Pill Coating Machine: The Complete Buying Guide In 2025

Pills are small, solid substances which are taken as medicine to either cure ones illness or improve their quality of life. It would be hard for a lot of people to take their medications on time. Thus they would be less compliant, making it hard to cure their disease and improve their lifestyles.

So is there a machine which has the capability to protect these highly vulnerable pill from getting damaged? Is there a way in which these pills can be made more aesthetically pleasing? Is there a machine which is not restricted to coating only one kind of pill or tablet but has the ability to coat pills of various shapes and sizes?

Fortunately, the answer to all these questions is yes, there is! And that is a pill coating machine, a machine which is used to coat pills with desired materials which refines them into a more desirable product.

1.What is pill coating machine?

Pill coating machine is an equipment which is used to coat the external surface of the pill with a thin film. This film is made of several substances such as surfactants, pigments, anti-foaming mechanisms, binders, opacifiers, anti-tacking agents etc. these substances together form a coating layer which is then applied on top of the pill to protect it from chemical degradation or from the environment.

This machine also helps to subside the unpleasant smell and taste of the pill which would make it hard for the patient to consume. Moreover, it also enhances the appearance of the pill, making it more attractive and pleasing to the eyes.

2.What are the advantages of pill coating machine?

Pill coating machine has several advantages. Its use has been increasingly growing for the past few years due to the growing demand of medicines and the huge benefits this machine offers. Let us discuss these advantages below.

Provides protection to the pills

One of the greatest advantage of using pill coating machine is that it protects the pill from harmful external environment factors such as dust, air, moisture and sunlight. Thus it helps in maintaining the potency of the pill and providing maximum therapeutic effect.

Gives an aesthetic look

Most of the pills which are manufactured are unattractive and colorless. As a result, the patient is not really excited to consume them regularly. This machine coats these pills with a layer of film which improves the aesthetic look of the pill.

Masks the unpleasant taste and odor

A lot of pills which are produced in industries have an unpleasant taste and odor which makes it really hard for people especially children to consume them. This machine solves this problem by coating the pills with materials which mask the unpleasant taste and odor.

Ability to coat pills of various shapes and size

This machine is very versatile since it has the ability to coat pills which come in different shapes and sizes. Thus, a lot of industries can install this machine who manufacture various kinds of pills in a single factory.

3.What are the applications of pill coating machine?

Due to its versatility, pill coating machine can be used in several industries such as pharmaceutical, food, nutraceutical, veterinary, agriculture, cosmetic etc. let us discuss each of these industries below.

Pharmaceutical industry

Pharmaceutical industry is a large scale industry which deals with the manufacture of thousands of pills in a single day. These pills need maximum protection to maintain their efficacy and potency in order to maximize their therapeutic effect. This machine helps in coating them, meeting all its requirements.

Food industry

This industry deals with the production of food tablets which need to look colorful and attractive in order to attract customers. Pill coating machine coats them with agents which give these food tablets the desired look and taste.

Nutraceutical industry

Many vitamins and food supplements are manufactured in this industry which are needed by vitamin deficient people to improve their quality of life. This machine coats them, providing protection and improved look.

Chemical industry

This industry is involved in the production of various chemicals such as paints, dyes, pigments, solvents, and plasticizers etc. These are then used in other industries to make final products. Since these chemicals are highly vulnerable to any damaging external factors, the machine coats them with layer which is capable of withstanding any external harm.

Agriculture industry

This industry is involved in the production of fertilizers, pesticides and herbicides which are used to increase crop yield. Pill coating machine can coat them to improve their effectiveness by maximizing the crop output.

4.What are the types of pill coating machine?

There are several types of pill coating machines available in the market. Each type has its own unique features and the customer can choose whichever type would be suitable for his production line. These types are:

a)Perforated pill coating machine

This type of machine is made up of a drum which rotates on a horizontal axis. This drum is either partially perforated or fully perforated. This drum is equipped with spraying nozzles through which the coating layer is sprayed onto the pills.

One of the prominent feature of this machine is that it sprays an aqueous based coating instead of a solvent based one. This greatly reduces the chances of any explosions since solvents are volatile and vulnerable to any harmful factors.

b)Standard pill coating machine

This type is one of the popular ones and is readily available in the market. It consists of a metallic circular machine ranging from 6-80 inches. The machine is placed horizontally at angle of 45 degrees.

It is equipped with an electric motor which facilitates the rotation of the drum on horizontal axis. Coating is applied through spraying and heated air is introduced via the air inlet and exits through the ducts.

c)Fluidized bed pill coating machine

This type of pill coating machine contains a vertical cylinder. In this, a column of air moves upward from the bottom center of the cylinder. This results in the fluidization of the pills which move upward in the air flow and fall downwards and outwards and re-enter the air stream from the bottom.

The spraying nozzles are located upward and downward for the coating process. However due to this process, the pills are highly vulnerable to getting damaged during their interaction with either the chamber or with each other. Two methods are employed to achieve a uniform coating. These are:

High pressure airless system

In this, the airless spray liquid is pumped at a very high pressure ranging from 1.7 to 20 MPa. A small orifice of diameter ranging from 0.02 to 0.2 mm is employed which accounts for a fine spray of coating is used.

Low pressurized air atomized system

In this, a large orifice is used of diameter ranging from 0.05 to 2.5mm. A low pressure is employed from 25 to 350 kPa. The low pressurized air interacts with the liquid stream at the top which results in the formation of fine spray, thus ensuring a uniform coating of the pill.

5.What is the difference between standard pill coating and perforated pill coating?

Standard pill coating machine consists of a circular metallic machine whereas perforated pill coating use either partially perforated or fully perforated drum. In standard pill coating, the pill rotate horizontally in a continuous manner.

This allows for a uniform and even coating of the pills. Whereas in perforated pill coating, the pills move upwards and downwards in the drum. The drying process of perforated pill coating is better than standard pill coating. As a result the whole coating process in it is faster and more efficient than standard pill coating.

6.What is the working principle of pill coating machine?

Pill coating machine is based on the principle of centrifugal force. The pills are added into a perforated rotating drum. The temperature inside the drum is monitored closely.

The drum then sprays these pills with a thin film of layer consisting of the desired agents. The air flow provides the drum with air causing the pills to rotate so that they can be coated evenly on all sides whilst keeping the temperature constant.

The coated pills are now dried by the heated air which blows in from the air inlet. The atmosphere inside the drum is kept at negative pressure value to keep the process isolated from the outside environment.

7.What are the components of pill coating machine?

There are several parts of this machine, each playing a unique role. Let us take a look at these parts.

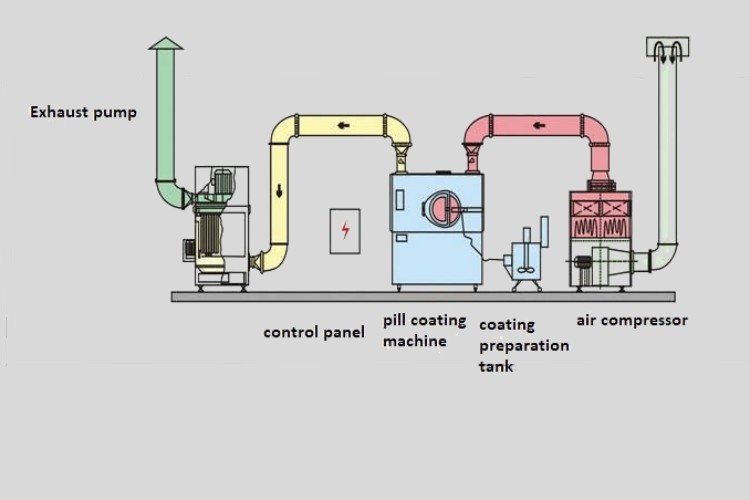

Electric motor: this is the main component of the body which provides the machine with electric current to run all its operation, from coating the pills to drying them.

Pill hopper:this hopper is used to hold the pill in place when it is being coated. It is customizable and comes in different shapes and sizes to accommodate the concerned pill.

Control panel:this is an automated part which controls the whole operation of the machine. It is also the site where the parameters can be adjusted accordingly.

Spraying system:this system consists of nozzles, tank and a pump which are responsible for spraying a fine coat of film onto the pill evenly.

Coating preparation tank:this is the area where the coating of the pill is prepared and stored.

Air compressor:air compressor provides a pressurized spraying of the coat so that a fine layer of film adheres to the pill.

Vacuum pump:it removes excess heat, moisture and air to ensure an even coating.

Exhaust pump:it ensures that any vapors or fumes are removed from the drum to ensure the safety of everyone working around it.

Heating system:this system ensures that the temperature is kept constant so that the pills are coated evenly.

8.How can you improve the coating efficiency of pill coating machine?

There are several ways to improve the coating efficiency of pill coating machine. This will not only minimize wastage but also increase your profit margin. Let us take a look at some of the ways below.

Installing a level sensor

Sometimes, when the pills are being coated, the coating suspension can get contaminated with foam, causing defects in pills. Installing a level sensor in your coating tank will prevent formation of foam, thus enhancing the efficiency of the machine.

Check the maintenance of the machine regularly

You should always check if your machine is working in optimum condition regularly to prevent its breakdown which will immediately halt the process. This will enhance the efficiency of the machine, making it more productive.

Install exchangeable drums

Exchangeable drums are excellent choice for installing in your production line. They can be allocated to a specific batch of drugs. Moreover, they do not have to be cleaned with every new batch since you can change it with a new drum. This not only saves time but also reduce costs.

Using continuous coating system

This system has a small diameter drum which ensures the uniform coating of the pills. It also doesn’t need a lot of changeover between each batch of pills. Thus, using this system will increase the overall output of the machine.

Training your staff

Consider training your staff about the basic skills required to maintain the machine. This will greatly reduce the possibility to call for specialized people every time there is a problem in the machine. The staff would easily be able to handle the minor problems.

9.What are different types of pharmaceutical pill coating?

Sugar coating

Sugar coating, as the name suggests, is made up of sugar solution with desired colored compounds which is then used to coat various substances such as capsules, tablets and candies. This coating provide sweet taste and vibrant color to the pills.

Film coating

Film coating uses polymer which provides strong mechanical support and protects the pills from oxidation. Moreover, it also helps in controlling the release of drug when it enters the body to target a specific tissue.

Enteric coating

Enteric coating is important in those drugs which need to pass through stomach due to its acidity. Enteric coating protects the pills from degradation due to acidic environment in the stomach. Plus, it also helps drug release only at its target cells.

10.What kinds of pills can be coated by using pill coating machine?

Several kinds of pills can be coated making this machine a highly versatile one. Let us take a look at some of the products which need coating.

Candies

Many candies require different coatings such as sugar and chocolate coating. Using pill coating machine can add sweetness to their flavor and make them more attractive.

Tablets

Tablets are medicinal drugs manufactured in pharmaceutical industry which are used to treat diseases. These tablets too need to be coated to mask the unpleasant taste and odor to make them easy to ingest.

Paintballs

Paintballs are used in gaming where the opponents put them in paintball guns and shoot and eliminate each other. They are coated with colorful pigments to make them attractive and shiny.

Wax beads

Wax beads are produced in cosmetic industry and are used to remove unwanted body hair. Using pill coating machine to coat them is necessary to protect them from melting and to give them a nice and shiny appearance.

Textile beads

Textile beads are small circular shaped balls which are stitched on clothes to give them an aesthetic look. Since their purpose is to make dresses prettier, coating them will make them more beautiful.

11.What materialsare used to coat pills?

The materials and films used for pill coating are specific for specific requirements. Each material and film has its own unique property.

Polymer

Polymer based material such as ethyl cellulose and methylcellulose are used to coat tablets, pills and capsules. These polymers provide strong protection and stability to these pills, making them highly resistant against harmful factors.

Plasticizers

Plasticizers are low molecular compounds which are used in coating to increase the elasticity and flexibility of the coating solution. This solution is then used in paints and dyes. Examples of plasticizers are glycerol, organic esters, coconut oil and castor oil.

Solvents

Solvents are primarily used in the drying process of the coating since it dissolves the coating layer quickly by evaporation process. Some examples are acetone and ketone.

Pigments

Pigments are insoluble materials which give color and a glossy shine to the pills and tablets. These pigments thus improve the overall appearance of the pills and make them more attractive and vibrant.

12.What are the problems and troubleshooting of pill coating machine?

| Problems | Troubleshooting |

| Sometimes, the pills stick together due to a defect in coating process | The temperature and air control should be adjusted to prevent pills from sticking together. |

| The uneven coating causes bumpy effect on pills due to low spraying pressure or extremely hot air. | Increase the spraying pressure and lower the temperature. |

| The pills become chipped or eroded due to brittleness. | Add the desired solvents to reduce the viscosity of the coating solution. |

| Presence of light and dark patches called mottling appear on pills. | Reformulate the coating solution to ensure a uniform coating. |

| The coating of pills peel off | Lower the spray rate and drying time of the pills. |

| Cracks appear on edges or tips of the pills due to excessive internal strain. | Add polymers in the coating solution to increase the weight, adding tensile strength to it. |

Conclusion

By discussing all the points above, we can deduce that pill coating machine is a versatile, highly efficient and a cost effective machine which is capable of coating several kinds of pills and tablets of various shapes and sizes. This machine has the ability to be used in several kinds of industries, ranging from small scale businesses to large scale industries. Thus, it is an excellent choice for any customer who is looking for a pill coating machine of a high caliber.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide