Tablet Bottle Filling Machine: The Complete Buying Guide In 2025

Tablet Bottle Filling Machine: The Complete Buying Guide In 2025

Filling exact amount of tablets, pills and capsules in bottles is the most responsible task in pharmaceutical packaging.This is because incorrect counting and filling of tablets in bottles will create difference in the amount of bottles mentioned on labels and tablets present in the bottle. In this way, it can lead to customer doubts about products and ultimately the demand for your products may fall. To tackle this issue, Allpack has manufactured innovative style cutting edge tablet bottle filling machine.

This tablet bottle filling machine is carrying with it immensely sharp technology for precisely filling the bottles with tablets on zero error principle. It also has simple operational procedure, compact structure and premonition to give excellent outcome. This, along with worthy to know information has been accumulated in this buying guide to better assist you in acknowledging the proficiency of tablet bottle filling machine. So, be ready to end your curiosity!

1.What Is A Tablet Bottle Filling Machine?

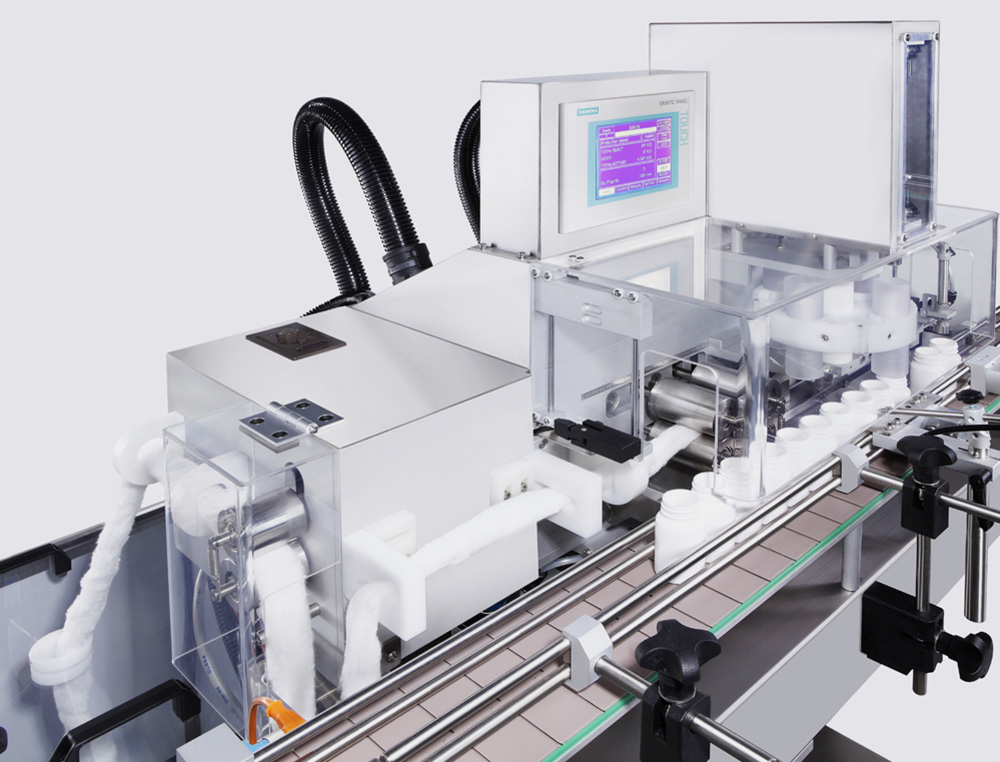

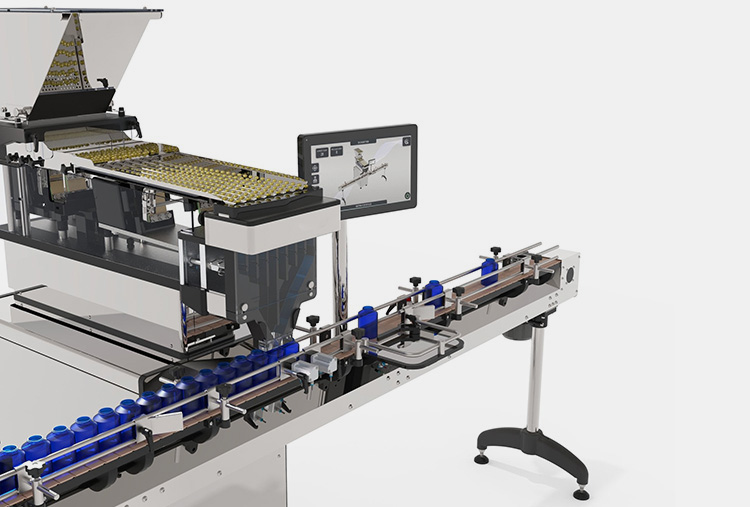

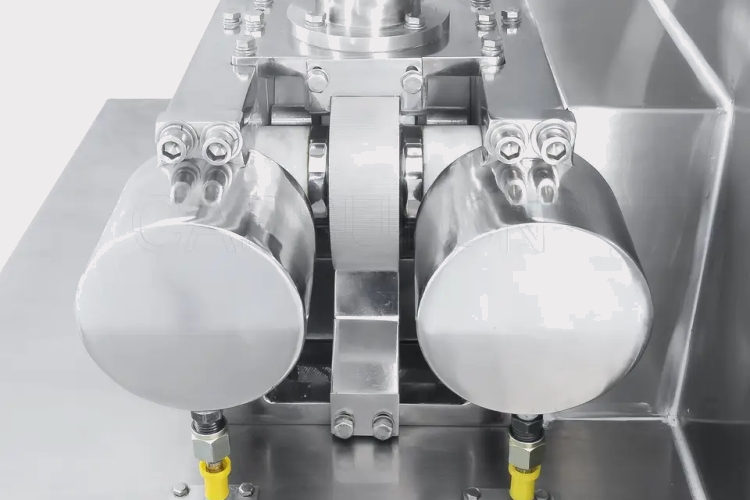

Tablet Bottle Filling Machine-Allpack

Tablet bottle filling machine is a composite assembly of various systems which together contributes to the fulfillment of its main task, precise amount of tablet filling in bottles. The machine is made up of 304 corrosion resistant stainless steel which is fully safe from bacterial presence. It has integrated system of electric detection which greatly helps in eliminating product waste as well as false counting and filling of tablets.

The machine adopts effortless procedure of tablet filling by releasing the tablets from hopper onto vibratory trays and passing them through counting phase and eventually accomplish the process. To add into context, it is perfectly capable of processing large number of products including tablets, capsules, candies and grains, thus, can be used in industries with diverse backgrounds.

2.Explain The Essential Attributes Of A Tablet Bottle Filling Machine?

A tablet bottle filling machine has been made with essential features which are discussed below:

Zero Fault System

No fault logo-Picture Courtesy: nofaultnoproblem.com

A tablet bottle filling machine is equipped with the most advance feature of automatic detection through which it follows the principle of no bottle no filling, empty bottle rejection and eliminating bottle overlapping. Hence, the chance of erroneous filling become zero.

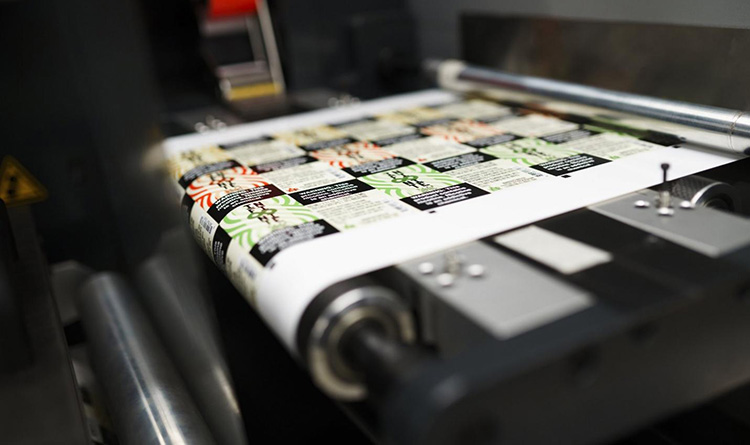

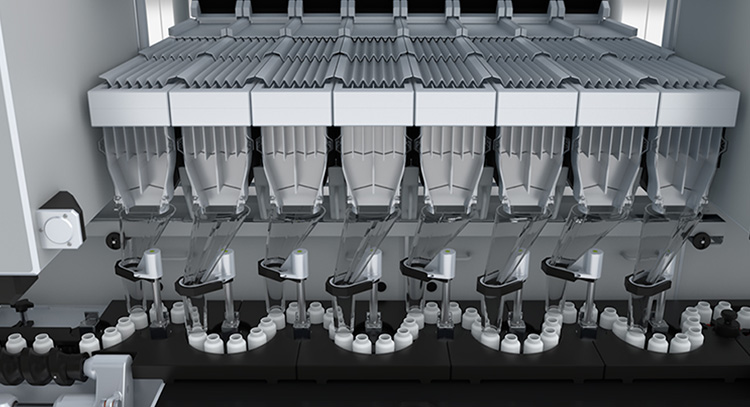

Multiple Channel Configuration

Counting channels of tablet bottle filling machine-Picture Courtesy: Cremer

With up to eight counting channels, this machine provides you multiple configuration for counting tablets. Each channel can process large number of tablets at the same time, similarly, the tablet bottle filling machine is helpful in larger production.

User-friendly

User-friendly icon-Picture Courtesy-pngkit.com

The PLC control system has made the machine more user-friendly. By using it, operator simply set all the desired commands into machine and the machine fulfill tablet bottle filling while following these commands.

Hygienic

Capsule filled bottles in machine-Picture Courtesy: Cremer

Tablet bottle filling machine is made with antibacterial stainless steel in compliance with GMP's requirements. It is fully safe for highly sensitive pharmaceutical tablets and pills as well as for other food items.

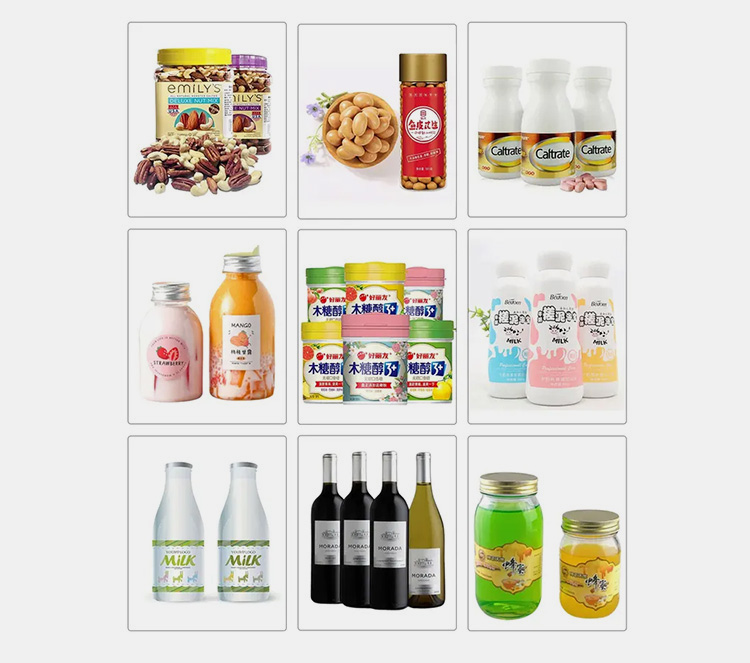

3.Is The Tablet Bottle Filling Machine Capable Of Filling DiverseContainers?

Definitely! A tablet bottle filling machine is perfectly capable of processing not only bottles but other packaging containers as well, such as:

Jars

Jelly in glass jar-Picture Courtesy: Lisa sligh

As jars are preferably used for their resistance to moisture, most of the confectionaries are packed in it. Therefore, these jars can be processed by this machine.

Cans

Confectionary presenting idea-Picture Courtesy: Alice Grey

Cans are metallic containers often used for their durable structure to store food items. Tablet bottle filling machine is capable to process it.

Bags

Standup pouches-Picture Courtesy: Behance

You might be surprised to know that bags are also eligible for filling by this machine. Hence, you can process your beautiful bags by tablet bottle filling machine.

Bottles

Tablet bottles-Picture Courtesy: stylish creative

All types of glass and plastic bottles can be used to filled with tablets by this machine.

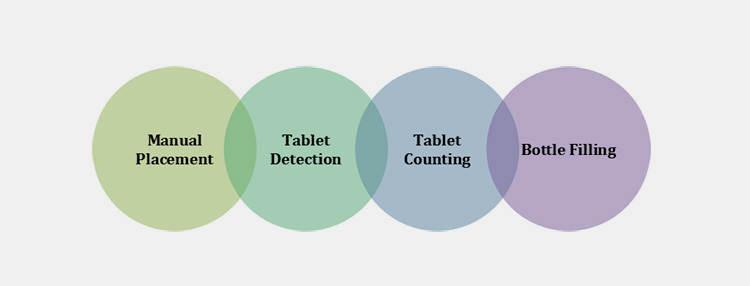

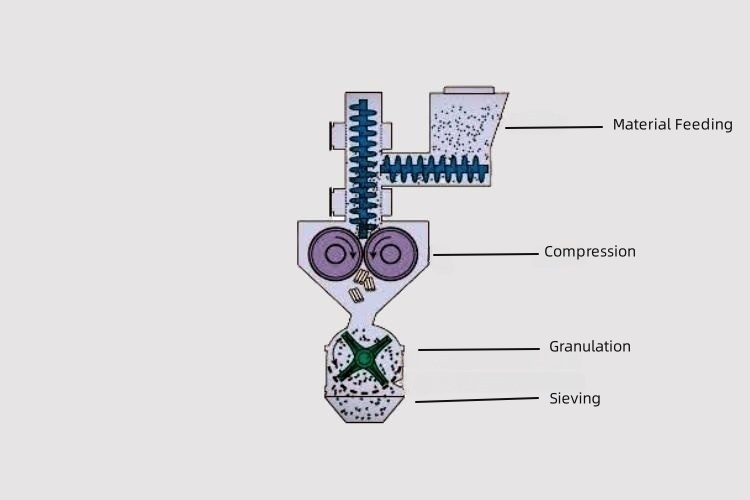

4.How Does A Tablet Bottle Filling Machine Function?

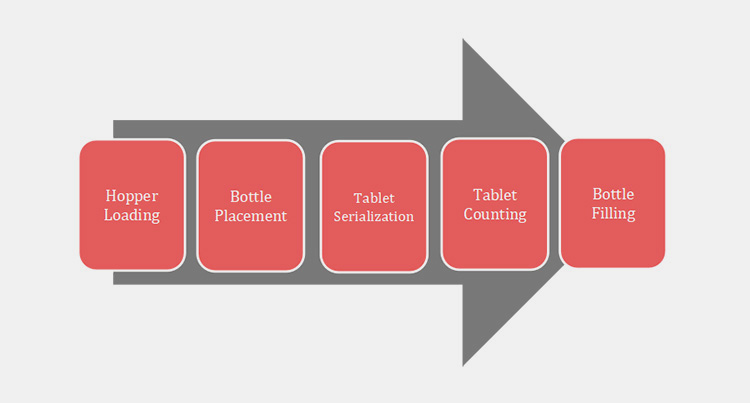

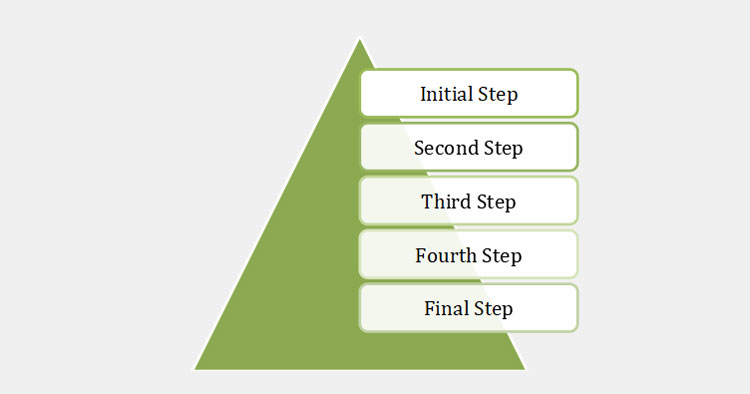

Tablet bottle filling machine follows pretty straightforward procedure for filling bottles with tablets. The steps which it follows can be better understood by looking into the underlying principles:

Hopper Loading

Hopper with capsules-Picture Courtesy: Bellatrx

In order to make the machine function, the foremost step required is to load the hopper of machine with enough volume of tablets or any other eligible stuff like candies or capsules etc.

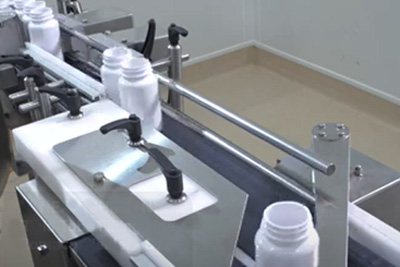

Bottle Placement

Bottles entering tablet filling station-Picture Courtesy:

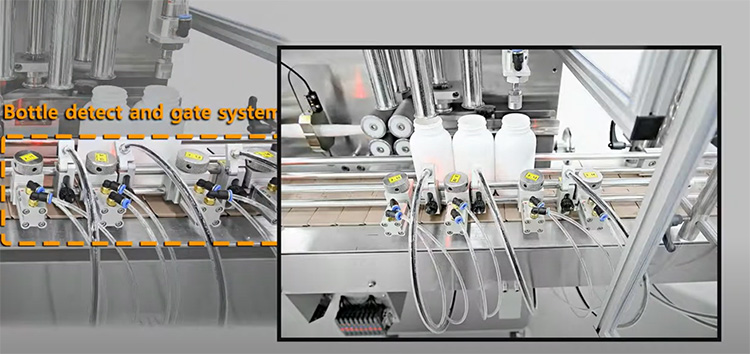

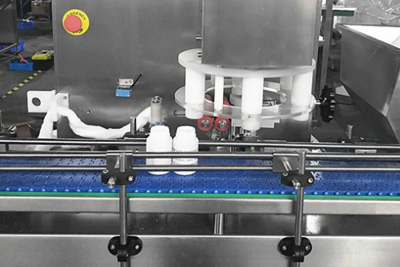

Now, the second step of tablet bottle filling machine requires an operator to have provided the machine with sufficient number of bottles for filling. For this, user can manually place bottles in case the machine is semi-automatic, or the bottles will be automatically fed onto conveyor belt through bottle unscrambler in fully automatic tablet bottle filling machine.

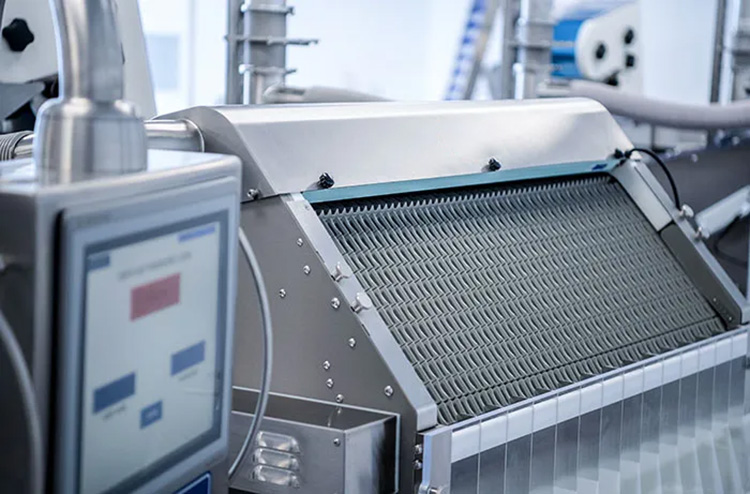

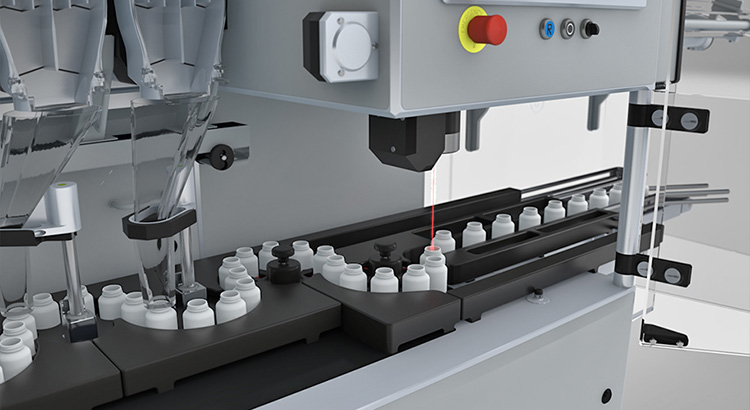

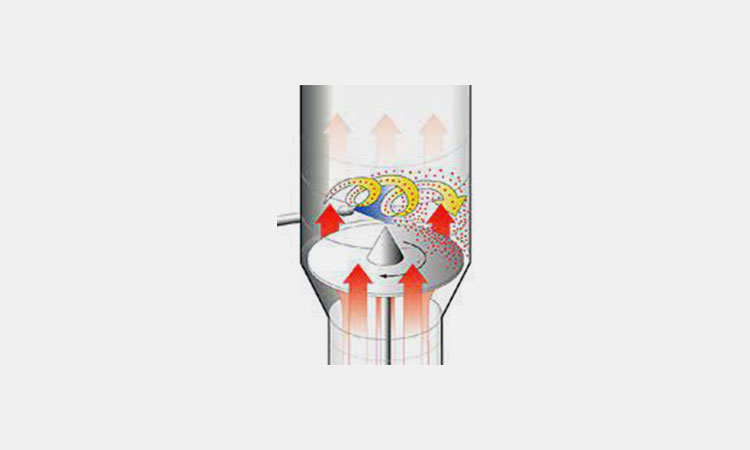

Tablet Serialization

Capsules on vibratory trays-Picture Courtesy: NJM packaging.com

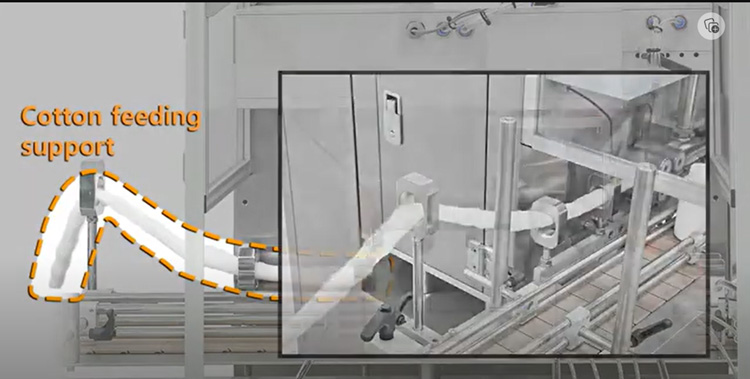

Proceeding further, right after the machine is switched on, tablets will start releasing from hopper onto vibratory trays. Here, the vibration motor creates shaking sensation which leads the tablets to fall into individual units of trays. Therefore, all tablets form the linear direction sequentially.

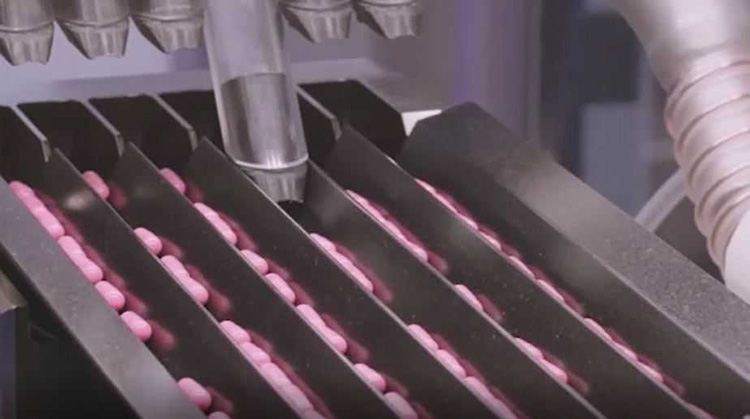

Tablet Counting

Moving to the next step, the serialized tablets fall into counting compartment where tablets are counted via electric detection system and delivered to the filling nozzles.

Bottle Filling

Filling of bottles-Picture Courtesy: Bellatrx

Finally, when the presence of bottles are detected by sensors, sleeve hopper putted down the accurate number of tablets into bottles.

Bottle Discharging

Bottles undergoing filling and detection-Picture Courtesy: Cremer

After the bottles get filled, conveyor belt takes them towards discharge chute. During this phase, the bottles which left empty or having broken tablets are separated from the accurate one via rejector.

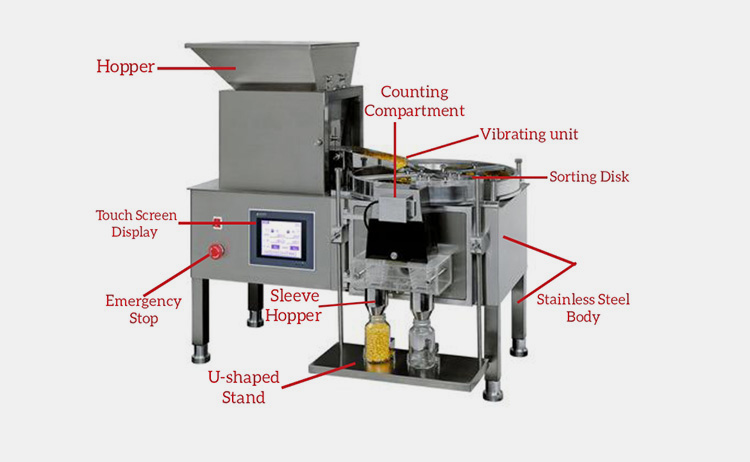

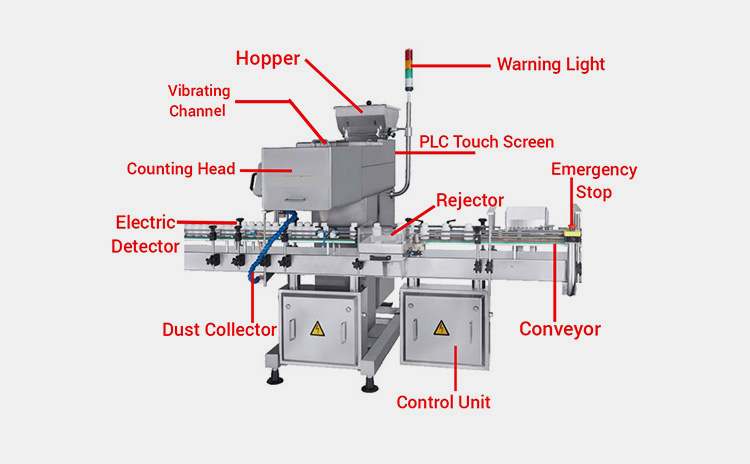

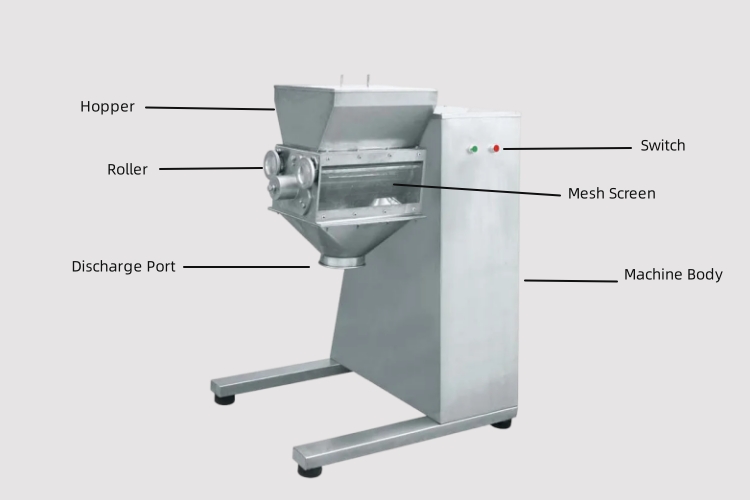

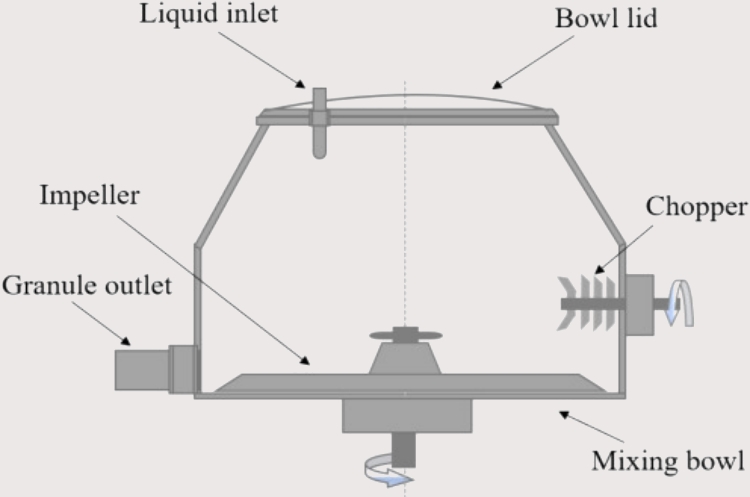

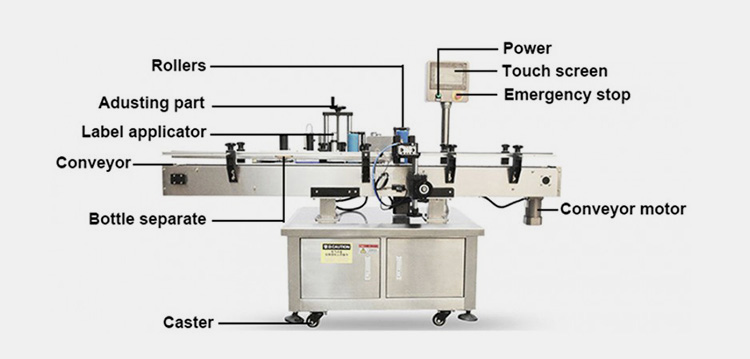

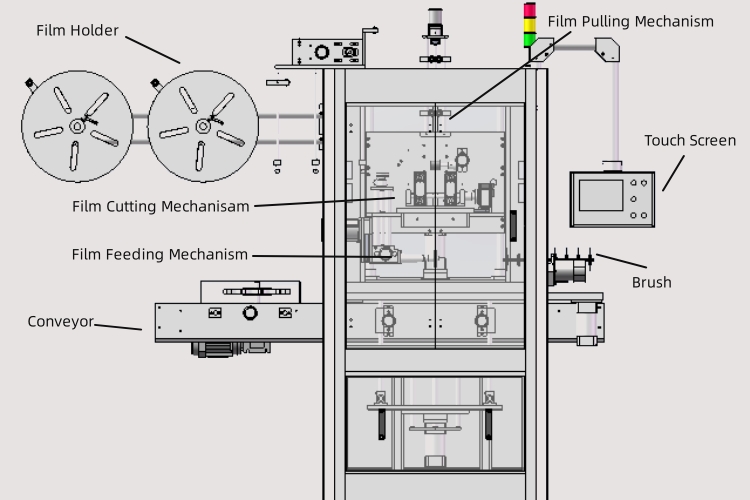

5.Describe The Various Components Of A Tablet Bottle Filling Machine?

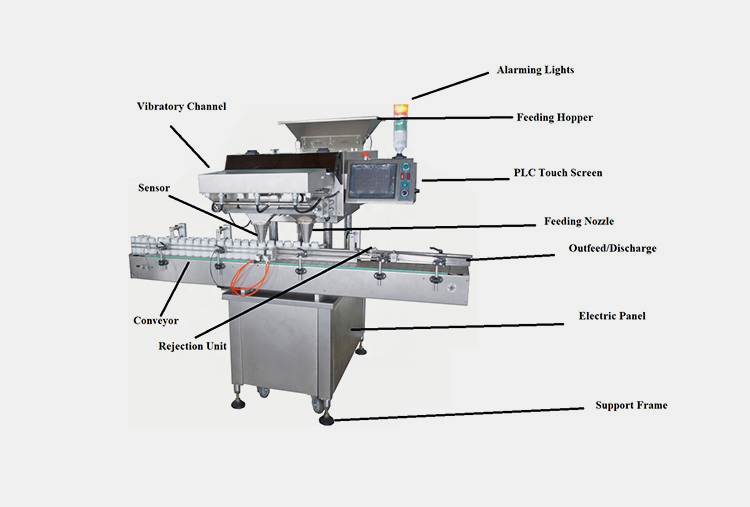

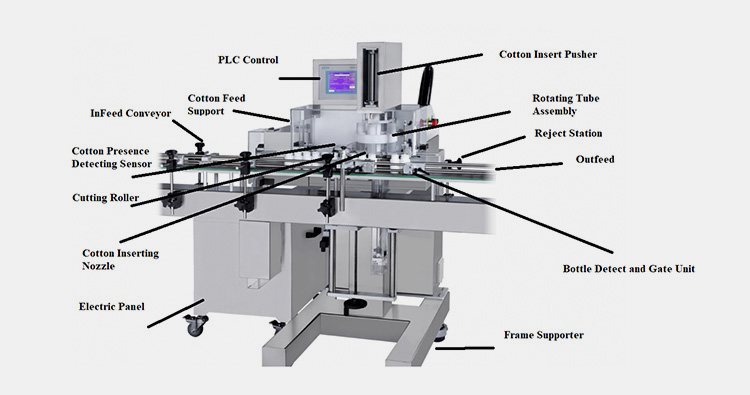

Structure of tablet bottle filling machine- Picture Courtesy: CVC Technologies

A tablet bottle filling machine is the composition of several components located top to bottom of the machine. These are described below:

Hopper

Hopper is the feeding unit of tablet bottle filling machine where tablets are loaded which are to be filled in bottles.

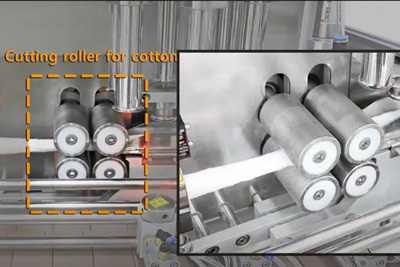

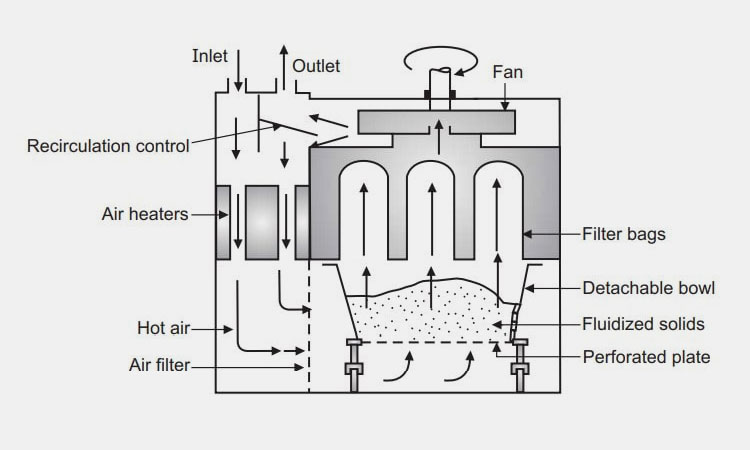

Vibrating Channel

Vibrating channel consists of vibratory trays attached to the hopper of machine. These vibratory troughs help in serializing the tablets which are released by the hopper.

Counting Head

This part of tablet bottle filling machine is also known as counting compartment. It has electric detection system which detect the tablets and count them before delivering to sleeve hopper.

Sleeve Hopper

Sleeve hopper is a type of filling nozzle which holds in it the counted tablets and dispense them into the bottles.

Electric Detector

It is the photo electric eye located on infeed conveyor. Its function is to detect the bottles and maintain distance between them to avoid haphazard.

Dust Collector

Dust collector play crucial role in sucking dust from tablets during vibration phase. With the help of attached pipe, dust is separated and collected in a bin.

Control Unit

Control unit is a box type device often located in the front lower side of the machine. It holds all the electrical components of machine including wires and switches, thereby, work as a core point of control.

Conveyor

Conveyor is a guide rail onto which objects like bottles are circulated for filling in a tablet bottle filling machine.

Rejector

The place of rejector comes after the bottles are filled. It thus helps in rejecting the bottles which are unfilled.

Emergency Stop

Emergency stop in tablet bottle filling machine serves as a security device which can be brought into use in case operator finds machine is misbehaving.

PLC Touch Screen

PLC touch screen is the main operational device in the machine which provides operator with multiple options in form of displaying the features of machine including speed, counting number and detector setting etc.

Warning Light

The warning light also known as tower light is the combination of audiovisual indicators which in tablet bottle filling machine enables the user about ongoing working process. For instance, if the machine gets over-heated due to constant working, the alarm will alert operator through red light and alarm bell.

6.Which Products Can Be Filled By A Tablet Bottle Filling Machine?

A tablet bottle filling machine is an excellent equipment to deal with vast array of objects for filling into bottles. These products are enumerated below:

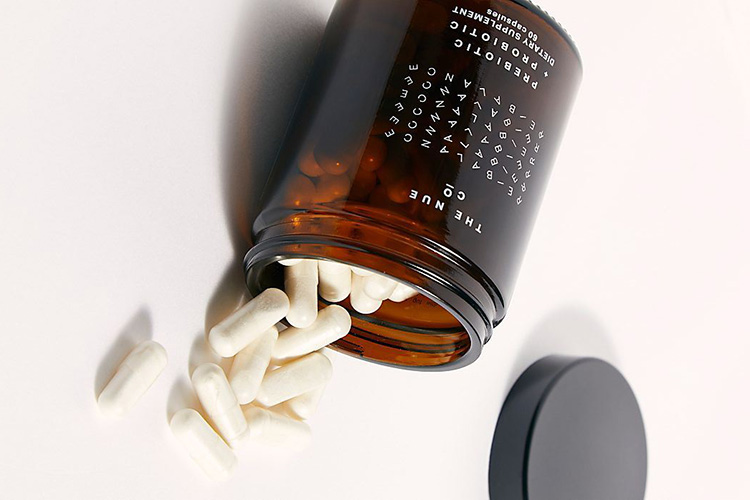

Tablets & Pills

Tablets & capsules-Picture Courtesy: Nu.nl

Tablets and pills consists of medicine powder which when compressed form the shape of tablets and pills. These can be filled by tablet bottle filling machine.

Hard Solid Capsules

Granulated solid capsules-Picture Courtesy: Conscious life news

Both solid and liquid capsules have hard external shell which is filled with solid or liquid dosage form including powder, granules, fluids or mixture of these.

Softgel Capsule

Softgel capsules-Picture Courtesy: Kimberly synder

As the title illustrates, softgel capsules are made up of soft gelatin-based shell inside which liquid dosage is filled. Some examples of softgel capsules include Omega-3 softgel capsules, vitamin and proteins softgel capsules etc.

Candies

Candy jar-Picture Courtesy: mylife.myloves

Candies and other sweet confections including jelly, toffee, chocolate balls and gummies etc., can be filled in bottles by tablet bottle filling machine.

Bubble Gum

Bubble bottle-Picture Courtesy: Behance

It is a type of chewing gum with different sweet and sour tastes. As the size of bubble gum is often small, so, they can be filled by tablet bottle filling machine.

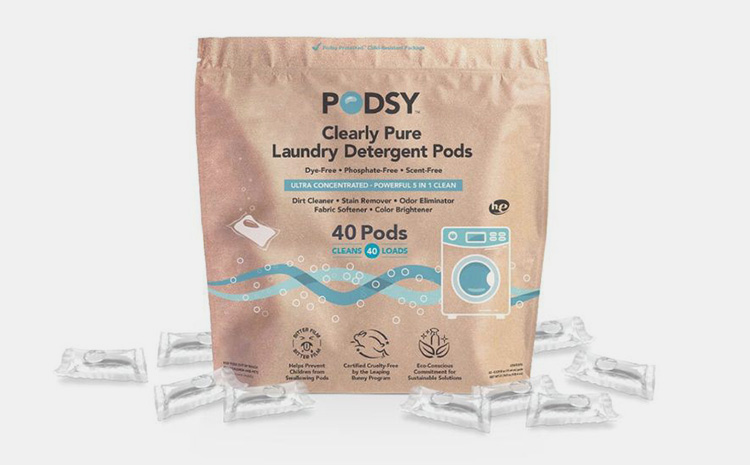

Liquid Pods

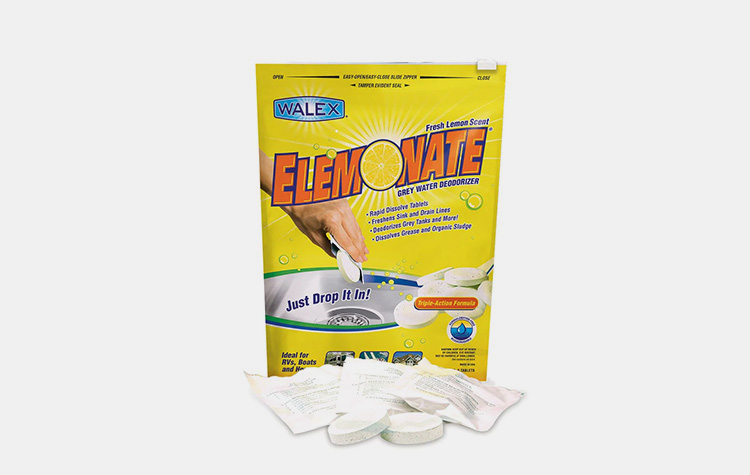

Double layer laundry pod-Picture Courtesy: Popsugar

Liquids pods are small plastic bags containing liquid dosage for various purposes. For instance, laundry pods contain liquid detergent which is used for washing clothes and similar stuff.

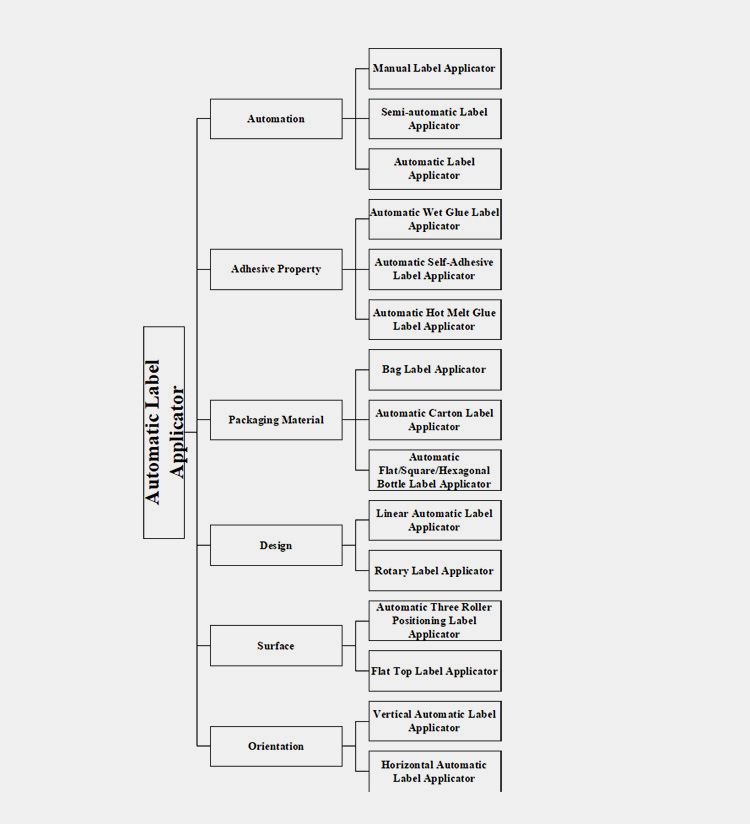

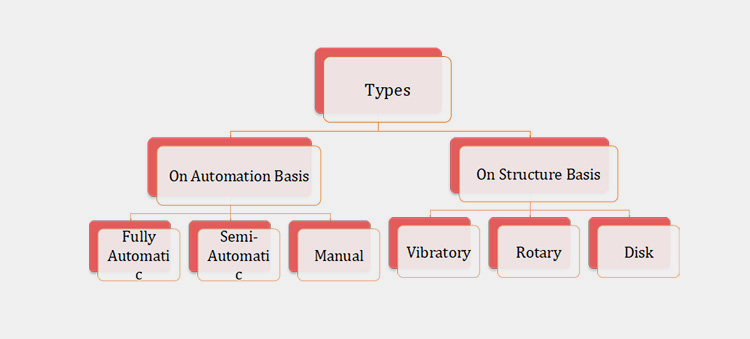

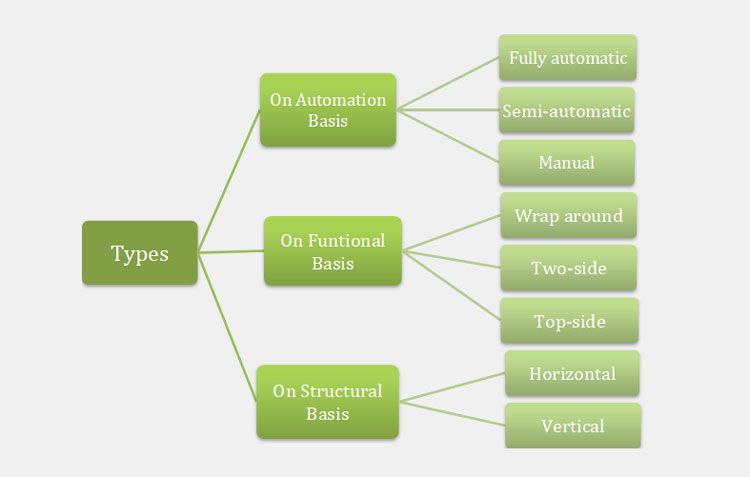

7.What Are The Types Of A Tablet Bottle Filling Machine?

Tablet bottle filling machine has various types which can be fundamentally divided into two classes: types on the basis of automation, and types on the basis of structure. In below paragraphs, these types will be elaborated clearly:

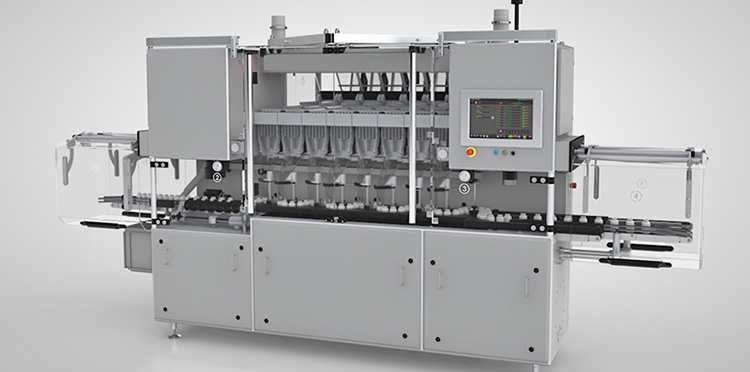

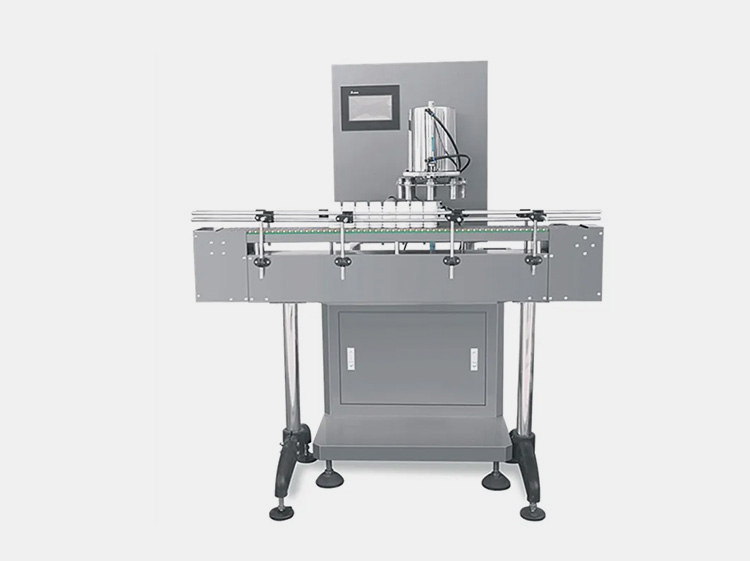

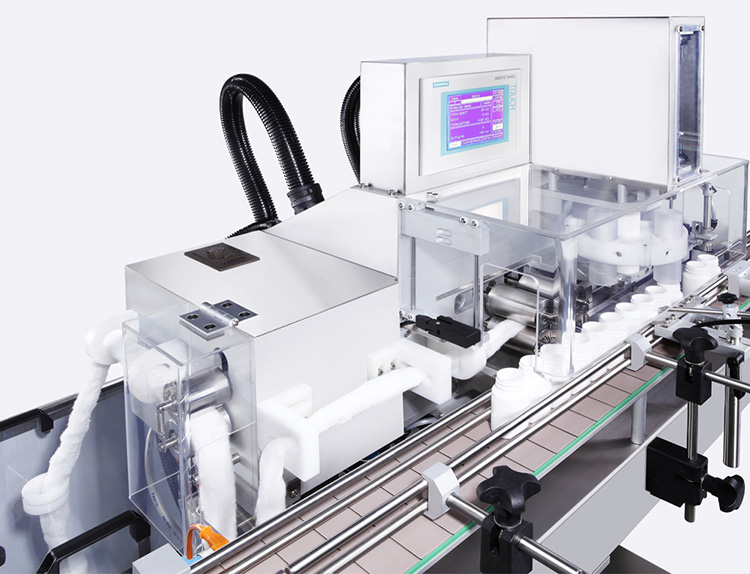

Fully Automatic Tablet Bottle Filling Machine

Fully Automatic Tablet Bottle Filling Machine-Allpack

Fully automatic tablet bottle filling machine is a lucrative machine with cutting edge technology of high automation. The machine has been made with automatic detection system, multi-channel configuration, rejection system and adjustable vibration frequency. It is mainly composed of a large hopper, followed by multiple vibratory channels, counting compartment, PLC and stainless steel body etc. It undertakes the filling of tablet bottles automatically once the setting is done by operator. Hence, its non-stop bottle filling mechanism is the great opportunity for large scale industries to boost their production.

Semi-Automatic Tablet Bottle Filling Machine

Semi-automatic Tablet Bottle Filling Machine-Allpack

Semi-automatic tablet bottle filling machine is on the second number in list of automatic machines. It has precise structure while encompassing all the attributes of fully automatic tablet counting machine except the limited production capacity and manual intervention. It requires an operator to be part of the tablet bottle filling during operation by manually placing and taking out bottles. Therefore, this affordable machine is the most suitable solution for medium scale production facilities.

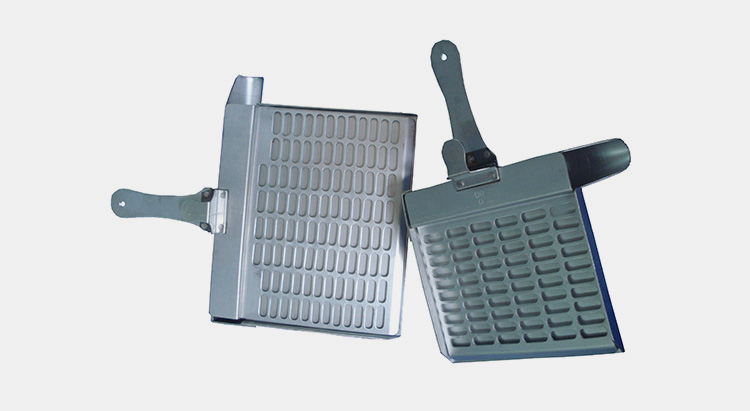

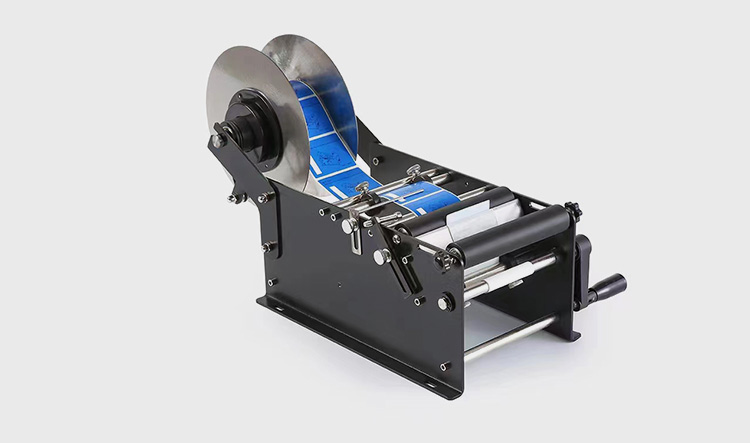

Manual Tablet Bottle Filling Machine

Manual tablet bottle filling machine-Picture Courtesy: Kahaninternational.com

Manual tablet bottle filling machine is the most handy machine with small footprint. Every layman can take advantage of this cheap but reliable machine for running their small business. It is small in structure in size with a handle, perforated tray, a back and small chute for discharging tablets. All these parts are made with stainless steel.

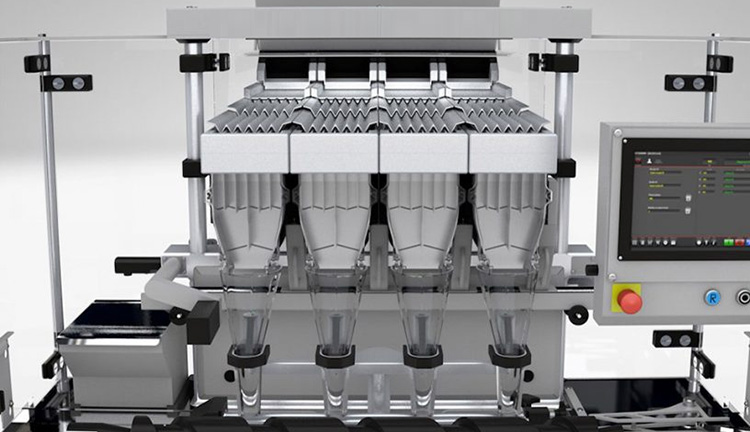

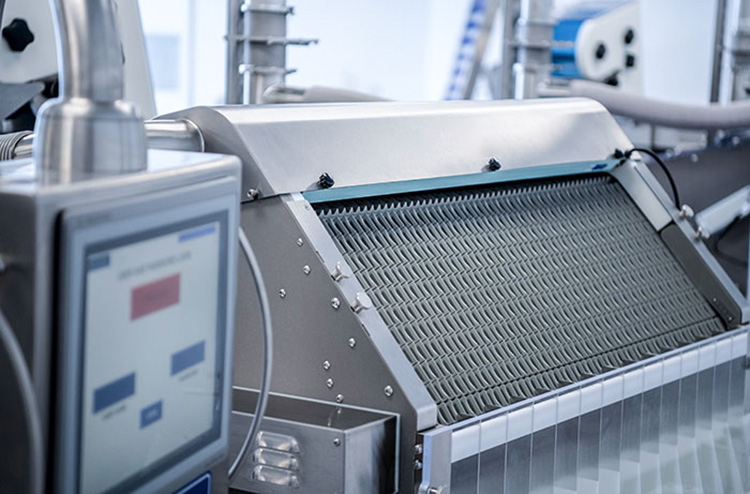

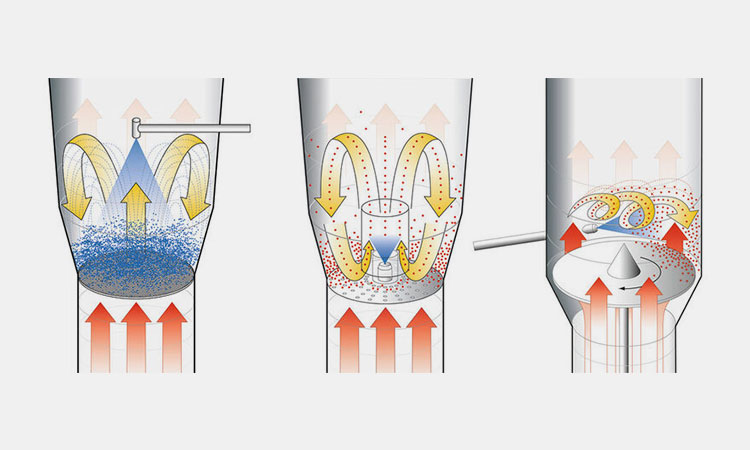

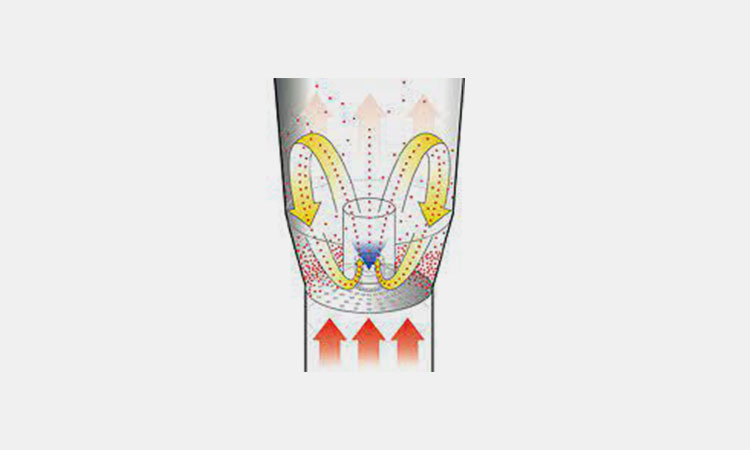

Vibratory Tablet Bottle Filling Machine

Vibratory Tablet Bottle Filling Machine-Allpack

Vibratory tablet bottle filling machine is the standard tablet bottle filling machine which has a vibratory channel for the counting of tablets. It mainly consists of a hopper, vibratory trays, counting head, filling nozzles, conveyor and main frame. The process of tablet bottle filling starts by machine releasing tablets from hopper onto vibratory trays where sequence takes place followed by the counting and ultimately filling of tablets into bottles. This machine has high production capacity, therefore, it is suitable for large scale industries.

Rotary Tablet Bottle Filling Machine

Rotary Tablet Bottle Filling Machine-Allpack

Rotary tablet bottle filling machine is an advance equipment with proficiency in tablet counting as well as filling in one go. Its rotary counting channels enable the user to fill large number of bottles with tablets. This machine by Allpack can store up to 10 groups of settings, thereby, allowing you to easily switch for the setting which you needed. It is applicable to all types of tablets, capsules, pills and candies etc.

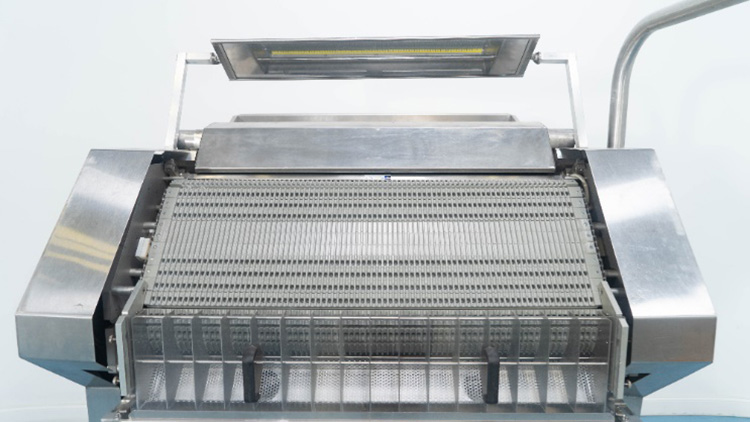

Slate Tablet Bottle Filling Machine

Slate Tablet Bottle Filling Machine-Picture Courtesy: Integrated Packaging System

Slate tablet bottle filling machine is unique design machine with unmatched speed and accuracy. It consists of a hopper, servo motor, single drive shaft system, perforated stale, automatic detection system, PLC control panel, stainless steel body and other parts. It undertakes the tablet bottle filling task by taking tablets from hopper and adding them into perforated mold slate. This slate is then powered by servo motor and move downward, where the tablets are released from molds into bottles. This fast tablet counting and filling has made this machine remarkable in its functioning.

8.What Are The Applications Of A Tablet Bottle Filling Machine?

A tablet bottle filling machine can be used for variety of products from different industries. Following details will disclose these areas:

Pharmaceutical Industry

Multiple hard dosage medicines-Picture Courtesy: freepik

All the solid dosage form of medicines under pharmaceutical industry can be processed by this tablet bottle filling machine including coated, uncoated tablets, capsules and softgel etc.

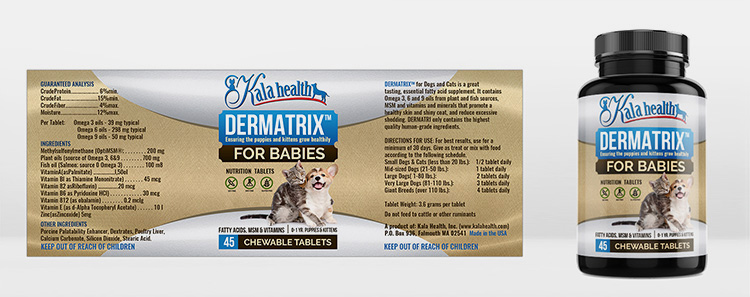

Nutraceutical Industry

Supplement capsule idea-Picture Courtesy: vitameros

Nutraceutical industry is engaged in manufacturing supplements from food sources like vegetables, fruits, pulses and dry fruits etc. Therefore, this industry is growing day by day due to the demand for supplements, and to achieve this aim, tablet bottle filling machine is often used.

Herbal Industry

Herbal powdered capsules-Picture Courtesy: smartfertilitychoices.com

There are plenty of herbal medicines extracted from herbs. These herbal medicines have little or even no side effects, as a result most of the people prefer using herbal medicines instead of pharmaceutical drugs. In this way, their need of tablet packaging in bottles can be fulfilled by this tablet bottle filling machine.

Confectionary Industry

Confectionary bottles-Picture Courtesy: confetti.co.uk

As there is no age restriction for experiencing the delicious and sweet taste of candies, gummies, chocolates and bubbles etc. Similarly, the significance of a tablet bottle filling machine can be realized in this sector where packaging confections is an obligatory task.

Skincare Industry

Beauty softgel capsules-Picture Courtesy: Carolin Hirons

Since skincare is the priority of every second person, skincare industry has introduced new ways of treating skin problems like tanned skin, dark circles and wrinkles etc., by manufacturing capsules and gummies containing vitamins, proteins and minerals.

Daily Use Chemical Industry

Detergent pods pouch-Picture Courtesy: Ralphs grocery

Another institution where the use of a tablet bottle filling machine can be find is the daily chemical industry, where detergent or laundry pods are counted and filled into bottles.

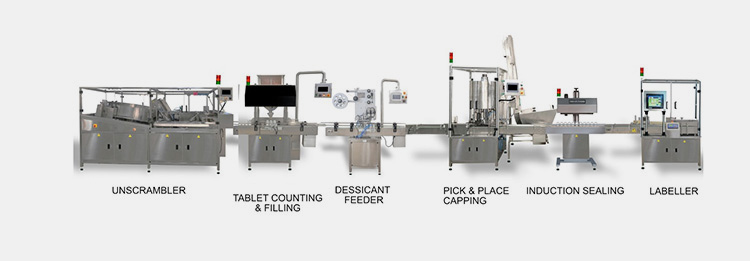

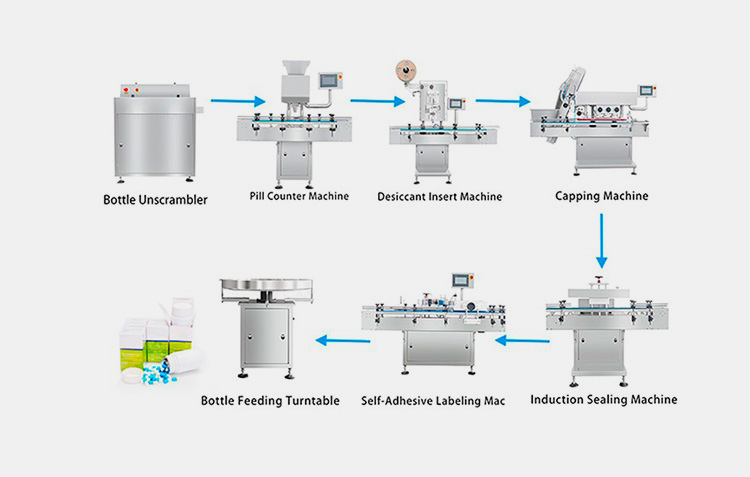

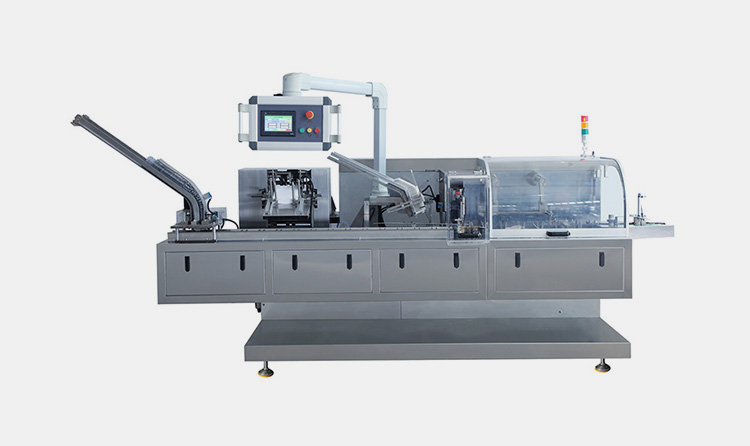

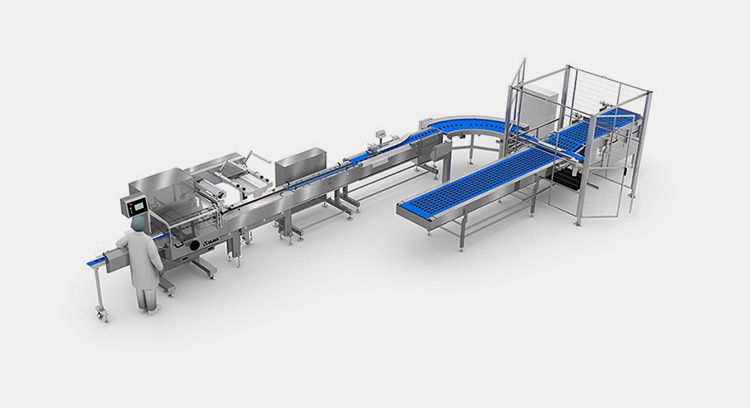

9.Can A Tablet Bottle Filling Machine Be Part Of The Full Fledged Production Line?

A tablet bottle filling machine can be integrated with other machines for forming an entire production line that holds in it every machine required for tablet bottle packaging. These machines are described below:

Bottle Unscrambler

Bottle unscrambler-Picture Courtesy: Aipak

This high-tech stable bottle unscrambler is particularly designed to end the complexity of positioning bottles manually. The operator loads the machine with bulk of empty bottles which are then processed by machine and feed the rightly positioned bottles to attached machine via conveyor belt.

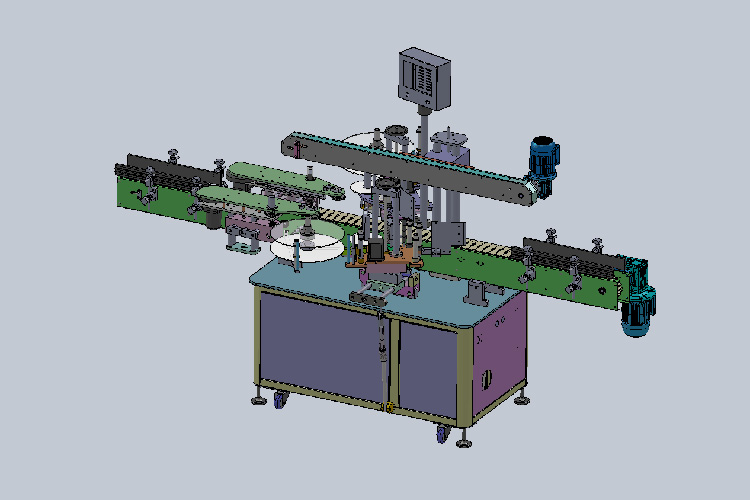

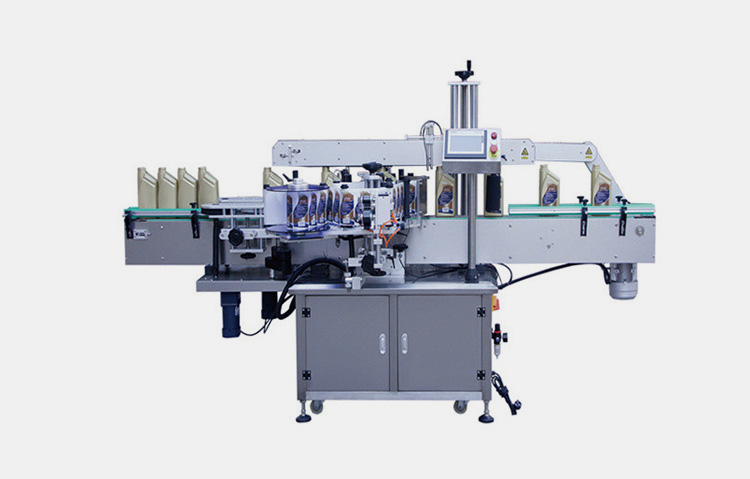

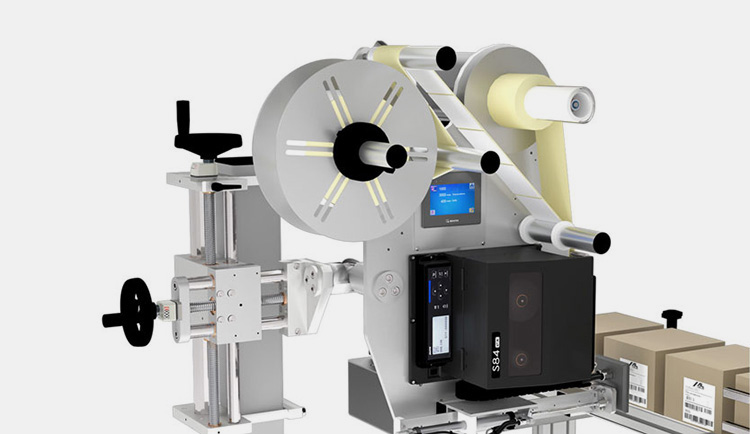

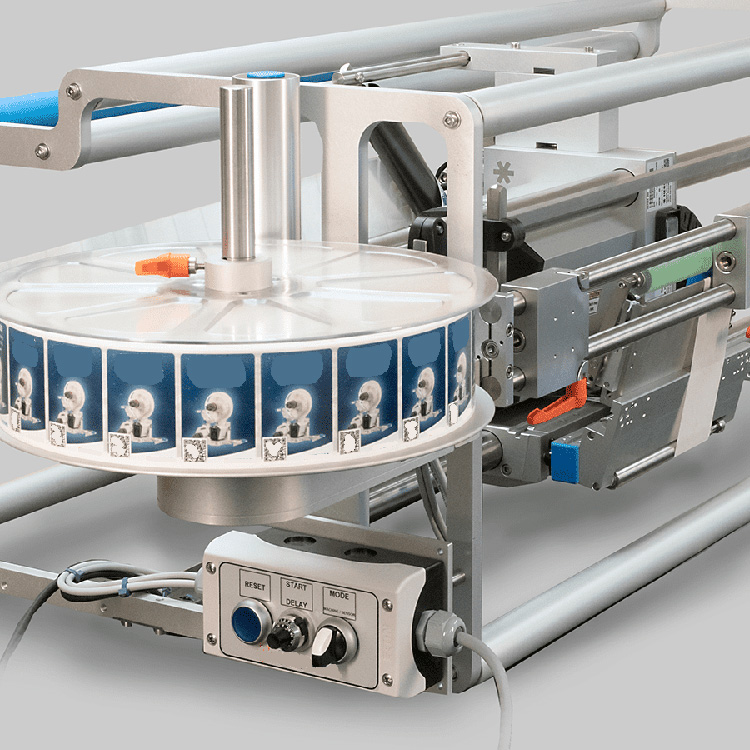

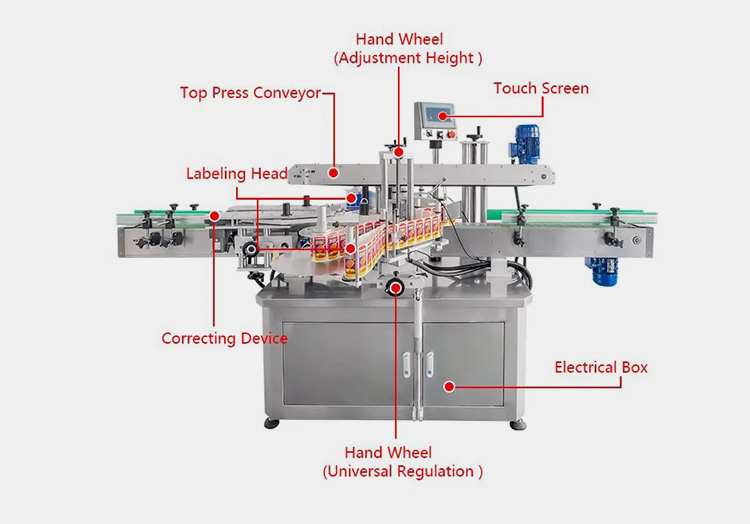

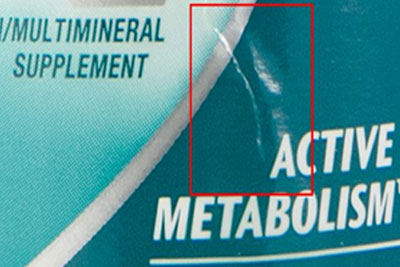

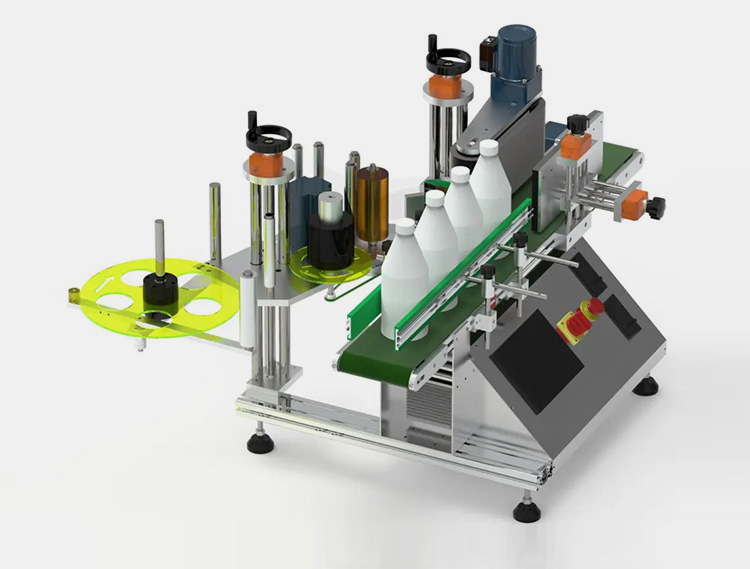

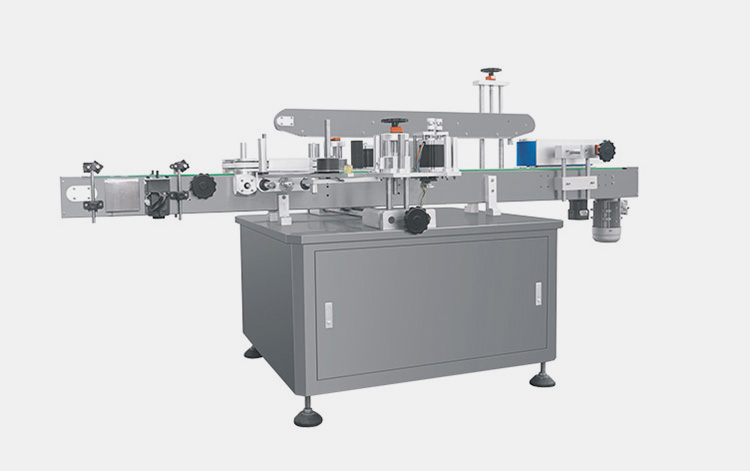

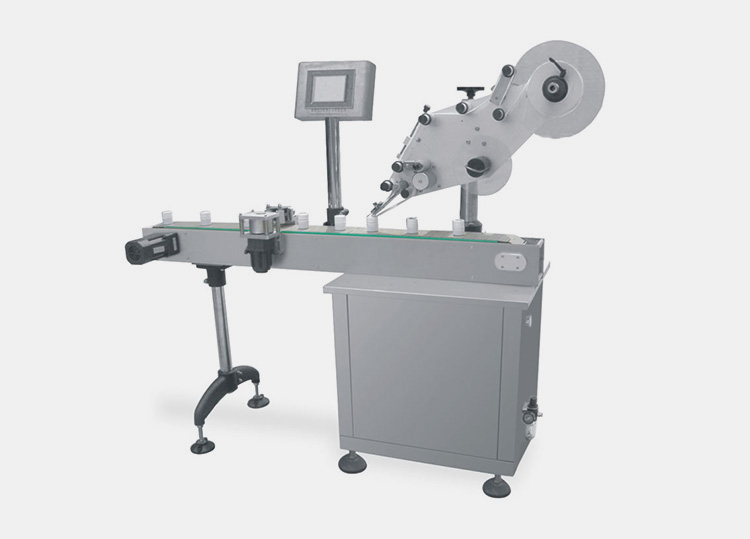

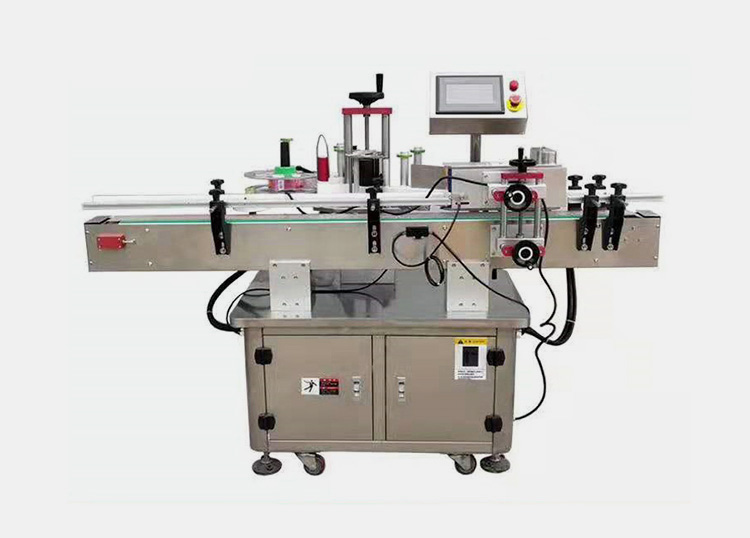

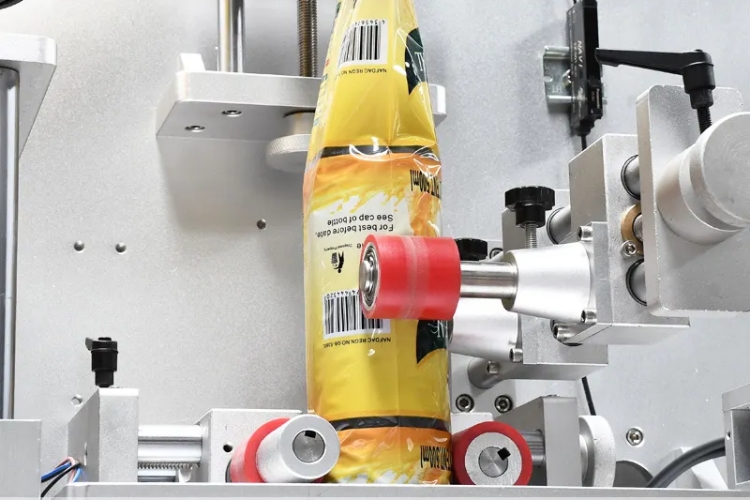

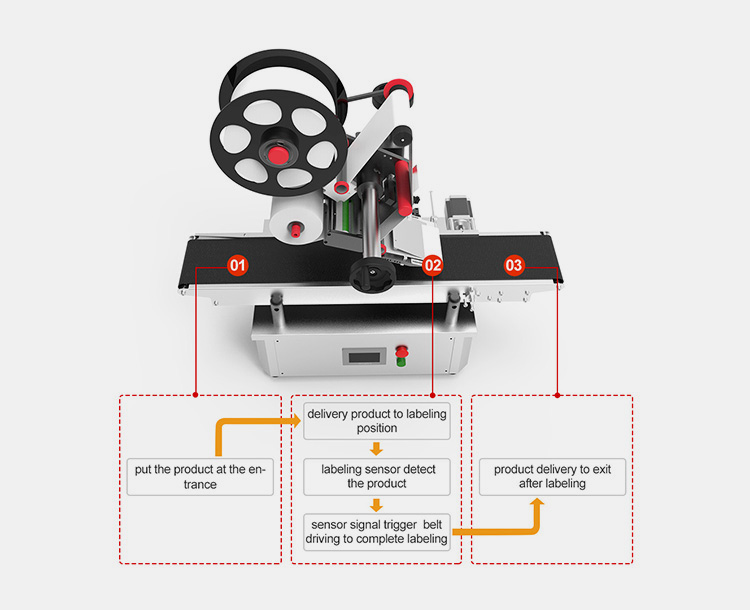

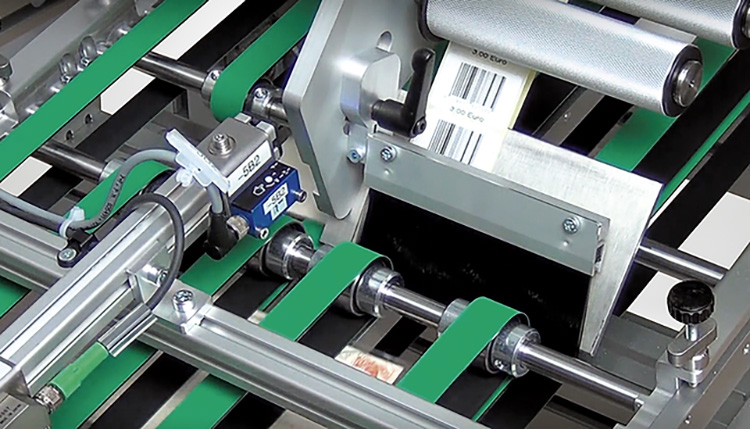

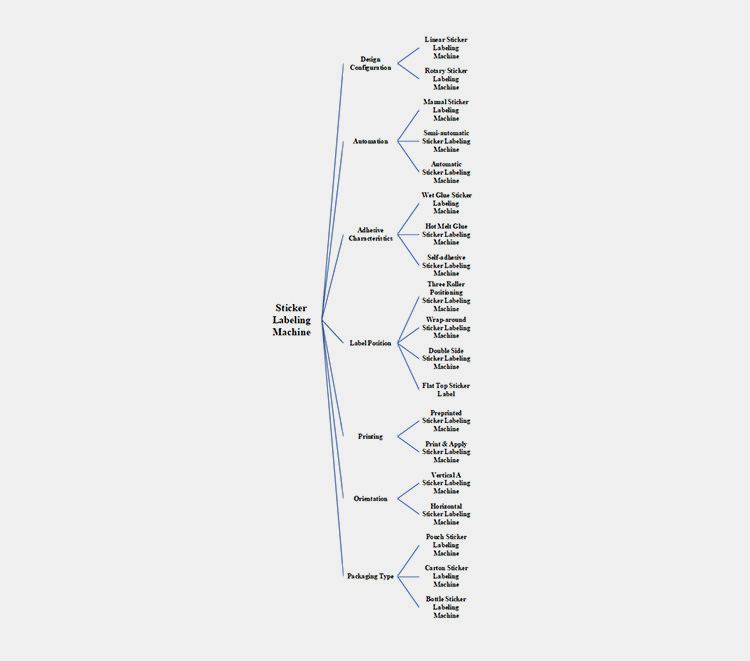

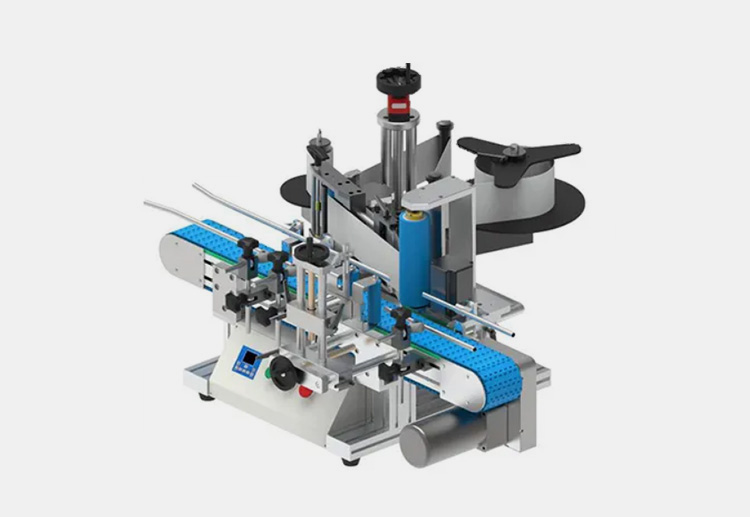

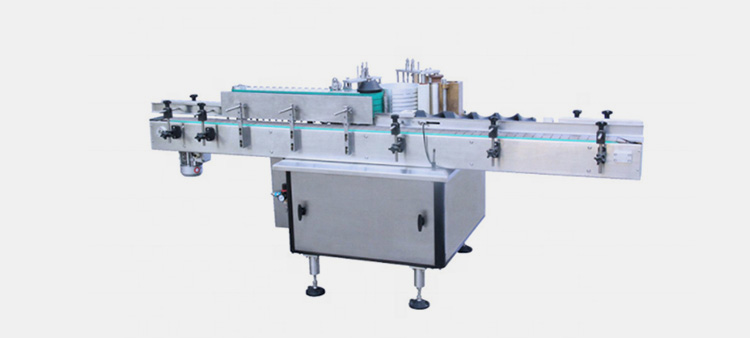

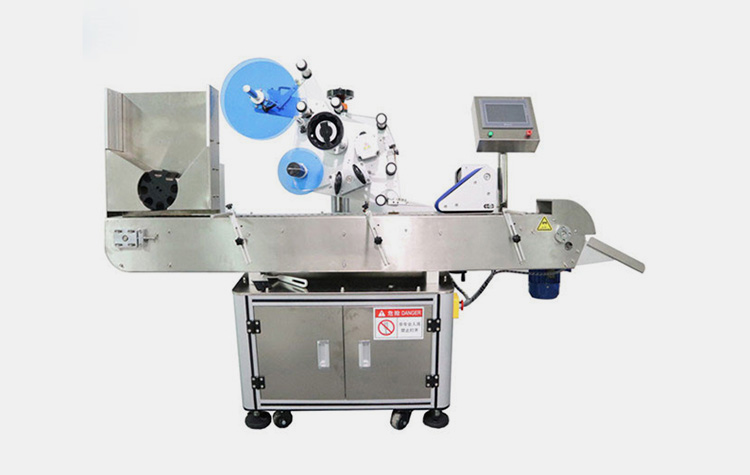

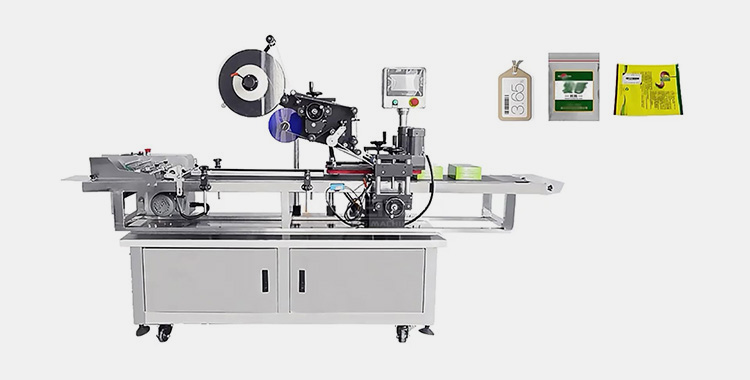

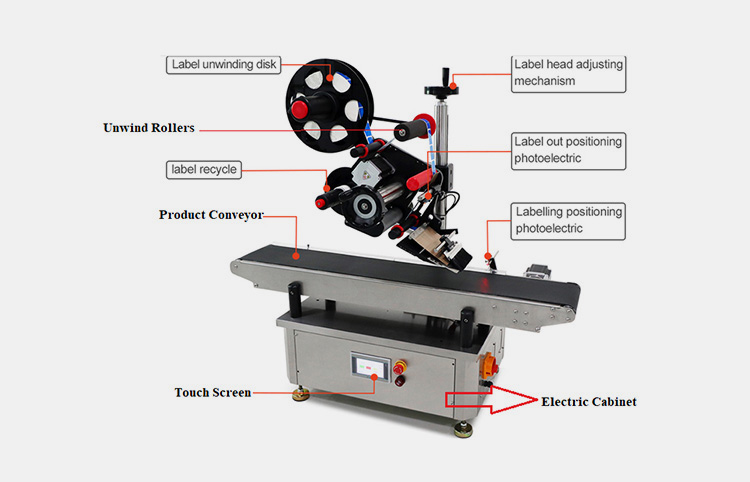

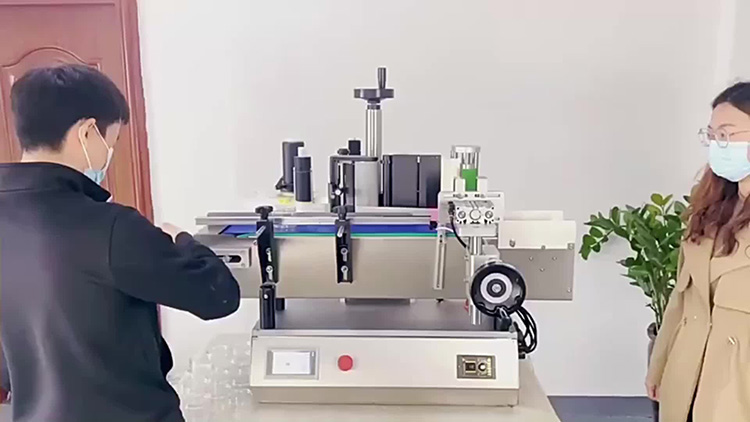

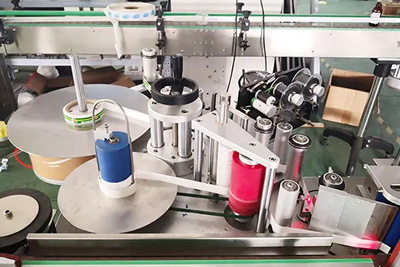

Bottle Labeling Machine

Bottle labeling machine-Allpack

Bottle labeling is the most important aspect of pharmaceutical packaging. It is constructed to apply all types of sticker labels to the tablet filled bottles with wrap around, two side or three side labels.

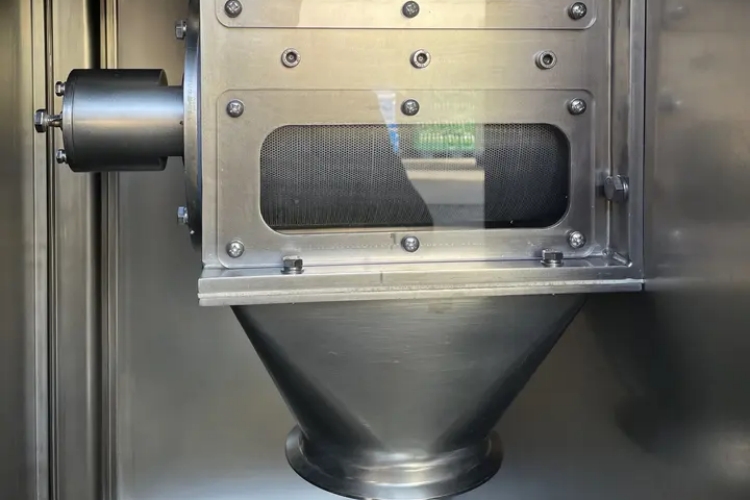

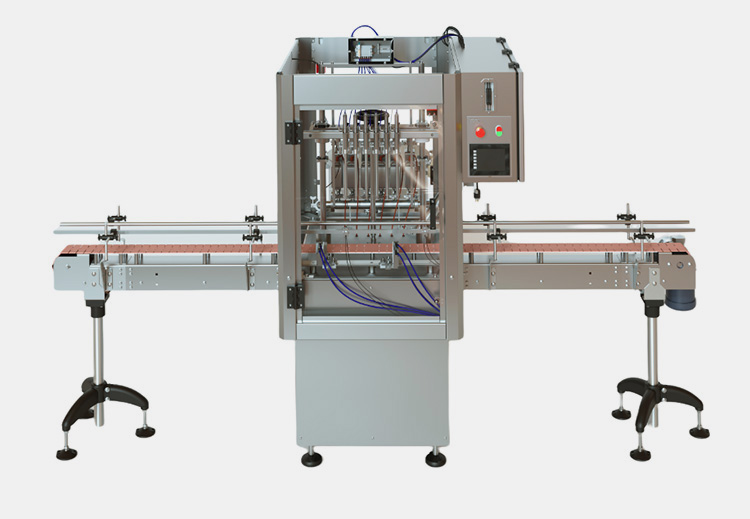

Desiccant Inserting Machine

Desiccant inserting machine-Allpack

Desiccant inserting machine is an excellent device that facilitates the pharmaceutical tablet processing by supplying the tablet filled bottles with precise cutted desiccant bags. These bags really helps in the preservation of quality of tablets by absorbing all the moisture and keeping it away from getting into the tablets.

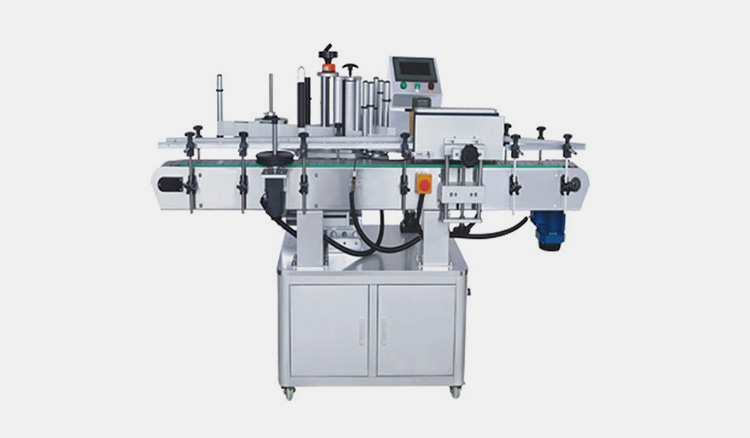

Bottle Capping Machine

Bottle capping machine-Allpack

As the bottles filled with tablets often have lids to be covered, Allpack's bottle capping machine is structured to undertake this task. The machine simply takes the caps of bottles from hopper and apply them over the tablet filled bottles intermittently.

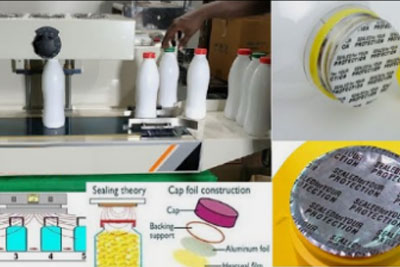

Induction Sealing Machine

Induction sealing machine-Allpack

Induction sealing machine is carrying immense significance for tablet filled bottles due to its profound task. It has an electromagnetic system through which it creates radiation into induction coil which eventually produce heat and seal the bottles' opening with aluminum foil.

10.What Is The Cleaning And Maintenance Procedure Of A Tablet Bottle Filling Machine?

It is important to regularly clean and maintain the tablet bottle filling machine for smart working. Below is the description of these two methods:

Cleaning

Cleaning machine-Picture Courtesy: iStock

Cleaning of the tablet bottle filling machine is an inevitable task due to the high sensitivity and hygiene of tablets. For this, you can disassemble the parts of machine like hopper, rotary trays and filling nozzles to completely remove the debris and residues of tablets. Use edible water for washing these parts and wipe over clean cloth. After cleaning, make sure to place all the components of machine on exact place by taking help from manual guide.

Maintenance

Girl maintaining machine-Picture Courtesy: salesforce.com

By maintenance, we mean to keep the machine under strict observation. It requires you to check the internal setting of machine such as bottle separator distance, amount of tablets that has to be filled in each bottle and the speed of conveyor belt. While as, adjustment of conveyor belt according to bottle size, tightening of screws and adjustment of bottle filling head which come under external setting.

11.Give Remedies To The Possible Pitfalls Occur While Using Tablet Bottle Filling Machine?

The table below contains the remedies for curing problems which you might face when operating a tablet bottle filling machine:

| No | Pitfalls | Causes | Remedies | Pictures |

| 1 | Too close nozzle create difficulty for bottles to pass | You may have switched for large diameter bottles | Make sure to adjust the height of bottle filling station whenever you change the size or diameter of bottle |

Bottle under filling nozzle-Picture Courtesy: Bellatrx |

| 2 | Machine does not deliver tablets to bottle | Their may be fault in detector for no bottle no filling | Check the setting of detector or clean it to clearly detect the presence of bottle |

Control board of tablet bottle filling machine-Picture Courtesy: Clevelandequipment.com |

| 3 | Bottles get overlapped on conveyor belt when moving for filling | The separator may have different setting of bottle distance or the conveyor belt has double space to that of bottles | It is obligatory to check the distance fixed for bottle separator and also adjust the conveyor belt width to avoid bottle falling |

Bottles on conveyor belt-Picture Courtesy: C.E King Limited |

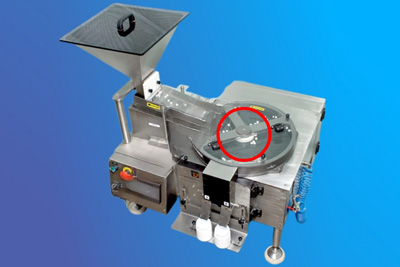

| 4 | Disk cannot rotate | Either the disk is jammed due to tablet get stuck or the loose of disk are too loose to support rotation | Lightly move the disk by hand and get the stuck tablet out, also tight the screws if loosen |

Coated tablets on counting disk-Picture Courtesy: indiamart |

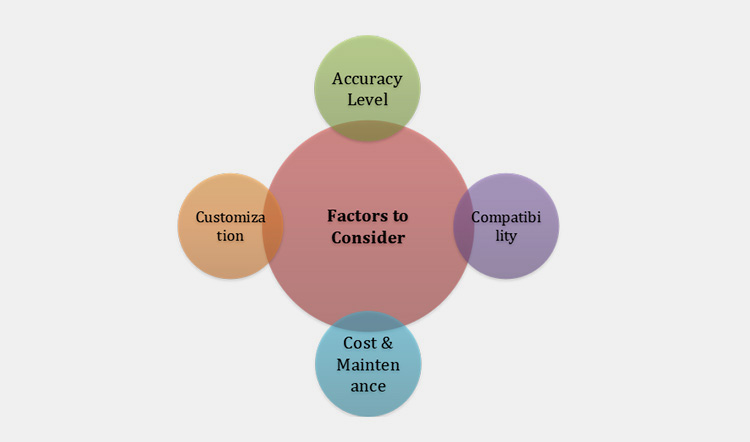

12.Consideration Of Which Factors Pave The Way For Getting Topnotch Tablet Bottle Filling Machine?

Purchasing the right tablet bottle filling machine becomes difficult and certain queries may arise in your mind. Hence, it is crucial to get them answered, by looking into the following points:

Production Volume

Beauty softgel capsules-Picture Courtesy: Olly

The first question has its origin from the purchaser. Suppose, you are interested in buying a tablet bottle filling machine, but for how much volume? If you are able to measure your production volume it will ultimately pave the way for determining whether you want fully automatic tablet bottle filling machine, semi-automatic or manual.

Features

Another significant factor to consider is to check the features of machine. As you are going to automate your packaging line, it becomes essential to have the machine which can help you in many ways. For instance, machine with rejection system, bottle separator, no bottle no fill, and dust collection will ultimately increase the charm of your packaging.

Adaptability

Now, it is crucial to check the adaptability of machine in many ways. For example, you can check whether the machine can process other objects like candies, grains and laundry pods etc., if your production is diverse.

After-Sale Service

After sale service logo-Picture Courtesy: Marketing91

The last but not the least, you must have to ask your vendor about the after-sale service they provide. It will also include the warranty policy, technical assistance and remote support.

Conclusion

To wrap up, tablet bottle filling machine is an innovative device which can bring much ease in the production facilities of different industries. It is safe, versatile and consequently reliable in a way that it can be used for multiple objects. The machine support diverse containers apart from bottles. Moreover, the tablet bottle filling machine offered by Allpack has one-year warranty. If you are interested in making a purchase, feel free to contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tablet Bottle Filling Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours