What Is Clamshell Packaging?

What Is Clamshell Packaging?

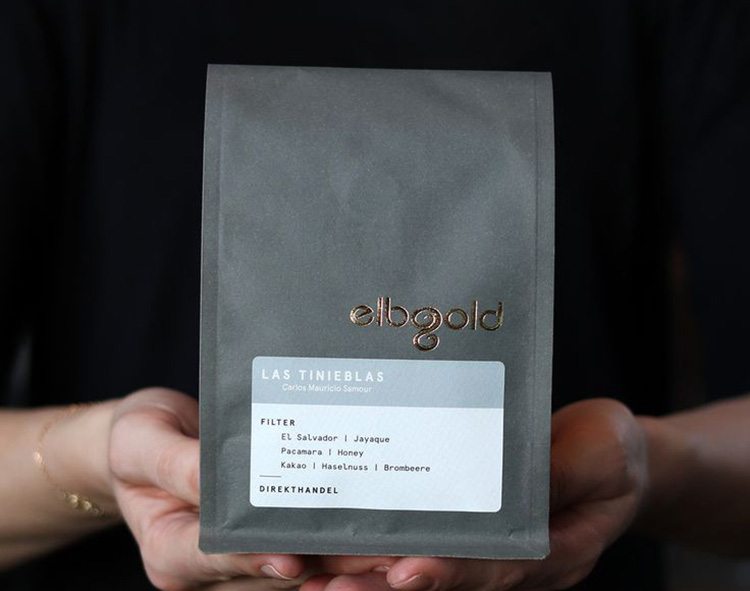

Earn more, spend less, and invest the rest, is the aim of every manufacturer. But the question is does the notion has practical application? If yes what will be the way? Shouldn't it be maintaining focus on outward manifestation of your products? Of course! In fact, your goods are known for how you showcase them on market shelves. Here is where the need for packaging arises.

You need to find a packaging solution that is cost-effective, more handy, and vibrant in appearance. Clamshell Packaging is the only way fulfilling all these requirements. But did you know What Is Clamshell Packaging? What components and materials constitute clamshell packaging? Its benefits, types, and application sphere? If not, welcome to this blog post by Allpack. Make sure to give it a thorough read!

1.What Is Clamshell Packaging?

Various food filled round clamshells

Clamshell packaging is a type of semi-rigid packaging employed to pack all sorts of fragile and hard objects. It is often made from plastic or can be derived from other materials as well such as paperboard, cardboard, and fiber etc., therefore, the packaging can be easily molded into any shape and design.

As the packaging resemble clamshell due to being manifesting hinged halves that can be joined for sealing containers, it is known as clamshell packaging. By using clamshell packaging, the products remain safe, clean, and can reach to consumers without any degradation in quality.

2.Highlight The Significance Of Clamshell Packaging?

Clamshell packaging is carrying great advantages for all its users. These benefits vary from its light weighted body to high visibility which ultimately contribute to the beauty of your products. Let's know these all one by one!

Enhanced Protection

Benefits of clamshell packaging- Picture Courtesy: Glitzhome

Indeed, the most eminent attribute of clamshell packaging is its durability and tamper proof barrier properties which restrict the entrance of airborne contamination and moisture etc., into products. Thus, your goods remain safe and secure from all kinds of damages particularly during shipping.

Transparency

Transparent plastic clamshell package displaying vibrancy of food

Most of the clamshell packages like those made up of plastic are highly transparent. No matter what type of food and other items you store in it, they will be clearly visible. Hence, it promotes the convenience for consumers' assessment of products on one hand, while as, grabbing their attention through visual appeal on the other.

Customization

Food clamshell with compartments

One of the reasons for popularity of clamshell packaging is its versatility and adaptability that it can accommodate to form any shape and size. In this way, you can create wonderful packaging styles to suit your vary needs.

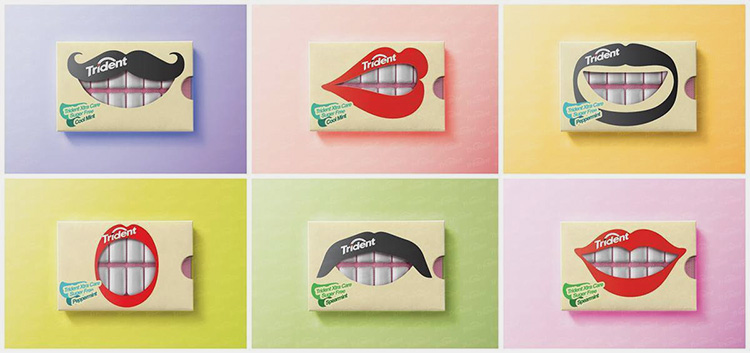

Branding

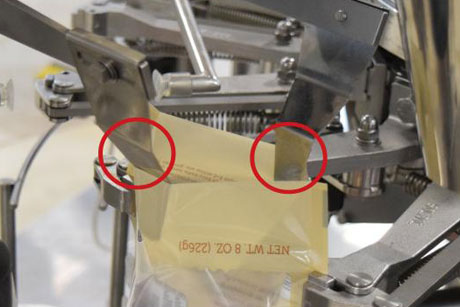

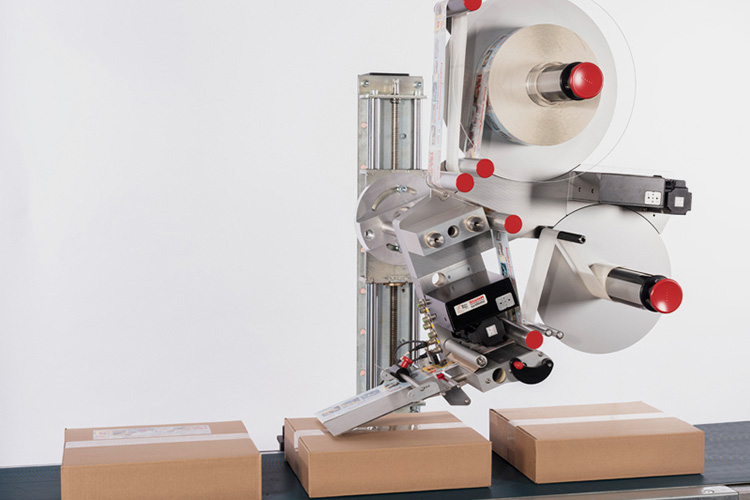

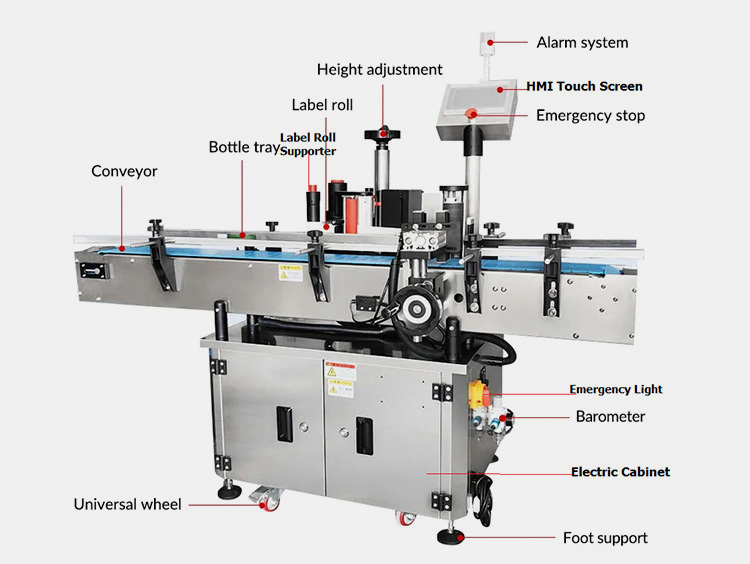

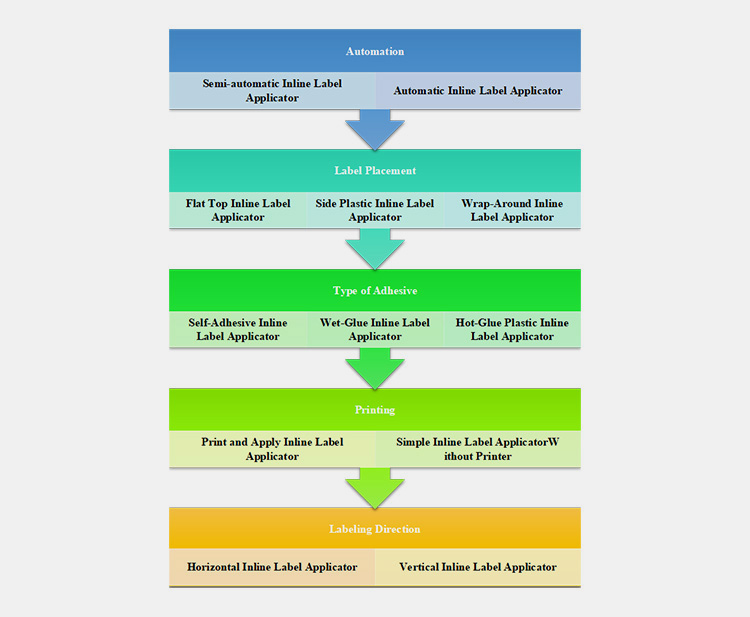

Broccoli clamshell container with appealing label- Picture Courtesy: packagingoftheworld.com

Manufacturers are found carrying multiple ends when it comes to product packaging. Clamshell packaging is one of the notable means through these aims can be achieved. For instance, you can increase your brand recognition among customers by attaching eye-catchy labels over packages and inserting graphic cards etc.

Handling Convenience

Consumer opening salad filled clamshell package- Picture Courtesy: WebstaurantStore

Clamshell packaging promote ease of use and handling on part of customers. It is because these packages can be easily opened and resealed which ends the frustration caused by other types of packaging.

3.What Components And Materials Constitute Clamshell Packaging?

Styrofoam clamshell takeout container- Picture Courtesy: Brenmar

Clamshell packaging is a type of carded packaging which is characterized by two identical shells joined at one side and recloseable on other sides. The lower side work as a body while as the upper layer is considered to be the lid which have tabs on front.

Besides the body of clamshell packaging, the material used in its making vary from rigid and moisture resistant plastic to biodegradable paperboard. Moreover, bagasse, wheat grain, polystyrene, and plant fiber are the other materials which are used to form and create clamshell packaging.

4.What Food Products Can Be Packed Through Clamshell Packaging?

The nature and flexibility of clamshell packaging make it applicable to all kinds of food and non-food products. However, here we will discover some of the prominent eatables which can be packed through clamshell packaging. These are as follows:

Fast Food

Burger laying in clamshell container- Picture Courtesy: watsonpak.com

Fast foods refer to food which can be quickly prepared and served such as burger, pizza, burrito, and sandwich etc. As their demand among people, especially youngsters, is growing you can use clamshell packaging for perfect packing and safe delivery of your fast foods.

Baked Food

Cook placing croissants in clamshell

Baked food like pastries, cookies, cakes, and breads are of sensitive nature and they require hygienic conditions for staying fresh and crispy. In this way, clamshell packaging is best suitable to be used which prevent the microbes and humidity from getting into food.

Fruits & Vegetables

Chopped fruits & vegetables in clamshell- Picture Courtesy: Restaurantware

Fruits and vegetables are the prerequisites for our survival. Hence, their selling and purchase is a routine task but at the same time their perishable nature lead them to quick deterioration and spillage. However, clamshell packaging can now be used to give your perishables a new and healthy life.

Sauces

Pomegranate sauce in clamshell container- Picture Courtesy: WebstaurantStore

Although, sauces are liquid and viscous in nature yet clamshell packaging is the most desirable one to be used for ketchup, mayonnaise, and other sauces. It is because the sealing of clamshell packaging is so durable that even a drop cannot be escaped from it.

Readymade Meals

User holding bowl filled with cooked food- Picture Courtesy: Polomarco

Who doesn't love having readymade meals all the time ready for them? Of course no one! So, here it is significant to mention that clamshell packaging is highly safe and recommended for the packaging of your meals whether in homes, restaurants, or hotels.

5.Enlist The Popular Styles And Shapes Of Clamshell Packaging?

Clamshell packaging comes in unique and beautiful formats which will indeed amaze you. These are as follows:

Single-Hinge Clamshell

Single-hinged plastic clamshell container- Picture Courtesy: WebstaurantStore

Single-hinged clamshells are the most common and basic style of clamshell packaging where the edges of upper and lower part of clamshell is joined to each other on one side. While as the rest sides are opened and attached via recloseable tabs.

Tri-Fold Clamshell

Tri-fold stand up toys clamshell- Picture Courtesy: fy.plasticblisterpack.com

Tri-fold clamshell is popularly known for their ability to hang or stand on shelf. Such type of clamshell has three part design including a triangular base to stand upright on shelf and a back and front where product is placed. Tri-fold clamshells are often employed for both primary as well as secondary packaging.

Cavity Clamshell

Wax melts in cavity clamshells- Picture Courtesy: Randall's Candles

This type of clamshells are having multiple cavities whose number may vary. Cavity clamshells can be found in plastic, paperboard, and other stuff. Similarly, their application is also not restricted to few objects, rather, you can pack in them the individual solid wax melts, eggs, and biscuits for intact packaging.

Double-Blister Clamshell

Double blister clamshells for baby essentials- Picture Courtesy: packagingoftheworld.com

Double blister clamshell is extremely renowned packaging format where flat plastic blister backing is adjoined with cavity blister. It may be also found in slid-blister clamshell with similar flat blister back but here the slid back is not attached rather removable.

Square Clamshell

Biodegradable square clamshell food box

This type of clamshell features square shape perfect for holding fruits, vegetables, hamburgers, and hardware objects. You can also form the square clamshells in small to large sizes for accommodating respective amount of materials like ketchup and cookies etc.

Rectangular Tray Clamshell

Various rectangular food clamshell trays- Picture Courtesy: Scratch

Rectangular tray clamshells are sturdy containers having large capacity to hold high volume of goods like cake rusks, meat, and vegetables etc. They are often flat shaped but may have compartments if customized.

Round Clamshell

Various round food clamshell containers

Round clamshell is another type of clamshell packaging frequently adopted for different material especially burgers, readymade meals, and salad etc. Their sealing vary from hinged halves to twist-open or pull up lids.

Triangle Clamshell

Cake pieces in triangle clamshell containers- Picture Courtesy: temu.com

The most charming and appealing format of clamshell packaging is undoubtedly the triangular clamshells which are particularly designed to safely preserve the similar shape items like pizza, cake pieces, and sandwiches etc. As these clamshells fit materials, the objects remain in their original condition till end users.

6.Are There Any Types Of Clamshell Packaging?

In a world of technology the reliance on traditional forms of clamshell packaging is reducing and its place has been taken up by new types. However, the relevance of conventional clamshell packaging still exists. Let's shed light on some of the prevalent types of clamshell packaging!

Plastic Clamshell Packaging

Multiple plastic clamshell containers- Picture Courtesy: dhgate.com

Plastic clamshell packaging is one of the most traditional and important types of clamshell packaging. It is sometimes called thermoform clamshell packaging due to the only method through which it is made. Such type of packaging is derived from PVC, RPET, PET, and PETG plastic. Although, plastic clamshell packaging is light weighted, often transparent, and cost-effective, but it is not eco-friendly.

Plastic clamshell packaging can be further divided into underlying types:

| No | Type | Picture |

| 1 | Food clamshell packaging

It refers to the type of clamshell packaging where different clamshell packages such as trays, containers, and bowls are made from food-grade plastic. It thus promotes safe storage and handling of various food products in restaurants, food trucks, and catering companies etc. |

Food clamshell packaging |

| 2 | Retail clamshell packaging

Retail clamshell packaging is made from durable plastic. The plastic may be transparent or dyed which is used to securely pack and deliver individual products like toys, cosmetics, and electronics. |

Mini Nivea lip balm ball retail clamshell packages- Picture Courtesy: dhgate.com |

| 3 | Blister clamshell packaging

Blister clamshell packaging unlike other types is characterized by its flat back usually made from hard paper or plastic and a clear plastic front displaying and resembling the shape of product laying inside. The purpose of such packaging is to allow customers to see the items inside the packaging. |

Blister clamshell packaging for glitters |

Paperboard Clamshell Packaging

Paperboard egg holding cavity clamshell

Paperboard clamshell packaging is another type on the list which is made from recycled paper that is biodegradable, hence, is more environmentally friendly than plastic clamshell packaging. It has two shells joined on one side while having interlocking tabs on the opposite side. Moreover, the application of wax layer over paperboard clamshell packages make them more favorable for liquid food. Therefore, it is frequently used in food bars, BBQ joints, and food retailers.

Plant Fiber Clamshell Packaging

Plant fiber clamshell boxes

Next up, we have plant fiber clamshell packaging which is created from wheat grain and chaff. This type of clamshell packaging is soak proof and has high resistance to water. This attribute make the packaging surpass over other types like paperboard clamshell packaging which has poor or no resistance to water while at the same time complying food safety standards. Ergo, you can serve your products in plant fiber clamshell packages to satisfy your diligent customers.

Sugarcane Clamshell Packaging

Bagasse food clamshell boxes- Picture Courtesy: Tessera Bio Products

Among other types, sugarcane clamshell packaging is popular one. It features two shells attached on one end while opened on the other with interlocking clasps. Its material, as the name indicates, is derived from the leftovers of sugarcane. This quality is beautifully justifying the packaging contribution for environmental sustainability while as its applicability for both hot and cold serving.

Styrofoam Clamshell Packaging

Styrofoam clamshell box for food- Picture Courtesy: letsgogreen.biz

Styrofoam clamshell packaging is another type of clamshell packaging obtained from smooth and bouncy polystyrene. Similar to sugarcane clamshell packaging, it supports both hot as well as cold food. Its structure resemble clamshell with same closure at one side while opening on the other. So, whether it is your cafeteria, a restaurant, or small food truck, you can use styrofoam clamshells for delivering burgers, fries, and much more.

7.What Are The Industrial Applications Of Clamshell Packaging?

Clamshell packaging is widely applicable in diverse industrial sectors. Some of these are explained below:

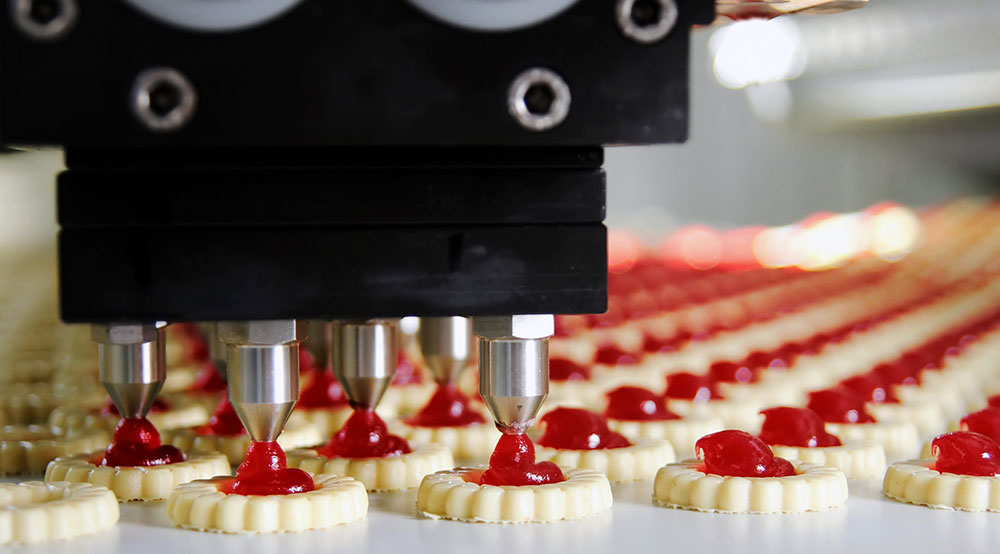

Food Industry

Food processing industry- Picture Courtesy: garmentprintinggroup.com

The term food industry is broad enough that it holds under its umbrella all kinds of associated sectors where food is processed and packed. For achieving this goal, clamshell packaging is now popularly employed for packing various fruits, vegetables, seafood, meat, and cooked meals etc.

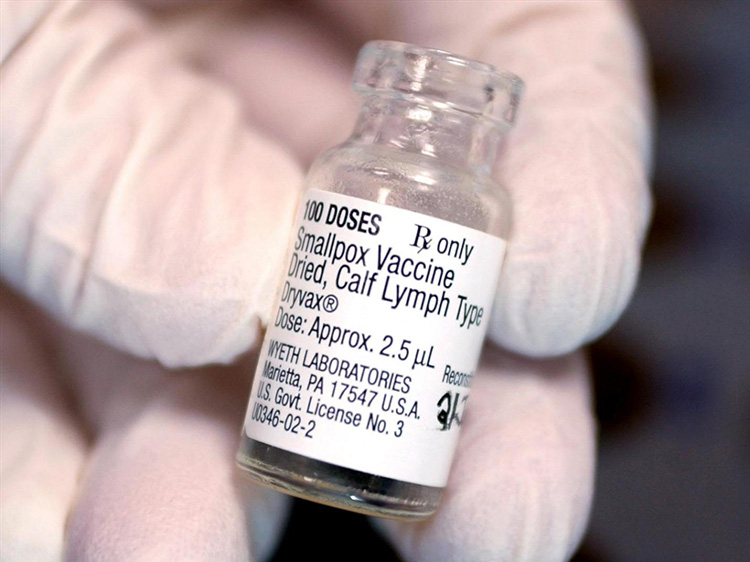

Medical Industry

Drugs & medical tools- Picture Courtesy: Freepik

Medical industry is another comprehensive field where clamshell packaging is adopted for the safe delivery of different drugs and surgical tools such as vaccines, injections, medicines, and gloves kit etc.

Cosmetic Industry

Facial cream tubes- Picture Courtesy: nivea.com

Well, beauty care products are manufactured and packed safely to reduce the wastage occurs to goods during their shipping. In this way, clamshell packaging is often utilized for packing cosmetic items like makeup kits, vaseline bottles, and brush kits etc.

Electronic Industry

Multiple chargers in plastic blister clamshells

Electronic tools of all kinds taking from mobile chargers to USBs and mobile phones, are now packed through clamshell packaging for the sake of guaranteeing protection. Hence, its significance is realized in electronic industry as well.

Hardware Industry

Multiple kitchen essentials packed in clamshells- Picture Courtesy: trendhunter.com

All kinds of hardware objects made from plastic, metal, and other materials like paper are commonly packed in clamshell packages. The common examples include stationary items, toys, nuts, and kitchen tools. Therefore, it can be said that clamshell packaging is also applicable in hardware industry.

8.Discuss The Environmental Impact Of Clamshell Packaging?

Environmental impact presentation idea- Picture Courtesy: tmforum

Despite offering so many advantages clamshell packaging is considered detrimental for the overall environment and ecosystem. It is because the various elements used in plastic clamshell packaging are sometimes difficult to separate making the packages harder to recycle.

However, to restrict this negative development on part of clamshell packaging, now various eco-friendly options like that of plant based and paper based clamshell packaging has been introduced. These alternatives are highly biodegradable and compostable which are contributing to reduce the environmental impact of clamshell packaging.

Conclusion

We end up with a positive gesture that you have finally got the answer to what is clamshell packaging? Clamshell packaging is a carded packaging that allows you to pack your multifarious small to medium size goods with much ease. You can opt for the type of clamshell packaging that suits you the most. Not only that, but you can take initiative for creating your own clamshell packaging business. So, what is your next move? Are you about to take this idea? If yes, let us know your intentions. We will further guide you about clamshell packaging and the machines required for it.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

What Is Clamshell Packaging? Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours