Shrink Wrap Tunnel Machine: The Complete Buying Guide in 2025

When you perform any kind of shrink wrap manually to wrap up a product in a plastic film you might got stuck on that process because it requires accurate heating ability.

To get over this kind of task you can use a special equipment called shrink wrap tunnel machine, it can assist you in wrapping many sorts of products in many ways through its unique working ability.

If you are interested in learning more about this vicious shrink wrap tunnel machine then you are on the right page because in this guide you will get complete information about shrink wrap tunnel machine & how it can help your business grow in a quick manner.

1.What is shrink wrap tunnel machine?

Shrink Wrap Tunnel Machine

Basically, the name tells all about the machine a shrink wrap tunnel machine is designed and structured in such a way that it has a tunnel shape processing unit that works on the heating to wrap different products.

You can think of a pipeline in which a free-flowing element enters from one side and comes out from the other, the difference is that when product enters from the one side it gets wrapped and comes out of the other side like icing on the cake.

Shrink wrap tunnel machine uses the heating system to completely and perfectly wrap the required item with the help of a plastic film.

2.Explain the different advantages of shrink wrap tunnel machine?

Well, every wrapping machine has some advantages so does the shrink wrap tunnel machine if there are no advantages then what is the purpose to have the machine right? So, let's see some of shrink wrap tunnel machine advantages.

Unique & Perfect Wrapping

Comparing with other wrapping machines shrink wrap tunnel machine is very strong in terms of providing in depth wrapping on multiple products.

Maybe you will not get satisfaction from other machines while wrapping your products but shrink wrap tunnel machine will not leave any leaf unturned & will do the amazing wrapping around the product in a unique and perfect fashion.

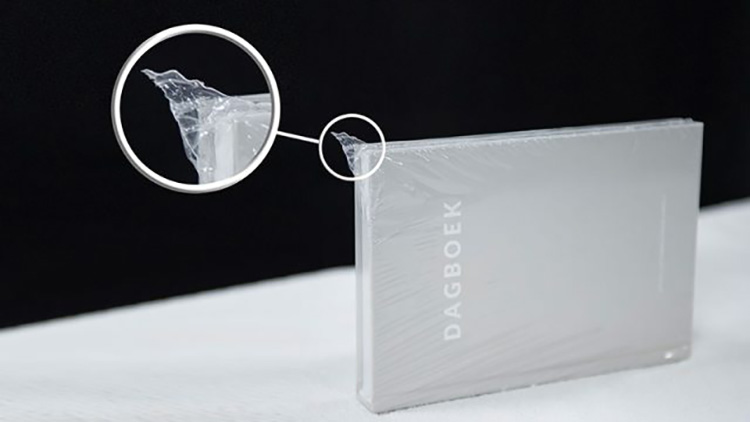

Tamper proof Work

One of the best things about shrink wrap tunnel machine is that it will not only wrap your product perfectly but it will also maintain the shape of your product as well.

So once the wrapping is done if there is any sort of tampering happens during the process or after it you can take immediate actions without losing the shape of future products.

As it is tampering proof and easy to handle so most of the pharmaceutical firms and also some other industries are shifting towards shrink wrap tunnel machine.

Merchandise Protection & Durability

Shrink wrap tunnel machine is a flexible equipment that very much durable and can protect any kind of merchandise by wrapping a plastic film according to the shape of the product by using heat.

The stand-alone ability of the shrink wrap tunnel machine comes very handy to protect the product during the wrapping process & wrapped product by this machine are more durable as compared to others.

Marketing & Branding

You can actually use your branding plastic films that have your custom-made logos on it and then all you need to do is just start the shrink wrap tunnel machine to wrap up your desired product.

Basically, you will get custom wrap items with your logos present on the wrapping element and covered in a perfect way so, it is a kind of free branding plus protection.

It is an astonishing equipment with modern features and advantages so you definitely need to have one for more productivity.

3.How does the shrink wrap tunnel machine works?

Thankfully, the working of the shrink wrap tunnel machine is simple as compared to its complex design. Well, that is not true as it designed in a completely different way so it also has different working process.

Initial stage

At the initial stage when the product enters into the machine it moves towards the tunnel where all the processing takes place.

Once the product started its movement the wrapping film goes down towards the tunnel and adjust itself according to the size of the product.

Middle Stage

It is a crucial stage in which the wrapping process takes place as once the product enters into the tunnel it gets wrapped and when the product is wrapped with the plastic film.

Then there comes the heating system into action which simply perform the heating operation and heat the wrapped product to give the wrapping a shape according the design and size of the product.

You can say that in this stage multiple processes takes place all at once.

Final Stage

Once the product is ready and wrapped perfectly the way you want it then it comes out the from mystery box which is called tunnel because you simply do not know how the product was wrapped and all that.

There you go the final stage of shrink wrap tunnel machine and your product is ready to be delivered.

4.What are key components in shrink wrap tunnel machine?

Every machine is made up with the combination of different working components so does the shrink wrap tunnel machine.

Heating Bank

This is a main component in the shrink wrap tunnel machine which control all the things related to heat.

For instance, heat is produced in this unit and then it kept the temperature according to the adjustments and requirements that you set.

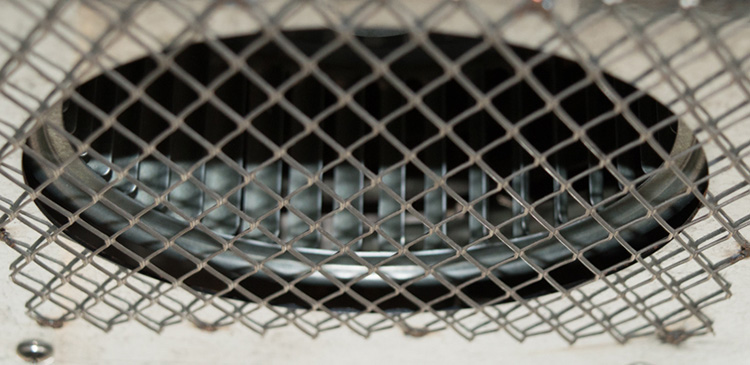

Air Blower Motor

The function of this component in shrink wrap tunnel machine is to blow the hot air towards the product when it is wrapped with a plastic film.

You can say it controls the heating air movement inside the tunnel when the product enters first it gets wrapped then hot air blows on the wrap to shrink the film according to the size and shape of merchandise.

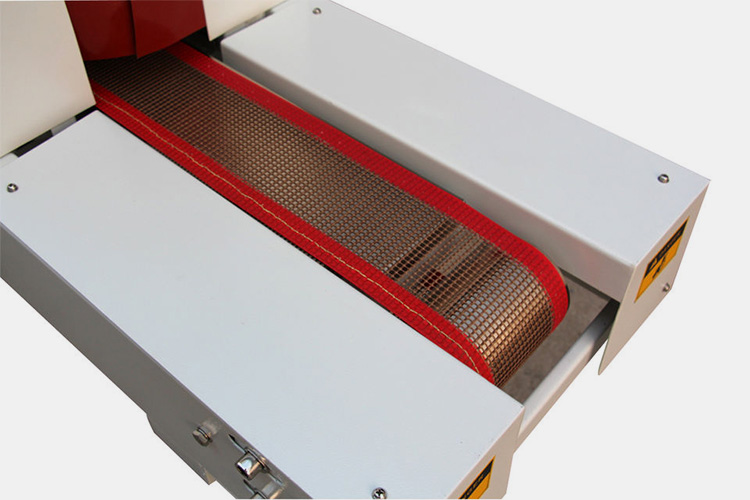

The Conveyor

As usual in all sorts of machines the conveyor actually controls the movement of the product & in the shrink wrap tunnel machine.

It helps the wrapping items to enter tunnel and once they are wrapped then it makes sures they came out from the other side.

You have the flexibility to control the speed rate of the conveyor depending upon the wrapping speed of the shrink wrap tunnel machine.

Cooling Fan

Once the product is wrapped and shrink with heat then cooling fan helps your wrapped product to cool down by providing fresh cooling air.

It is an important component that also make sure that your product remains in its good quality because heat can do the damage.

5.How many types of shrink wrap tunnel machines are there?

According to the design & working capability to deal multiple shape and size products there are two main types of shrink wrap tunnel machines.

L-Bar Shrink Wrap Tunnel Machine

It is conveniently used for large level products wrapping. The main thing about this machine is it has a cutting blade in the shape L which cuts the product once the film is wrapped around.

L-bar shrink wrap machine comes in three different variants such as manual, semi-automatic and fully automatic so, you can make your choice as you want.

Working

L-bar shrink wrap tunnel machine mainly rotates around its heat-sealing L-bar frame which gives the flexibility to wrap multiple size products by simple modification.

Once the product enters the tunnel then it gets wrap around completely and then L-bar sealer holds the item to give it a hot air for perfect wrapping.

The ability of this machine is that you can work with it by installing heat gun or a tunnel for heating purpose.

Advantages

- Semi-automatic ability to handle many sorts of products.

- You can literally wrap thousands of products in a single cycle.

- Pretty good for to deal high level objects.

Disadvantages

- You can only use perforated shrink films for wrapping.

- Tunnel parameters need to be set every type you set the wrapping film.

Components

Moat of the components are same in almost all the types of shrink wrap tunnel machines but here are unique ones present in L-bar shrink wrap tunnel machine.

L-Bar

It is metallic rode which is present at the top of the L-bar shrink wrap tunnel machine. This flexible L-bar gives the ability to cut the film into desired length during processing.

Motor & Assembly

Motor & assembly is a main component present at the front side of the L-bar shrink wrap tunnel machine. But in some other machines these are may be located somewhere else.

Height Adjustment Rode

In an automatic L-bar shrink wrap tunnel machine there is a rode that holds the sealing unit and you can easily adjust the level of sealing according to size of the product by using that rode.

I-Bar Shrink Wrap Tunnel Machine

L-bar shrink wrap tunnel machine is a basic kind of machine that gives you ability to work with small size & basic products.

In this machine the wrapping is not done completed in steps instead the product is wrapped completely at once then the long I-bar rode cuts the wrapped film.

After the film is wrapped around and cut as required then heating make the wrap to shrink around the product.

Working

Basically, the I-bar shrink wrap tunnel machine works manually in most of the cases and its wrapping process is done with the help of a feeder & I-bar cutter.

Once the product comes into the tunnel the feeder feeds the product & I-bar cuts the wrap when the wrap covers one side of the object & then same process is repeated on the other side.

Advantages

- Reliable enough for medium applications.

- Quick and can shrink wrap 200 items per cycle.

- Single design infrastructure & easy to maintain.

Disadvantages

- Not much efficient in wrapping & sealing.

- Require extra effort at the end for sealing.

Components

L-bar shrink wrap tunnel machine also has some main working components different from other machines.

I-bar

L shape metal bar along with a sealing film are placed on top of the machine at one side & there is a tunnel on the other side.

Feed Conveyor

The basic purpose of a feed conveyor is to controls the initial stage movement of the product when it gets in contact with the I-bar for wrapping & sealing process.

Operation Panel

All the processing steps are controlled using the operation panel it contains multiple sorts of buttons and settings to adjust the speed of the machine.

Industrial Shrink Wrap Tunnel Machine

Industrial shrink wrap tunnel machine works out of the box by minimizing any human effort during its working principle.

Well, if you are dealing with a huge industry then this specific equipment is designed for you to get rapid production in huge-figures.

Basically, you can utilize its maximum potential for high production rate in less time frame & low labor involvement.

Working

As the industrial shrink wrap tunnel machine is structured to handle big kinds of products there is a assembly line attached with this machine for quick & automatic processing.

You just need to upload the products onto the assembly line and leave the rest because the machine will configure the size of the product and will seal it as you expected.

Advantages

- You can use it to shrink wrap products in any industry line.

- Huge products to wrap no worries at all.

- Safe, durable & efficient wrapping.

Disadvantages

- Do not set high temperature it will make the wrap wrinkles away.

- Not recommended for eatable items.

Components

Industrial shrink wrap tunnel machine is used at a very high level so it contains multiple sorts of working components.

Handy body frame

Every machine does have a frame but in the industrial shrink wrap tunnel machine its frame is very big and completely made with stainless steel body to handle large products.

Chain

The chain at the side bar help the conveyor to move forward so the element present on it also move. It is a kind of connector that gets the power from motor and then rotate the conveyor and other small parts.

6.What are the applications of shrink wrap tunnel machine?

Shrink wrap tunnel machine have many applications & almost used in every industry that we encounter in our daily life.

Food & Beverage

In this industry there are many applications of this machine for instance most of the drinkable products that comes in plastic bottles are wrapped with the help of shrink wrap tunnel machine.

It can also wrap a bundle of products for example a group of similar items assembled in such a way that they made a group then the wrapping will be done on a whole group.

Electronics

Most of the electrical appliances are shrink wrapped by using the shrink wrap tunnel machine because shrink wrap uses a rigid form film which will keep the electronic appliances safe if they got hit during traveling.

Pharmaceutical & medical

In the pharmaceutical industries the vials & bottles that we see are wrapped by using this machine. Such as eye drops bottle, drip vials & many more.

You can also shrink wrap packed tablet packs by giving them a secure outer layer so that your branding details do not get damage if the packed box encounter something during the traveling.

Well, shrink wrap tunnel machine is not just limited to these applications you can literally wrap any kind of product by setting the required settings on the machine.

7.Difference between shrink wrap tunnel machine & plastic wrap?

There is a one huge difference point between a shrink wrap tunnel machine and a plastic wrap machine.

As you know the shrink wrap tunnel machine not only wraps the machine it also shrink the plastic wrap around the product using heat according to the design of the wrapping item.

Whereas, a plastic wrap machine just simply wraps the product with a plastic film and seal it at the end.

You can give desired shape to your product using the shrink wrap tunnel machine but you can not do that by using a plastic wrap machine.

8.Why heat is necessary in shrink wrapping?

Heat is very important element in a shrink wrap tunnel machine processing because it plays a vital role to wrap the product.

For example, once you wrap the product with a PVC or polyolefin film then how you are going to shrink it that is the reason heat is important.

And by using hot air you can perfectly wrap the product with a plastic film so it is a kind of main piece of shrink wrap processing. You will get quality wrapped product while using heat in the form of hot air.

9.What types of materials you can use to work with shrink wrap tunnel machine?

You can basically work with three main plastic wrapping films while using shrink wrap tunnel machine.

PVC

Polyvinyl Chloride is a plastic film that comes in multiple kinds of flexibility and rigidness depending upon the business requirement you can select that best suit your needs.

It comes in such a thin quality and visibility that you can stretch it up to a limit and also see through or your can choose the invisible one.

PE

Polyethylene film is extracted from some natural resources such as hydrocarbons that we get rom or daily life elements like gasoline or petroleum elements.

It is one of the widely used film most of the plastic bags are formed with PE.

POF

Polyolefin is a polymer based plastic film which is taking over the wrapping industry in all most every sector.

POF is very effective when it comes to shrink wrapping and most of the shrink wrap tunnel machine workers use this film because of its shrinkable ability.

10.Can a shrink wrap product get wet?

No way, once the product is wrapped by using a shrink wrap tunnel machine then it is very hard for water to get inside.

But in some cases this can happen if there is any kind of tampering happen during the wrapping then may be there are some holes left on the wrap so make sure that no tempering happen while wrapping the product.

Once the wrapping is done the shrinking of the film left no holes open to make sure that the item inside remain safe, secure and durable in the best possible way.

11.How to troubleshoot shrink wrap tunnel machine problems?

You may encounter some problems while working with shrink wrap tunnel machine.

Problem 1: One of the most basic one is that your wrap got wrinkles & your product not wrapped perfectly.

Solution: To handle this kind problem always set appropriate heating temperature because it mostly happens because of high heating temperature.

Problem 2: Sometimes your wrapping film will not be cut appropriately according to the size of the product.

Solution: It is also a good practice to check your film cutting clamp pressure because this can cause irregular cutting of wrap film.

Problem 3: Bad sealing during the shrink wrap process.

Solution: In most of the cases bad sealing of shrink wrap happen because of your sealing film properties. Maybe you are using a very thin film which can not bear greater heating rate.

12.How to select best shrink wrap tunnel machine for your business?

When you are selecting a shrink wrap tunnel machine you need to remember some of these key points.

Focus on Speed & Size of Machine

Choose a machine with a moderate size that can be easily adjusted & installed within your working space.

Some of the shrink wrap tunnel machines are slow in terms of their working principle so slow speed will lead you to less production so, choose wisely.

Look for low air velocity tunnels

If you select a suitable tunnel-based shrink wrap tunnel machine that has minimum air velocity rate then there will be less chances that your wrap got wrinkles during the process.

Flexible working ability

You have to remember that flexibility matters when you are working with a shrink wrap tunnel.

It simple means your machine is capable to work with different plastic films having different thickness rate.

Conclusion

As this guide explain most of the vital points about the shrink wrap tunnel machine so you must have understood the importance of this machine in packaging and sealing. It is a win-win situation for you if you made up your mind to have a shrink wrap tunnel machine for your production line to pack different size products. Do not wait and Contact Us as early as possible to boost your business in a positive way.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours