foil sealing machines can be used for storing and shipping hazardous chemicals that require an airtight seal. This helps to prevent hazardous leaks and spills.

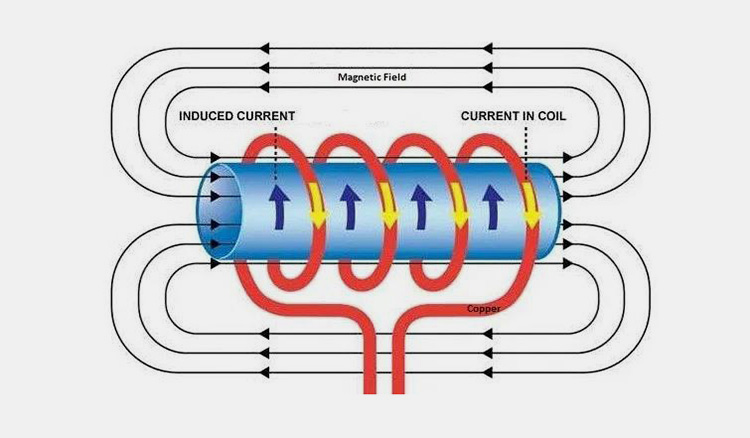

7.What Are The Working Principles Of An Induction Foil Sealing Machine?

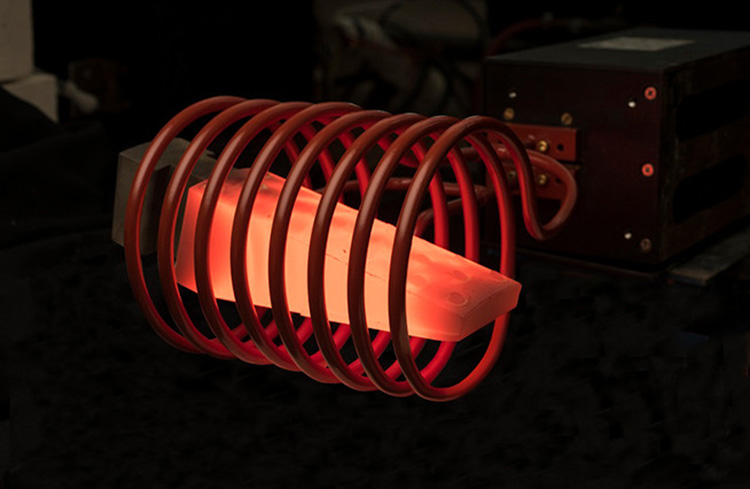

The working principle of this type of machine is based on the induction process, which creates an electromagnetic field when electricity passes through a coil. When the induction foil sealer comes into contact with this coil, it produces heat and can melt the induction-sensitive material. This seals the package, creating an airtight seal that can protect products from damage.

8.What Are The Different Types Of Induction Foil Sealing Machines Available On The Market?

a) Manual Induction Foil Sealing Machines

Manual induction foil sealing machines are devices that are operated manually and they have a hand wheel that moves the induction foil sealer head up and down over the container. These machines are great for short runs of containers with induction seals and are also inexpensive compared to other induction systems thus making them ideal for start-ups or small companies.

b) Semi-Automatic Induction Foil Sealing Machines

Semi-automatic induction foil sealing machines are automatic in nature, but also they require manual intervention to place the induction foil liners on the container and seal them in place. These devices can be used for medium runs of induction sealed containers and are very cost effective.

c) Fully Automatic Induction Foil Sealing Machines

Fully automatic induction foil sealing machines are the most advanced induction foil sealers available on the market. The induction seals themselves are automatically placed on the container, sealed in place with heat and pressure, and dispensed from the machine all in one step.

9.What Is The Difference Between A Manual Induction Foil Sealing Machine And An Automatic Induction Foil Sealing Machine?

The manual induction foil sealing machine requires manual operation for the process of heat sealing and setting up. It is a manual, low-cost and effective solution that provides users with an efficient way to carry out the task. The manual induction foil sealing machine has no additional settings to be taken care of by the operator and it can be used on a variety of containers.

An automatic induction foil sealing machine, on the other hand, requires no manual operation and it can be operated with a single touch or button press. It is also equipped with multiple settings and controls that allow the user to customize the seal according to their needs.

Additionally, this type of machine is much more efficient than manual models, as it seals the container in a very short amount of time. The automatic induction foil sealing machine is more expensive than manual machines and comes with increased safety measures to protect against electric shock.

10.What Is The Difference Between An Automatic Induction Foil Sealing Machine And A Semi-Automatic Induction Foil Sealing Machine?

The main difference between an automatic induction foil sealing machine and semi-automatic induction foil sealing machines lies in the number of steps it takes to complete the sealing process.

An automatic induction foil sealing machine is capable of completing all steps involved in the process from start to finish, including filling containers with product, sealing, and labeling them. In contrast, a semi-automatic induction foil sealing machine requires manual intervention between steps, such as manual product filling and labeling.

Also, automatic induction foil sealing machines typically employ sensors that detect the presence of containers and products. When a container is detected, the automatic system will then apply the induction coil to heat-seal pre-cut aluminum seals onto each container in succession.

This automatic induction foil sealing machine is also capable of labelling each container as it passes through the machine.

On the other hand, semi-automatic induction foil sealing machines require more manual intervention, mainly during filling and labeling processes. You must manually place products into containers before they pass under the heating coil for sealing.

Additionally, semi-automatic machines may not have automatic labeling capabilities, requiring the operator to manually label containers after they have been sealed.

11.Can Induction Foil Sealing Machines Be Used To Seal Different Types Of Containers?

Yes, induction foil sealing machines can be used to seal a variety of different containers.

An induction foil sealing machine is designed to work with many different types of containers, including plastic and glass bottles, jars, tins, tubes, and other types of containers.

The induction foil is also available in a variety of sizes so it can be customized for use with any container size or shape.

12.What Type Of Containers Can Be Sealed Using An Induction Foil Sealing Machine?

Induction foil sealing machines can be used to seal a wide range of containers including:

Plastic Containers

Induction foil sealing machines can be used to seal plastic containers made of materials such as HDPE, LDPE, PP, and PET. The induction foil seals the container tightly and securely thus preserving its contents.

Metal Containers

Metal containers such as aluminum cans and tins can also be sealed using induction foil sealing machines. The induction process creates a strong bond between the metal container and the induction foil seal, creating an airtight barrier against contaminants.

Glass Containers

Glass containers can also be sealed with induction foil sealing machines, although this is less common due to the fragility of glass containers compared to plastic or metal. The induction process still creates a strong bond between the induction foil and the glass container, ensuring an airtight seal.

Cans

Induction foil sealing machines are ideal for quickly and securely sealing cans with induction foils. This ensures the contents remain fresh, secure, and look attractive.

13.What Are The Cost Considerations When Buying Induction Foil Sealing Machines?

When purchasing induction foil sealing machines, there are a variety of cost considerations that need to be taken into account.

The induction foil sealing machine itself is typically the most expensive part of the equation, and can range anywhere from a few hundred dollars for basic models up to tens of thousands of dollars for more advanced units.

Additionally, other costs may include proper installation and setup, maintenance and repair, as well as consumables such as induction foil, induction cap seal liners, induction susceptors, etc.

Therefore, when choosing an induction sealing machine, it is important to first consider what your needs are in terms of production volume and speed. Higher-end models may be necessary for more demanding applications, while basic induction foil sealing machines may suffice for less frequent applications.

Also, it is important to consider the total cost of ownership over time, as induction sealing machines require regular maintenance and consumables, which can add up over time.

Finally, when evaluating induction foil sealing machine options, be sure to compare not only the initial purchase price, but also any additional fees for installation, setup and maintenance. Doing so will help ensure that you make the best decision for your particular application and budget.

14.What Are Some Of The Common Problems Experienced With Induction Foil Sealing Machines And How Can You Solve Them?

Poor Induction Coil Contact

Poor induction coil contact is a common problem experienced with induction foil sealing machines. This can be caused by the induction coil not being firmly secured to the package, or if it is not positioned correctly on the material.

Possible Solution

The solution to this problem lies in making sure that the induction coil is securely attached and placed properly before each seal.

Inconsistent induction power

Induction foil sealing machines can experience inconsistent induction power due to a faulty induction coil or an induction coil that has become too hot due to frequent use.

Possible Solution

Making sure the induction coil is properly tuned and maintained, as well as taking regular breaks to allow it to cool down.

Poor Quality Seals

Poor quality seals can also be a challenge experienced by induction foil sealing machines and its normally caused by inadequate induction power, too much induction power or improper induction coil alignment.

Possible Solution

Ensuring that the induction coil is properly tuned and maintained, induction power is at an appropriate level and that the induction coil is properly aligned with the material being sealed.

15.How Can You Select The Right Induction Foil Sealing Machine For Your Particular Application?

Selecting an induction foil sealing machine best suited for your particular application is an important decision that requires careful consideration. There are several key factors to take into account when making this selection, including:

Consider your budget

Firstly, it is important to understand the cost implications associated with induction foil sealing machines. These machines can vary significantly in price, depending on their features and specifications. As such, it is important to have a clear understanding of your budget before making a purchase.

Consider the Size of the machine

Also, you need to consider the size requirements of your induction foil sealing machine. This will be determined by the size of the containers that you need to seal, as well as the production speed requirements. The induction foil sealing machine should be able to handle the size and shape of your containers, as well as being capable of running at the desired speed.

Consider induction foil type

Different induction foil sealing machines are designed to work with different types of induction foils, so make sure you select the induction foil sealing machine that is compatible with the induction foil you plan to use.

Consider production speed

Choose an induction foil sealing machine that can meet your production needs in terms of speed and volume. Consider both short run and long run requirements when selecting this type of machine.

CONCLUSION

Induction foil sealing machines have become an essential tool within the packaging industry as they make it easy to quickly and accurately seal containers. From key benefits such as improved food safety to more efficient operations, it’s not hard to see why these innovative machines are here to stay. If you are looking for a reliable induction foil sealing machine that offer not just quality but also cost-effectiveness, look no further – contact Allpack today! With our wide range of induction foil sealing machine models, we can help you find what best suits your needs.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide