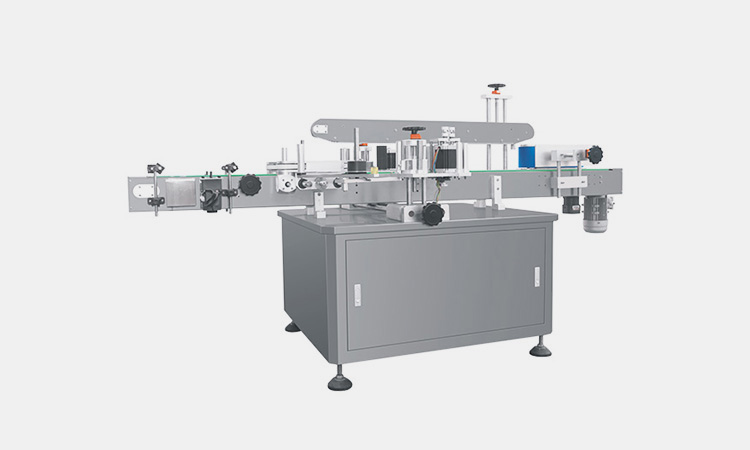

Round Bottle Labeling Machine:The Complete Buying Guide in 2025

Round Bottle Labeling Machine:The Complete Buying Guide in 2025

Many business owners faced with reduced time and cost have been opting to invest in automated solutions that can help them manage part of their production process more efficiently. While making such investment decisions may seem complex, this guide seeks to make it easier for you! Here we will explore what makes the perfect round bottle labeling machine, from budget considerations to essential features – helping you determine which option best meets your needs so that come 2023, you’re equipped with the right solution for your business!

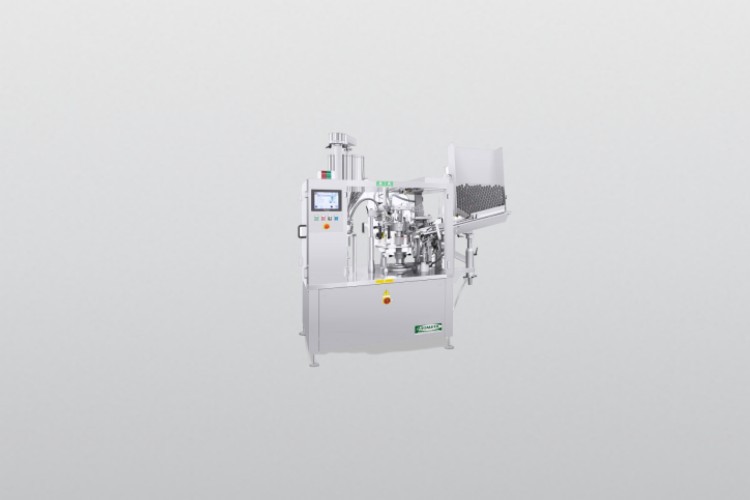

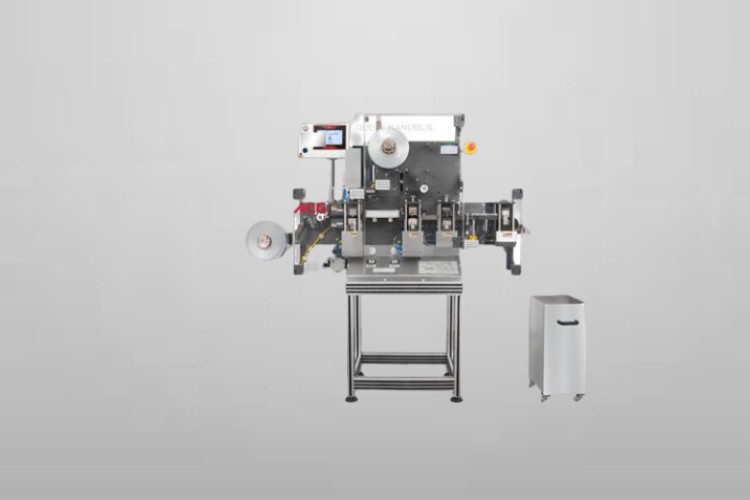

1.What Is A Round Bottle Labeling Machine?

A round bottle labeling machine is an equipment used to apply labels to cylindrical containers such as bottles, jars, and tubes. This machine is designed to automate the labeling process, improving production efficiency and reducing labor costs.

It works by feeding the bottles into the labeling system, where they are automatically rotated and aligned for accurate label application. Labels are then applied using a variety of methods, including pressure-sensitive, hot melt, or glue application.

Furthermore, round bottle labeling machines can handle a range of label sizes, materials, and shapes. They can be used to apply product information, branding, logos, and warning labels to a variety of consumer products including food, beverages, pharmaceuticals, and cosmetics.

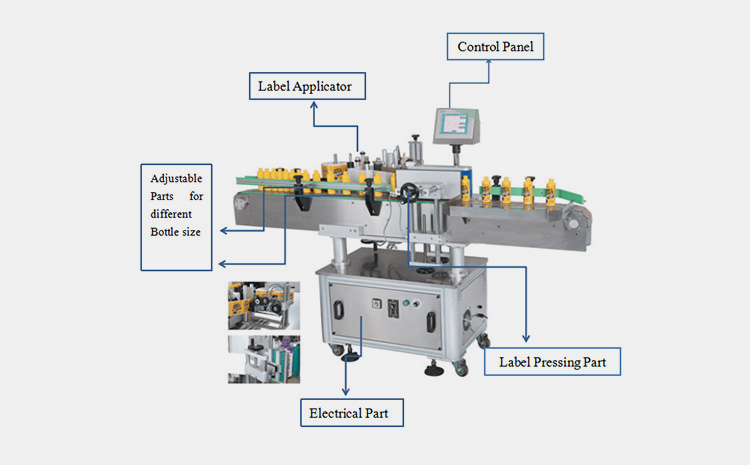

2.What Are The Different Components Of A Round Bottle Labeling Machine?

Round bottle labeling machines have various components that work together to ensure efficient and accurate labeling. Here are some of the key components of a round bottle labeling machine:

Bottle Feeding Table

This component is responsible for feeding the bottles to the machine. The feeding table can be adjusted to accommodate different bottle sizes and shapes. This component is also designed to prevent the bottles from getting damaged during the feeding process.

Bottle Separation Wheel

The bottle separation wheel is responsible for separating the bottles on the feeding table and aligning them in the correct position to be labeled. The wheel rotates to move the bottles along the conveyor system.

Adjustable Rails

These are used to guide the bottles through the labeling machine. They can be adjusted to accommodate different bottle sizes and shapes. The rails ensure that the bottles are held in the correct position during the labeling process.

Label Stand

The label stand holds the roll of labels that will be applied to the bottles. It is designed to ensure that the labels are fed through the machine smoothly and that there is no interruption in the labeling process.

Pressing Wheels

These are used to apply pressure to the labels as they are applied to the bottles. The pressing wheels ensure that the labels are firmly attached to the bottles and that there are no air bubbles or wrinkles in the label.

Conveyor

The conveyor is responsible for moving the bottles through the machine. The speed of the conveyor can be adjusted to accommodate different labeling speeds.

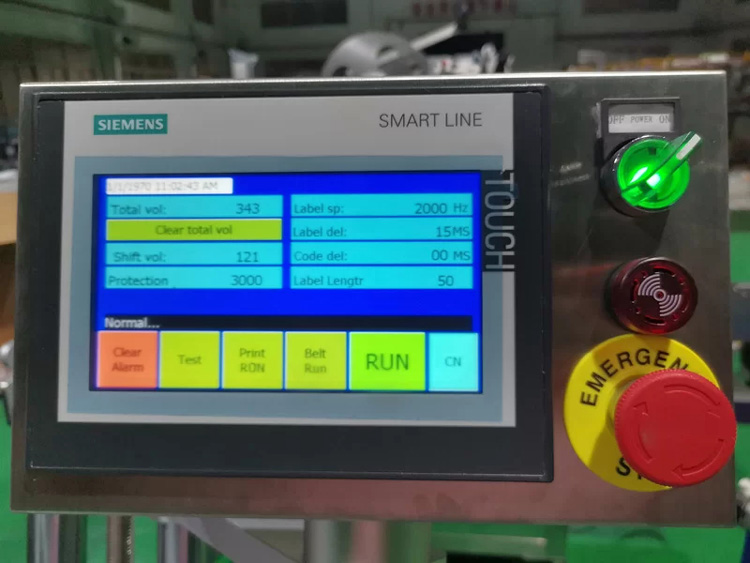

Control Board

The control board is the main interface for operating the round bottle labeling machine. It allows the operator to set labeling parameters such as label size, bottle size, and labeling speed.

Electrical Box

The electrical box houses the electrical components that power the round bottle labeling machine. It may include a frame and wheels for easy mobility.

3.How Does A Round Bottle Labeling Machine Work?

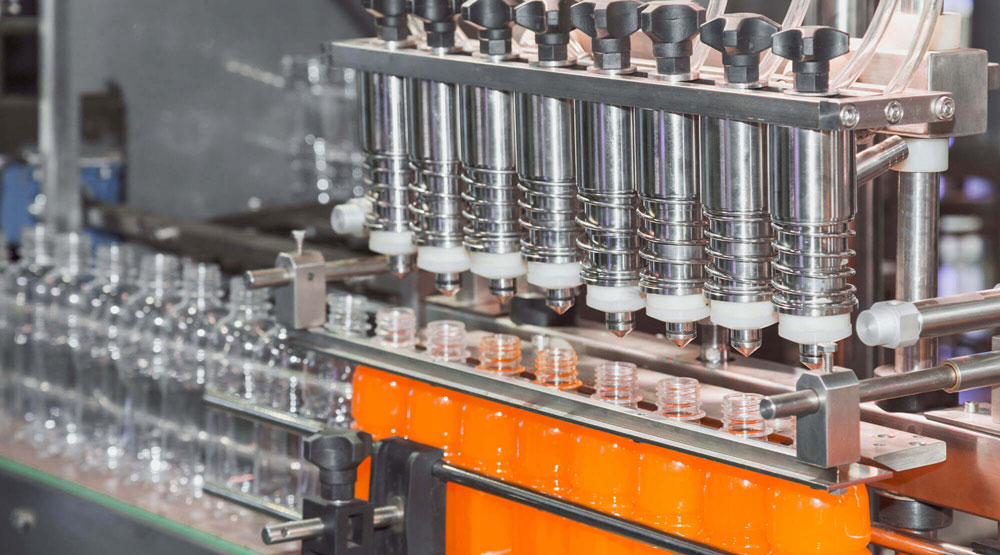

When it comes to the round bottle labeling machine it consists of a conveyor system that moves the bottles through the labeling process. Also, a label dispenser that holds and releases the labels, and a labeling head that applies the labels to the bottles.

The labeling process begins with the bottles being loaded onto the conveyor system. As the bottles move through the machine, the label dispenser releases a label onto the surface of each bottle. The label is held in place by the labeling head, which uses a combination of pressure and adhesive to apply the label securely to the bottle.

After the machine applies the labels, it ensures that it has been applied correctly and is properly aligned. That ensures there are no errors or misalignment with your labels. Finally, bottles are then discharged from the machine, usually onto another conveyor system, where they can be packaged and shipped.

Additionally, many of these round bottle labeling machines are equipped with sensors and other features, ensuring the labels are applied accurately and consistently. For example, some machines use optical sensors to detect the position and orientation of the bottles as they move through the machine. This ensures that the labels are applied in the correct location and orientation.

4.What Are Some Common Industries That Use A Round Bottle Labeling Machine In Their Manufacturing Processes?

Here are some common industries that use round bottle labeling machines in their manufacturing processes:

Food and Beverage Industry

This industry requires the labeling of products such as juice bottles, soda bottles, and beer bottles. The labeling machine helps to accurately apply labels to round containers, ensuring that product information, nutrition facts, and branding are easily identified by the consumer.

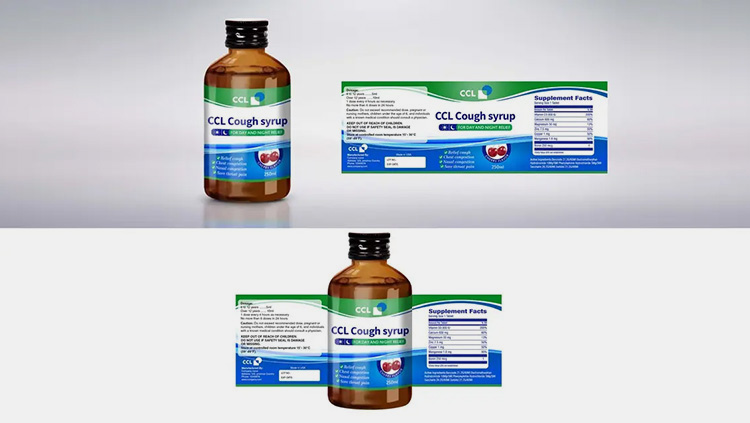

Pharmaceutical Industry

The pharmaceutical industry has stringent labeling requirements to ensure that the right medication is being used by the right patient. Round bottle labeling machines are used in this industry to label medication bottles, syrups, and other pharmaceutical products. These machines can handle high-precision labeling and can apply labels with variable information such as expiration dates, batch numbers, and barcodes.

Cosmetics Industry

Round bottle labeling machines are used in the cosmetics industry to label products such as shampoo bottles, lotion bottles, and other personal care items. These machines ensure that the labels are applied accurately and neatly, giving the product a professional and polished appearance.

Chemical Industry

This industry requires labeling of containers that contain hazardous materials. The round bottle labeling machine helps to ensure that the correct warnings and hazard information are accurately and prominently displayed on the containers.

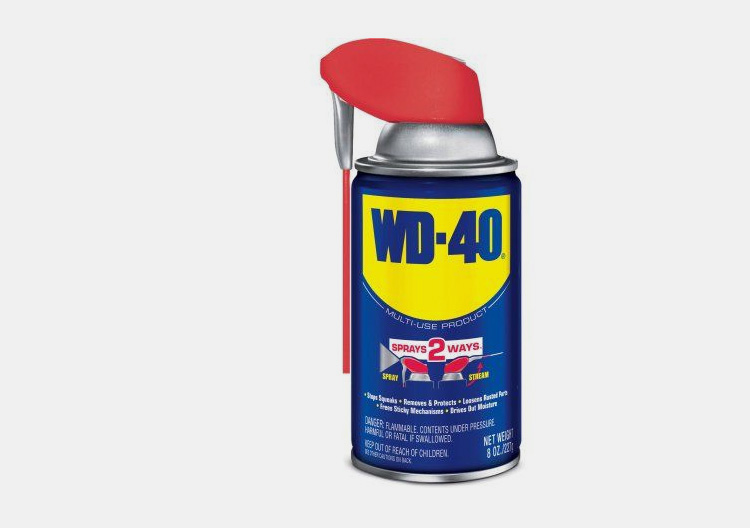

Automotive Industry

Round bottle labeling machines are used to label automotive products such as engine oils, transmission fluids, and brake fluids. These machines ensure that the product information and branding are accurately displayed on the containers.

5.What Are The Advantages Of Using A Round Bottle Labeling Machine In Production?

Increased Efficiency

One of the primary advantages of using a round bottle labeling machine is its ability to label products quickly and efficiently. It can label hundreds of products per minute, which is much faster than manual labeling. The machine can also operate continuously for long periods, ensuring that production targets are met.

Improved Accuracy

A round bottle labeling machine ensures that labels are applied to products accurately, minimizing errors and waste. With the machine’s precise positioning system, it can apply labels in the same position and orientation, ensuring consistency in branding and packaging.

Versatility

Round bottle labeling machines are versatile and can label different container shapes and sizes. The machines can accommodate various label materials, including paper, vinyl, and polyester, allowing manufacturers to choose the label material that best suits their product.

Flexibility

Round bottle labeling machines can be customized to meet specific production needs. Manufacturers can choose from different models, sizes, and configurations to fit their production requirements. They can also integrate the machine into their existing production line, ensuring seamless operation and improved efficiency.

Cost-effective

Investing in a round bottle labeling machine can be cost-effective in the long run. The machine can replace the need for manual labeling, which can be time-consuming, labor-intensive, and error-prone. By automating the labeling process, manufacturers can save on labor costs, reduce waste, and improve overall productivity.

Quality Control

With a round bottle labeling machine, manufacturers can ensure quality control throughout the labeling process. The machines can detect and reject defective products, ensuring that only high-quality products are labeled and sent out to the market.

6.What Are The Types Of Round Bottle Labeling Machines Available In The Market?

Round bottle labeling machines come in different types and designs to suit different needs and preferences. Here are some of the common types of round bottle labeling machines available in the market:

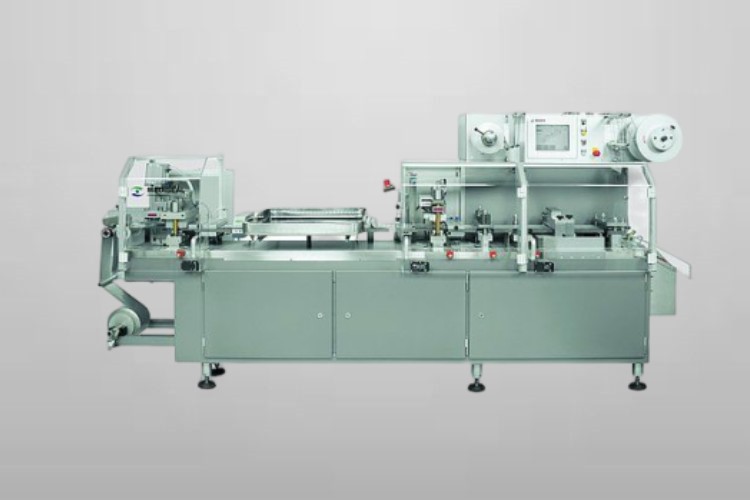

Manual Round Bottle Labeling Machine

This type of labeling machine is operated manually, and it is suitable for small scale production or startup companies with a limited budget. The manual round bottle labeling machine is simple to operate, and it can label bottles of different sizes and shapes. However, it is slower and less efficient than other types of labeling machines.

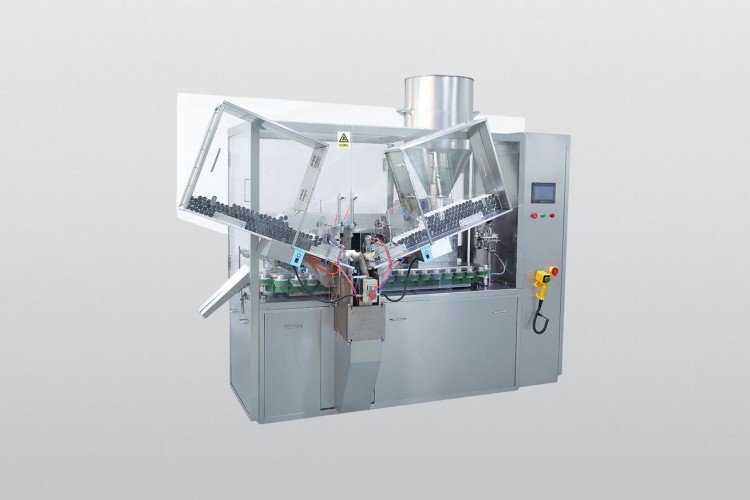

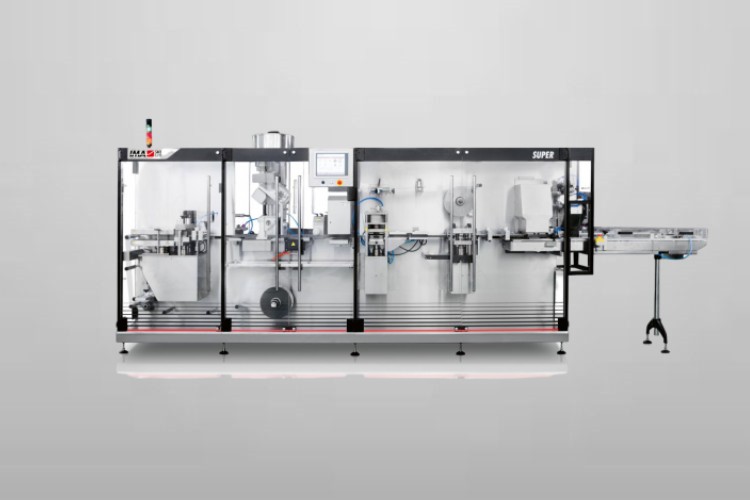

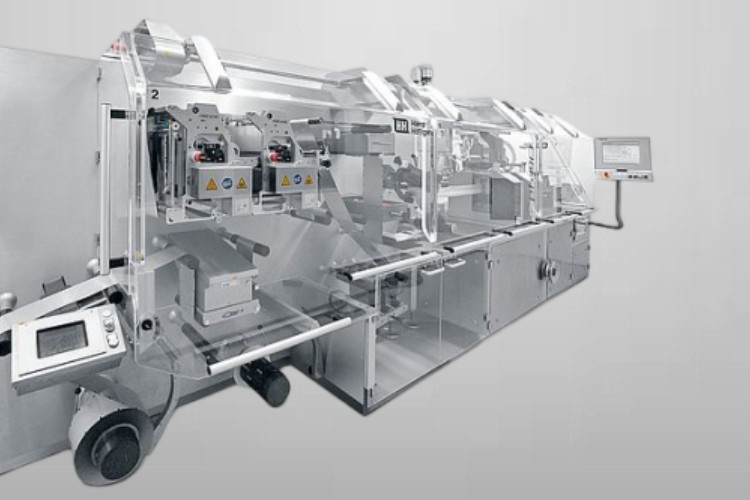

Semi-Automatic Round Bottle Labeling Machine

This type of labeling machine is partially automated, meaning that the operator needs to place the bottle on the machine and start the labeling process manually. The semi-automatic round bottle labeling machine is faster and more efficient than the manual machine, but it requires some human intervention.

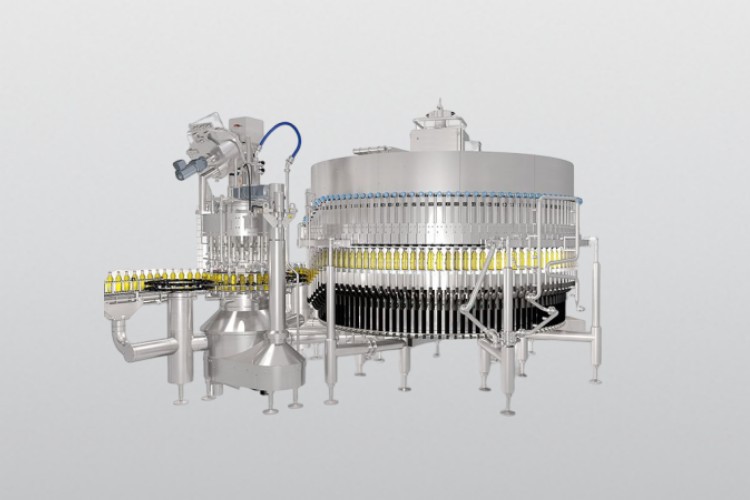

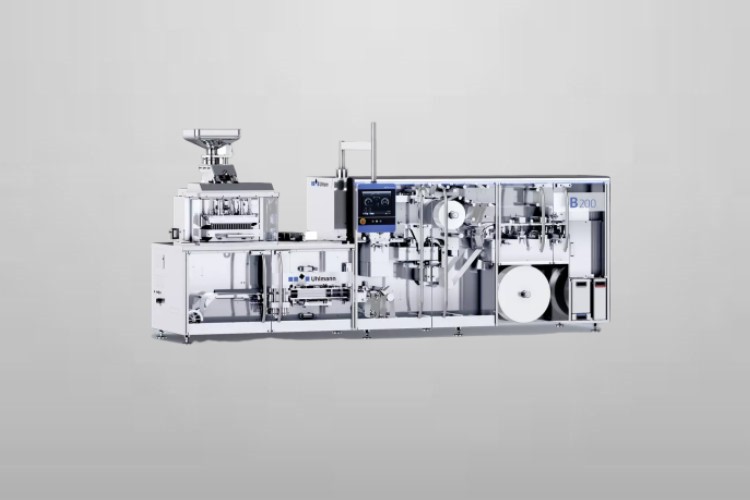

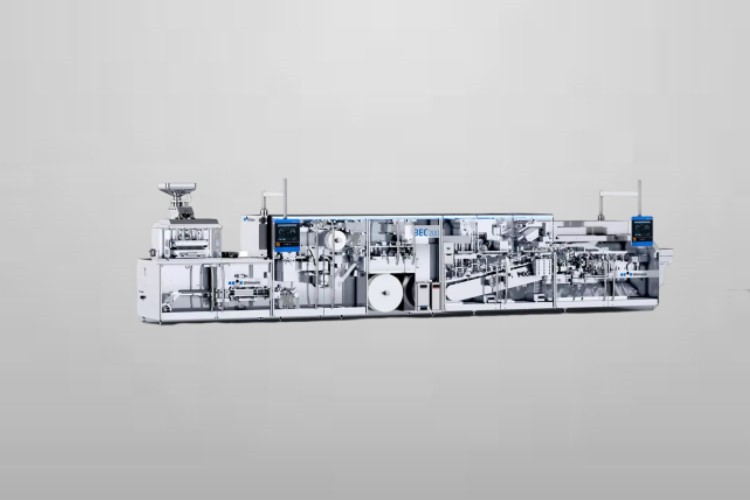

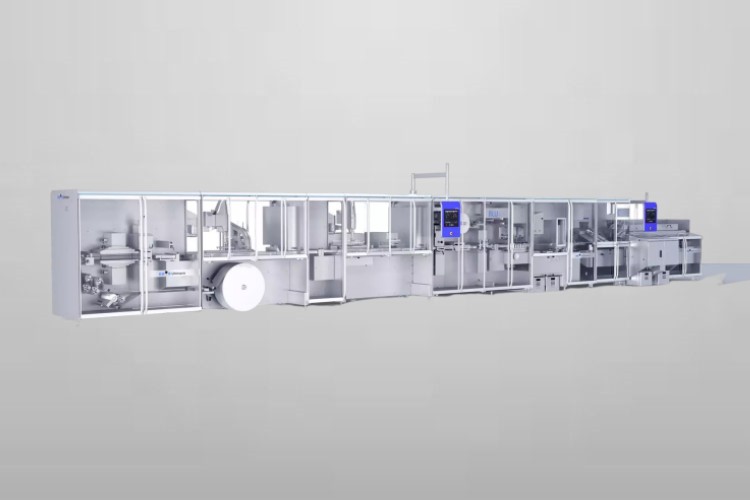

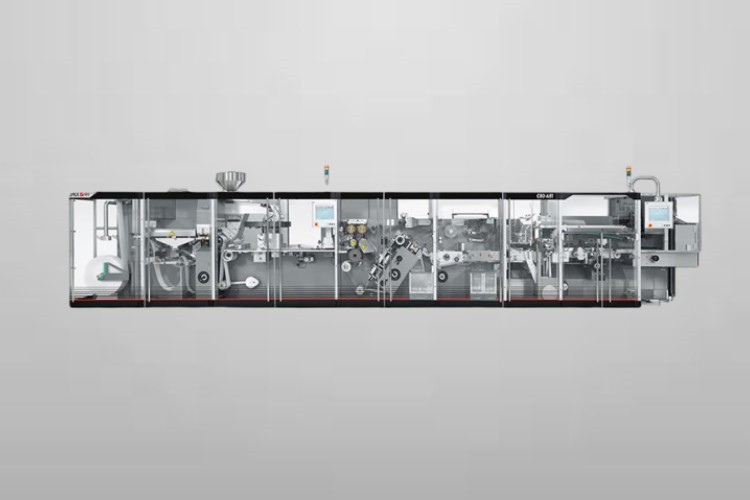

Fully Automatic Round Bottle Labeling Machine

This type of labeling machine is fully automated and requires minimal human intervention. The operator only needs to load the bottles onto the machine, and it will automatically label them according to the preset parameters. The fully automatic round bottle labeling machine is the most efficient and fastest of all the labeling machines, and it is suitable for large scale production.

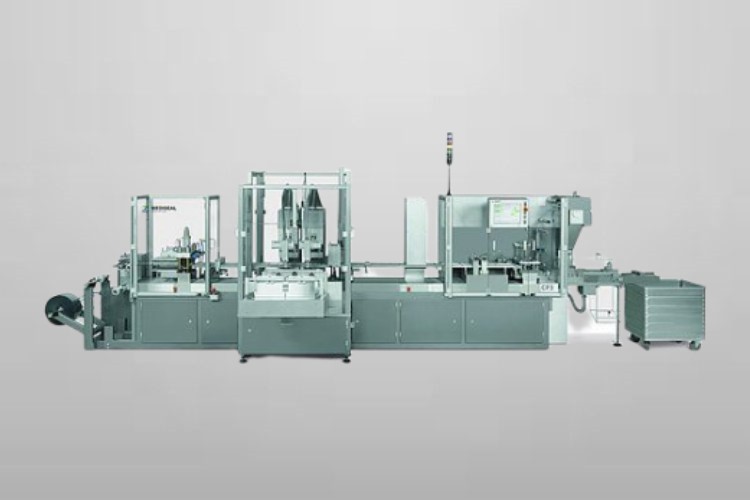

Round Bottle Side Face Labeler

This type of labeling machine applies a label on one side of the bottle. The wrap-around labeling machine is suitable for labeling cylindrical bottles, and it can label bottles of different sizes and shapes.

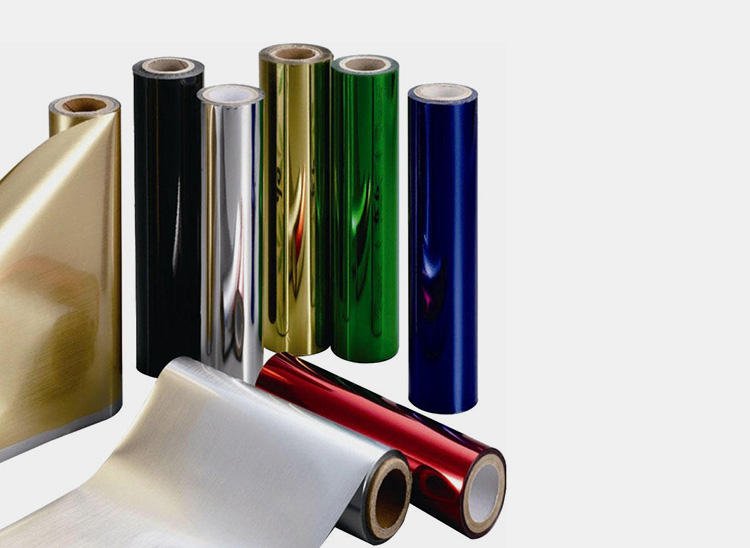

7.What Are The Different Types Of Label Materials That Can Be Used With Round Bottle Labeling Machines?

There are several different types of label materials that can be used with round bottle labeling machines. These materials vary in terms of their composition, texture, and adhesive properties, and are chosen based on the specific needs of the product being labeled. Here are some of the most common label materials:

Paper Labels

Because they are affordable and simple to print on, paper labels are a common option for labeling round bottles. These labels are adaptable for various labeling applications because of their range of finishes, which include matte, glossy, and textured. Additionally, they are available with a variety of adhesives, such as repositionable, removable, and irreversible.

Plastic Labels

Plastic labels are another common type of label material used with round bottle labeling machines. They are made from various types of plastic, such as polypropylene (PP), polyethylene (PE), and polyester (PET). Plastic labels are more durable than paper labels and can withstand exposure to moisture and heat. They are also resistant to tearing and scratching, making them ideal for products that are transported frequently.

Synthetic Labels

A more robust and weather-resistant alternative to paper labels is synthetic labeling, which is constructed of materials like polyester or vinyl. They are frequently applied to things that will be subjected to moisture, heat, or UV radiation, making them perfect for outdoor use or for identifying items that need to be washed frequently.

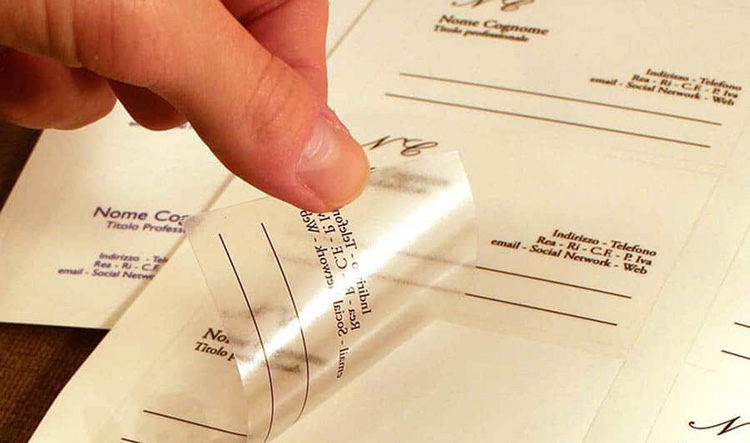

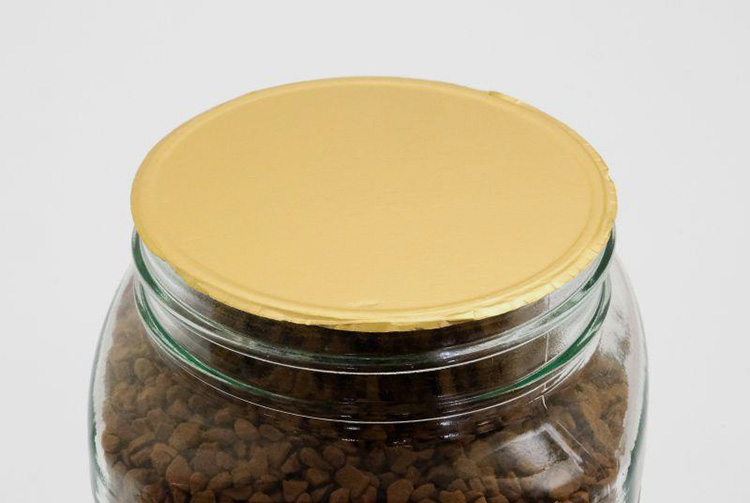

Clear Labels

The material used to make clear labels is transparent, allowing the contents of the bottle to be seen through the label. These labels are frequently used for goods like juices, oils, and perfumes when the liquid’s color or texture plays a significant role in the branding of the item.

Foil Labels

Foil labels are made from thin sheets of aluminum or other metal foils. They are commonly used for high-end products such as perfumes, wines, and liquors. Foil labels have a shiny metallic finish that adds an elegant touch to the product. They are also resistant to moisture, heat, and UV light.

Fabric Labels

Textiles such as cotton, satin, or nylon are used to make a variety of fabric labels. They are frequently used for goods like apparel and bed linens that need to feel soft and cozy. Screen printing and digital printing are two printing methods that can be used to print fabric labels.

Holographic Labels

In order to create a three-dimensional effect that can be particularly eye-catching, holographic labels are created of a substance that reflects light in various directions. These labels are frequently applied to goods like energy drinks and supplements that need to stand out on the store.

8.What Types Of Adhesives Are Used In Round Bottle Labeling Machines?

Round bottle labeling machines require adhesives that can effectively bond the label to the curved surface of the bottle. The choice of adhesive will depend on the type of label material, the shape and size of the bottle, and the application method used by the labeling machine. Below are some of the commonly used adhesives in round bottle labeling machines:

Hot Melt Adhesive

Hot melt adhesive is a thermoplastic material that is melted and applied in a molten state onto the label. When the adhesive cools and solidifies, it forms a strong bond with the surface of the bottle. Hot melt adhesive is commonly used for labeling applications that require a high degree of adhesion and fast-drying time.

Water-based Adhesive

Water-based adhesives are also often utilized; they are applied as liquids and dry through evaporation. When a strong attachment between the label and the bottle is required for labeling purposes, this product is frequently employed. It is also appropriate for labeling applications on a variety of materials, including paper, plastic, and metal.

Solvent-based Adhesive

Solvent-based adhesive is a type of adhesive that contains solvents and dries by evaporation of the solvent. It is suitable for labeling applications where a strong bond is required. Solvent-based adhesive is commonly used in labeling applications on metal, glass, and plastic surfaces. It is resistant to moisture and chemicals.

Wet glue Adhesive

Wet glue labeling is a technique used to apply a label to the product’s surface using a liquid adhesive. The labeling machine applies a small amount of adhesive to the label’s backside, and then the label is applied to the product’s surface. This method is ideal for labeling products that need a strong bond and can withstand moisture and humidity.

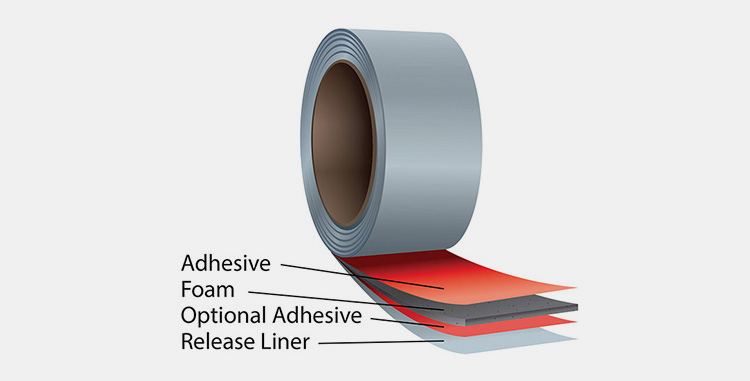

Pressure-sensitive Adhesive

A type of adhesive called pressure-sensitive adhesive makes a bond when pressure is applied to it. Because it can adapt to the curvature of the bottle, it is frequently utilized in labeling applications on curved surfaces. For labeling purposes, pressure-sensitive adhesive can be used on a variety of surfaces, including paper, plastic, and metal. It is simple to apply and remove without leaving behind any residue.

9.What Are The Different Types Of Labels That Can Be Used With A Round Bottle Labeling Machine?

Round bottle labeling machines can be used to apply various types of information labels on the surface of the container. Below are the different labels that can be used with a round bottle labeling machine:

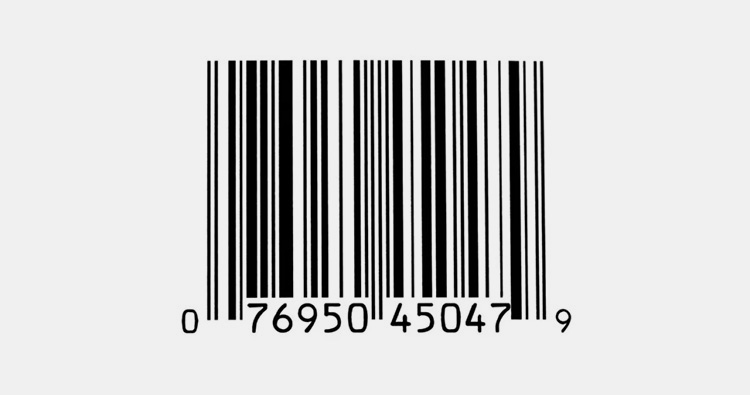

Barcodes

Barcodes are machine-readable labels that contain a series of vertical bars and spaces of varying widths. They are used to store and retrieve information about the product, such as its price, stock keeping unit (SKU), and serial number. Round bottle labeling machines can print and apply barcodes on labels using thermal transfer or direct thermal printing technologies.

Product name and description

Round bottle labeling machines can also print and apply labels that contain the product name and description. These labels help consumers identify and differentiate products on the shelf, and they also provide important information about the product’s features, ingredients, and usage instructions.

Logos and graphics

Round bottle labeling machines can print and apply labels that contain logos, graphics, and images. These labels can be used to promote brand awareness and recognition, and they can also enhance the visual appeal of the product.

Regulatory information

Round bottle labeling machines can print and apply labels that contain regulatory information, such as warning labels, safety instructions, and ingredient lists. These labels help ensure that the product complies with regulatory requirements, such as those set by the Food and Drug Administration (FDA) or the Consumer Product Safety Commission (CPSC).

Expiration dates and batch codes

Round bottle labeling machines can print and apply labels that contain expiration dates and batch codes. These labels help ensure product safety and quality by providing information about when the product was manufactured and when it should be consumed or disposed of.

Safety information

Labels can also be used to provide safety information, such as warning labels, handling instructions, and other safety precautions.

Nutritional information

Labels can be used to provide nutritional information, such as the number of calories, fat, protein, and other nutritional facts.

10.How Is The Label Alignment Ensured On A Round Bottle Labeling Machine?

Label alignment is crucial in round bottle labeling machines to ensure that the label is applied accurately and neatly on the bottle. Here are the steps that are typically followed to ensure label alignment on a round bottle labeling machine:

Bottle positioning

The bottle is positioned on the machine using a conveyor or a rotary table. The bottle is placed in a specific position to ensure that the label is applied accurately.

Label sensor

A label sensor is used to detect the label’s position as it moves along the labeling machine. This sensor is usually a photoelectric sensor that detects the gap between the labels or the label’s edge.

Labeling head

The labeling head is responsible for applying the label onto the bottle. The labeling head’s position is adjusted to ensure that the label is aligned correctly with the bottle.

Feedback control

Many labeling machines are equipped with feedback control systems that monitor the labeling process in real-time. The feedback control system uses sensors to detect any misalignments or errors and makes the necessary adjustments to ensure accurate label placement.

11.Can A Round Bottle Labeling Machine Be Integrated Into An Existing Labelling Line?

Yes, a round bottle labeling machine can be integrated into an existing production line. In fact, it is a common practice in many industries to automate the labeling process using such machines. The integration process will depend on several factors such as the type of production line, the layout, and the available space.

The compatibility of the labeling machine with the current line is a crucial factor to take into account. It’s critical to confirm that the machine can process the quantity and variety of bottles that the production line generates. The machine should also be able to seamlessly interface with the other devices in the line, such as the machines that fill and cap containers.

Also, the design of the production line is another thing to take into account. With a conveyor system that can move the bottles to and from the labeling machine, the labeling machine can be integrated into the line if it is already completely automated. The integration procedure, however, can be more difficult and call for both extra equipment and adjustments to the current line if the line is not entirely automated.

The space that the labeling machine will occupy is another crucial factor. Depending on its size and the number of bottles to be branded, the machine can need its own spot on the assembly line. As a result, it’s crucial to make sure the machine has appropriate room and does not obstruct the operation of any other machinery.

Conclusion

Investing in a round bottle labeling machine is a smart decision for any business looking to improve efficiency, accuracy, and productivity in their labeling process. As such, we recommend that investors seeking a high-quality round bottle labeling machine should contact Allpack, a trusted manufacturer with a track record of delivering top-notch labeling machines that meet industry standards. Contact Allpack today and take the first step in improving your labeling process.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Round Bottle Labeling Machine:The Complete Buying Guide in 2025 Read More »

Company Background & Information

Company Background & Information

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours