Steam Tunnel For Shrink Sleeves:The Complete Buying Guide in 2025

Are you looking for a new way to package and print your products? Have you heard of the steam tunnel technique but need to figure out how it works or if it’s right for your business? Don’t fret! This guide will demystify everything you need to know about the process in 2025. We’ll go over all the details of using shrink sleeves, from choosing the right sleeve type to using a steam tunnel machine effectively and efficiently.

With this guide, you can become an expert on shrink-sleeve technology in no time – so what are you waiting for?

1.What Is A Steam Tunnel for Shrink Sleeves?

Steam tunnels are an essential piece of equipment for shrink sleeve applications. They are used to generate steam that is directed over the sleeve, which shrinks it tightly around the container. This ensures a secure fit and a professional finish on your packaging. Steam tunnels come in various sizes and provide adjustable steam flow so you can tailor your shrink sleeve application to your needs.

You can also get steam tunnels with adjustable conveyor speeds, which allow you to adjust the speed of your shrinking process depending on the size and shape of the container. With a steam tunnel, you can ensure a perfect fit every time. Using a steam tunnel is an efficient and economical way to apply shrink sleeves and create attractive packaging for products. Get your steam tunnel today and take your shrink sleeve packaging to the next level!

2.What Are The Components Of A Steam Tunnel for Shrink Sleeves?

A steam tunnel for shrink sleeves is composed of several different components, all of which work together to create the perfect heat seal. These components include:

Steam Generator

This is the main source of heat that will be used to heat up the sleeve material and cause it to shrink around the product or container. The steam generator should provide enough heat in order to achieve a good quality finish on the product.

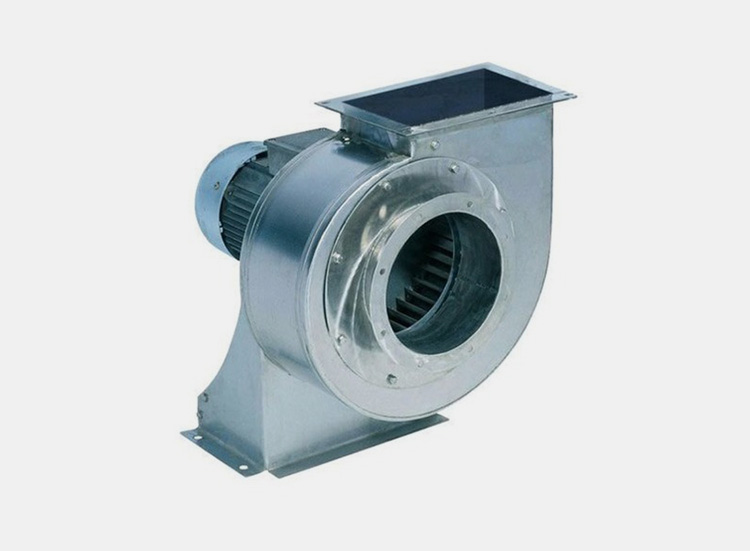

Blower

The blower is used to provide a steady flow of air into the steam tunnel. This helps to ensure that the heat is evenly distributed throughout the tunnel and that it reaches all parts of the sleeve material, allowing it to shrink around the product or container.

Heat Exchanger

The heat exchanger helps maintain a constant temperature in the steam tunnel. It contains a thermal reservoir that stores heat and then releases it when necessary to keep the tunnel at an optimal temperature for shrink sleeve application.

Conveyor System

The conveyor system is responsible for transporting containers or products into and out of the steam tunnel. This allows for efficient production speeds and helps to ensure that the shrink sleeve is applied correctly.

Temperature Control System

This ensures that the temperature in the tunnel remains at an optimal level for shrinking and sealing of the sleeve material around containers or products. It helps to maintain a consistent product finish throughout every batch produced.

Cooling Fan

A cooling fan is installed at one end of the tunnel to rapidly cool down the product as it passes through. This helps to set the shrinkage in place and ensures that your sleeves are perfectly shrunk.

3.What Are The Applications Of A Steam Tunnel for Shrink Sleeves?

The Steam Tunnel is a versatile piece of machinery and can be used across a variety of industries. It helps shrink sleeves onto products quickly and efficiently, providing clear labels for businesses. Here are some common applications:

Food and Beverage Industry

Steam tunnels are used to shrink wrap multi-packs of drinks, snacks, and other food items. Shrink sleeves provide a tamper-proof seal that increases the shelf life of food products. It also allows for customized branding which can help with product marketing.

Pharmaceuticals Industry

Shrink sleeves can be used to package pharmaceutical products, such as tablets and capsules. It helps keep the product tamper-proof and safe from external contaminants.

Cosmetics Industry

Steam tunnels are often used to shrink wrap cosmetics containers, such as lip balm tubes and shampoo bottles. This helps ensure that the cosmetic products remain fresh and safe for use.

Industrial Packaging

Shrink sleeves are used to package industrial parts and components, such as bolts, screws, and nuts. This helps protect the parts from damage during transit or storage. It also makes it easier to identify the parts quickly and accurately in large warehouses.

Household & Industrial Cleaning Products

Shrink sleeve sealing with a steam tunnel is an effective way to package cleaning products such as detergents, bleach, and aerosol cans. The steam tunnel provides an airtight seal that protects these items from leakage and contamination.

4.How Does A Steam Tunnel for Shrink Sleeves work?

A steam tunnel for shrink sleeves works by tightly shrinking the sleeve around your product. It does this by using hot, pressurized steam to reduce the size of the sleeve material. This process is done in three steps.

First, the container and sleeve are placed inside a chamber of the steam tunnel. Hot, pressurized steam is then directed onto the sleeve, which causes it to heat up and shrink. Pressure is maintained throughout the tunnel in order to keep a steady stream of steam flowing over the product.

Next, as the sleeve shrinks and conforms around your container, it tightens into place due to tension created by opposing forces such as centrifugal force and gravity. This tension is necessary to ensure a tight fit and seal when the sleeve is finished.

Finally, cool air is then directed over the container and sleeve in order to quickly cool down the material and finish off the process. The cooling step helps produce a secure shrink wrap with uniform consistency that won’t easily come apart or unravel.

5.Are There Different Types Of Steam Tunnel for Shrink Sleeves Available?

There are several types of steam tunnels available for shrinking shrink sleeves. Depending on the size and complexity of the application, you may need to choose from any one of these models.

Automatic Steam Tunnel For Shrink Sleeves

An automatic steam tunnel is an ideal solution if you need to shrink a large number of sleeves quickly and accurately. It uses pressurized steam, applied directly onto the sleeve from all sides. The conveyor belt moves the sleeve through the tunnel in a continuous operation, making it incredibly efficient and cost effective.

Semi Automatic Steam Tunnel For Shrink Sleeves

This type of tunnel combines the efficiency of an automatic steam tunnel with the flexibility of an open steam tunnel. It uses a conveyor belt to move the shrink sleeve through the chamber, but it also has manual controls that allow you to adjust the pressure of the steam and time spent in the tunnel. This makes it easier to achieve optimal results for more complex shrink sleeve shapes.

Open Shrink Steam Tunnel

This type of steam tunnel is the most traditional and popular model, as it is easy to use and cost effective. The shrink sleeve goes through an open chamber with a conveyor belt and steam is applied directly onto the sleeve from one or two sides. This can be a time consuming process, but it provides good shrinkage and cost benefits.

Closed Chamber Steam Tunnel For Shrink Sleeves

Such a steam tunnel is more efficient than the open chamber model, as it utilizes a closed environment to quickly apply steam heat to the shrink sleeve. This tunnel features two components: an outer chamber that houses the sleeve and a smaller inner chamber with a conveyor belt. The steam is applied directly to the sleeve from both sides of the inner chamber.

Rotary Steam Tunnel For Shrink Sleeves

This type of steam tunnel features a rotating drum with a conveyor belt that carries the shrink sleeves through an enclosed chamber filled with steam. The drum rotates at high speeds, ensuring fast and uniform heating for maximum shrinkage results.

Infrared Steam Tunnel For Shrink Sleeves

The steam tunnel uses infrared heaters to generate steam and quickly apply heat to shrink sleeves without direct contact. It is a more efficient option than open chamber or rotary models, as it provides fast heating with minimal energy consumption.

6.What Are The Differences Between Automatic And Manual Tunnels For Shrink Sleeves?

The primary difference between automatic and manual tunnels for shrink sleeves lies in the speed and ease of operation. Automatic tunnels are faster, more efficient, and require fewer people to operate them. They can also produce larger volumes of product with greater consistency than a manual tunnel. Manual tunnels involve a much slower process, as each sleeve has to be placed onto the tunnel by hand. This can be a time-consuming process, as well as a physically demanding one.

In addition to speed and ease of operation, automatic tunnels also offer greater control over the heat applied to the shrink sleeve. With manual tunnels, there is no way to adjust or monitor the temperature of the air heated by the tunnel. Automatic tunnels, however, allow users to adjust the temperature and humidity of the air used to heat the shrink sleeve. This ensures that each product is heated uniformly and accurately.

Another key difference between automatic and manual tunnels is in the type of equipment used. Manual tunnels typically require more manual labor and are limited by their physical size and capacity. Automatic tunnels, on the other hand, require less manual labor and can accommodate larger products. This makes them ideal for high-volume production of shrink sleeve products.

Finally, automatic tunnels tend to be more expensive than manual tunnels due to the complexity of the machines and their higher energy consumption. However, they are often considered a better investment in the long run due to the greater efficiency and consistency they offer.

7.How Is A Steam Tunnel for Shrink Sleeves Different From Standard Shrinking Machines?

The main difference between a steam tunnel for shrink sleeves and standard shrinking machines is the way they heat the wrap. A traditional shrinking machine uses an electrical coil to apply heat directly on the film, while a steam tunnel heats the air around it, causing convection currents that warm up the sleeve from all directions. This kind of heating method allows for more even and consistent shrinkage of the sleeve.

Steam tunnels also offer better temperature control than traditional shrinking machines, meaning that the wrap can be heated more precisely to meet exact specifications for a particular product or application. Steam tunnels provide gentler heat than direct heat from electrical coils, reducing the potential of damage to delicate materials such as food packaging or labels. Additionally, the steam tunnel system is much quieter than traditional shrinking machines and it can offer quick turnaround times with high throughput rates.

Furthermore, steam tunnels for shrink sleeves can also be used to shrink multiple sleeves at once, making them ideal for large production runs. This is not possible with standard shrinking machines which can only shrink one sleeve at a time. Furthermore, steam tunnel machines are able to work with a variety of container shapes and sizes, giving you more flexibility when it comes to labeling.

8.What Types Of Products Can Be Sealed By A Steam Tunnel for Shrink Sleeves?

Shrink sleeve sealing with a steam tunnel is an efficient process for many different industries and products. Here are some of the most common types of products that can be sealed using this method:

Soda

Carbonated beverages such as soda contain a great deal of pressure. As the steam tunnel seals the shrink sleeve around the bottle, it assists to release this pressure and maintain a secure seal on the product.

Bottled Water

Bottled water is often packaged in shrink-sleeved containers for added protection and tamper-resistance. The steam tunnel helps to ensure that the shrink sleeve is sealed tightly around the bottle, keeping it safe and secure.

Pill Bottles

Pill bottles typically have a thin plastic film that needs to be securely sealed in order for them to stay fresh. By using a steam tunnel to shrink-seal the sleeve around the container, the contents stay safely contained.

Detergents

Detergent bottles are often packaged with shrink-sleeve packaging in order to increase product shelf appeal and add extra protection against tampering. The steam tunnel assists to seal the shrink sleeve tightly around the bottle, keeping it safe and secure.

Shampoo Bottles

Shampoo bottles are often sealed with shrink sleeves for added protection against tampering and to maintain product freshness. The steam tunnel makes sure the shrink sleeve is sealed tightly around the bottle, giving it a secure seal.

Lotion and creams

In cosmetic industries, lotions and creams are often packaged in shrink-sleeved containers for extra protection against tampering. The steam tunnel ensures that the sleeve is securely sealed around the bottle, keeping it safe and secure.

9.What Are The Different Types Of Packaging Materials That Can Be Used With A Steam Tunnel for Shrink Sleeves?

When using a steam tunnel to shrink sleeve packaging, the types of materials that can be used are varied. Generally speaking, most shrink-sleeved products are made of plastic or film, but a wide range of materials can also be used. The most common packaging materials for use with steam tunnels for shrink sleeves include:

PVC (Polyvinyl Chloride)

PVC is a popular material for shrink sleeves because it’s durable, flexible and resistant to moisture. It can be printed on easily, and has a high shrink ratio which makes it ideal for use with steam tunnels.

Polyethylene (PE)

PE is one of the most popular and widely-used packaging materials in the industry, as it has excellent heat resistance, is flexible, and offers good mechanical properties. It also provides superior protection against moisture and gas permeability.

Polypropylene (PP)

PP is another popular choice for shrink sleeves due to its excellent strength and flexibility, as well as its ability to be easily heat-sealed with a steam tunnel. It also provides robust resistance to most chemicals and solvents.

PET (Polyethylene Terephthalate)

This material is known for its strength and durability, as well as its resistance to chemicals and moisture. It’s also popular because it can be recycled. When used with a steam tunnel for shrink sleeve packaging, it offers a high-shrink ratio and an excellent barrier layer.

Conclusion

Purchasing a Steam Tunnel for Shrink Sleeves can be a bit overwhelming. There are a lot of things to consider, such as budget, maintenance requirements, and speed of production. With this buying guide as your starting point, you should be well on your way to finding the perfect steam tunnel for your needs. When you are ready to begin shopping around, contact Allpack — they have some of the highest-quality models on the market today. Whether you need a small or large machine, they have something that will fit into any budget and deliver superior performance. So don’t wait too long – get in touch with them today!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide