Grape Beverage Bottling Line: The Complete Buying Guide In 2025

Grape Beverage Bottling Line: The Complete Buying Guide In 2025

Did you know grape beverage is a health-smart option because it is rich in antioxidants?

For preserving quantities of antioxidants, grape beverages must be packed, and this is where the grape beverage bottling line shines. It automatically and efficiently loads grape beverages in different-sized unique design bottles.

The grape beverage bottling line is a complete turnkey solution, assisting in the smooth and durable packaging of grape beverage bottles. This bottling line handles and treats bottles with speed and steadfastness.

If are you interested in installing a grape beverage bottling line, then take a step back and carefully go through this guide to discover all the useful features of this bottling line. Let’s get started.

1.How to Define Grape Beverage Bottling Line?

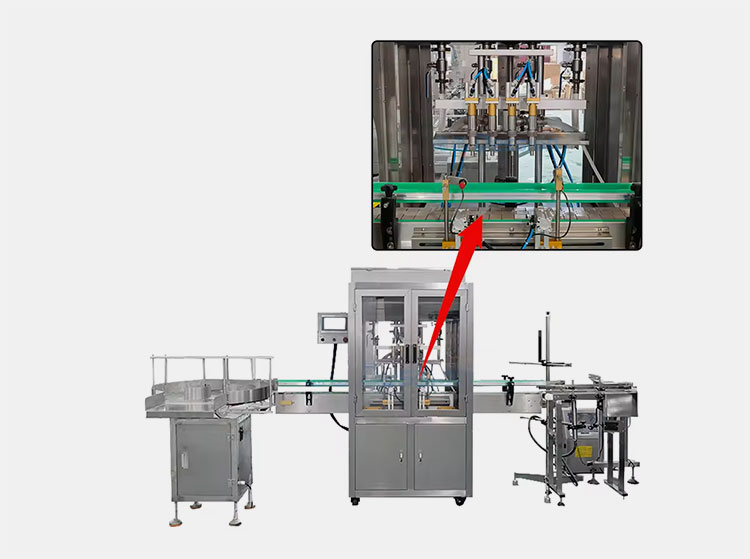

Grape Juice Bottling Line

A grape juice bottling line has a set of machines developed to perform different functions like aligning, filling, sealing, and labeling grape beverage bottles. Hygienic processing and fast packaging are two key goals of the grape beverage bottling line.

It is an indispensable solution to ascertain productivity, accuracy, and uniform packaging quality. This bottling line has tailored technology to provide flawless results. Different devices like bottle unscrambling, bottle rinsing, bottle filling, bottle capping, and bottle labeling machines are linked with each other in the grape beverage bottling line to automatically package grape beverages.

2.Why Grape Beverage Bottling Line is So Popular in Businesses?

Grape beverage bottling line is extremely popular in businesses because it packs a large assortment of benefits and takes businesses to the highest level of success. This bottling line has proficiency and delivers the absolute best packaging results. Here is the list of outstanding benefits of the grape juice bottling line.

Product Consistency

Product Consistency- Picture Courtesy: FAB News

It is what matters most to the manufacturer because product inconsistency, often results in poor packaging accuracy and product recall. But product inaccuracies in the thing of the past with grape beverage filling line. Every process in this bottling line has accuracy and consistency because it is tailored with advanced and high-tech sensors that ensure precision throughout packaging steps.

Operation Efficiency

Operational Efficiency- Picture Courtesy: Packaging of the World

Manufacturers put up the grape beverage bottling line into their productions because of its operational efficiency. It is because manual labor has limited packaging speed, packaging a few bottles at a time. But this bottling line is quite a productive unit, processing numerous quantities of grape beverage bottles in a short time interval.

Labor-Saving

Labor Saving- Picture Courtesy: Packaging of the World

Grape juice beverage bottling line has automation, resulting in autonomous bottling handling. It only needs human operation for setting up the machine and there is no need to supervise this bottling line. Hence, it requires just one to two operators, saving the need to hire heavy labor.

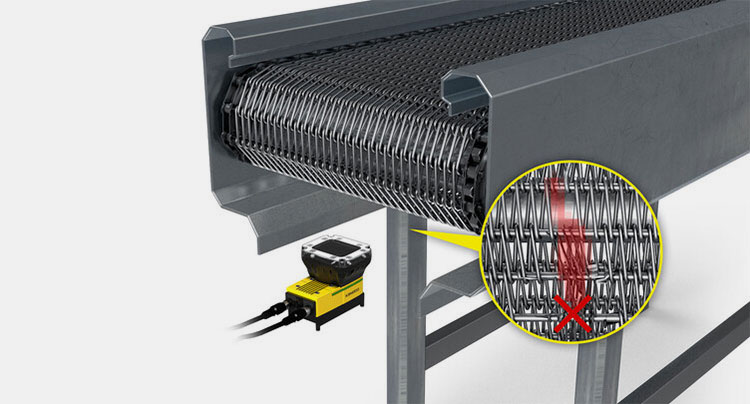

Quality Control

Quality Control- Picture Courtesy: Packaging of the World

Because there is no human involvement, the grape beverage bottling line delivers high-quality packaging. Humans often produce packaging errors, resulting in poor product quality. Conversely, there is no processing and packaging error with this bottling line. It allows brands to attain customer satisfaction.

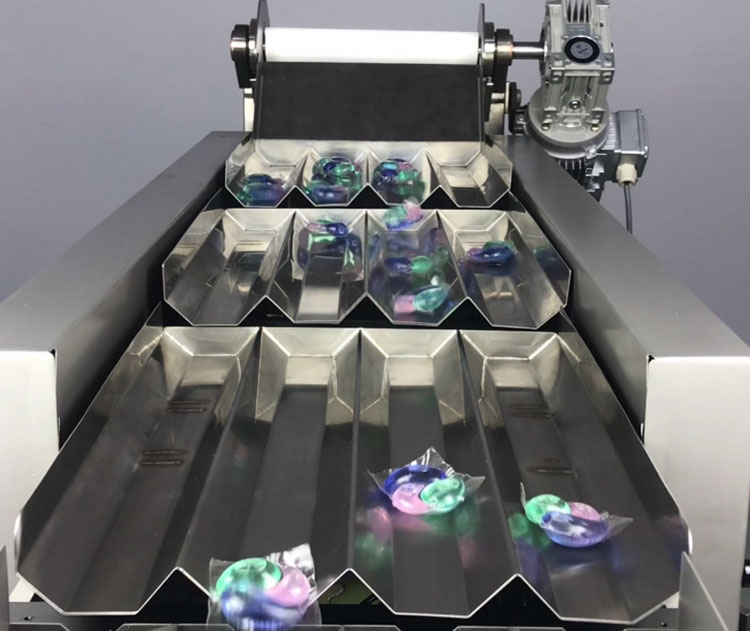

Packaging Versatility

Packaging Versatility- Picture Courtesy: Behance

There are no fixed standards for bottles when it comes to the packaging of grape beverages. Therefore, machines in the grape beverage bottling line are flexible to accommodate diverse designs of bottles. Packaging versatility with easy format change increases the packaging efficiency. Moreover, this flexibility allows the manufacturer to improve their brand image.

3.In What Industries Grape Beverage Bottling Line is Found?

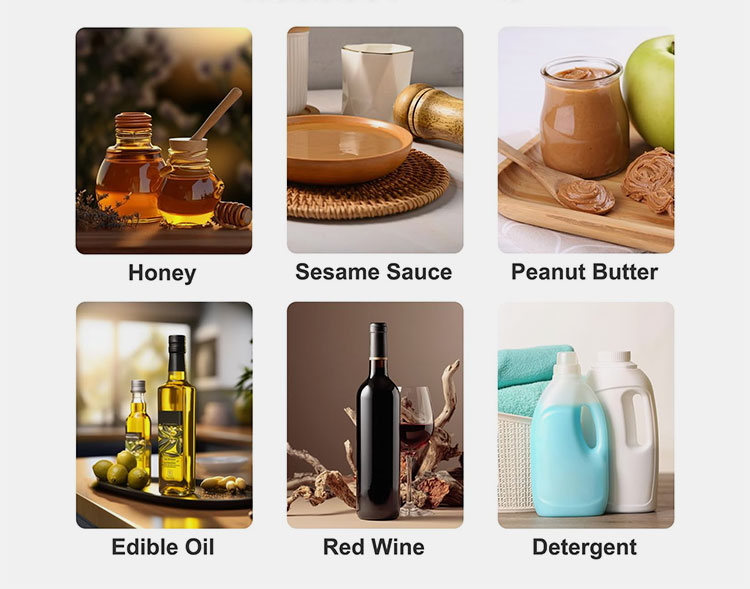

Various industries have adopted the grape beverage bottling line because of its faultless processing, stylish packaging, and resilience. It fills and seals countless liquid products with speed and precision. Some of the basic industries in which grape beverage bottling line is found are written below:

Beverage Industry

Beverage Packaging Design- Picture Courtesy: Really Design

It is the primary industry that employs the grape beverage bottling line. With its seamless efficiency, it packs different types of beverages, juices, tea, sodas, etc. This bottling line has a significant role in preserving the taste, aroma, and nutritional value of the beverages.

Food Industry

Food Sauce Packaging- Picture Courtesy: Behance

The grape beverage bottling line is also high in demand in the food industry because of its robustness, hygienic, and clean processing. Avoiding cross-contamination is the main goal of the food industry and this bottling line fulfills this requirement. It is utilized to pack different kinds of sauces, condiments, vinegar, cider, and syrups in the food industry.

Cosmetic Industry

Cosmetic Packaging- Picture Courtesy: PackFixed

Aesthetic appeal and branding are two main aspects of the cosmetic industry and the grape beverage bottling line is highly recommended in the cosmetic industry because it beautifully packages different types of cosmetic bottles like lotion, cream, hair color, face mask, and many more.

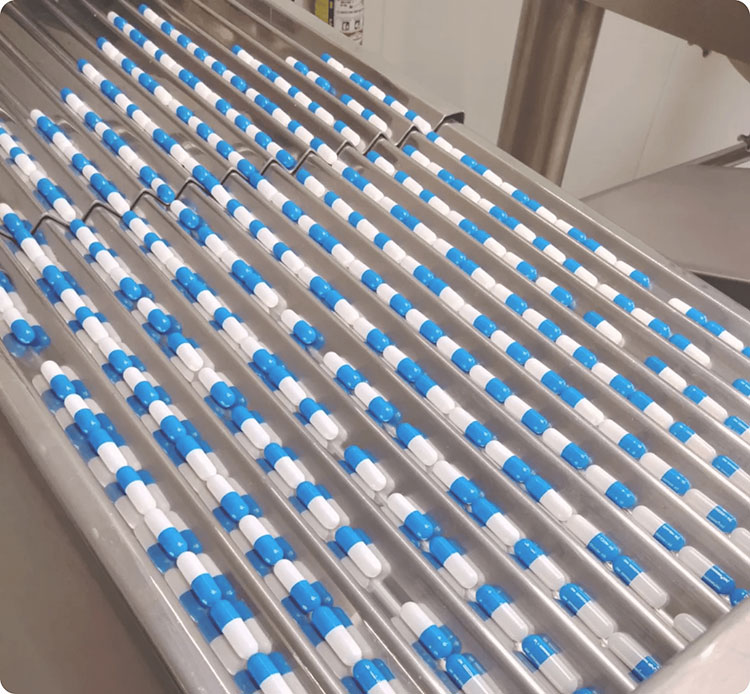

Pharmaceutical Industry

Pharmaceutical Syrup Packaging- Picture Courtesy: Behance

A grape juice bottling line is also present in the pharmaceutical industry. It fills and caps different types of emulsions, solutions, and pharmaceutical syrups. It is renowned in the medical and healthcare sectors due to its dose accuracy and hygienic filling.

Automotive Industry

Automotive Packaging- Picture Courtesy: Coroflot

Yes, the automotive sector also installs the grape beverage bottling line to process and pack different types of automotive engine oils, lubricants, anti-freeze, and battery oils, to name a few. Its consistency and uniform packaging are what make this bottling line a great addition to the automotive industry.

4.What Type of Bottles are Accommodated by Grape Beverage Bottling Line?

Upon the type of audience and needs of grape beverage, there are two main types of bottles accommodated by the grape beverage bottling line. These are:

Glass Bottles

Glass Beverage Bottle- Picture Courtesy: Behance

These bottles are typically used for storing different types of grape wines because of their premium look and feel. They are made of non-reactive glass materials that maintain the taste and quality of grape beverages. It showcases the quality of grape beverages.

Plastic Bottles

Plastic Grape Beverage Bottles

They are light in weight and have breakage resistance. Plastic grape beverage bottles are made of PET and HDPE. They are a more cost-effective solution than glass bottles and can be easily molded into different designs.

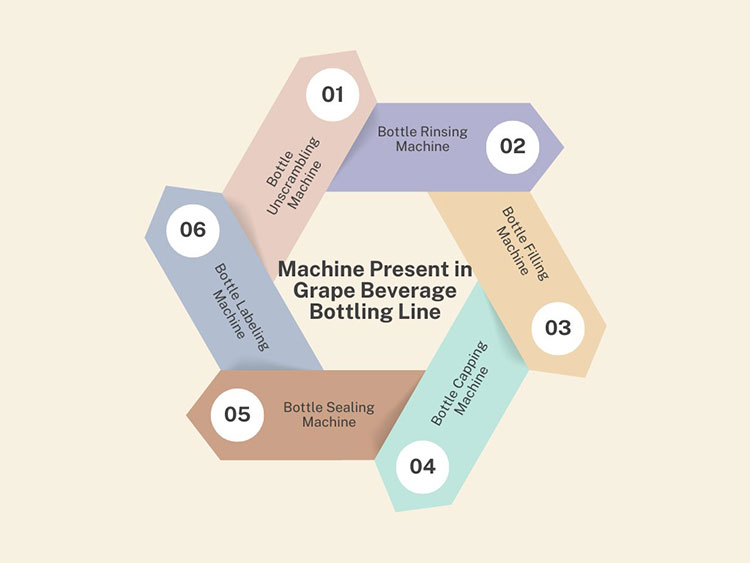

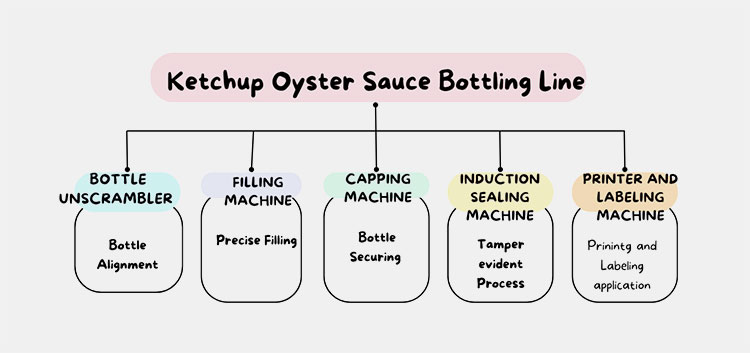

5.What Types of Machines are Integrated in Grape Beverage Bottling Line?

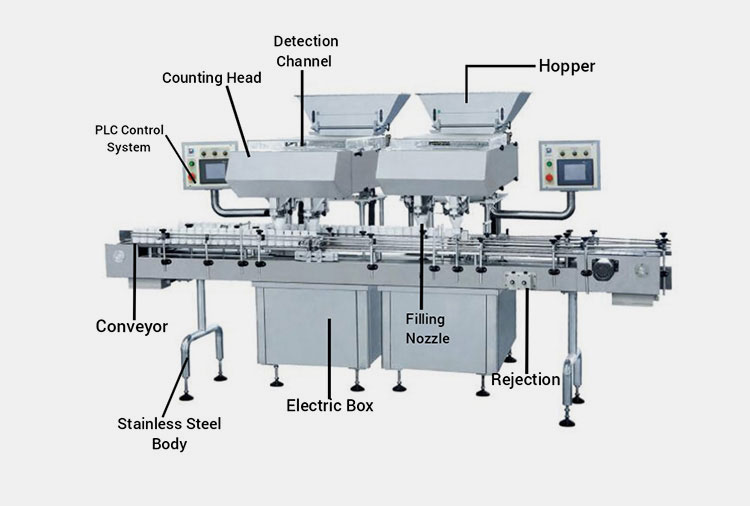

Numerous types of machines are integrated into the grape beverage bottling line to provide quality control and efficiency. Here is a breakdown of all the important machines present in the grape beverage bottling line.

Machines Integrated in Grape Beverage Bottling Line

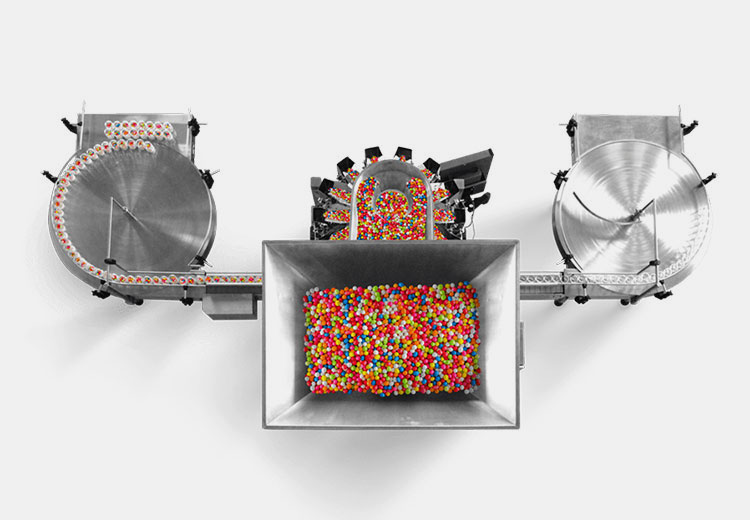

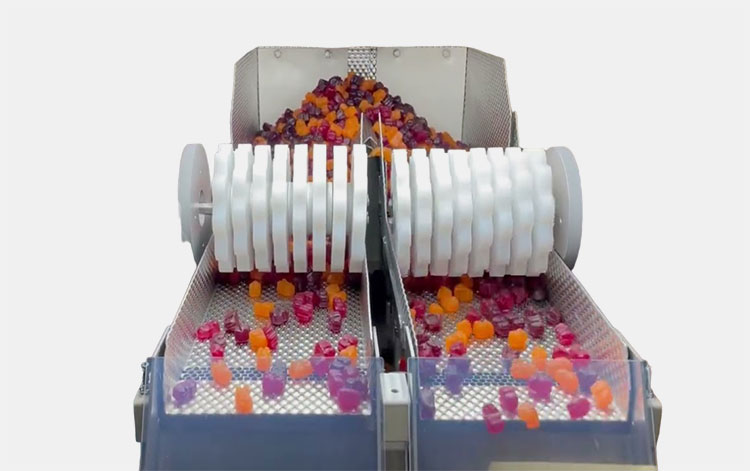

Bottle Unscrambling Machine

Bottle Unscrambling Machine- Picture Courtesy: Traktech

This machine receives bottles in unorganized form and places them randomly on the conveyor. Its main purpose is sorting, which is carried out by the rotary disc and blower. These two systems are essential in keeping bottles in order.

The bottle unscrambling machine transports bottles in organized form towards the bottle rinsing machine.

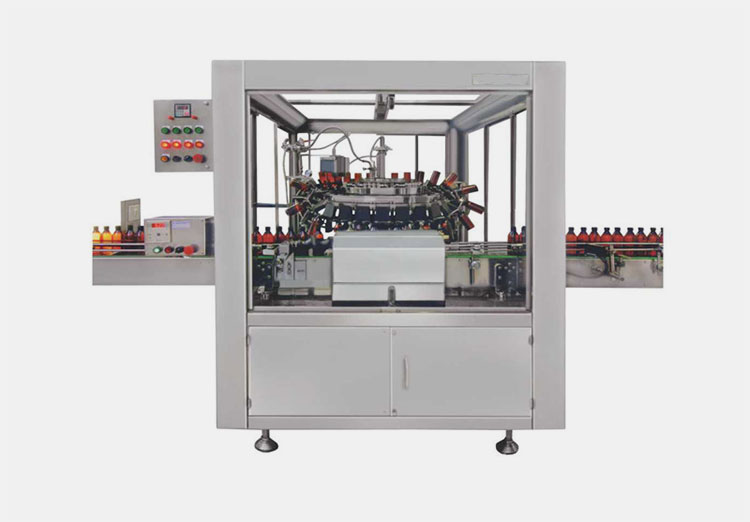

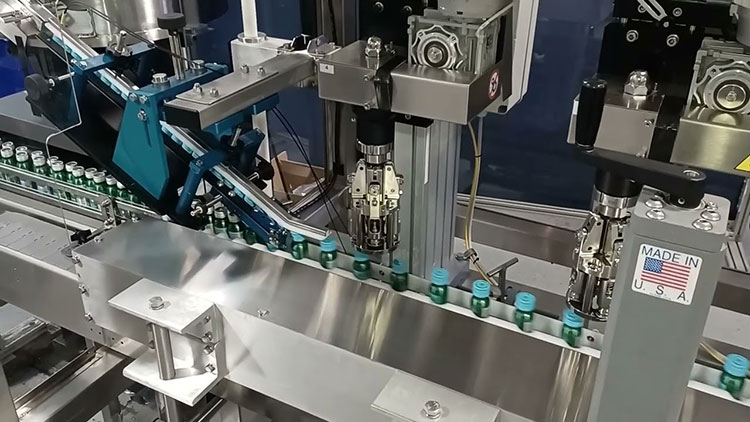

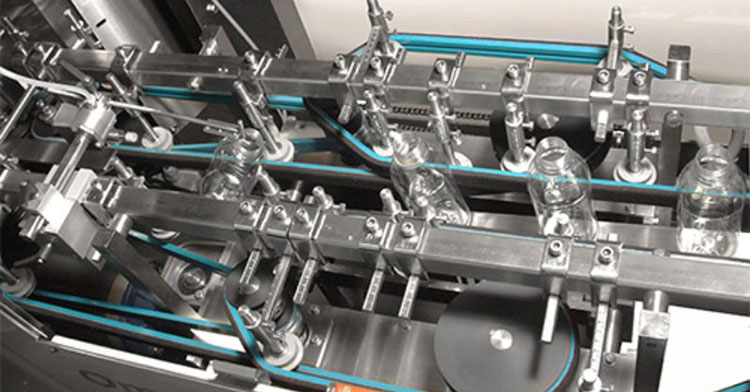

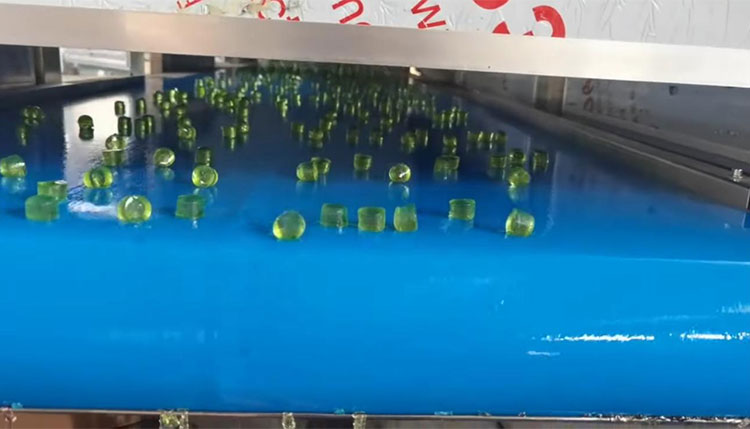

Bottle Rinsing Machine

Bottle Rinsing Machine

Bottles are often contaminated and have dust or debris. Therefore, a bottle rinsing machine is utilized in the grape beverage bottling line. Cleanliness and sterility of contaminated bottles is achieved by bottle rinsing machine

It has high-speed water jets and compressed air systems that thoroughly clean the grape beverage bottles. Using these systems, rinse the bottles so that they are free of dust, debris, and microbial contamination.

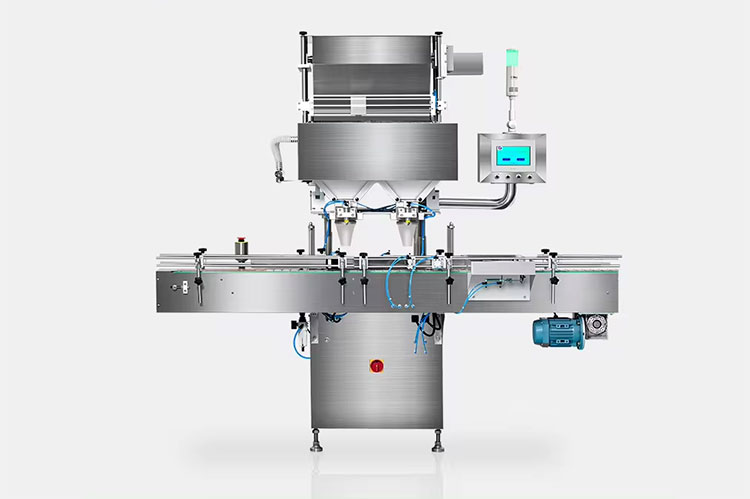

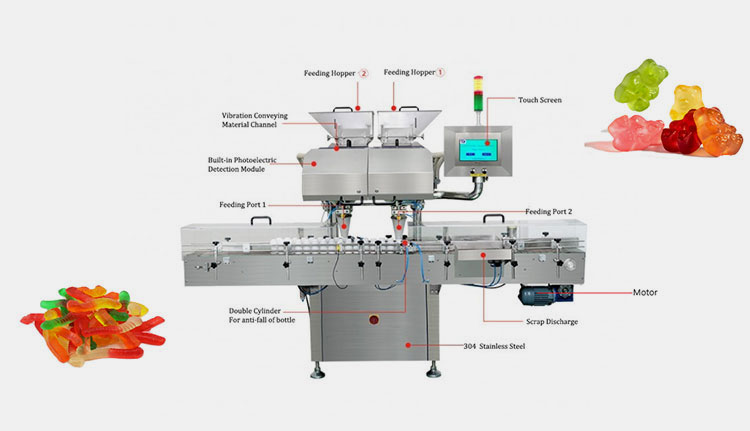

Bottle Filling Machine

Bottle Filling Machine- Picture Courtesy: Packleader

It is the core part of the grape beverage bottling line. Different types of nozzles and filling devices are tailored in this machine to complete accurate filling. Detection of bottles is carried out by the sensors. Precisely loaded grape beverage bottles are moved from filling systems to the next-in-line machine called the capping machine.

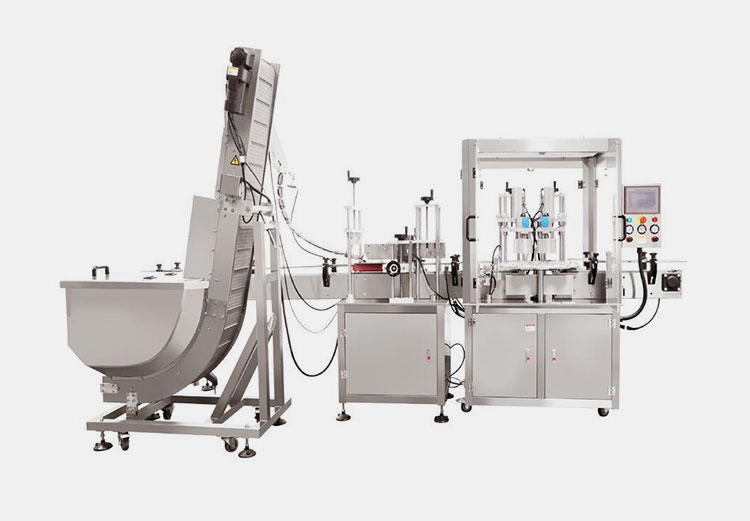

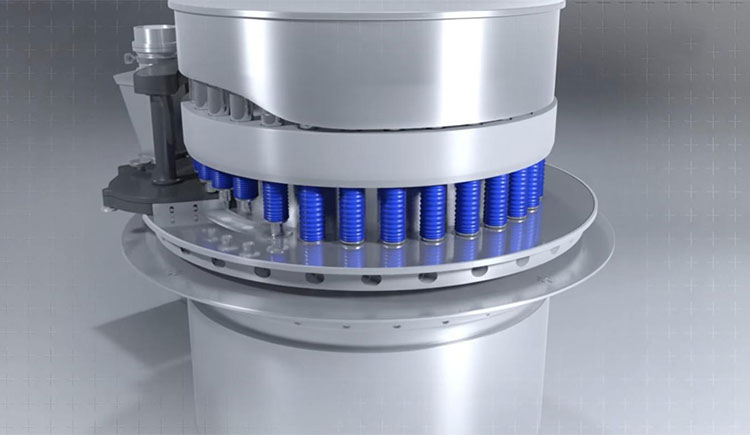

Bottle Capping Machine

Allpack Bottle Capping Machine

This machine secures bottles by capping them. The foolproof capping is accomplished by chucks and rotating discs. Capping heads apply torque forces to tightly close the bottles. It secures the inner contents of the grape beverages and protects them from contamination.

Bottle Sealing Machine

Allpack Bottle Sealing Machine

It is an integral machine in the grape beverage bottling line. Its function is to tightly apply seals on the openings of bottles to protect them from leakage. It places a liner on the mouth of bottles by melting it with electromagnetic pulses. This machine creates a hermetic seal with the bottle opening. This seal is tamper-proof and durable.

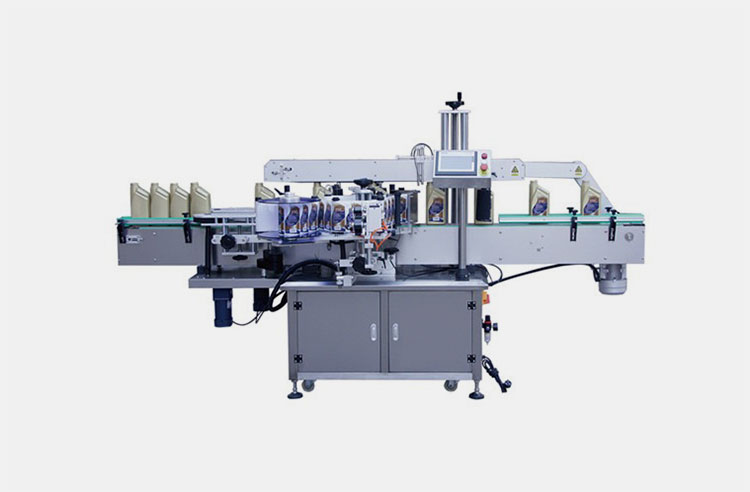

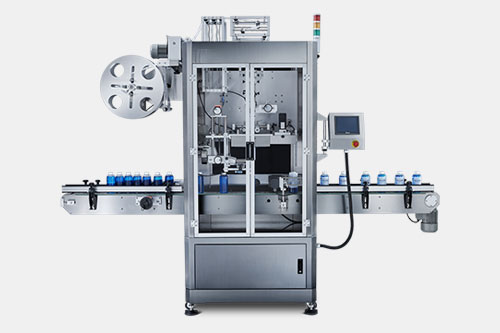

Bottle Labeling Machine

Allpack Bottle Labeling Machine

The bottle labeling machine is integrated into the grape beverage bottling line for notifying users about the packed contents of the grape beverage bottles. Labeling heads and label presses in these machines stick perfect labels on the bottles.

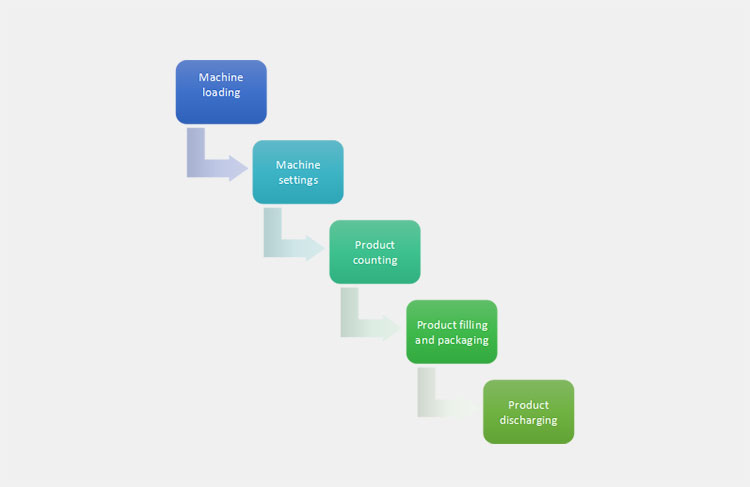

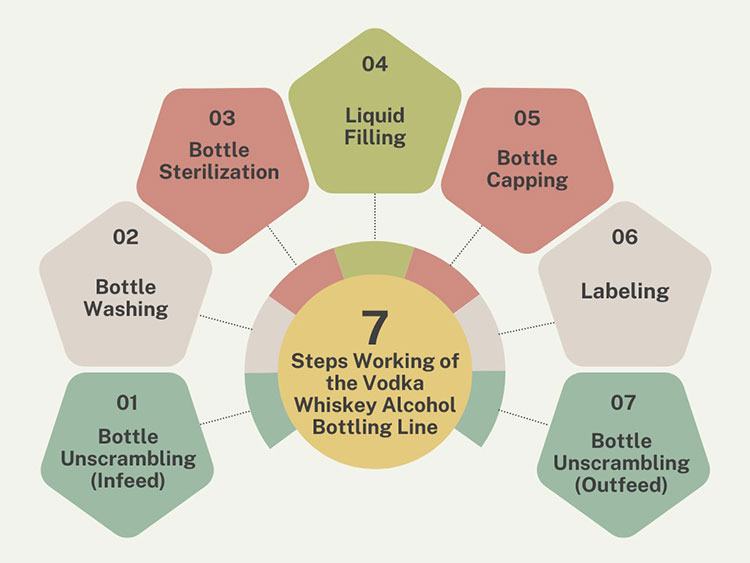

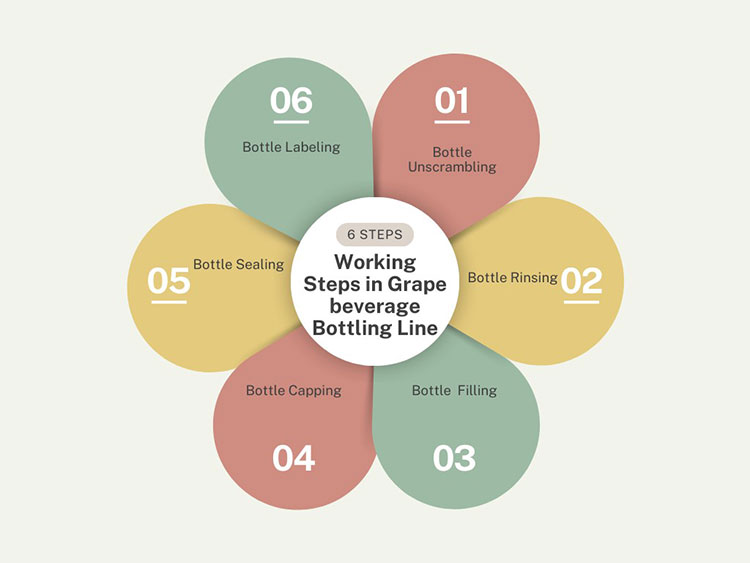

6.Discuss the Step-by-Step Working of the Grape Beverage Bottling Line.

An interconnected series of machines in the grape beverage bottling line have perfected their role of smoothly packaging grape beverage bottles. Each step in the grape beverage bottling line is executed seamlessly to obtain flawlessly packed bottles. Here is a step-by-step guide to the working stages in the grape beverage bottling line.

Working Steps in the Grape Beverage Bottling Line

Step 1: Bottle Unscrambling

Bottle Unscrambling- Picture Courtesy: Icon Equipment

It is also called bottle orientation or bottle-feeding step. It is a significant stage in the grape beverage bottling line. In this step, bottles are arranged automatically in an upright direction. A large collection of bottles is placed in the hopper. Grippers hold the bottles and deploy them in the required direction.

Step 2: Bottle Rinsing

Bottle Rinsing- Picture Courtesy: PERRIER Bottling Machines

It is a bottle-washing step that is carried out before bottle filling. Air blasts and water jets are utilized to clean the bottles and make them sterile for the filling step. These water and air systems are efficient in dislodging loose and sticky contaminants from the bottles.

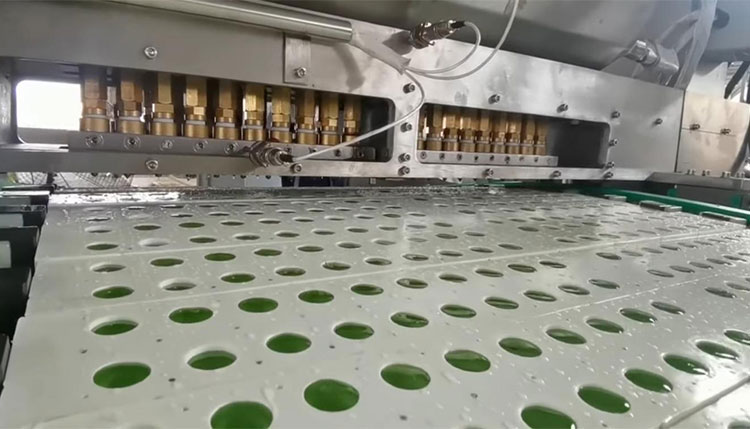

Step 3: Bottle Filling

Bottle Filling- Picture Courtesy: GEA

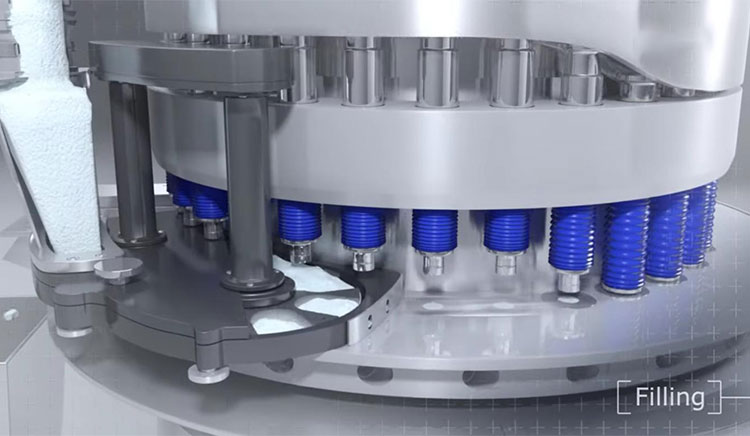

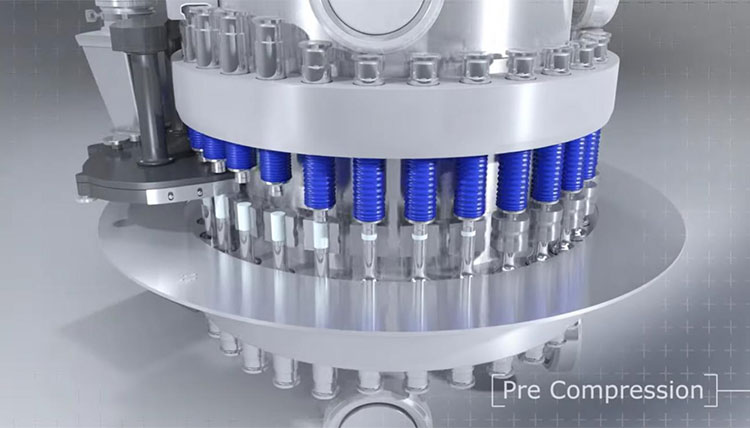

After drying, the bottles are transferred to the bottle-filling machine. upon detection of bottles by the sensor, the filling commences. First, the bottles are dosed speedily by the filling nozzles. Then this process gradually slows down to attain the desired fill volume.

It is the main step in the grape beverage bottling line that minimizes spillage and wastage of grape beverages.

Step 4: Bottle Capping

Bottle Capping- Picture Courtesy: Liquidpackaging

It is an important step in the grape beverage bottling line. Caps in the hoppers are transferred to the capping head by the gripper. At this unit, the rotating disc exerts torque on the caps to secure them on the bottle tops. Chucks also have a role in the correct rotation of caps and closing of bottles.

This step protects the inner contents from spoilage and extends the shelf-life of the products.

Step 5: Bottle Sealing

Picture Courtesy: iPharmachine

At this stage, a strong and tight seal is placed on the bottle tops to avert the chances of leakage and contamination. Bottle caps are secured by the plastic or paper liner to form a seal that has additional security against tampering.

Step 6: Bottle Labeling

Bottle Labeling- Picture Courtesy: HERMA

In this phase, labels are applied to the exterior of the bottles by the labeling heads. This bottle labeling process is essential in communicating product information, branding, and regulatory compliance.

7.What Grape Beverages are Processed by Grape Beverage Bottling Line?

There are numerous grape beverages processed by the grape beverage bottling line such as:

Grape Juice

Grape Juice- Picture Courtesy: Packaging of the World

Different types of grape juices like pure grape juice, grape concentrates, and grape blends are processed by these bottling lines. These drinks have unique grape flavors with the nutritional value of grapes.

Grape Sodas

Grape Soda- Picture Courtesy: Beverage Direct

Carbonated and diet grape sodas are fizzy drinks with sweet and savory grape flavors. They make an energizing drink in the hot summer months.

Grape-Flavored Water

Grape-Flavored Water- Packaging of the World

Still and sparkling grape water has added natural and artificial grape flavoring. Numerous people fancy grape-flavored water more than plain water because of its refreshing taste.

Grape Smoothies

Grape Smoothies- Picture Courtesy: Raw Pixel

They are made by combining grape juices with yogurt or protein powders and provide a rich source of important vitamins and minerals.

Grape Wines

Grape Wines- Picture Courtesy: TheCoolist

Red, white, rose, and sparkling wines are fermented using grape concentrates. They have sweet, tart, and light palate and pack dozens of health benefits.

8.What Type of Labeling Machines are Present in Grape Beverage Bottling Line?

There are four main types of labeling machines based on their type of adhesive in grape beverage bottling line. These are:

| Wet-Glue Labeling Machine

Picture Courtesy: Infismash |

It consists of a glue applicator that smears the glue on the back of labels. This adhesive does not require melting. It is typically used in the grape beverage bottling line because it pastes intricate types of labels on glass and plastic bottles. |

| Hot-Melt Glue Labeling Machine

Picture Courtesy: Chinaplas |

In this machine, glue is melted and then applied to the surface of labels. Dispensing nozzles help apply the precise amount of glue on labels. |

| Self-Adhesive Labeling Machine

Picture Courtesy: focusonpack |

Rather than apply glue on labels, it sticks pre-glued labels on the bottles. Back papers are peeled off before affixing labels in this machine. |

| Shrink-Sleeve Labeling Machine

Picture Courtesy: Packleader |

This machine is quite popular in industries because of its full-body labeling. It places a thermoplastic sleeve over the bottles that are transferred to a heating tunnel for shrinking. With shrinking, thermoplastic acquires the shape of bottles. |

9.What Filling Technology is Present in Grape Beverage Bottling Line?

Filling Technologies- Picture Courtesy: Liquor

A broad range of filling technologies are present in the grape beverage bottling line. They have an integral part in the precise measurement of grape beverages. Filling technologies in the grape beverage bottling line are discussed below:

| Linear Filling | In this filling principle, filling nozzles are arranged in a straight line, and grape beverage bottles are filled one by one. This type of filling is present in linear bottle-filling machines. Bottles are usually placed on the conveyor and move sequentially towards the filling nozzles. |

| Rotary Filling | It is also called carousel filling. This type of filling is found in rotary bottle-filling machines. In this filling, a circular carousel with various filling nozzles is utilized. The bottles are filled simultaneously in the rotary filling system. |

| Pump Filling | It relies on different kinds of pumps to move the grape beverage from the supply tank and load them smoothly into the bottles. A controlled flow of grape beverages is achieved with the rotation of pumps. |

| Piston Filling | Here, a suction force is produced by the movement of the piston in the chamber. This force is crucial in dispensing a precise load of grape beverage into the bottles. The forward and backward motion of the piston in the cylinder move liquids in the cylinder and filling nozzles, respectively. |

| Gravity Filling | Natural gravitational force is utilized for filling thin viscosity grape beverages. There are no special filling devices in the gravity filling. |

| Pressure Filling | This filling technology works by using pressurized air to move the grape beverage into the bottles. It produces a pressurized environment in the supply tank and this pressure is applied on the liquid to move it through the filling nozzles at increasingly swift rates. |

10.What are the Main Problems and Solutions of Grape Beverage Bottling Line?

There are different problems in running a grape beverage bottling line; however, there is no need to be concerned. Because with proper planning and care, these problems can be easily rectified. Some of the basic problems and their solutions in grape beverage bottling line are:

Product Contamination

Product Contamination- Picture Courtesy: Creativeawards

| Cause | Solution |

| Inadequate sanitation procedures.

Faulty filtration devices. Dust and other contaminants are present at the filling stage. |

Invest in clean-in-place equipment to properly clean the equipment.

Check and repair faulty filtration systems. Fill surroundings must be cleaned before the filling stage. |

Improper Bottle Placement

Improper Bottle Placement- Picture Courtesy: Pace Packaging

| Cause | Solution |

| Improper bottle placement is caused by differences in the dimensions of bottles.

Feed rates are not accurate. Incorrectly adjusted guide rails. High vibrations lead to misalignment. Damaged bottle unscrambling machine. High-speed movement of the conveyor. |

Uniform shapes and sized bottles should be used.

Reset the feed rates. Properly align the guide rails. Decrease the vibrations in the system. Fix and repair the bottle unscrambling machine. Decrease the speed of the conveyor. |

Inaccuracy in Grape Beverage Filling

Inaccuracy in Grape Beverage Filling- Picture Courtesy: infinitypakistan

| Cause | Solution |

| There are differences in the dimensions of the bottles.

Jamming or blockage of fill nozzles. Imprecise calibration of the fill equipment. Variation in the product consistency. |

Ensure that bottles are of the same sizes.

Clear the jamming in the fill nozzles. Recalibrate the fill equipment properly. The product should have uniform viscosity. |

Over-tightened Caps

Over-tightened Caps- Picture Courtesy: Packaging of the World

| Cause | Solution |

| A high amount of torque during the capping process.

The settings of the capping process are inaccurate. Poor quality of caps and bottles. |

Decrease the amount of torque during the capping process.

Adjust and reset the capping parameters. Use best-quality caps and bottles. |

Partial Seal

Partial Seal- Picture Courtesy: ULINE

| Cause | Solution |

| Presence of particles around the neck of the bottles.

Differences in the dimensions of the bottles. Inadequate heat energy. Incorrect positioning of heat coil. |

Clean the surfaces around the neck of the bottles.

Ensure consistency in the shape and sizes of bottles. Provide sufficient heat to melt and bond the seal. Properly position the heating coil. |

Peeling off Label

Peeling off Label- Picture Courtesy: Label Market

| Cause | Solution |

| There is dust or product residue on the labels.

The labeling temperature and pressure are not sufficient. Labeling heads are damaged or worn out. There is insufficient glue on the labels. |

Properly wipe out the exterior of labeling stickers.

Temperature and pressure should be adequate for labeling. Repair or replace damaged labeling heads. There should be a sufficient amount of glue for sticking. |

11.What are the Consideration Factors for Procuring the Grape Beverage Bottling Line?

Procuring the grape beverage bottling line is a serious feat that decides the fate of your business. So, you must proceed carefully and consider several factors before deciding on the right grape beverage bottling line. Here is a list of factors that must be taken into account before buying this bottling line.

Speed and Production Capacity

Speed and Production Capacity- Picture Courtesy: Australian Organic Limited

Production capacity relies on the speed of the grape beverage bottling line. Rapid speed means more production capacity. Different bottling lines have diversity in their packaging speeds. So, before procuring the bottling line, first determine the scale of your business like small, medium, and large. This will help you in selecting the right speed and production capacity for the grape beverage bottling line.

Budget and Cost

Budget and Cost- Picture Courtesy: Vinpearl

Consider productivity gains and potential business expansion when determining on budget. Your allocated budget will help you in deciding the cost of the grape beverage bottling line. However, it is recommended to not compromise on the quality and durability of the bottling line.

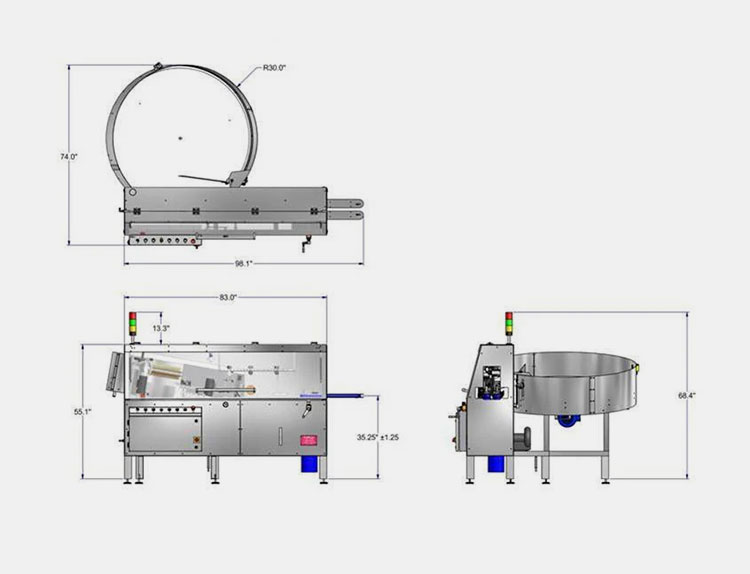

Space and Layout

Space and Layout- Picture Courtesy: Daily Update

The grape beverage bottling line is a massive construction both in small- and large-scale capacity. It is important to look at the layout and space available at your facility. This will help you in selecting the footprint and layout of your potential bottling line.

Spare Part and Repair Warranty

Spare Parts- Picture Courtesy: Maxi Group

Grape beverage bottling line does not always run smoothly and unexpected issues can arise in the parts of different machines. Therefore, it is crucial to select a manufacturer, who has spare parts in inventory and provides repair warranty.

Conclusion

The bottom line is grape beverage bottling line is one of the handiest inventions. It supports and processes all kinds of grape beverages like juices, soda, and wines. By installing this bottling line in your facility, you can make the future of your business brighter. Because, with it, you can gain substantial income. The use of a grape beverage bottling line can solve the problems of packaging inaccuracies and lengthy processing times. But it is important to select the right manufacturers. We, Allpack solve these problems by providing trust-worthy and reliable machines at the best discounted prices.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Grape Beverage Bottling Line: The Complete Buying Guide In 2025 Read More »

Giant Gummy Bear - Sourced: theheadnut

Giant Gummy Bear - Sourced: theheadnut Giant Gummy Bear Near Me - Sourced: strangecarolinas

Giant Gummy Bear Near Me - Sourced: strangecarolinas

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours