Lotion Manufacturing: The Complete FAQ Guide In 2025

Lotion Manufacturing: The Complete FAQ Guide In 2025

What topical solution makes your skin moist and hydrated? This is a lotion that acts as a transporting barrier and carries moisturizing effects from the outer surface towards inside your skin. They are available and various categories and it all depends on your skin type and particular needs. Today, lotion manufacturing is a sensitive and most demanding process in the worldwide manufacturing industries. Due to so many benefits, the pharmaceutical industries are hooked to specified departments that are meant to formulate and market lotions into the market.

How are they prepared? What important ingredients does it hold and how do they firmly bind together? Moreover, in this article, we will also discuss the various challenges associated with lotion manufacturing. Come on let’s start it now!

1.What is lotion manufacturing?

Lotion Manufacturing

It is the process of making whether oil in water or water in oil emulsion that are emollient in nature and provides you with a high level of lubricant properties with high viscosity.

This manufacturing series also contains a number of important ingredients that you will explore in the later part of the article.

The basic of lotion manufacturing relies on a specific percentage of ingredients utilization as well as the specified blending of the mixture to avoid phase separation.

The technical points in lotion manufacturing are so many such as blending time, role of temperature, and the particular velocity of the machine to give you the final products with improved texture, efficacy, and spreading properties.

Lotion manufacturing can take place by using various ranges of natural extracts too; therefore, this is the perfect emulsion of natural and non-natural constituents in a single merged phase to retain greater potency.

2.Why lotion manufacturing is in demand?

Today, lotion manufacturing is in high demand due to the following described reasons:

To meet high demand in the market

High demand

There is always a noticeable high demand for lotion as you all prefer lotion-related products over various other topical applications. This is all because of its smooth application along with so many beneficial properties to your skin.

So, every manufacturing company meets with a high production demand from the market of cosmeceuticals and related fields. Secondly, more awareness about such products is also one of the reasons that consumers grab lotion for various skin-related issues.

To support your skincare and appearance

Improving skin appearance- Picture Courtesy: French Beauty Co.

Whether it is sunblock, skin hydrating lotions, or therapeutic lotions, there is always a high surge in lotion trends, which not only improve wellness but also greater appearance. For example, its anti-aging properties help to reduce the chances of premature- wrinkles, aim to reduce dryness and crackiness, and many more. That’s one of the prime reasons for the greater lotion manufacturing demand across the globe.

To produce a broad-spectrum formulation

Broad range formulation- Picture Courtesy: Eucerin

As you know every individual is hooked to a specific skin type. For example, some are with dry skin, and some are oily, etc. Therefore, lotion manufacturing encompasses with broad range of formulations required for a variety of applications depending on the different demographic regions.

It gives you high profitability!

High Profit

You can consider your business more profitable as your lotion manufacturing process is taking place at a very low expense as compared to other relevant formulations. You will just need to promote your brand with effective marketing strategies. The rest of your business will be running tremendously by offering lotion manufacturing with stable investment output.

It requires a low expenditure!

Economical lotion manufacturing

You need lotion manufacturing as it is one of the flexible ways to start up your business. Yes, we have observed many enterprises that began with home-based or small projects. Due to high success and demand, your business can be boosted up high due to lotion manufacturing. In a nutshell, there’s a high chance to expand your business growth via retail as well as online supply of your product.

Emerging with day-to-day new formulation

New formulations- Picture Courtesy: natio

Lotion manufacturing is in demand due to day-to-day constant evolution of new formulations and developments. Therefore, every manufacturing company is always seeking to produce new and effective formulations whether it is therapeutic, herbal, or skincare products.

3.What are the different lotion manufacturing types?

Lotion manufacturing is a designed procedure that offers soothing, protective, and emollient effects to your skin. It comes in various types that depend on your skin type and of course, a specific purpose to fulfil your skin demand. We have described different lotion manufacturing types below:

Based on Action

Simple Lotion Manufacturing

Simple Lotion- Picture Courtesy: EOS

The purpose of simple lotion manufacturing is to offer the basic skincare to you. This means the formulated type of product is capable of meeting essential needs for your skin such as working as a super hydrated entity and keeping the soothing effect.

This lotion is composed of simple ingredients such as glycerine, water, stabilizing agent with any potent ingredient such as herbal extract with preservative and fragrance. A lightweight and simple product mainly acts as a source of humectant properties and produces mild to moderate moisturizing effects.

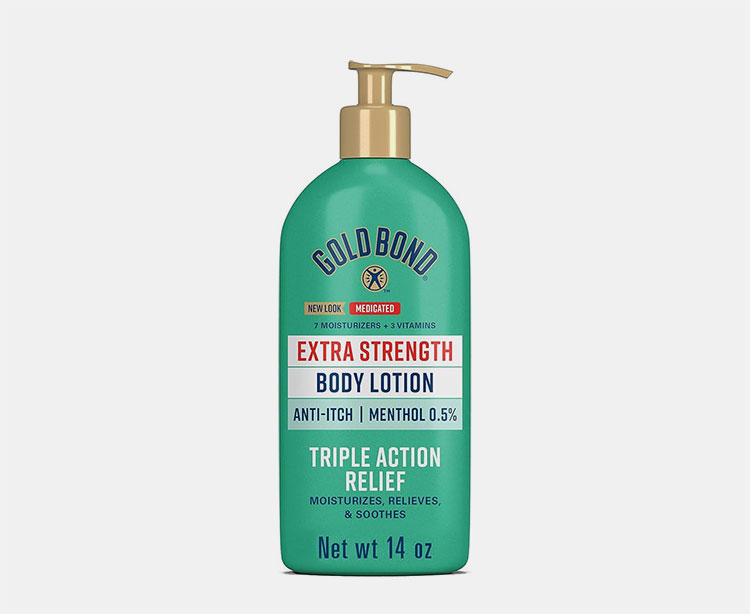

Therapeutic Lotion Manufacturing

Therapeutic lotion- Picture Courtesy: Azeal Dermatology

As its name shows, this mainly acts as a therapeutic agent for your skin. This is prepared to give medicated effects and is mainly used either over the counter or as a prescribed lotion to address certain skin-related ailments.

Therapeutic lotion manufacturing is formed by the merging of oil and water phases with simple ingredients along with medicinal or active pharmaceutical ingredients as the main active ingredient.

You must have heard about calamine lotion corticosteroid lotions, anti-fungal lotions, etc. They come in the categories of therapeutic lotion manufacturing. The prime purpose of such lotion is to treat disease by utilizing the topical surface as the medium to target the site. For example, anti-inflammatory, anti-aging, anti-bacterial, acne, eczema, etc.

Based on Formulation

Suspension Type Lotion Manufacturing

Suspension type lotion- Picture Courtesy: Healthline

This type of lotion is mainly manufactured by utilizing ingredients that are somehow dispersed in the solvent or fluid phase of the lotion. The type of lotion is basically available for topical applications which is attained as over-the-counter medication.

They are mainly applied over the skin to treat issues such as chicken pox, bug bites insect bites, or any dermal discomfort. As it is a suspension-type lotion, therefore it is recommended to shake the bottle thoroughly before applying. The common ingredients of such lotion manufacturing are sulfur, zinc, or bentonite which are mainly dispersed with the help of any suspending agent.

Emulsion Type Lotion Manufacturing

Emulsion Type Lotion Manufacturing- Picture Courtesy: Lazada

This is a lightweight kind of lotion manufacturing where the water content or water phase is intense and best known for various skin types. In this type of lotion manufacturing, the particles of oil droplets remain dispersed in the water phase, making it a good choice for sensitive skin. Here in lotion manufacturing the emulsifying agents help in the stability of two phases and keep them intact against phase separation.

4.How does lotion manufacturing suit different skin types?

The lotion manufacturing can be suited to different skin types, there are various skin types we talked about.

Dry Skin

Dry skin- Picture Courtesy: Cosmetic dermatology

The lotion manufactured with constituents like hyaluronic acids, natural oils, and glycerine, helps in the replenishing moisture level of the skin and ensures comfort against crack and dry texture thus preventing dehydration or water loss.

Oily Skin

Oily Skin- Picture Courtesy: Vichy

Lotion manufacturing with lightweight consistency is always preferred for those individuals that are having oily skin. Thus, without making it more oily or shiny, it makes your skin extra light and idea against progressing clogging the pores. Such lotion manufacturing is incorporated with constituents such as rice powders, silica, and related ingredients that make your skin oil balanced.

Combination Skin

Combination skin- Picture Courtesy: Hotel Marhilf

In this type of lotion manufacturing, you need to keep hydration and drying factors balanced to keep the surface of the dermal layer with improved texture. In this type of lotion, the percentage composition is formulated in a way the dry as well as oily regions of your skin can be treated with equal effects.

Sensitive Skin

Sensitive Skin

This type of skin requires lotion manufacturing with a gentle and non-irritant composition which makes your sensitive skin to treat with a gentle application of the product. Such lotion manufacturing process is accounted with the incorporation of calming ingredients such as plant or herbal extract specially meant for improving smoothness once you apply over the skin. Moreover, it gives a nourishing effect such as aloe vera, chamomile, orange extract with enriched vitamin C content and so much more.

Normal Skin

Normal Skin- Picture Courtesy: Italic

This type of skin requires lotion manufacturing with ingredients that keep your skin moisture level significantly promising with the involvement of non-greasy and lighter composition of the ingredients. Such lotion ensures the possible hydration and comfort to your skin.

5.What are the 7 basic properties of lotion manufacturing?

There are the enlisted properties of lotion manufacturing, for example:

Properties of the lotion manufacturing- Picture Courtesy: The herbal gardener

1: Emollient

In lotion manufacturing, the utilization of emollients makes your soft smooth, and subtle.

2: Emulsifier

The emulsifier properties in lotion manufacturing aid in the combination of the oil phase with the water phase or vice versa, therefore keeping the consistency stable.

3: Fragrant

This property of the lotion manufacturing ensures a pleasant and refreshing aroma in many lotions.

4: Humectant

This is a key property of lotion manufacturing that supports the retaining of moisture over the surface of your skin.

5: Occlusives

The moisture content evaporation from your skin is slower due to the presence of occlusives agents in lotion manufacturing.

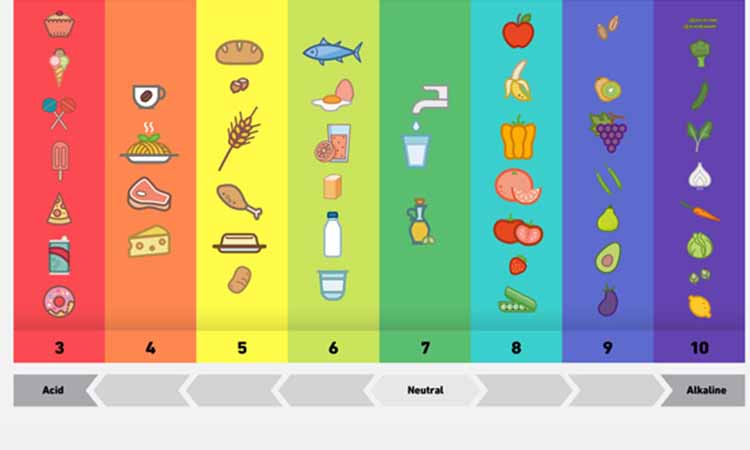

6: pH Adjusters

Of this property, lotion application is suitable for every individual skin type. By adjusting pH lotion manufacturing is almost suitable for different kinds of skins with safety.

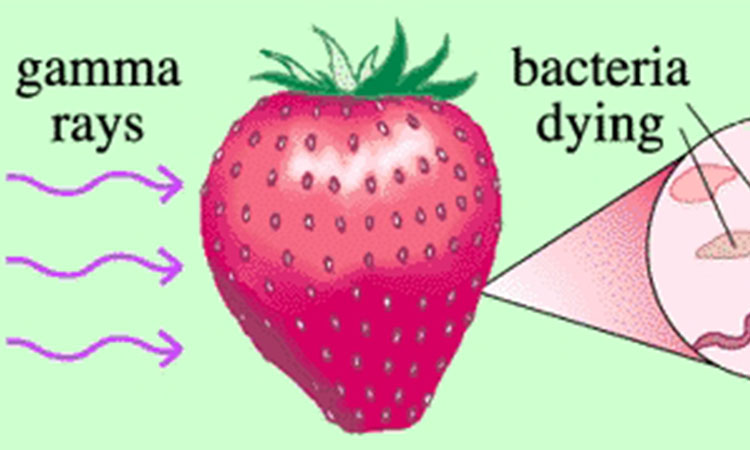

7: Preservative

The long and extended life of lotion manufacturing products is achieved by the addition of preservatives that resist microbial progression.

6.What’s the process for lotion manufacturing?

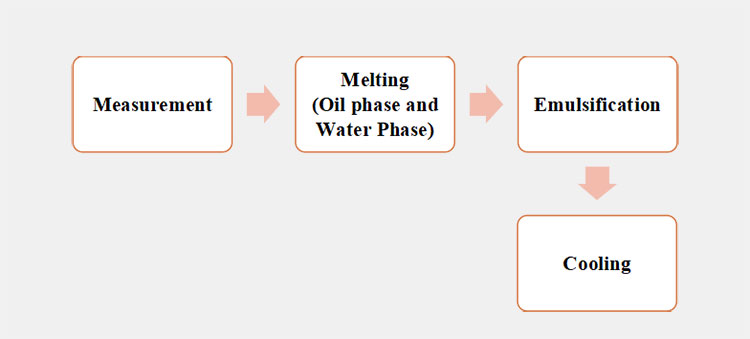

The process of lotion manufacturing is quite simple involving a series of steps that finally produce a formulation with quality texture and efficacy. The description about the steps are described below:

Process steps of lotion manufacturing

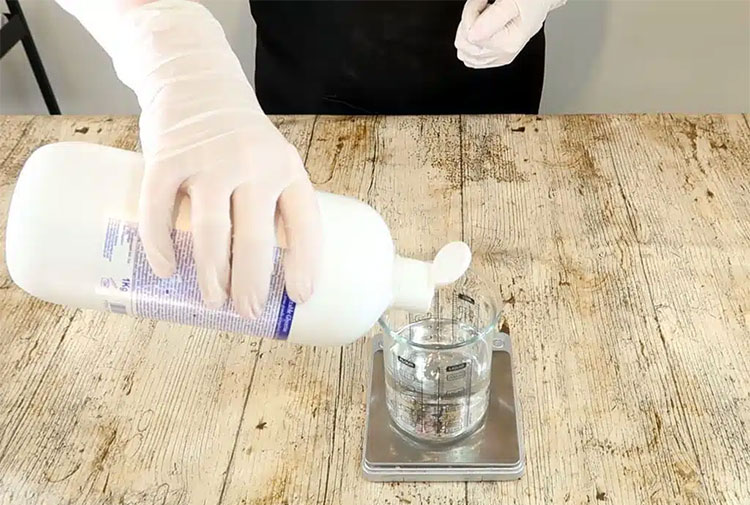

Measurement

Measurement- Picture courtesy: Savvvy

The careful measurement of the constituents takes place by using the physical balance. It includes the ingredients used in the oil phase, (beeswax, ceto ctyle alcohol, various oils), as well as the water phase (glycerine, water), active ingredients or extracts, preservatives, fragrant, etc.

Melting (Rising in Temperature)

Melting of ingredients

In the lotion manufacturing heating vessel, you can add the ingredients of the oil phase that are left to melt under the temperature range of 60 to 80°C. The melting takes place by gentle shaking of the blades inside the vessel of a machine such as high shear mixer, a propeller mixer, etc,

Side by side, a similar method is applied for water phase ingredients under utilizing the similar temperature induction.

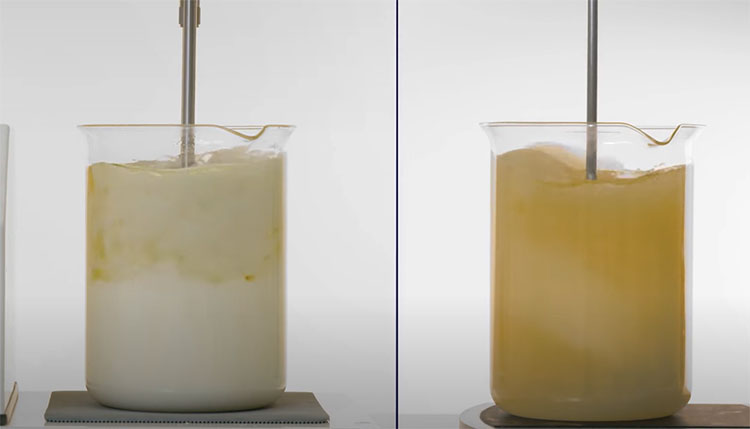

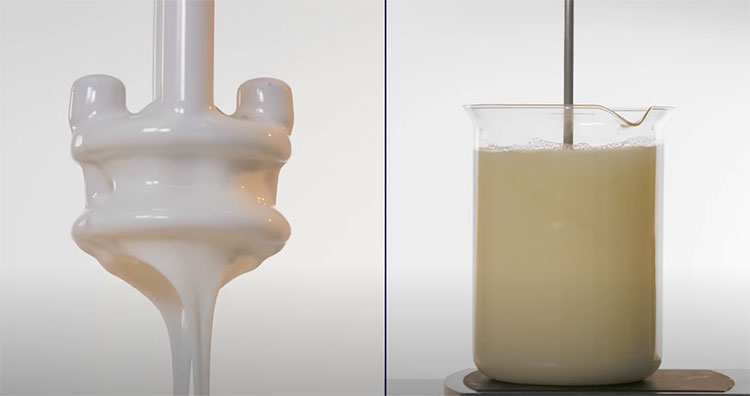

Emulsification

Emulsification

The mixture of the oil phase was slowly poured into the water phase under gentle and constant mixing of the blades. It helps in proper emulsification and formation of the stable lotion emulsion. In this state, you can observe the lotion consistency as a foaming solution.

Cooling

Cooling

After the particular time of mixing, you can gradually reduce the temperature of the mixture and bring it to the room temperature. Sometime the cooling tanks are used for this process. The cooling process leads to the lotion manufacturing in its stable form and it mostly happens around 30-40°C. This is the ideal phase where you can add your additives to the mixture such as active ingredients, colorants, fragrance, etc with mixing.

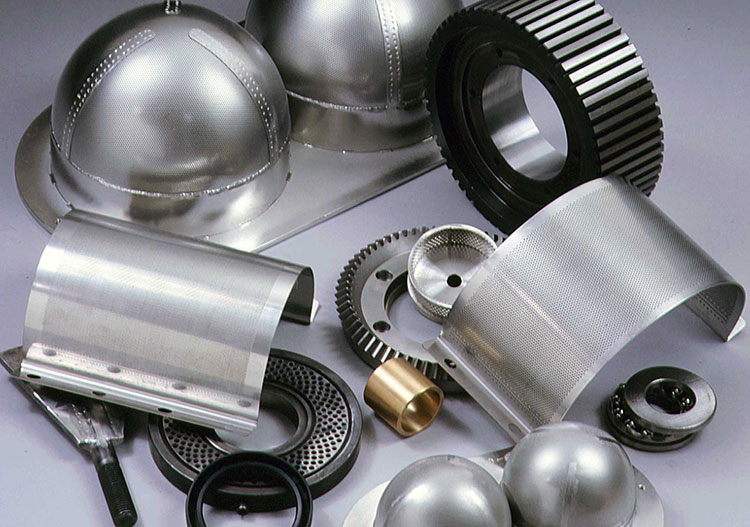

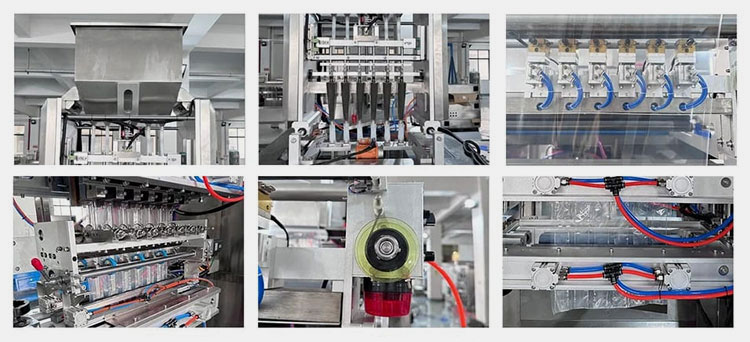

7.What machines are used in lotion manufacturing?

In lotion manufacturing, the main role is played by the following series of emulsifiers or mixers. For example,

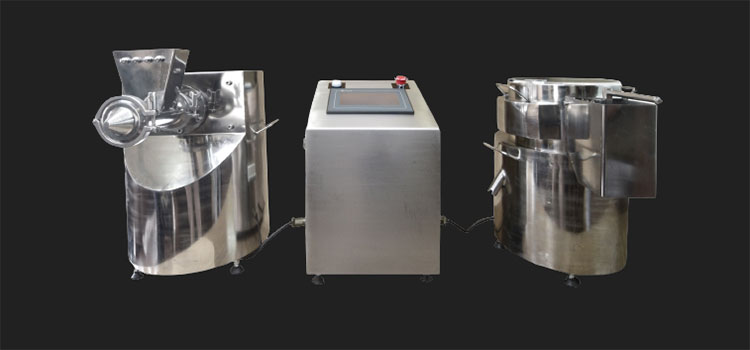

Homogenizer Vacuum Mixer

AIPAK homogenizer vacuum mixer

This machine performs a key role in the emulsification of lotion manufacturing that works for the mixing of high matrix solutions. It is composed of a network of vacuum pipes that suck solvents to bring into the main dissolving vessel. The solvent can be heated by induction of gentle heat and mixing blades ensure the breakdown and thorough emulsification of the materials.

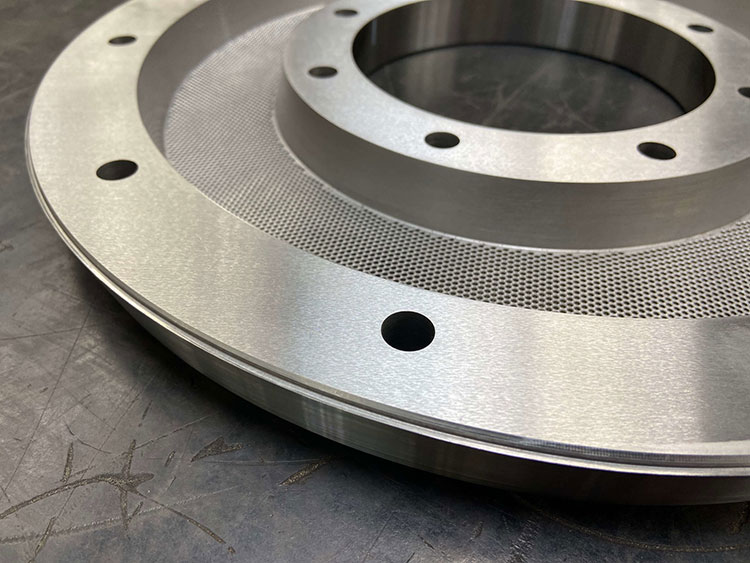

High-Shear Mixers

AIPAK High shear mixer

Strong and stable equipment for the emulsification of the oil phase and water phase to bring a uniform texture and balance consistency of the product. The machine works by induction of high shear forces inside the mixing vessel ensuring the promising blend of the ingredients without risk for phase separation.

Rotor Stator Batch Mixer

Rotor Stator Batch Mixer- Picture Courtesy: Silverson

This machine is popular to get more than mixing the lotion. It is used for emulsification, homogenization, dispersion, and disintegration of the particles and gives outstanding performance to produce quality products.

8.Where does lotion manufacturing mostly take place? What are different industries meant forlotion manufacturing?

The lotion manufacturing process mostly takes place in the described below industries. The following enlisted companies perform a major role in the production of lotion manufacturing across the globe.

Cosmetic Industry

Cosmetic industry- Picture Courtesy: Clarin

This is the first industry that comes to your mind if it is lotion manufacturing. To some extent, you're right as this sector is the core of its production. This section is not only responsible for just simple lotion manufacturing but also gives you an extended series of formulations including hands lotions, hydrating lotions, night and day skincare lotions, sunblock lotion, manicure, pedicure lotions, cleaning lotions, toning lotions, hair toning lotion, coloring or developer lotions, etc.

Pharmaceutical or Medicinal Industry

Pharmaceutical or medicinal industry

Lotion manufacturing is not just a game of skincare! Though there are various therapeutic applications associated with it. `You can treat various problems like skin burn, skin injury, or skin diseases like eczema, fungal infections, bacterial infections, other complications such as acne, psoriasis, dermatitis, etc are mainly treated with medicated lotions that are mainly produced by the pharmaceuticals industry. Lotion manufacturing is mainly categorized into the special category of topical applications such as corticosteroid lotion, ketoconazole lotions, various antibacterial lotions, etc.

Herbal Industry

Herbal industry

The fast-growing sector and hooked to high demand due to more inclination toward natural products and awareness about herbal products. The herbal industry is mainly associated with lotion manufacturing of constituents that produce emollient and soothing effects on your skin, for example, it is mostly composed of ingredients such as essential oils, herbal extracts, and organic elements giving you satisfactory results without prominent side effects.

Food Industry

Food emulsions

There are various food grade emulsions such as mayonnaise, kinds of ketchup, various sauces, and dips are prepared as lotion manufacturing. In such preparations, you will need to emulsify either oil in water or water in oil phases to improve the consistency and good effects in food products to be supplied.

Research and Development (R&D) Industry

R&D- Picture Courtesy: RHEONIS

The research and development (R&D) industry is at the heart of innovation in lotion manufacturing. R&D departments within cosmetic companies and third-party research organizations conduct studies to develop new ingredients, improve formulations, and ensure that lotions are effective and safe for consumer use. This industry is crucial in testing new technologies, such as anti-aging compounds, UV filters, or skin repair agents. Additionally, R&D focuses on improving product stability and shelf life, ensuring lotions remain effective throughout their lifespan.

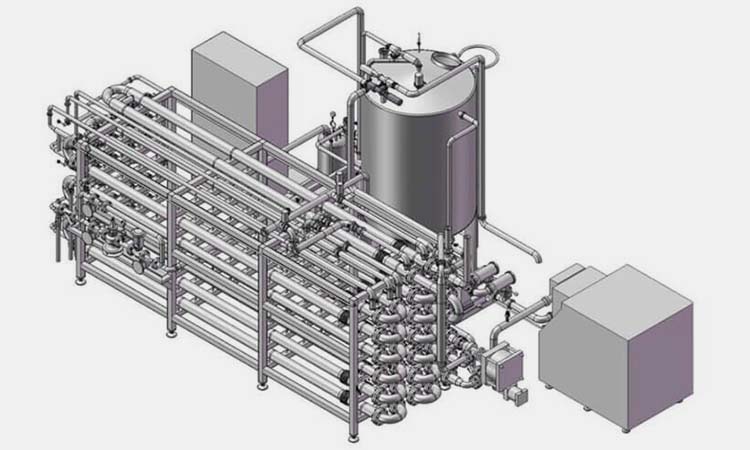

9.What is the production line for lotion manufacturing?

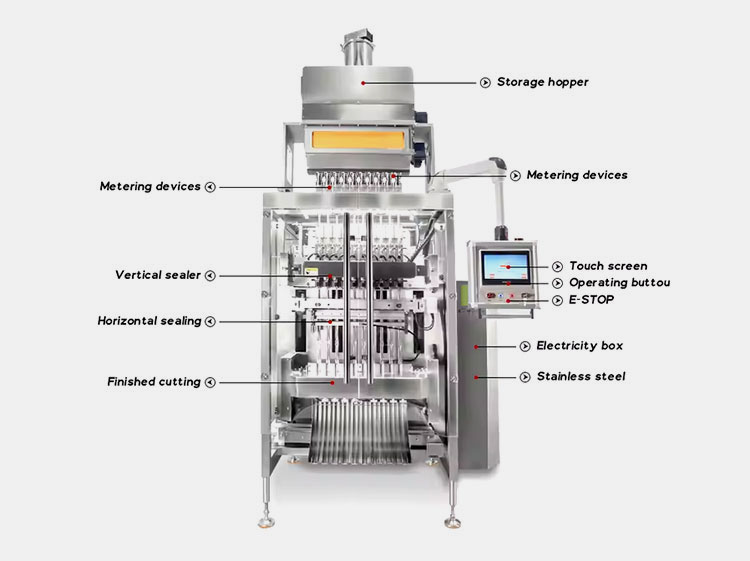

The lotion manufacturing production line is composed of the following set of machines to support workflow. Let’s have a look at the essential components of the production line.

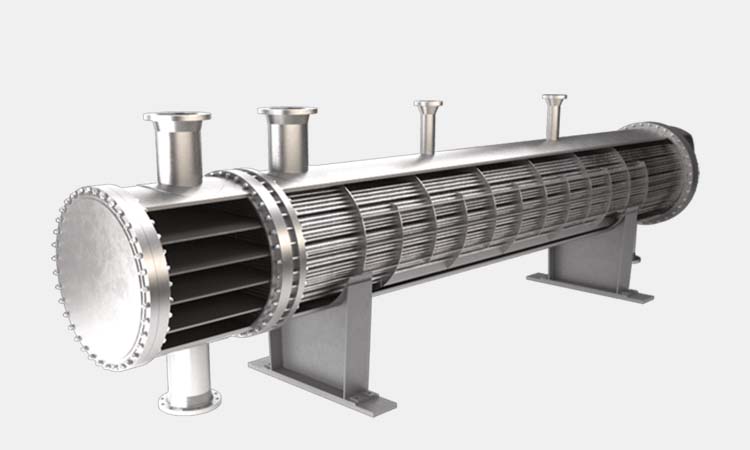

Heat Tank

Heating Tank

A stainless-steel heated vessel is specially intended for inducing the heat and melting the ingredients inside the tank. The oil phase and water phase are heated in separate heating vessels where hot steam and water circulation in double jackets ensure temperature control. The machine is designed with a bottom valve for discharging the melted ingredients.

Storage Tank

Storage Tank

The double-jacketed and insulated storage tank is mainly used to store the raw materials in bulk and provide supply for other equipment with the help of vacuum pipes. The storage tank is composed of temperature temperature-maintaining gauge, a monitoring window, and is capable of retaining the required temperature without prominent fluctuation. An attached agitator ensures the gentle mixing of the store solution to maintain uniform heat and material well distributed.

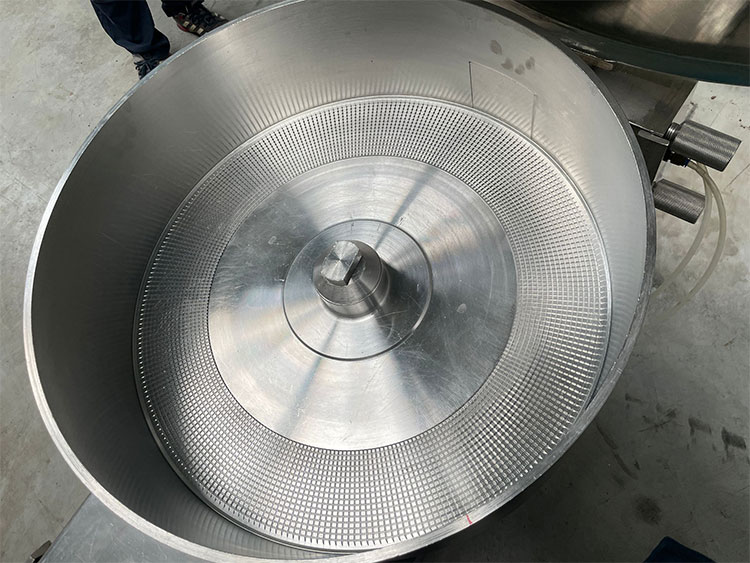

Bottle Unscrambler Machine

Automatic bottle unscrambler machine

The random bottles are organized by using the bottles unscrambler which ensures proper orientation of the bulk packaging material. It is composed of a rotary vibratory disc and a high-pressure blower to ensure the correctness of the bottles for the further stages.

Bottle Washing and Drying Machine

Bottle washing and drying machine- Picture Courtesy IC Filling

The machine is mainly used to clean and dry the bottles by the action of high jet water spray and high pressurized air to provide dust-free and dry materials for the filling of the lotion.

Lotion Filling Machine

Lotion Filling Machine

The prepared lotion is dispensed into each bottle with the help of a lotion-filling machine. This machine uses a piston or peristaltic filler for the dispensing of thick lotion accurately. The design is significantly advanced to bring small, medium, and large batch production efficiently. For example, greater automation, multiple-filling heads, excellent monitoring and sensing systems, and much more allow the user to facilitate the tasks without leakage or spillage.

Capping Machine

Capping machine- Picture Courtesy: C.E king

The bottles are secured against contamination or leakage by placing the caps. This is achieved by integrated capping machines in the production line. With the help of torque and pressure, the caps are placed and applied automatically over the lotion bottles. This includes screw capping, pump capping, flip-top capping, etc.

Labeling Machine

AIPAK labeling machine

This machine is considered the final and essential section of the lotion manufacturing production line. The labeling machine is capable of identifying the correct position and application of the labeling followed by pressing the roller to ensure they are fixed properly. Labels provide attractiveness to your product along with necessary information such as branding, batch number, expiry date, how to use the lotion, benefits, etc.

10.What is the role of temperature in lotion manufacturing?

Temperature impacts- Picture courtesy: Ammarie Cosmetic

The modulation of temperature is a critical factor that must be fully understood once you are lotion manufacturing. Whether it is a small batch or a large production. The temperature relationship with lotion stability is paramount. The increase in temperature can result in more dispersion of particles and high homogenization. Whereas the lower proportion of heat can make this process very slow and difficult. It makes your formulation quite unstable too.

Different categories of emulsion may need specific temperatures. It is not limited to every lotion manufacturing phenomenon. For example:

Oil in Water or O/W lotion manufacturing

Oil in Water

If you’re manufacturing lotion that is oil in water, then it can be possible if your temperature lies in the range of 25 to 40 degrees centigrade. When you maintain this temperature in lotion manufacturing then there would be lesser chances of phase separation.

Water-in-oil or W/O lotion manufacturing

Water in Oil

In this type of lotion manufacturing, you will need a greater intensity of the temperature as compared to the above section. It typically ranges between 40 to 60 centigrade or 104 to 140F. This range mainly keeps the lotion constituent in a balanced form and your lotion manufacturing process can be performed with high consistency.

So, the temperature balance should be your major aim to ensure the best quality product. It must be maintained during mixing, adding phases, and cooling. If you ignore any of them can result in thermal decomposition with simultaneous loss of your time and valuable products you have used in the process.

Therefore, sensitively monitor the temperature prior to emulsification of lotion and it must be till you get a homogenized product. Once the viscosity and texture are attained to your desirable outcomes then you can modulate the temperature by cooling it.

11.What are common ingredients used in lotion manufacturing & their melting points?

Ingredients of lotion manufacturing- Picture Courtesy: Glimmer Goddness

There are various ingredients used in the lotions and nevertheless, every ingredient has its particular melting temperature. The lotion manufacturing composition with different melting points is described in the below table.

| Composition | Explanation | Melting Temperature |

| Cocoa Butter/Shea Butter/Mango Butter, etc | Organic kinds of butter are used to offer rich moisturizing effects to your body and mainly of them have moderate melting points. | 93–100°F or 34–38°C |

| Glycerine | This is the common component used as a thickener and humectant. | 65°F or 18°C |

| Beeswax | This ingredient possesses a high melting point and has a hard texture. It is added to bring stability to your lotion manufacturing product and is also used in other cosmetics formulations.

A relatively high melting point adds thickness and stability to cosmetic formulations, such as lip balms and solid perfumes. |

145°F or 63°C |

| Silicones such as small cyclohexasiloxane, polymers such as dimethicone, and functional such as dimethiconol | The silicones with various categories are used to improve smoothness in lotion and they vary with melting points. | -4°F or -20°C |

| Lanolin | This is also a must-have constituent of lotion and is added to enhance the moisturizing properties in lotion and have a high melting point. | 100°F or 38°C |

12.What is the difference between lotion manufacturing and cream manufacturing?

The major key differences between lotion manufacturing and cream manufacturing are described below table:

Difference Between Lotion Manufacturing And Cream Manufacturing- Picture Courtesy: Upcircle

| Lotion Manufacturing | Cream Manufacturing |

| In lotion manufacturing, you are encountering high water content and lower oil content. | The cream manufacturing is composed of high oil phase ingredients such as butter, waxes, stearic acids, etc. |

| It has 2/3 of the water phase whereas 1/3 of the oil phase. Generally, it has a high ratio of water content. | The cream manufacturing has 2/3 of the oil phase whereas 1/3 of the water phase. Usually, it has a high percentage of oil content. |

| It has a lighter and thinner texture with rapid skin absorption upon application and is effective for various skin types and covering a large area. | It has a thick texture with high moisturizing capabilities and it makes the stickier application. |

13.How do you know the lotion manufacturing product is stable?

Body Lotion

You can check the stability of the lotion manufacturing by various tests. It is mainly done by storing the sample under induced temperatures up to various periods.

If the lotion manufacturing product is stable for three months under specified conditions such as 113°F or 45°C. Then it is known that the products are composed of good and stable qualities.

Mainly three testing samples are always subjected to temperature alteration with a range of 14°F or -10°C for twenty-four hours to 77°F or 25°C for twenty-four hours in each cycle.

Whether your product is stable in all three states without decomposition, then the test will be considered approved. Whereas, if your product shows sample separation or decomposition, then it will be not considered as an approved product.

14.What are the challenges with lotion manufacturing?

Lotion manufacturing is not an easy task but not something very complicated. There are few technical problems that may occur commonly due to certain mishandling or equipment issues.

We have discussed them below, have a look at them and learn how to deal with certain conditions.

Instability of lotion

Instability- Picture Courtesy: TY cosmetic

When you manufacture lotion, you may observe instability among the ingredient’s emulsifications. For example, colorant, and fragrance may be insufficient or change with time.

Solution

Indeed, this problem can occur due to instability in mixture emulsification, pH problems, and alteration in the viscosity of the ingredients. Therefore, to deal with certain situations it is recommended to add some proportion of chelating agent that helps in the restoration of the color. Keep monitoring and balancing the pH of the mixture by using pH throughout the process.

Phase Separation

Phase separation

During lotion manufacturing, you will observe the phase separation which is either fully or partially layered. This ultimately reduced the quality of the lotion, affecting your brand identity and market value.

Solution

This problem may occur due to greater levels of oil or high concentrations of stabilizing agents in a solution that tends to grasp the oil content.

Moreover, the change in pH also is one of the problems that tend to cause phase separation. Thirdly, temperature differences and variations during mixing also result in layering. To solve them, it is recommended to use the specific concentration of ingredients as given in the protocol and it must be optimized.

The pH should be monitored and maintained; the temperature range must be stable from the start till the end of the reaction to get a stable and consistent result.

Lotion with more waxy or grainy consistency

Grainy or waxy texture- Picture Courtesy: Organic beauty cosmetic

Lotion manufacturing faces the challenge of the progression of waxy or particle setting disrupts the homogeneity of the product.

Solution

If you do not melt the ingredients with hard textures such as beeswax, or other constituents such as ceto cetyl alcohol, or any stabilizing agent, it may set a weak emulsion with induction of grainy or waxy particles in the lotion.

To fix these issues, you should keep both phases such as the oil phase and the water phase at the same temperature, and the ingredients inside must be fully melted and mixed slowly with each other with proper and gentle mixing to form a consistent lotion.

Secondly, due to the crystallization reaction waxy and grainy particles also appear. It can be dealt with by using an ionic or cationic emulsifier in lotion to fix the issue.

Conclusion

After reading the blog, we assume you would be capable enough to know the different categories related to lotion manufacturing, its composition, manufacturing, equipment, and much more. Indeed, lotion manufacturing is a challenging process following sequential steps. Each step needs particular attention to bring a quality outcome. But ALLPACK has eased your job by offering a helpful series of machines for lotion manufacturing at affordable prices. Want to look into it? Please contact us right now to explore equipment for your business.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Lotion Manufacturing: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours