What Are Medicine Capsules Made Of?

What Are Medicine Capsules Made Of?

Have you ever wondered, the medicine capsule that you consume is exactly made up of what materials? Your curiosity is about to end here when reading ‘What are medicine capsule made of?’. The medicine capsule whether hard or soft, animal based, or plant based are made up of certain specific set of ingredients.

The manufacturing process of the medicine capsule is almost simple as the ingredients. What those ingredients could be? To deal with this mystery, let’s go for further part of the post to know more.

1.What Is Medicine Capsule? Is Capsule Shell Used For General Action?

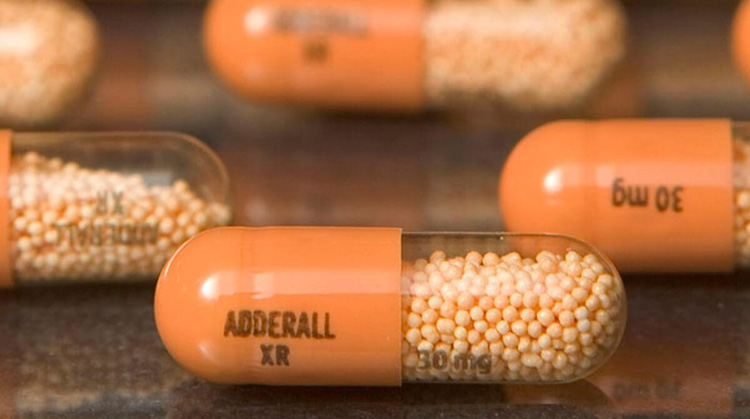

In medicinal terminology a medicine capsule refers to a pharmaceutical dosage form encompassing of a shell structure usually made up of collagenous nature such as gelatin or any other gelling agent. Capsule, which has small powder like, or granule sized drug substance filled into it can be delivered orally or rectally for intended use of action. They are used by pharmaceutical manufacturers to create such a drug which cannot be compacted into a tablet form or when the drug needs to be mixed with liquid additive for aiding absorption.

Capsules has many benefits over tablet dosage form. Firstly, it is easier to swallow compared to tablets and has great palatability as medicine capsules are usually manufactured as tasteless and colorless. From patient’s perspective the rate of dissolution and onset of action is much quicker than that of a tablet.

Capsules For Generalized Uses

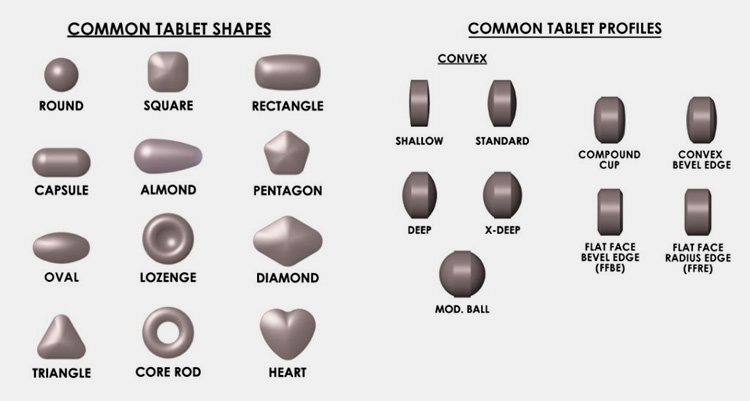

Generally, the capsule shell is available in markets in many specifications tailored to suit different purposes. Hence, they come in many different sizes, shapes and colours. Ideally it is used more commonly in pharmaceutical and nutraceutical industries, however a capsule shell is seen to have more diversified actions.

Capsule intends to deliver lifesaving emergency drugs owing to its immediate release rate, provide multivitamins supplement, delivering essential vitamins and proteins for beauty and cosmetics industry, medicines for veterinary, fertilizer and edible baits for agricultural applications.

Strangely, technologies have advanced enough to bring out nano capsules as well, which are only about few nanometers in size but bring great advantages of it’s use. Such nano capsules are employed by agrochemicals, genetic engineering, healthcare, waste water treatment, cleaning products, cosmetics and also as tumor fighting drugs

2.What Are Types of Medicine Capsules?

Types of Medicine Capsule- Picture Courtesy: Rousselet

Medicine capsules are categorized depending upon the type of their physical structure, hard shelled or soft shelled, and upon the basis of their ingredient formulating its shell vegetable sourced or animal sourced.

Hard Shelled Capsule

Hard Gel Capsules – Picture courtesy: Capsuline

This type of capsule is constituted of a rigid covering made up of gelatinous shell or plant cellulose. It is the more commonly used medicine capsule, enclosing drug pellets or powder of fine size manufactured with the process of spheronization which are released upon reaching the target site of action. Hard shell capsules can be identified as a small body diameter that fits properly with a cap that is of larger diameter. They are made prior to be filled with the drug and so are also available as empty capsules.

Soft Shelled Capsule

Soft Gel Capsules- Picture Courtesy: Lifevision

Soft shell capsules are also composed of gelatin surrounding the liquid filled drug such as mineral and vitamin supplements or any semi solid drug. Soft gel capsules are made up of gelatin, water and opacifier along with adding of sorbitol or glycerine. Soft gelled capsules are hermetically sealed and unlike hard gelled capsules, are filled at the time of manufacturing only and they aren’t available as empty shell capsules.

Gelatinous Capsule

Gelatin for capsules formulation -Picture courtesy: Dr Axe

Gelatinous capsules as the name indicates are made incorporating gelatin solution which is the most commonly used traditional form of capsules. The ‘gelatin’ is derived from animal sources such as beef, pork, chicken or fish as well.

Hard gelled capsules are formulated using mixture of pork bone and skin or even bovine bones as it produces a tough but brittle texture. They are oftentimes used for medications and nutritional supplements as they are gluten free, tasteless and have rapid dissolution aiding easy swallowing.

Non- Gelatinous capsule

Non- gelatinous capsules

Vegetarian capsules were formulated when use of gelatin capsules had become objectionable for many of the consumers due to some religious and other cultural beliefs. Capsules were than formulated replacing gelatin as a gelling agent with those made up of plant-based sources such as hydroxypropyl methylcellulose (HPMC), pullulan, carrageenan, polyvinyl acetate (PVA) and alginate. You will read about them in further heading.

3.What Are Medicine Capsules Made Of?

Contents Of Medicine Capsule – Picture courtesy: SE Tylose

Medicinal capsules are composed by one of the two; gelatinous shell (either hard or soft) or non-gelatinous shells. These are generally formed by the hydrolysis of collagen protein which is obtained by acidic, alkaline, enzymatic, or thermal hydrolysis process extracted from an animal source or plant source.

Capsules are manufactured involving aqueous solution of gelling agents, such as animal protein (mainly gelatin) or vegetable polysaccharides or their derivatives (such as carrageenan and modified forms of starch and cellulose).

Each ingredient carries their own benefits, you’ll read them below.

Animal Based Ingredients

Animal Derived Medicinal Capsules- Picture Courtesy: Firstspot

Animal based ingredients are derived from gelatin protein, as discussed earlier, which is derived from bovine , pig or sometimes fish bones and skin. Gelatin is a miraculous substance which has been used for over several years improving physical and mental health and so being generally formulating capsules.

Plant Based Ingredients

Plant Derived Medicine Capsule

Vegetarian capsules are generally made from plant cellulose. There are different types of cellulose (starch or polysaccharide) that make up plant-based capsules. One of these materials is hypromellose. This type of cellulose is derived from coniferous trees such as pine, spruce and fir trees, or starch containing plants like tapioca root, potato etc.

HPMC Capsules

HPMC Capsules – Picture courtesy: Capsuline

HPMC Capsules are made to be vegan friendly derived from 100% plant based wood pulp , used by nutritional supplement manufacturers as it doesn’t require any additional use of fillers or binders. These capsules are tasteless, colorless and odorless and mostly people find it easier to swallow.

Pullulan Capsules

Pullulan Capsules

These capsules offer excellent plasticity and foaming properties, being derived from plant based corn starch , locust bean gum and xanthan gum , all of which being naturally occurring vegetarian sources. It can be used for encapsulating dry ingredients such as powder, pellets and herbs and specially oxygen sensitive substances as pullulan carries great oxygen barrier.

Carrageenan Capsules

Carrageenan based capsules – Picture courtesy: Vegetology

As a carbohydrate polymer based on carrageenan seaweed plant (red algae) it has also worked to replace gelatin capsules. Three types of carrageenan are employed for the making of capsules kappa, iota and lambda; however owing to it’s great gelling property kappa form is mostly used. However, this type of vegan capsule is known to have a slow disintegration rate.

PVA Capsules

PVA Capsules

PVA Capsules is another form of vegan based capsules that is into enhanced development. Polyvinyl acetate capsules have the ability to encapsulate drugs which are hydrophilic in nature or those that are insoluble and is assumed to have increased bioavailability effect.

Starch Capsules

Starch based capsules

Starch based capsules are derived from tapioca root ,potato based starch or cassava root, which are made up of hypromellose. They have great oxygen barrier property making them shelf stable and can also handle ingredients like essential oils without leakage, therefore used in dietary supplements.

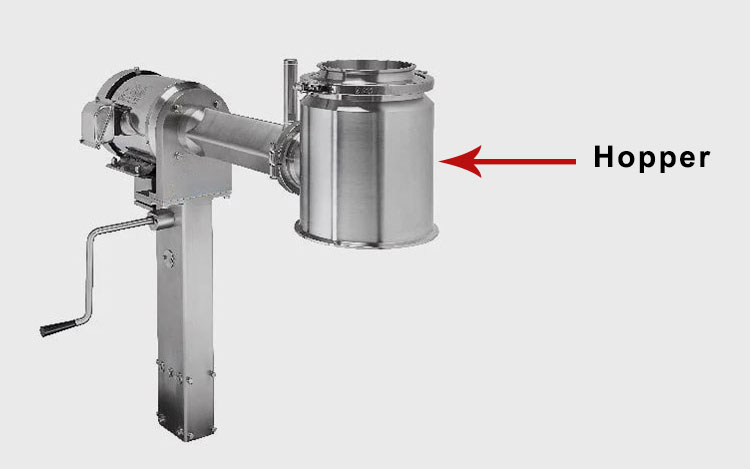

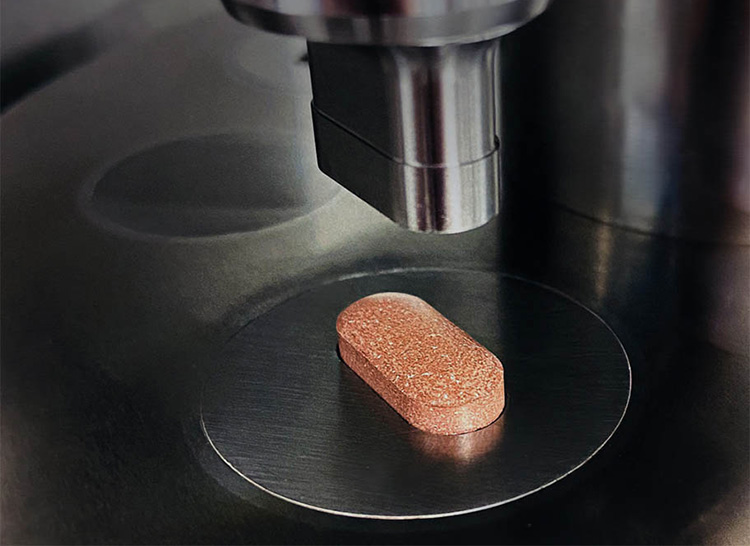

4.How To Estimate Dosage Of Medicine Capsules?

Medicine capsule – picture courtesy : Nutrition insight

Estimation or calculation of exact capsule size would decide the required adequate amount of medicine to be filled inside it. Various sizes of capsules are available to suit specific needs and that would of course mean difficulty for you to choose one. But do not worry, the below presented capsule size chart will help you to find out what you need.

Size Chart

| Size | Overall Capsule Length (In) | Average Mg Capacity | Volume Capacity |

| 000 | 1.029 | 800-1600mg | 1.37ml |

| 00E | 0.996 | 600-1200mg | 0.90ml |

| 00 | 0.921 | 600-1100mg | 1.00ml |

| 0E | 0.909 | 462-924mg | 0.78ml |

| 0 | 0.85 | 400-800mg | 0.68ml |

| 1 | 0.764 | 300-600mg | 0.48ml |

| 2 | 0.693 | 200-400mg | 0.36ml |

| 3 | 0.618 | 162-324mg | 0.27ml |

| 4 | 0.563 | 120-240mg | 0.20ml |

Milligram or dose holding capsules

Size “000” can be able to contain the maximum dosage of medicine encapsulated, which is 800-1600 mg

Size “00E” has the capability to contain 600 to 1200 mg of medicinal powder. This is known to be the average sized capsule and used popularly by nutraceutical industry for it’s great filling capacity. However, ‘00’can hold 600- 1100mg.

Size “0” can hold up to 400-800 mg of drug substance. This sized capsule is employed by pharmaceutical and cosmetics industry.

Size “1” is the alternative choice for people facing difficulty in swallowing capsules as it is comparatively small in size and can hold up to 300-600 mg of drug.

Size “2” is the smaller version of size 1 capsule. However due to it’s formulation difficulty it’s less often manufactured, but still preferred. It has ability to hold 200 to 400mg of medicine.

by patients who find it difficult swallowing even the size 1 capsules.

Size “3” , size “4” and size “5” are the less common used ones, in fact only size 4 is used in dispensing pharmacy and that too in specialized cases.

Estimation Of Capsule Dosage

Dosage ordered ÷ Dosage strength × Unit of measurement = Unknown dosage (requirement)

The dosage ordered means the amount your prescriber has instructed you to take, whereas the dosage strength denotes the available dosage form (in weight) of that particular drug and the unit of measurement is the standard unit for your dosage. Calculating your capsule dosage through this formula would help you to find out what dose of medicine you require to take.

5.How do Medicine capsules dissolve in the body?

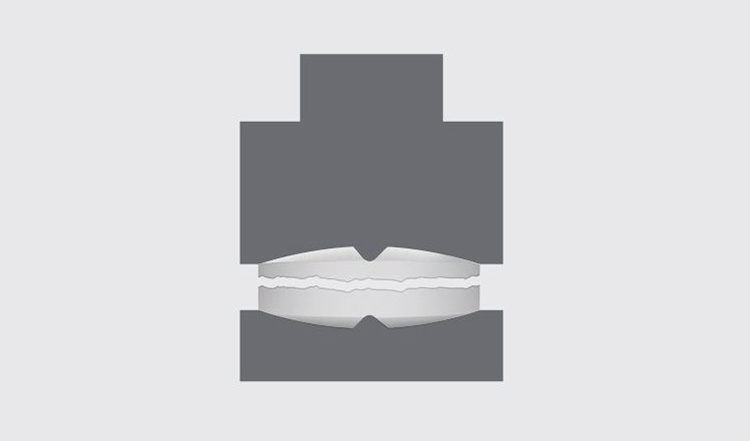

Mechanism of action of a Capsule

Medicated capsules that are enclosed in an outer shell are pharmaceutical dosage forms that are broken down in the stomach before getting transported into the bloodstream. The outer shell is broken down into digestive tract & the drug is dissolved into the bloodstream and then distributed and metabolized in much the same way as drug from a tablet.

It usually takes about 20-30 minutes for most of the drug to dissolve. When the capsule is enteric coated it protects the drug degradation from stomach acids, in case where site of action is to be reached undestroyed.

Drug molecule inside the medicine capsule affects the body by binding to multiple receptors on cells that may trigger a certain response. Although drugs are made to target particular receptors to make an intended effect, it's not possible to keep them from continuously circulating in the blood and binding to non-target sites that might be causing unwanted side effects.

Therefore, the dissolved medication moves to your liver and is then distributed to one or more target areas in your body so that it can perform its action. All over this process, the drug undergoes chemical changes, which is called as metabolism. It ultimately is expelled in your urine or feces.

Conclusion

Medicinal capsules are an intended pharmaceutical dosage form for delivery inside your body, but surprisingly they have some generalized actions too. These capsules can said to be versatile in their applications as they find it’s many purposes. Ingredients comprising these capsules are usually gelatinous or non gelatinous. They are available in different sizes as per different needs. You may take help from our given capsule size chart and dosage calculation method to solve any of your query. Still if you have any problem you can talk to our experts regarding “What Are Medicine Capsules Made Of?”. Our Allpack experts will contact you shortly.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

What Are Medicine Capsules Made Of? Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours