Bag Closer Machine Near Me | Top Bag Closer Machine Nearby

Bag Closer Machine Near Me | Top Bag Closer Machine Nearby

Bag closer machines are one of the latest technologies that industries are using globally. Bag closer machines can increase your productivity and are one of the best advancements to enclosed bags efficiently and quickly. Not only industries but bag closer machine is now used in the home or cottage industry too.

But getting a bag closer machine near me for households or industries still remains a question. How can we find bag closer machine near and what are its basic requirement. This article will guide you regarding bag closer machine near me or nearby. So let us go!

1.Bag Closer Machine Near Me

Strategies are required before selecting a bag closer machine near me as it supports in interacting with professionals and taking their guidance. Online advertisement can be pleasant but getting bag closer machine near me from offline stores can be more beneficial. All your doubts can be cleared by going for bag closer machine near me.

This article supports you to learn what bag closer machine near me is and how can we get benefit from it. How these machines can be selected and what are the steps to navigate the best bag closer machine near me to get convenient solutions?

2.What Is Bag Closer Machine?

A bag closer machine can close your filled bags in a highly efficient and precise manner like a sewing machine. Bag closer machines are demanded globally nowadays because they stand up to sew poly, textile and paper bags with high reinforcements. You can operate a bag closer machine in a simple manner and there is no requirement of any prior expertise.

You can apply bag closer machine in packaging, agricultural and industrial environments. Depending upon the usage, a bag closer machine is available in manual, semi-automatic and fully automatic mechanism.

3.Benefits Of Buying From Bag Closer Machine Near Me

Buying the right type of bag closer machine near me can benefit you in numerous ways like

Experienced Professionals

Bag closer machine near me offers its customer to get directly interact with experienced and professional individuals that can guide, help and advice you. These professionals can assist you in buying the right type of bag closer machine for the right place and help you in selecting the one that best suits your business.

Quality Assured Machine

Bag closer machine near me allows you to first check and then purchase a bag closer machine. Bag closer machine near me ensures timely availability of spare and incase of any mishap, the seller can directly be contacted for further assistance rather than waiting for delay responses.

Bargaining Facility

The seller gets physically involved in the purchasing situation in bag closer near me. This process creates a room for bargaining and obtaining maximum possible discounts. The prices are not stagnant and flexibility can be shown by the offline dealer of bag closer machine near me.

Quick Buying Facility

Bag closer machine near me allows you to get your desire machine in no time and eliminates long waiting factor due to shipment. You can go through variety of options near me and get the best one back in a short time of period.

Pre-sale and After-sale Expertise

While going to purchase a bag closer machine near me, highly experienced professionals are there to guide you completely regarding the machines feature. You can learn all the machine related operation before getting it.

Once you have purchased the machine, after-sale services are also always there to guide and facilitate regarding any problem. They can even conveniently and voluntari

4.How To Find A Bag Closer Machine Near Me?

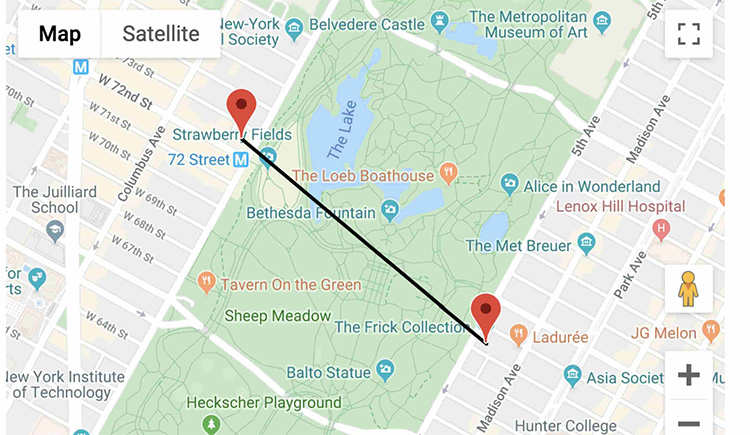

For finding the right and authentic store for bag closer machine near me, you have to get assistance from technology. You can use either of the navigation system on you mobile, laptop or any of the electronic devices and then follow following steps

Searching For Bag Closer Machine Near Me

At the initial step, you need to identify keywords regarding bag closer machine near me. Type the keywords like “bag closer machine near me”, “what are the top bag closer machine stores near me”?, “bag closer machine” or etc into the search engine, such as Google.

It will show you all the available coordinates near me and help you to find their locations. The technology will calculate you the exact distance from your place to the store of bag closer machine near me.

Locate The Bag Closer Machine Near Me

In the next step, you need to filter out the best and closest bag closer machine store near me that best fits on all required criteria’s. Calculate the total distance of that store from your place.

All the external factors like whether the store contains variety of brands or not, their price ranges and also their previous customers review should be checked properly. This will save your time and get you complete knowledge and market reputation of that store.

Heading Toward Bag Closer Machine Near Me By Following Directions

After selecting the best offline store, you need to head towards it in the final step. Plan your route according to your feasibility and transport conditions. Navigate your device towards the store and follow the direction to reach your destination. Travel safely and select the best mode of transportation for you.

5.How To Choose A Bag Closer Machine Near Me?

Keeping all the requirements under consideration, you need to select the best bag closer machine near me because you cannot rely on each of those. They key points for choosing a bag closer machine near me are

Near Me Distance To Store

The first and foremost requirement of a bag closer machine near me is the calculated distance of that store from your location. Number of factors including far distances, unsafe travelling, not suitable voyage, unavailability of public transport and etc. can be considered before choosing the right bag closer machine near me.

Product Brand Reputation

These machines are bought once in a blue moon for any operation. This is why it is necessary to select the best and experienced brand for a bag closer machine. Also it is important to select the best bag closer near me that have accumulated variety of brand options and with good market reputation.

Machine Quality

Relevant manufacturing websites of brands can be searched in parallel to gather maximum information regarding bag closer machine. This searching will prevent in selection of poor quality brands and help to go for the right choice of bag closer machine near me.

In Hand Stocks

In a bag closer machine near me, you have complete access to go through all the available machines and select the one according to your requirement. Although less stocks can be found in an offline store but this will ensure you to see greater inventory maintained in a bag closer machine near me.

Top Bag Closer Machine Near Me Online Ranking

5.0

INPAK SYSTEMS

Description:

Inpak Systems are expert in producing and distributing variety of industrial bagging and packaging equipment with over 20 years of experience. The company was founded back in 1986 and is not Midwest’s leading supplier and manufacturer.

Their two locations have a stock limit of over 10,000 units and ship 24 hours a day. They have been associated with 45 manufacturers globally and are increase on daily basis.

Recent Review:

“Inpak systems are expert in providing quality bag sewing and closing machines that I require for my business. It has been a great experience in using their product”.

5.0

Allpack

Description:

Allpack is a professional packaging equipment manufacturer with 11 years experience in packing machine labeling, and they focus on round bottles. They can solve & support your packaging equipment challenges, so you can grow your business.

The company covers range of production areas like carton packaging, sealing, strapping, vacuum packaging, capping packaging, labeling, pharma machinery, coding and marking machines, and so on.

Recent Review:

“Allpack is the most professional partner I have ever met. They provide the excellent great pre-sales and after-sales service and 24/7 online support. With the complete shop and return policies, all my requirements are fulfilled. They are responsible for all after-sales problems.”

5.0

VEVOR

Description:

VEVOR is a leading brand specialized in equipment and tools with an experience of over 10 years. Over 10 thousand motivated employees, VEVOR has shown dedication in providing DIYers and professionals with tough equipment & tools at the lowest prices. Today, VEVOR has satisfied over 10 million customers in more than 200 countries and regions.

Recent Review:

“I needed to re-stitch a mattress cover after cutting the mattress to custom fit a different shape. This thing is strong, durable and easy to use. Definitely able to handle strong thread from versatile positioning. Buy it.”

5.0

OK SEALER

Description:

With over 40 years of experience, OK sealer was founded in 1982 in United States Of America. They have spread their network in 0ver 60 countries globally and are leaders in producing bulk packaging systems and heat sealing bag technology. OK sealer provide wide ranges of bag closer machines depending upon their application.

Recent Review

“ Great experience to use product of OK sealer corp.”

5.0

SALTECH

Description:

Sal-Tech EasyPackaging started in 1992 in Denmark and began its operations in 1995. Sal-Tech EasyPackaging is specialists in packaging machinery solutions within the fields of wrapping, strapping, banding, sealing, filming, loading, positioning and packaging related machines and tools.

Recent Review

“Can’t find a better experience than Sal-Tech easypackaging. It has been an amazing source for providing the best sealing and closing solutions”.

Conclusion

Bag closer machine near me will help you out in selecting the desire products that falls on the requirements. Offline stores provide benefit in physically inspecting the machines and looking into its features. This article best explains you how to get a bag closer machine near me and if still there are some questions you can feel free to ask 24/7 or visit our website http://www.allpackchina.com/ .

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Bag Closer Machine Near Me | Top Bag Closer Machine Nearby Read More »