Ketchup Packaging: The Complete FAQ Guide In 2025

Ketchup Packaging: The Complete FAQ Guide In 2025

Do you know ketchup is the king of condiments and the earliest form of ketchup did not contain tomatoes? People both- adults and kids prefer to have their burgers, pizza, fries, hotdogs, and more with a topping of ketchup. It is one of the rarest food types that contains all tastes, such as sweet, salt, sour, bitter, and umami. So, to preserve the freshness of tomatoes and all these flavours, tomato packaging plays a significant role.

Not only this, vibrant red ketchup packaging increases the craving for ketchup thus, resulting in impulse buying. Interested in ketchup packaging and want to know more about this exceptional packaging then read through our informative guide. Let’s get ready.

1.What is Ketchup Packaging?

Ketchup Packaging- Picture Courtesy: Dieline

Ketchup packaging is carefully enclosing a precise quantity of thick viscous ketchup types into different containers for its management, shipment, and distribution. Tomato ketchup and its other forms such as mushroom, fruit, curry, and many more are packed in airtight and fully sealed packaging to keep them away from environmental elements and biological pathogens.

This packaging is indispensable for bringing perfect tangy and sweet ketchup to your tables. Freshness, yummy flavour, and sweet tomato aroma are all due to ketchup packaging. Many consumers prefer ketchup over fresh tomato sauce because of its easy-to-handle packaging.

2.What are the Different Pros of Using Ketchup Packaging?

Packaging is the first thing that captivates consumers and usually, they perceive good packaging as an indicator of the quality of products. Brands opt for illustrative packaging due to various reasons:

Basic Communication

Ketchup Packaging- Picture Courtesy: Packaging of the World

Market goners make split-second decisions while looking at the products on the retail shelves. Hence, brands often innovate their ketchup packaging and it serves as a means of communicating their brand information and product advantages. After colour, striking labels are the best way to bring end-users to display shelves.

Locking Freshness

Safe Transportation with Ketchup Packaging

One thing that end-users like the most in ketchup is tomato freshness, spicy and tangy taste, and mouthwatering aroma. Therefore, manufacturers use resistant and weatherproof materials that bottle up freshness and increase ketchup shelf-life. Typically, sugars in ketchup are food for pest growth. But due to sturdy and tough ketchup packaging, no pest can gain entry inside the packaging.

Branding

Branding with Ketchup Packaging

Manufacturers employ different design elements and attributes on ketchup packaging, such as unique designs and creative combinations of topography and fonts to break through the crowd in the display area and to get noticed by the passersby. This witty advertising inspires customers to buy certain ketchup products. Moreover, careful branding builds consumer memory and is a failsafe way to ensure a place in the grocery cart on a return visit.

Transportation

Freshness With Ketchup Packaging- Picture Courtesy: nerbot

Ketchup is often exported overseas and to far-off countries of the world that require hours of journey on planes and ships. There is a chance that products might spoil and get damaged while in transit. However, robust, strong, and hermetically sealed ketchup packaging minimizes this chance. Ketchup packaging contains products and prevents their chance of spillage and leakage.

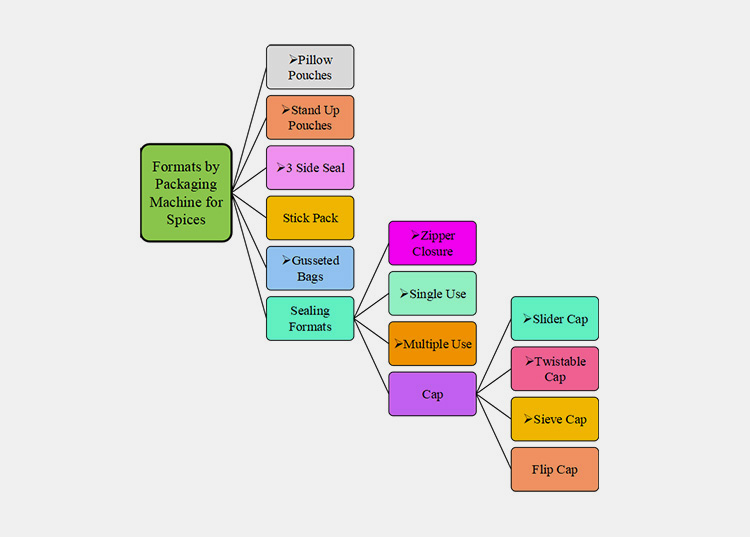

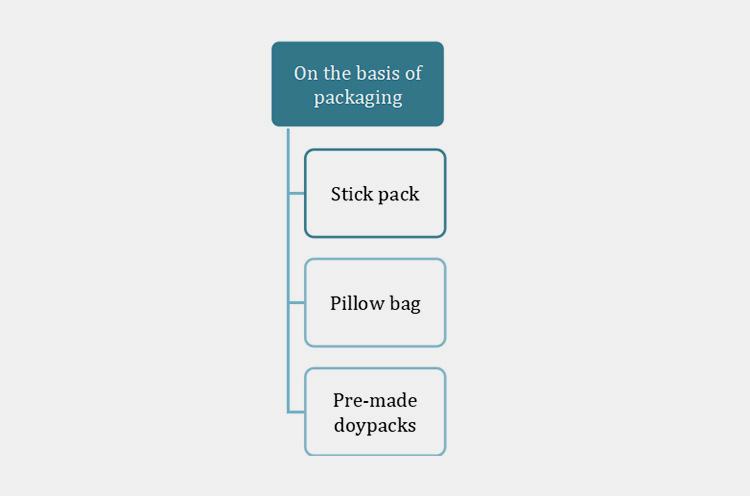

3.What are Different Kinds of Ketchup Packaging Formats?

Ketchup is one the fewest food items that is available in almost every packaging format. Ketchup has its section at retail stores due to its diverse packaging styles like pouches, bottles, jars, and many more.

Complete details of ketchup packaging formats are discussed below for your understanding:

Standup Ketchup Pouch

Standup Pouch- Picture Courtesy: HUACANG Spout Pouch

Standup pouch is routinely seen on display shelves of grocery shops due to its ease in standing upright. Brands use this pouch for their ketchup packaging as it has huge sides and panels for marketability, labeling, and brand promotion. Its vibrant red packaging readily catches the eye of customers thus tempting them to buy it.

Spout Ketchup Pouch

Spout Pouch Ketchup Packaging: Packaging of the World

Are you tired of squeezing ketchup pouches and resulting in large puddles? Then spout pouch ketchup packaging is perfect for dispensing ketchup. These spout pouches come with straw-like tubes either at the side or at the centre of the ketchup pouch for ease of use. It metes out a measured quantity of ketchup without creating a mess. It has the best features of standup pouches, such as standability and printing with spouts.

Ketchup Sachet

Ketchup Sachet Packaging

This small 3 or 4-sided pack has a small serving of ketchup. But due to its lightweight and ease of carrying around, it is a favourite among consumers. It saves the hustle of carting large bottles and heavier pouches.

Ketchup Stick pack

Ketchup Stick Pack- Picture Courtesy: AMS Distribution

This is a tubular and narrower pack containing a quantity of ketchup for single-serve. Portability and convenience are the main aspects of the designs of stick packs. It is mostly seen in fast food restaurants and comes with order delivery.

Jars

Ketchup Jars- Picture Courtesy: Design Crowd

These jars are mostly made of glass and occasionally with plastics. These jars vary in design and style and look great on dining tables. Ketchup usually comes in economic jars that have a wide opening and no neck. These jars are also designed in tall configurations and can have a rectangular or cubic shape.

Bottle

It is one of the most popular design styles for ketchup packaging. Bottles have been used for packaging ketchup since the earliest times. Bottles accommodate bulk quantities of ketchup and are available in different sizes. Some common ketchup bottle designs are:

| Rigid Ketchup Bottle

It is one of the original designs for ketchup packaging. This bottle has an unbendable round or cylindrical shape and can hold a minimal quantity of 8 ounces. Ketchup is usually dispensed upon shaking these bottles. |

Rigid Ketchup Bottle- Picture Courtesy: Yummy.ph |

| Squeezable Ketchup Bottle

This bottle is usually made with plastic and comes with a dispensing cap that squirts a small quantity of ketchup on squeezing. Moreover, it comes in a design that is quite easy to grab and this bottle can stand upside down. |

Squeezable Ketchup Bottle- Picture Courtesy: WebstaurantStore |

| Double Cap Ketchup Bottle

Yes, you are reading correctly. This ketchup bottle has two caps- both at the upper and lower ends of the bottle and you can pour ketchup from either side. It is designed to access the last drop of ketchup and to reduce product waste. |

Double Cap Ketchup Bottle- Picture Courtesy: Packaging Getway |

| Large Ketchup Bottle

Often, on market shelves large plastic ketchup bottles are seen that pack about 4 litres or more volume of ketchup. It usually comes with a handle that provides a place for holding this bottle. It is cylindrical or slightly rectangular. |

Ketchup Bottle- Picture Courtesy: EPH Online |

Can

Ketchup Cans- Picture Courtesy: Dieline

Ketchup is also packed inside the metallic cans for a luxurious look and ultimate feel. Cans are also rigid containers that are designed with sealing lids and the metal surfaces of cans give exceptional printing results. These containers are customized on special occasions and the brands launch limited edition cans to create brand awareness among customers.

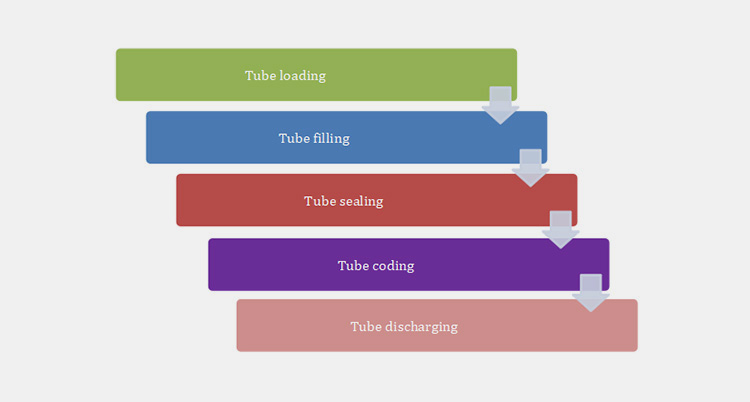

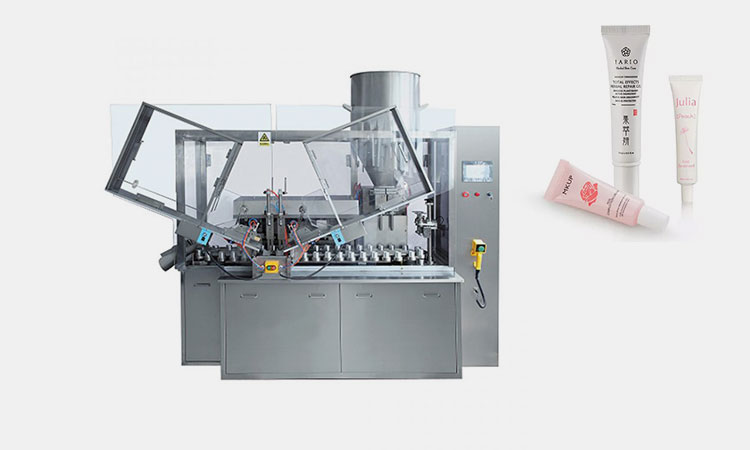

Tube

Ketchup Tube- Picture Courtesy: Motatos

Are you surprised that ketchup is also packed inside a tube? Tube design is popular because of its squeezability and holding. It is a cylindrical shape container with tapering edges. It is closed with a twist-off or dispensing cap.

Bucket

Ketchup Buckets- Picture Courtesy: IIC Packaging

Ketchup is also packed in bulk quantity containers for restaurant or eatery-based consumers who often require a large quantity of ketchup on hand. These ketchup buckets can hold about 20 litres of ketchup. It has a Snap-On lid that is inserted into the container after use.

Jerrycans

Ketchup Jerrycans

These are rectangular or round containers usually employed for holding large volumes of ketchup. They are manufactured using sturdy types of plastics that can withstand large shipping distances without breaking apart.

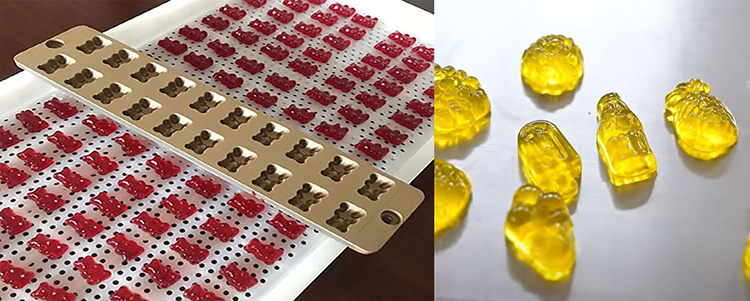

Trays

Dip and Squeeze Ketchup Trays/ Pouches- Picture Courtesy: bakeryandsnacks.com

Recently, a new packaging format for ketchup is gaining popularity. This dip-and-squeeze ketchup packaging is a two-in-one format that can be used as a tray or as a sachet. It comes with a peel-off seal, serves as a tray upon opening, and is used for dipping any snack, for instance, fries, or burgers. Similarly, just like a sachet, the top edge of this container is torn off and ketchup comes out upon squeezing the packaging.

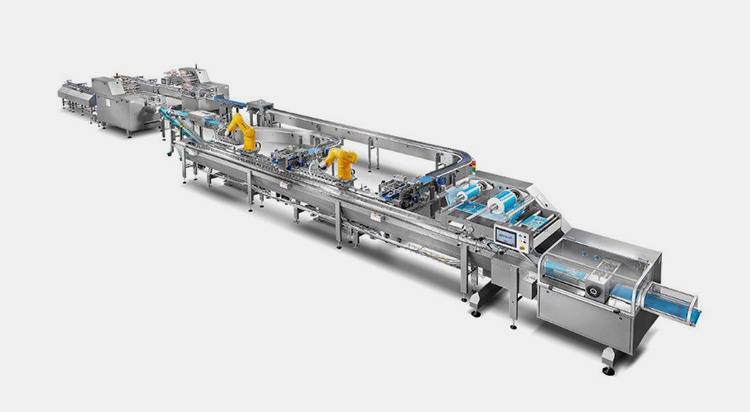

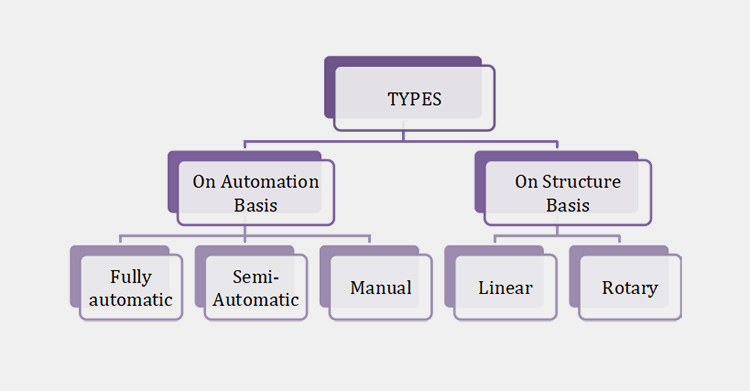

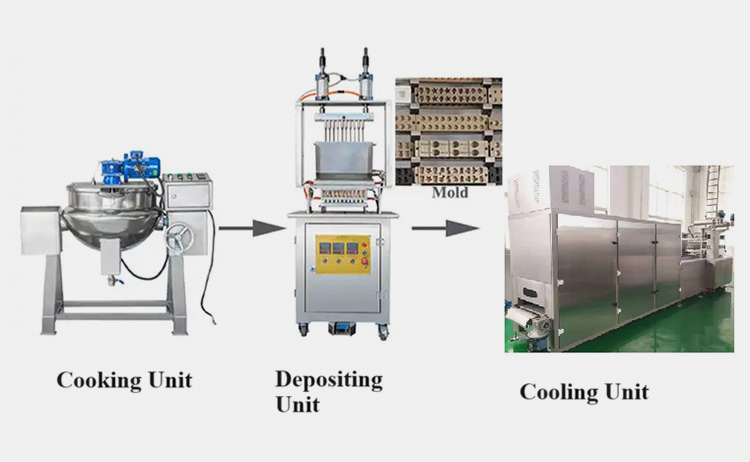

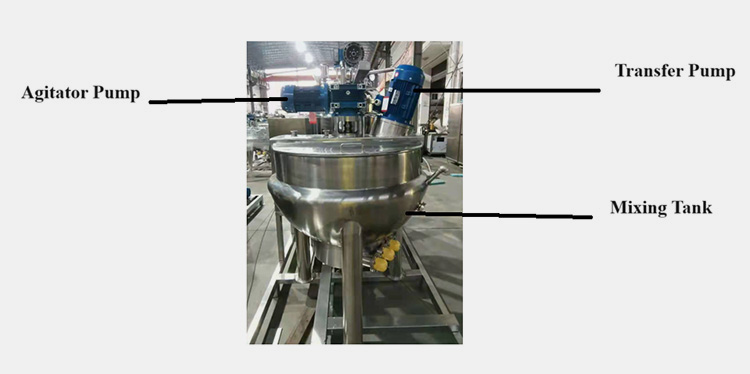

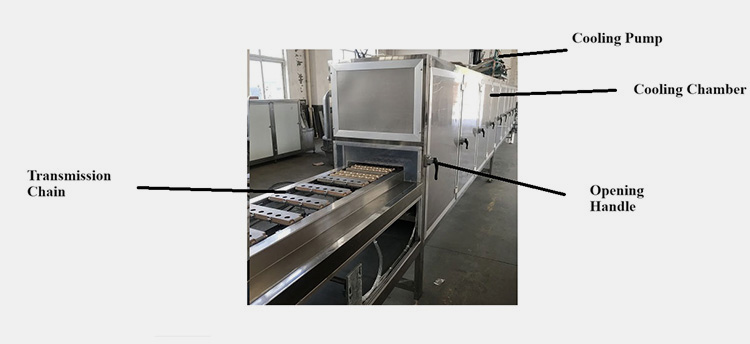

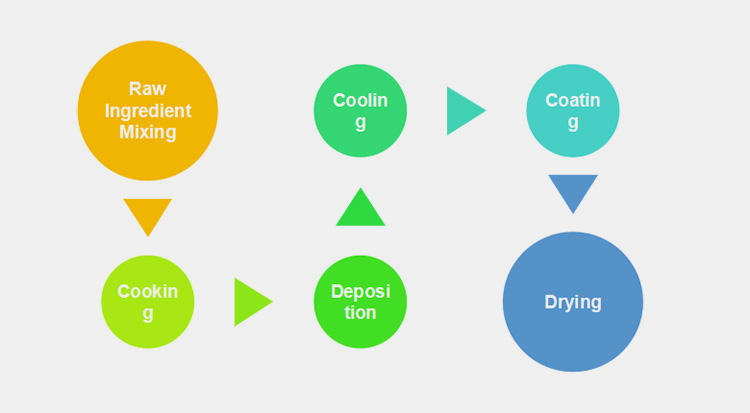

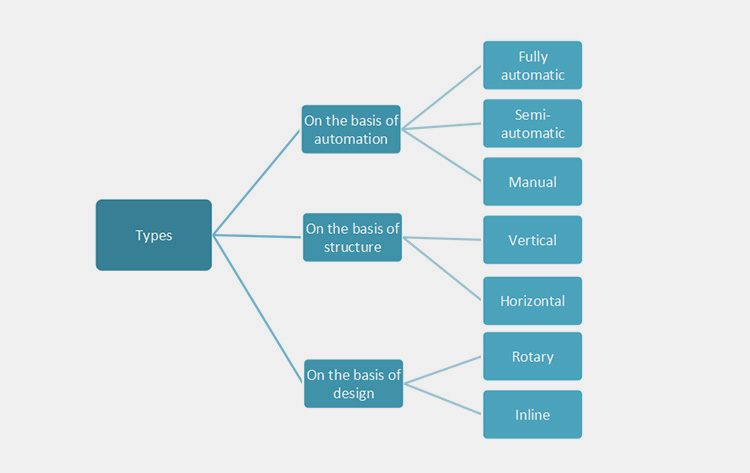

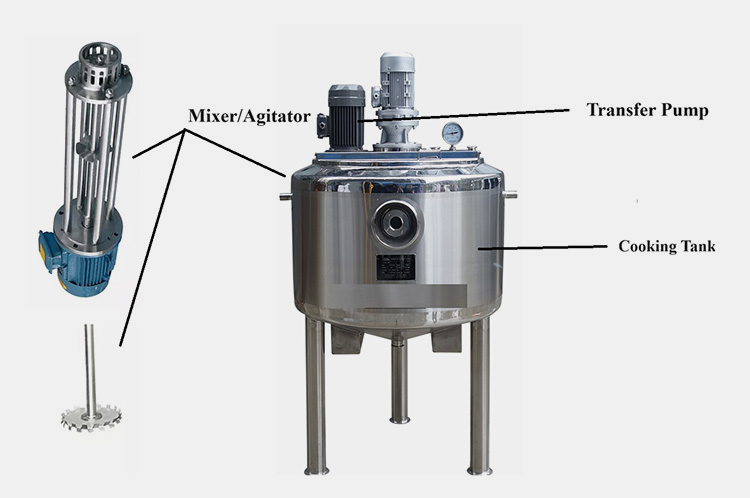

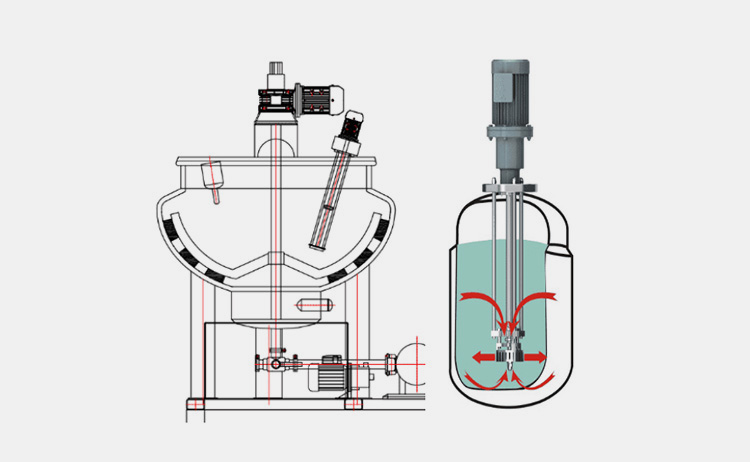

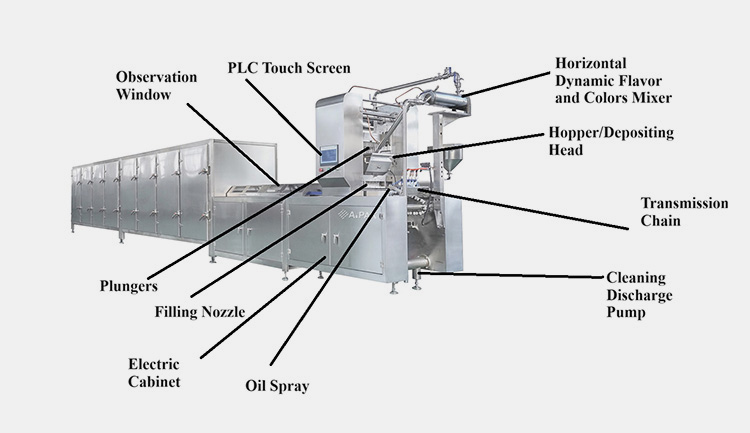

4.What are the Machines Employed for Ketchup Packaging?

As already discussed, there are wide range of ketchup packaging formats, hence to process these diverse packaging styles, different makes and models of ketchup packaging machines exist in the market. Below discussed is the list of ketchup packaging machines.

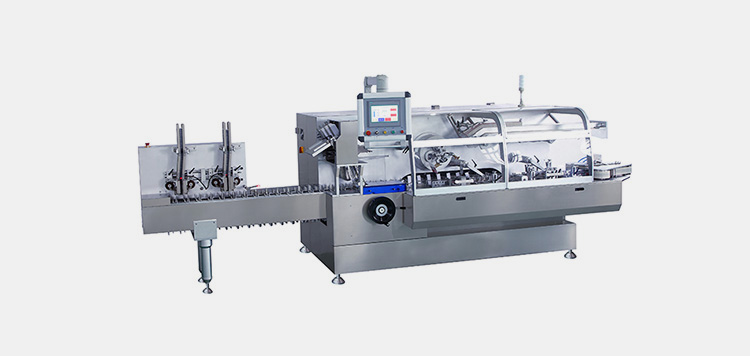

Premade Ketchup Pouch Packaging Machine

Premade Ketchup Pouch Packaging Machine

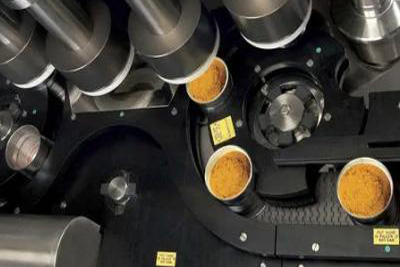

This machine is popular in many industries due to its flexibility and versatility. It uses already-formed pouches for ketchup filling. This saves a lot of packaging film waste. It has a higher processing rate as time is saved that is otherwise spent on making pouches. It is typically available in rotary configuration and thus can fill multiple ketchup pouches simultaneously.

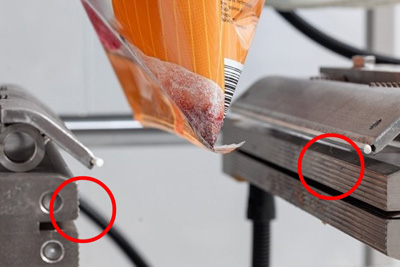

Working Principle

At the start, a large bulk of pouches is put on the magazine unit from where gripper devices carry them around to the inflation area for their opening. At the filling station, the preprogrammed volume of ketchup is introduced into the inflated pouch. And finally, at the sealing jaws heated bars or induction sealing is applied to fully close pouches.

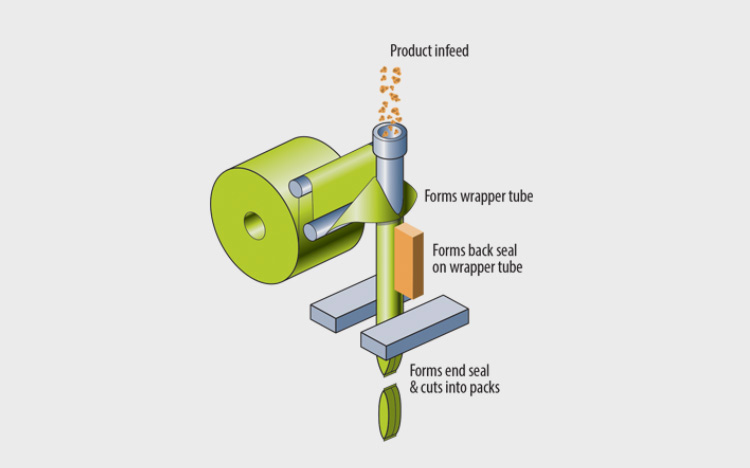

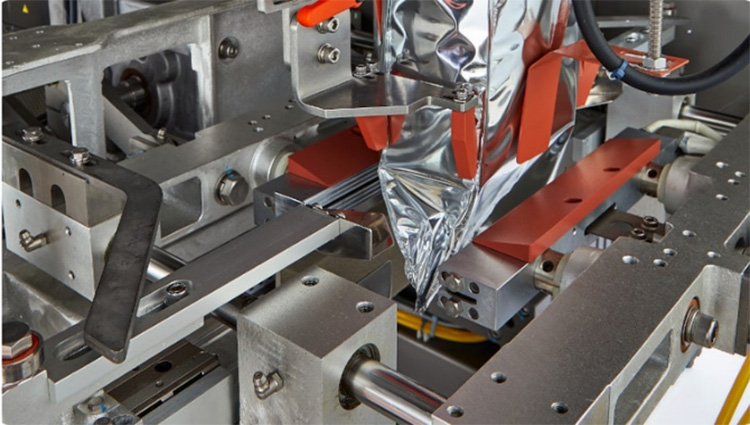

VFFS Ketchup Packaging Machine

VFFS Ketchup Packaging Machine- Picture Courtesy: Soontrue

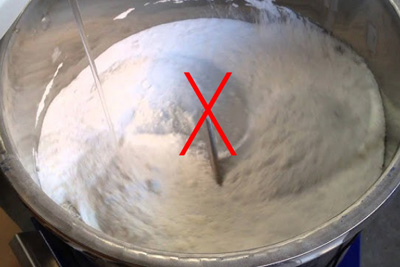

It is one of the most popular and widely used machines for flexible ketchup packaging. The machine simply forms pouches from packaging film, loads them with ketchup, and seals them. Its effectiveness, ease of use, and high productivity make it hit among industrial sectors. Moreover, it accurately measures the ketchup amount before feeding it into pouches, thereby, lowering ketchup waste.

Working Principle

It processes large batches of ketchup by unrolling the packaging film placed on the holder. The rotation of the unwinding disk and rollers aid in its unwinding and also keeps the film under the right amount of tension which can otherwise slip and cause machine jam. After going over rollers, it reaches a cone-like forming tube where the film is shaped and fashioned into pouches. Next, filling devices, load a preprogrammed portion of ketchup into a pouch. The final seal is made over the pouch top after filling.

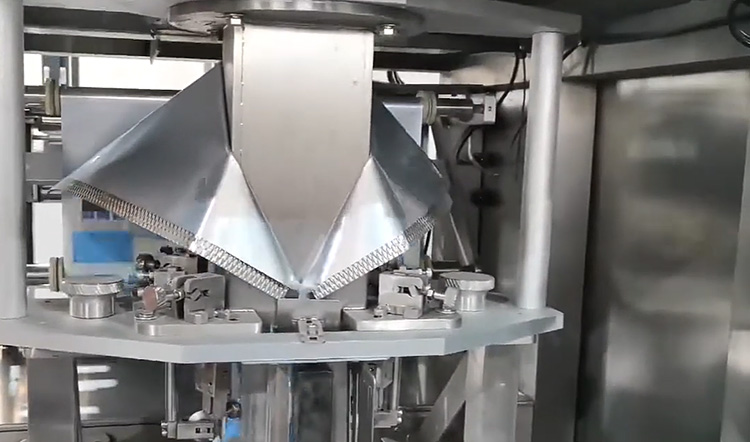

Spout Ketchup Pouch Packaging Machine

Spout Ketchup Pouch Packaging Machine

This machine uses premade pouches and also form, fill, and seal pouches for ketchup filling. It installs a spout on the pouches after ketchup filling for ease in dispensing ketchup. This lowers the waste of products and is quite convenient for end-users. This equipment can add a spout at the centre of the pouch or its top corner.

Working Principle

Its working principle is identical to a premade pouch packaging machine or VFFS machine depending upon the starting packing material. At the filling station, the pouch is mechanically opened and vacuumed. After its inflation, the ketchup is fed into the pouch and then spouts are sorted, heated, and welded onto the top side of pouches. Ultimately, heat sealing is made to hermetically seal pouches.

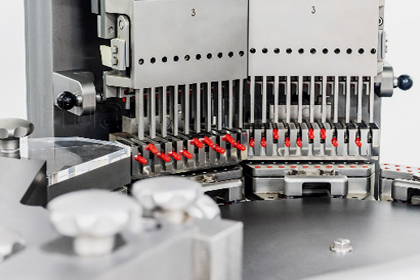

Ketchup Stick pack Packaging Machine

Ketchup Stick pack Packaging Machine

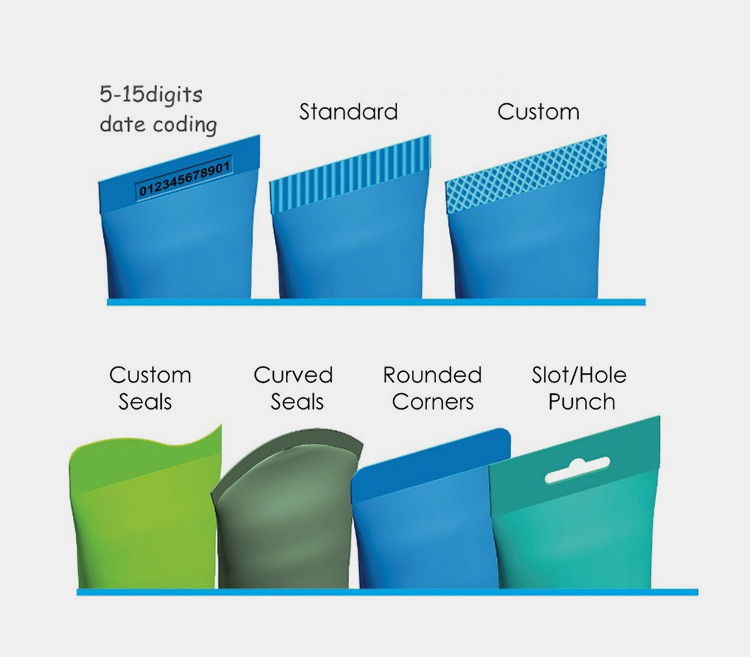

It packs a small amount of ketchup in a stick pack for one-time use. It has multiple lanes and servo-driven technology that speeds up the ketchup filling. Ketchup stick pack packaging machine can also include tear notch and other patterned seals in the stick packs and can also emboss seals.

Working Principle

This machine uses a single film roll that is unwounded and introduced to roller and dancer arms. These components keep the film under uniform pressure. From rollers, the packaging film is moved to the slitter assembly where a single piece of film is cut into numerous strips depending upon the lanes present in the ketchup stick pack packaging machine. After cutting, each strip goes to a separate forming station and is fashioned into a tube-like pack. Then ketchup is filled into each stick pack and the top side is sealed using sealing jaws.

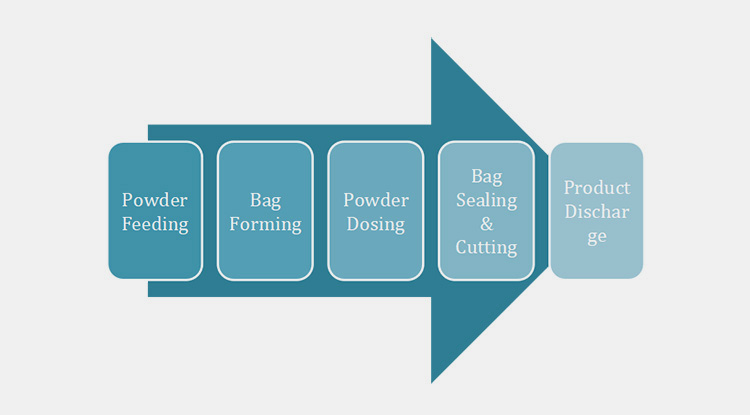

Ketchup Sachet Packaging Machine

Ketchup Sachet Packaging Machine

Sachet packaging for ketchup is the most popular format hence ketchup sachet packaging machine is ideal for businesses processing single-serving ketchup. This machine is identical in design construction to the VFFS machine and can make square or rectangular-shaped sachets with seals at 3-4 sides. It is a robust and versatile unit routinely employed in the food industry.

Working Principle

At the start, the plastic or aluminium film is uncoiled and folded and after passing through rollers reaches the forming station. This top cone-shaped part assists in folding and shaping a small pack-like sachet. This sachet is sealed at the sides and bottom and then filled with thick vicious ketchup. In the end, horizontal sealing jaws glued the topside of the sachet, and cutting blades cut the edges of joined sachets.

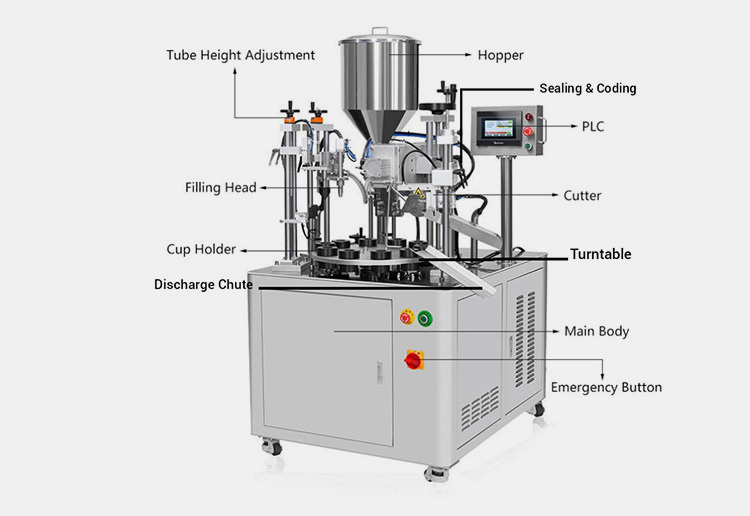

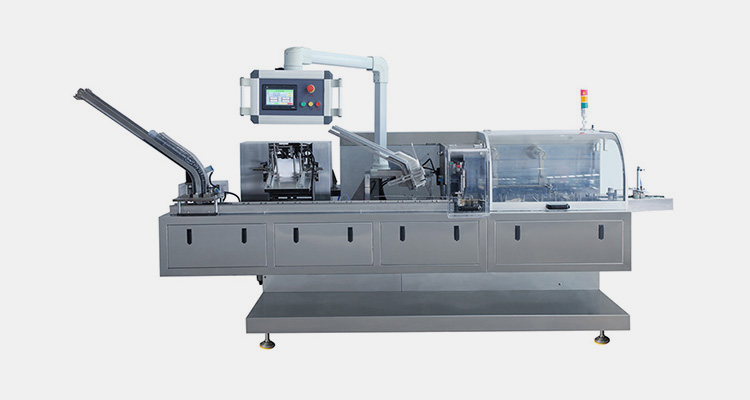

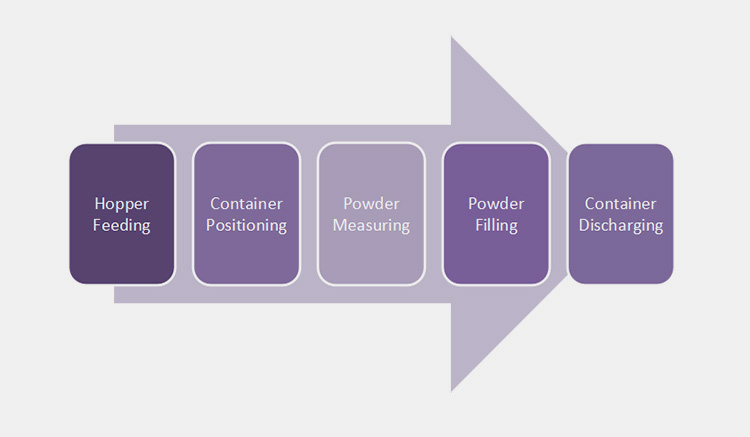

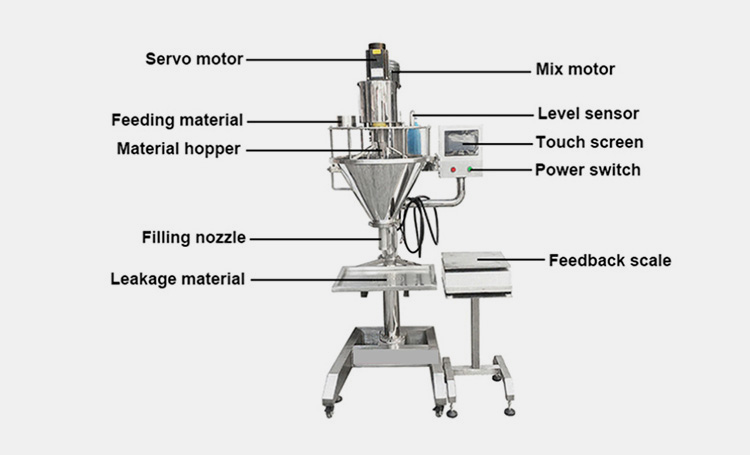

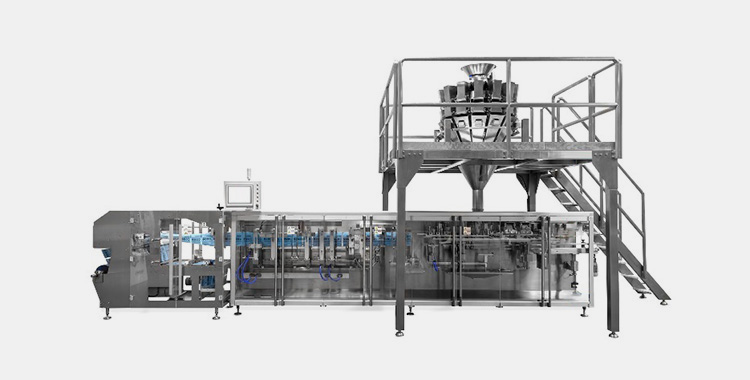

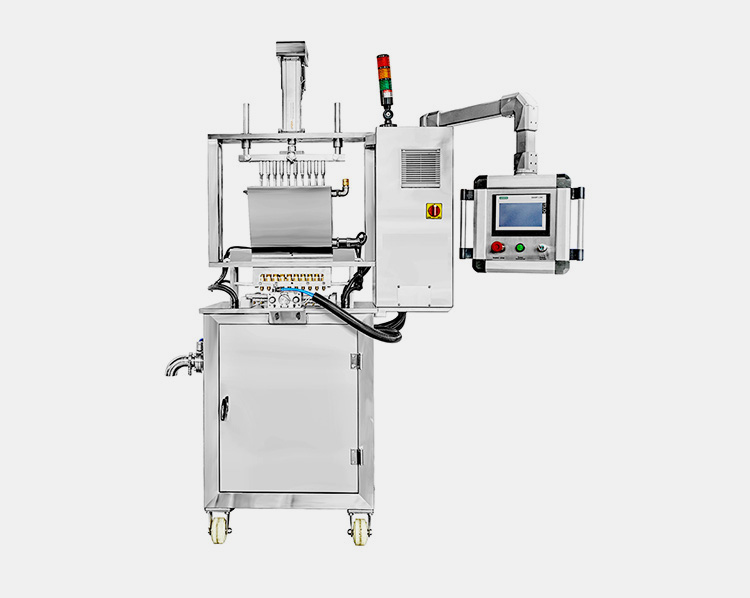

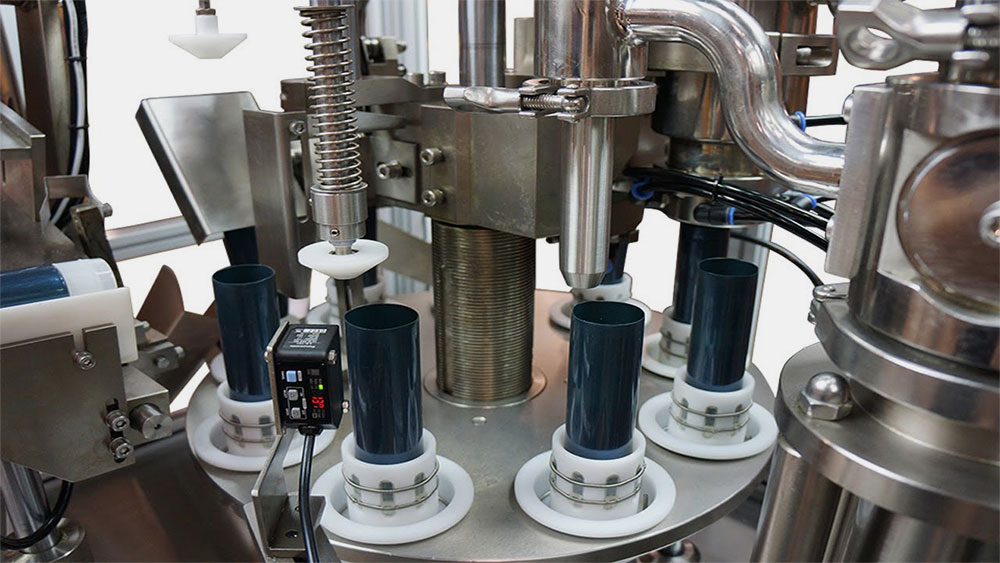

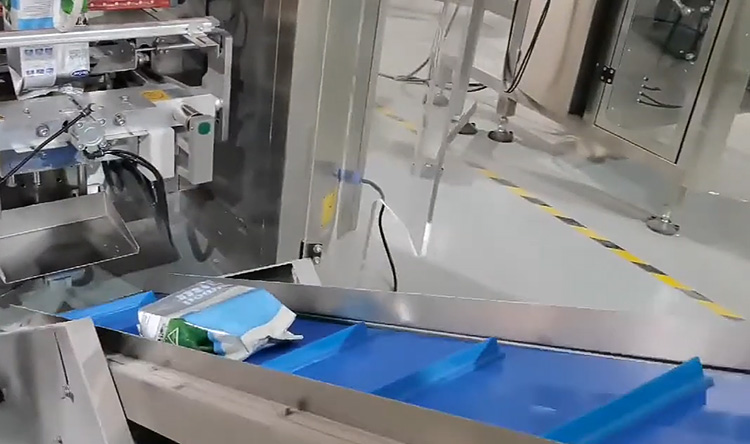

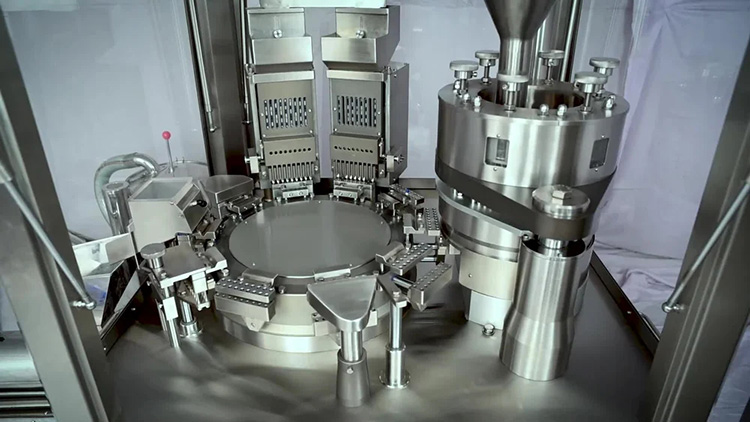

Ketchup Bottle/Jar/Bucket Packaging Machine

Ketchup Bottle/Jar/Bucket Packaging Machine

It is a versatile and dependable ketchup packaging machine that can pack a bulk volume of ketchup in jars, bottles, jerry cans, and buckets. It can handle large-capacity containers of any shape and size whether large, medium, or small, rectangular, oval, or round. This machine is popular, as it processes re-closable and reused containers, thus making it a desired choice for end-users.

Working Principle

Large volumes of ketchup are fed into a hopper before the start of operation. The containers are loaded on the conveyors one by one after the precise interval. Once the packaging jar or other container arrives under the filling head, a measured quantity of ketchup is loaded inside the jar or bottle, etc. The packaging container leaves the filling area and is transported to the capping area whether twist-off caps, pre-cut lids, or other cap styles are placed on the container for permanent closing.

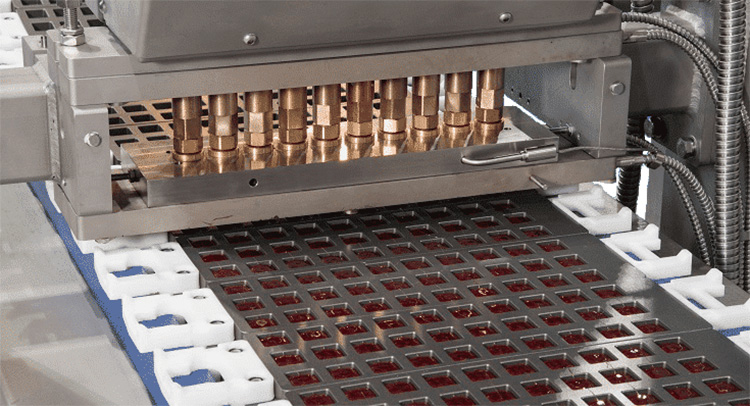

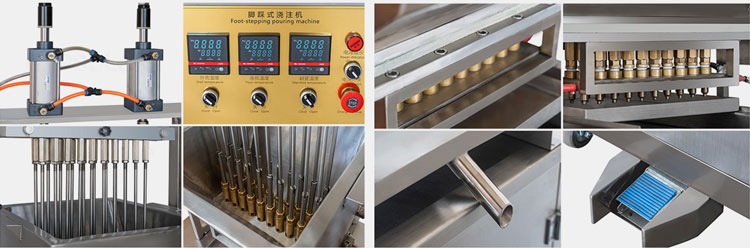

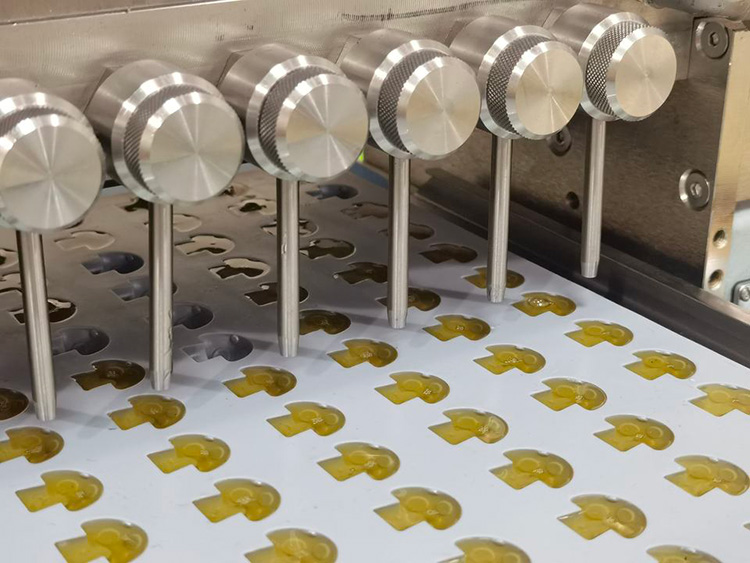

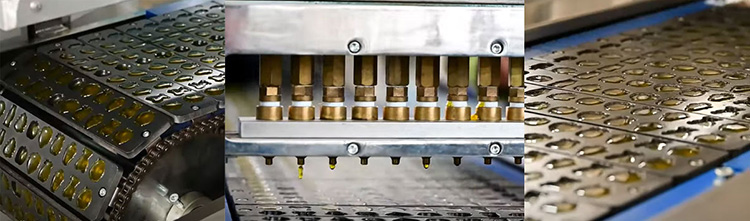

Tray Ketchup Filling and Sealing Machine

Ketchup Tray Filling and Sealing Machine

Ketchup also comes in tray-style packaging for ease of use. The tray ketchup filling and sealing machine is a linearly design machine in which a ketchup hopper is placed at the top. It dispenses the right quantity of ketchup in a tray and seals it with plastic or aluminium film.

Working Principle

The trays are loaded on the integrated conveyors manually or by robots. This container moves to the filling head and on detection of a tray, the filling nozzle metes out an accurate quantity of ketchup into the tray. Trays are then subject to a sealing area, where the opening of these containers is fully covered and sealed using film. Cutters are employed in the end to give ketchup trays a neat look.

5.In What Kinds of Shapes Do Ketchup Pouch Packaging Come?

Over the years, there have been a lot of innovations in ketchup pouch packaging to attract customers with individuality. Uniqueness is a way of standing out of saturated ketchup packaging aisles. There are diverse kinds of ketchup pouch packaging shapes that are discussed one by one below:

Rectangular Shape Ketchup Pouches

Rectangular Shaped Ketchup Pouches- Picture Courtesy: World Brand Design Society

Ketchup is typically packaged in rectangular or square-shaped pouches. These shaped pouches are the most widely utilized pouch packaging design for ketchup. These pouches have four distinct corners and can stand in an upright position. Also, stick pack and sachet for ketchup are also available in standard square design.

Bean Shaped Ketchup Pouches

Bean-shaped Ketchup Pouch

These ketchup pouches have curved corners and have a slightly cylindrical shape. They are narrow in the middle and bulge out from the ends.

Trapezoid Shape Ketchup Pouches

Trapezoid Shape Ketchup Pouches- Picture Courtesy: Packaging of the World

This design style for ketchup pouch packaging provides tactility as well as inclusivity. This pouch has two equivalent sides that differ in their length and on opening, it resembles a funnel that allows for dipping.

Bottle Shape Ketchup Pouches

Bottle Shape Ketchup Pouches- Picture Courtesy: Undefined

The dip and squeeze tray/pouch comes in a bottle shape. It has a wide base that tapers off at the top and it has tear-away foil that resembles a cap.

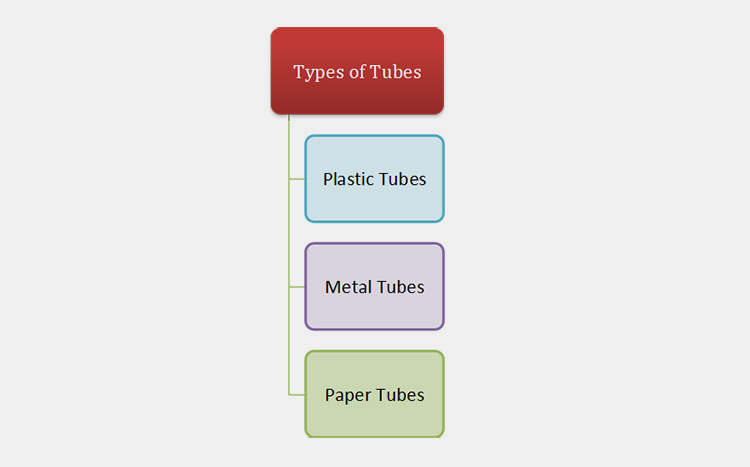

6.What are Different Ketchup Packaging Materials?

Due to the popularity of ketchup and saturation in the ketchup market, brands are trying different combinations of packaging materials to entice customers toward their ketchup products. A list of ketchup packaging materials is detailed below:

Plastic

Plastic Ketchup Packaging- Picture Courtesy: zircontech.com

This material is now everywhere from bottles to pouches, from tubes to buckets. Bottles are made with rigid plastic, such as HDPE and flexible lightweight easy-to-squeeze plastic, such as PET. Moreover, plastic flexible packaging for ketchup is emerging as a strong candidate for ketchup packaging due to lower carbon print while manufacturing plastic pouches and also because, during shipment, they are easily stacked on top of each other consequently reducing fuel consumption and saving space.

Glass

Glass Packaging for Ketchup

Although, plastic has greatly replaced glass bottles for ketchup packaging, however, even today, these glass bottles are a popular choice in many countries due to their premium look. Clear glass offers the advantage of visibility. Moreover, it is considered safe for packaging by the food regulatory authorities because of its zero permeability against moisture, gas, light, and microbes. It has been studied that glass packaging extends the expiry date of ketchup by 33%.

Metals

Ketchup Metal Cans- Picture Courtesy: L Hong to Rtai

Aluminium, steel, and tin are employed for making cans as they provide foolproof protection against elements. Moreover, aluminium is also used in combination with plastics to create pouch packaging for ketchup. Aluminium foils are employed for fabricating peel-off lids of dip and squeeze containers.

Paper

Paper Ketchup Packaging- Picture Courtesy: Food and wine

Recently, brands have teamed up to create paper-based ketchup packaging. Efforts are underway to develop paper ketchup bottles from wood pulp. This future ketchup packaging will be 100% sustainable and will be easily recycled in paper recycling units.

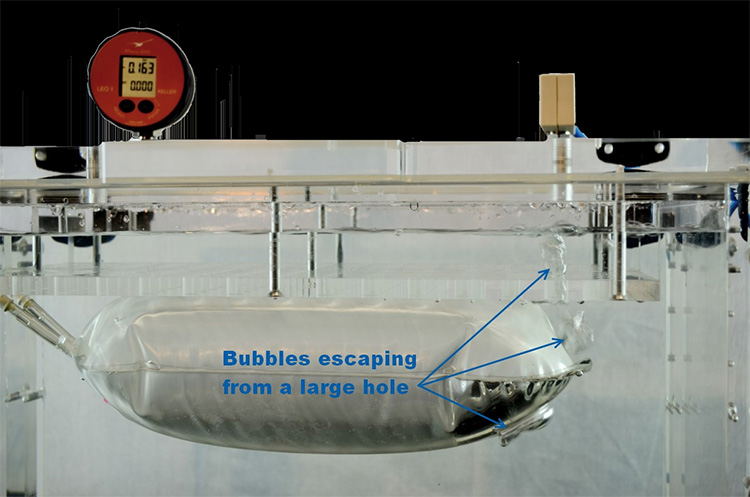

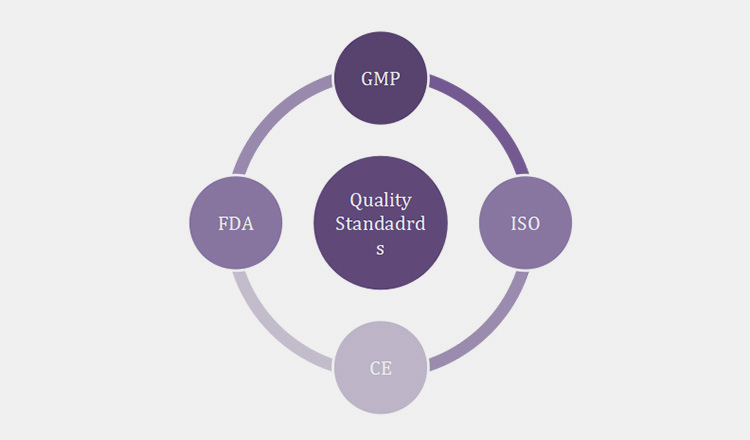

7.What are Different Sealing Tests for Ketchup Packaging?

Seal Integrity Test of Ketchup Pouch Packaging-Picture Courtesy: Behance.net

Seal examination is an essential part of the ketchup packaging. Proper sealing of ketchup packaging ensures its nutritional quality, extends shelf-life, and prevents contamination by microbes. Some different tests for checking seal integrity are:

| Visual Inspection Test | In this test, the operator critically examines the ketchup package to look for any defects, such as wrinkles, tears, misalignment, burns, or any other abnormalities that affect the integrity of the seal. This test focuses only on visual imperfections in the package and does not provide information about the toughness of the seal. |

| Dye Penetration Test | It is also referred to as a liquid penetration test. It identifies cracks, pores, or gaps in container sealing. Dye is usually sprayed or brushed on the surface of the container and sometimes the packaging is immersed in dye solution. Time is given for the absorbance of dye into the packaging after which it is dried. In the next step, the developer is applied to the surface of the packaging to see the imperfection in the sealing. |

| Burst Test | In this test, air is subjected and fed inside the packaging at a fixed rate. This is also known as a rupture test and detects the strength test of the sealed packaging as it measures the maximum level of pressure withstood by the packaging. The seal usually ruptures at the weakest point when the burst test is performed. |

| Air Bubble Leak Test | It is a simple and non-destructive test in which ketchup packaging is placed inside the water bath. The air above the water level is evacuated using a pneumatic nozzle. If bubbles are seen on the surface, this shows that there is a gap in the seal. |

| Vacuum Decay Leak Test | This test does not damage ketchup packaging. It is a simple test involving vacuum formation around the ketchup packaging to eliminate air molecules. A sensor is utilized to measure the disruption in pressure due to air leaking out of the sealing or perforation present in the ketchup packaging |

| Pressure Decay Test | It is an inexpensive test to determine the leakage in the ketchup packaging seal. In this test, pressure is introduced inside the packaging. Once it reaches a certain level, pressure is cut off. If there is a leak in the packaging, it is determined by the pressure drop. |

8.What Are Basic Ketchup Packaging Mistakes and How to Avoid Them?

Ketchup packaging can make and break your business. Exceptional-quality ketchup packaging rapidly gains the trust of the customers and hence increases the chances of buying. To produce ketchup packaging without faults, here is a list of mistakes that should be avoided while packing ketchup.

Incorrect or Mislabelled Packaging

Ketchup Packaging- Picture Courtesy: It’s Nice That

Labeling has a significant role in informing users about the expiry date, ingredient list, serving size, calorie count, etc. Poor, incorrect, wrinkled, torn, and poorly printed labels miscommunicate users. Moreover, poor use of topography leads to unreadable labels that drastically reduce the quality of ketchup packaging. To design irresistible labeled ketchup packaging, ensure that you are using quality printed inks, a visible and readable combination of topographical fonts, and water-proof sturdy sticker labels.

Wrong Size Selection

Ketchup Packaging- Picture Courtesy: Decolore.Net

It is one of the most common mistakes while packaging ketchup. Brands chose large-sized packaging for packaging small quantities of ketchup and sometimes small containers for packing large volumes of ketchup. This leads to wastage of both product and container. Therefore, it is important to revise your packaging size.

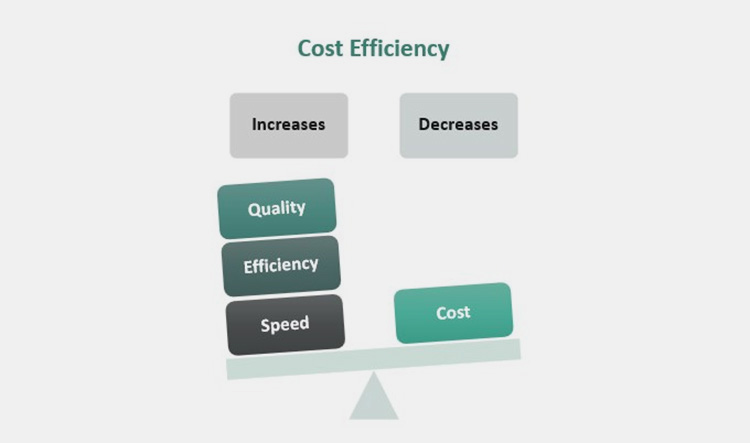

Going with the Cheapest Option

Ketchup Packaging- Picture Courtesy: Packaging of the World

Businesses are always trying to cut down their costs. Nevertheless, it is vital to not select the packaging material and design based only on price because it can result in defects in ketchup packaging, such as leakage or bursting during shipment and handling which could jeopardise your business. Therefore, invest in your ketchup packaging because it builds brand identity and encourages impulse buying.

Wrong Selection of Ketchup Packaging Machine

Ketchup Packaging Machine

As already discussed, there is a wide range of ketchup packaging styles and different machines catering to specific ketchup packaging styles are available in the market. A ketchup bottle packaging machine cannot handle ketchup pouches. Similarly, the VFFS machine cannot process bottles or jars. Before machine purchase, you must determine your desired ketchup packaging format and then select the machine accordingly.

Sustainability is the Key

Ketchup Packaging- Picture Courtesy: Dieline

Last but not least, customers want to purchase products that come in sustainable packaging. Thus, avoid using large bulky excessive packaging to store your ketchup as they create huge landfills and poorly reflect your brand values. Always use material with low impact on the environment as this packaging is the winner in the eyes of end-users.

Conclusion

Designing ketchup packaging is not only an art but also a science. Different materials for ketchup packaging are meticulously chosen to protect ketchup from harm, microbes, air, chemicals, water vapours, and sunlight. Besides this, it is customized with silky smooth finishes, bold vibrant colours, and tomato design for captivating customers. Ketchup is packaged in every single possible format that varies in their designs. Different machines are innovated to handle special design styles of ketchup packaging. Want to know more about ketchup packaging and related machines, then go to our main Allpack website for more details.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Ketchup Packaging: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours