Meal Replacement Powder Stick Packing Machine: The Complete Buying Guide In 2025

Meal Replacement Powder Stick Packing Machine: The Complete Buying Guide In 2025

The worth of meal replacement powder is best known to all the people who are either body builders, obese, or have specific diet plan. This is the reason, why every concerned person is not only in need of getting the best meal replacement powder but to carry it around wherever they go. It thus underscores the importance of a Meal Replacement Powder Stick Packing Machine which turn this aim into reality.

This machine is the creation of modern technology and is tailored with user-friendly features encompassing both structural and functional facets. In addition, it is fully automatic and, therefore, enable you to get your desired throughput with utmost precision and let your customer value your production. So, make sure to give this buying a thorough read and discover each of its question in well manner to get benefited from Meal Replacement Powder Stick Packing Machine!

1.What Is Meant By Meal Replacement Powder?

Weight loss meal replacement powder- Picture Courtesy: nakednutrition.com

Meal replacement powder is a term used for powder which is meant to be consumed in liquid form like shake and juice etc. It is a mixture of nutrients and other food materials with fewer calories than those found in regular solid meal.

Therefore, meal replacement powder can be better described as a substitute for breakfast, lunch, or dinner in order to help you in managing your specific diet or appetite plans.

2.Define Meal Replacement Powder Stick Packing Machine?

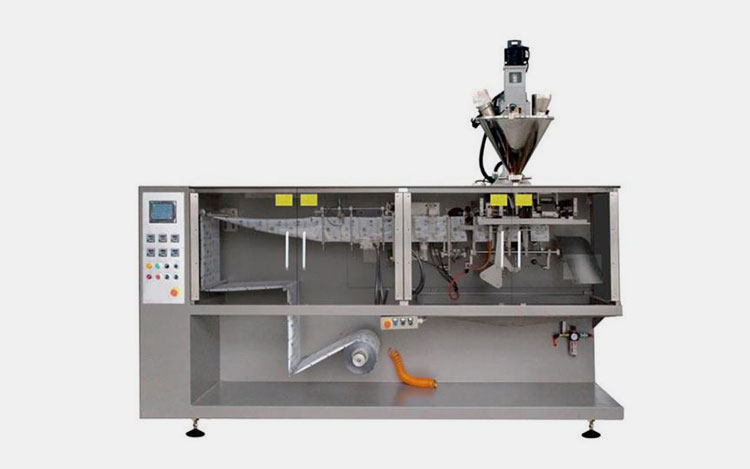

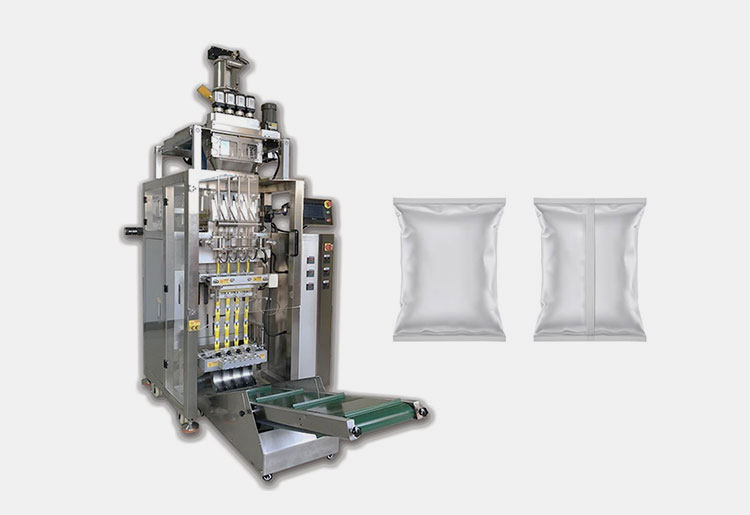

Allpack- APK 2-220 Automatic Vertical Single Lane Powder Stick Packing Machine

Meal replacement powder stick packing machine is a unique design equipment particularly designed to accomplish the task of packing meal replacement powder into stick packs responsibly.

The machine is an assembly of several components which are powered by automatic system for packing. This stick packing simply encompasses the bag forming, powder weighing, filling and stick pack sealing for packaging. Hence, all you get is the high efficiency, precision, and consistency with wide applicability for different types of materials.

3.Enumerate The Features And Advantages Of A Meal Replacement Powder Stick Packing Machine?

There are multiple features of a meal replacement powder stick packing machine among which prominent ones are highlighted below:

Advanced Performance

Advanced performance 3 side seal packaging machine- Picture Courtesy: chengyipacking.com

Meal replacement powder stick packing machine has advanced performance. It is the result of astonishing compact structure with low maintenance requirement and high strength which together leads to the steady functioning of machine. Moreover, it is controlled by a PLC control panel making it easy for user to operate the machine.

Production Efficiency

Multiple stick packs- Picture Courtesy: plasticfreedom.co.uk

As the meal replacement powder stick packing machine comes in automatic technology, it cut off all the delays caused by manual packaging. In addition, it carries out multiple tasks in single run which makes it capable of producing thousands of stick packs in just a single hour.

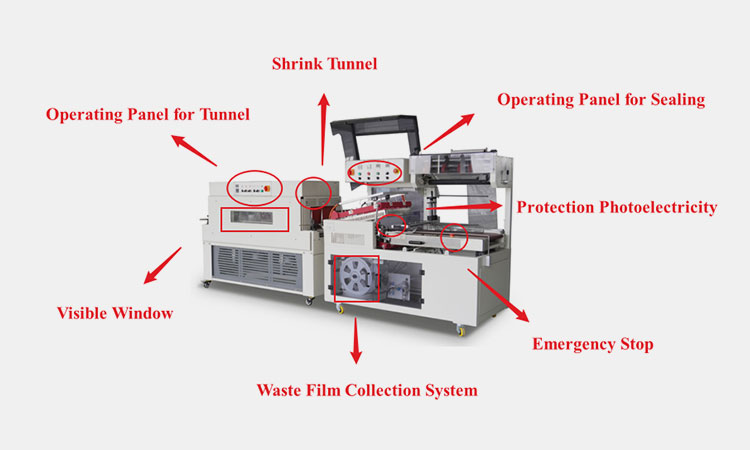

Ensure Safety

Hygienic stick packs- Picture Courtesy: aguulp.com

The most crucial attribute of this machine is its protection against corrosion, bacteria, and sudden malfunctions. Similarly, it encases different features like stainless steel body, protection window, and emergency stop etc., which helps in ensuring the safety of product as well as operator.

High Accuracy

Precisely packed stick pack- Picture Courtesy: celsius.com

Meal replacement powder stick packing machine is best known for its high accuracy in terms of product weighing, filling, and stick packs sealing. Moreover, with varying nature of powder, it can adapt to relevant metering system for ensuring consistent filling and creates same size packs by using sensors.

Customization

Various customized stick packs- Picture Courtesy: aguulp.com

In this age, where you will never come disappointed from a market because there were lines of the product you went to buy. But is it okay to just have the product you want and not the quality? Definitely not! Every person want to choose best for him/ her. Similar is the case with meal replacement powder which must be packed carefully and in beautiful packs to attain consumer trust.

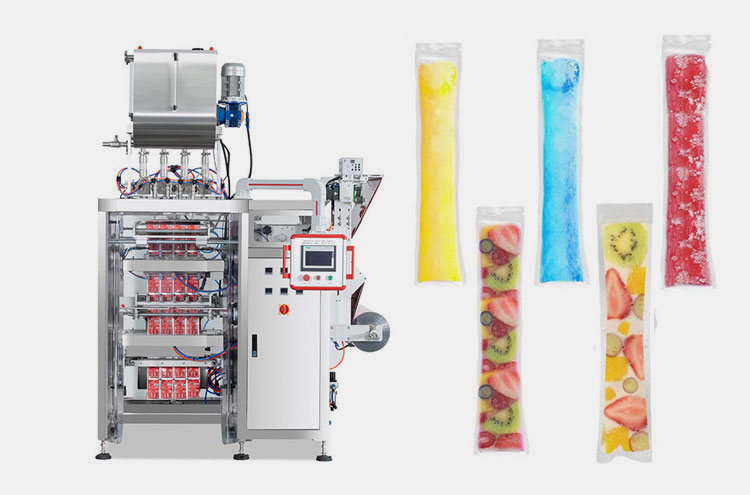

4.What Are The Packaging Varieties Offered By A Meal Replacement Powder Stick Packing Machine?

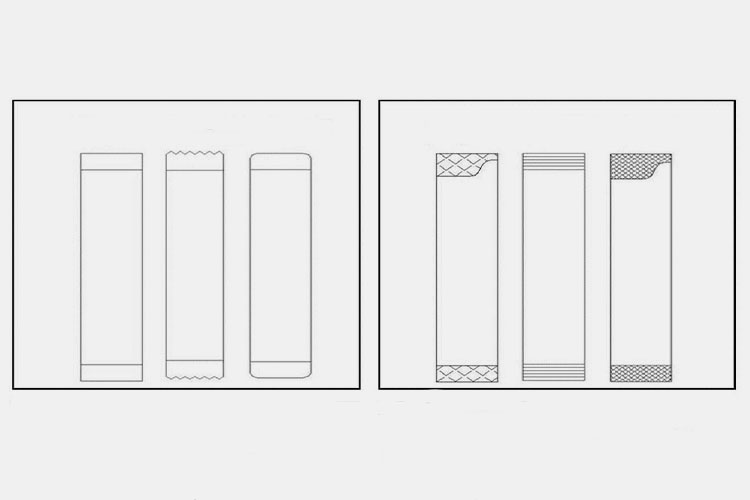

Meal replacement powder stick packing machine offers you an extensive line for packaging varieties in sealing and cutting. Let's explore some of the major ones!

Seal Shape Options

Side neck seal shape stick packs- Picture Courtesy: abigailjames.com

Seal shape refers to the length and width of seal being made on stick packs. As a meal replacement stick packing machine is highly versatile, it can produce seals of different shapes for enhancing the charm and sealing strength of stick packs. In this way, the common seal shapes are side neck, central neck, straight, and round etc.

Seal Type Options

Stick pack with straight seal type- Picture Courtesy: nurished.com

Seal type options cover the design of seal being added to the stick packs. For instance, a meal replacement powder stick packing machine may create square, serrated, triangle, and diamond type sealing over stick packs. The purpose of seal type options is to distinguish your products from that of the other ones.

Cut Type Options

Flat cut stick packs- Picture Courtesy: celsius.com

Cutting is an important aspect of stick packs. That's why, a meal replacement powder stick packing machine has integrated features to adapt to different cutting styles. For instance, by changing the cutting tools or blades of the machine you can create zigzag cut, flat cut, or perforated cuts on meal replacement powder stick packs.

Easy Cut Options

V-cut stick pack- Picture Courtesy: kollohealth.com

Facing trouble while opening a meal replacement powder stick packs is one of the annoying things. To end this bother, a meal replacement powder stick packing machine is tailored with astonishing features which enable it to add various easy cut options to your packs including side tear notch, perforation, or v-cut etc.

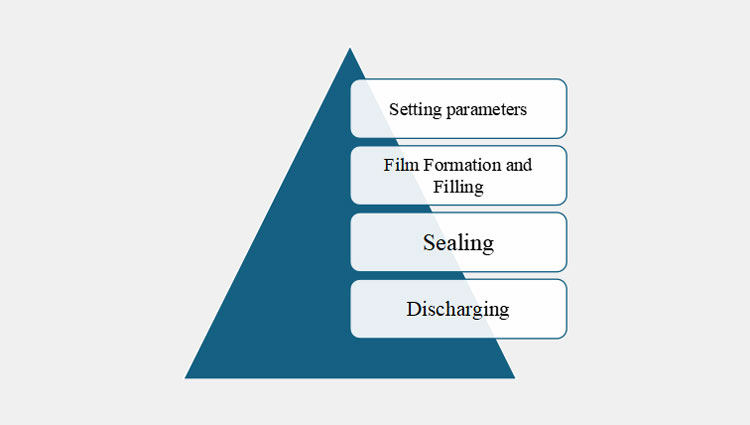

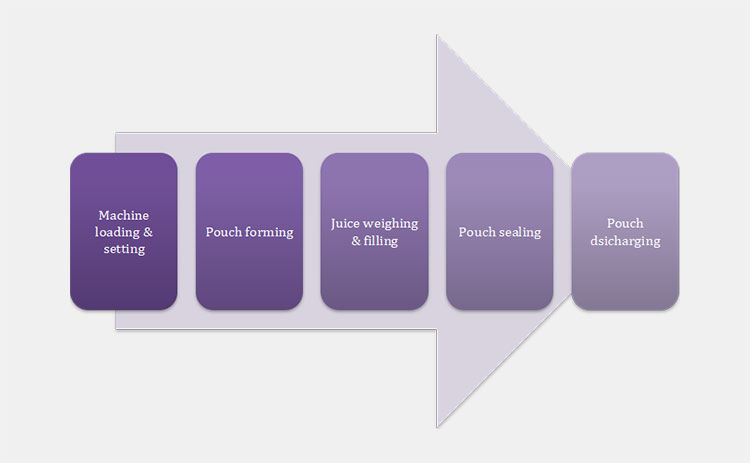

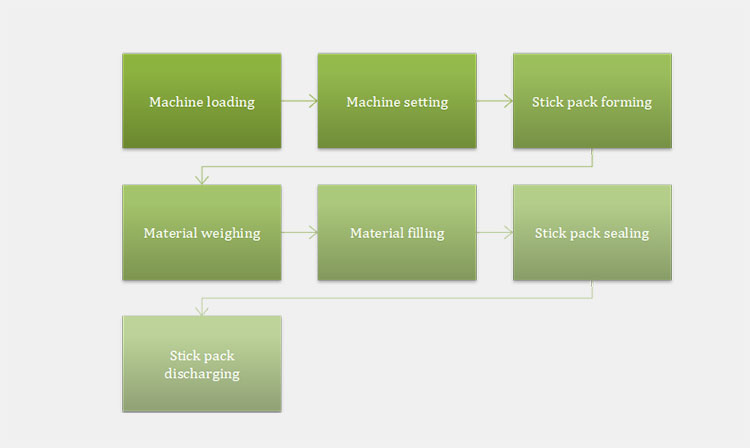

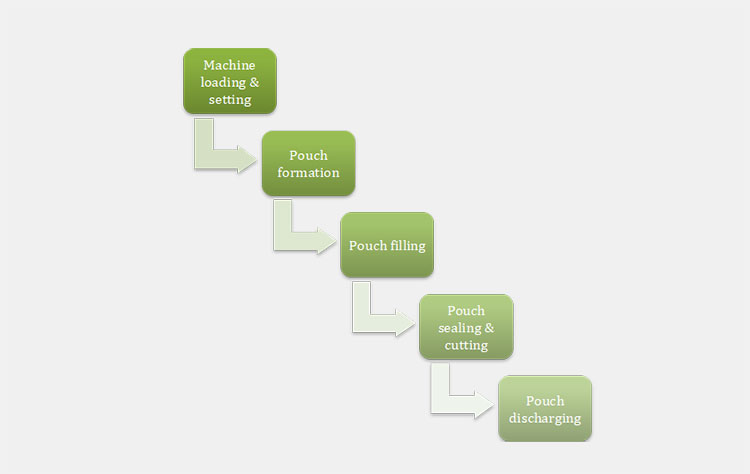

5.How To Operate A Meal Replacement Powder Stick Packing Machine?

The operational procedure of a meal replacement powder stick packing machine is extremely convenient and user-friendly. You can operate it by just knowing the basic working principles. So, let us disclose them in few steps!

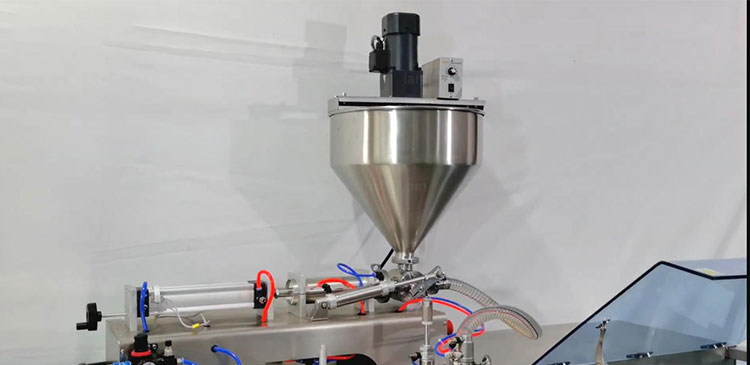

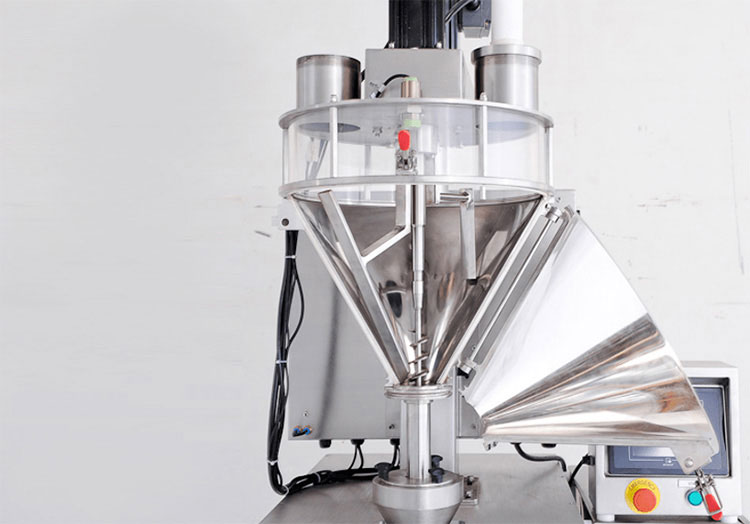

Machine Loading

Powder loaded in hopper- Picture Courtesy: chengyipacking.com

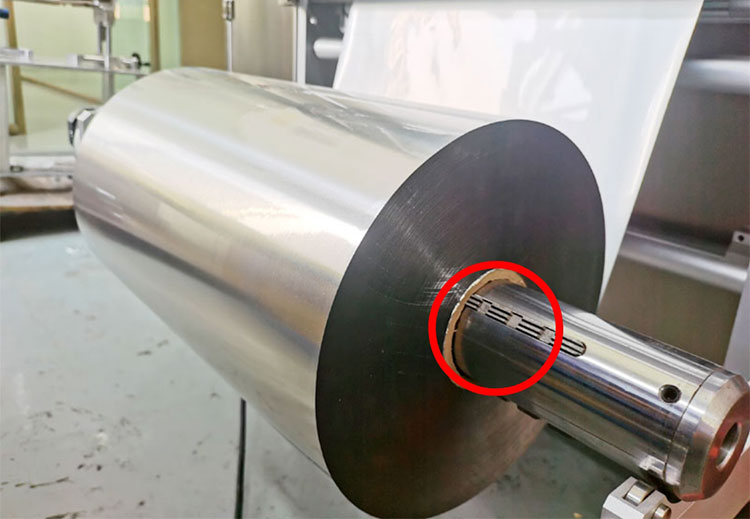

To begin with the meal replacement powder stick packing machine operation, the very first step needed for it is the loading of machine with essentials including the bulk of powder and a stock of film. Bulk powder should be poured in the machine hopper, while as, film reel is settled at the rear part of machine over frame.

Machine Setting

Machine setting- Picture Courtesy: chengyipacking.com

Once loaded, the machine is in need of proper setting. This setting is carried out in a simple way, where operator is required to set the parameters of machine regarding material amount, printing data, sealing heat, and cutting type etc., via control panel.

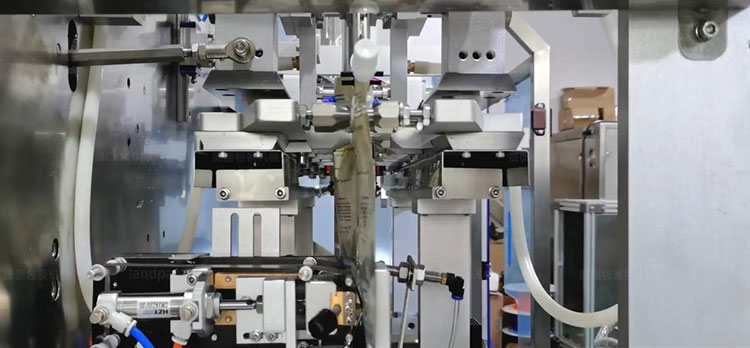

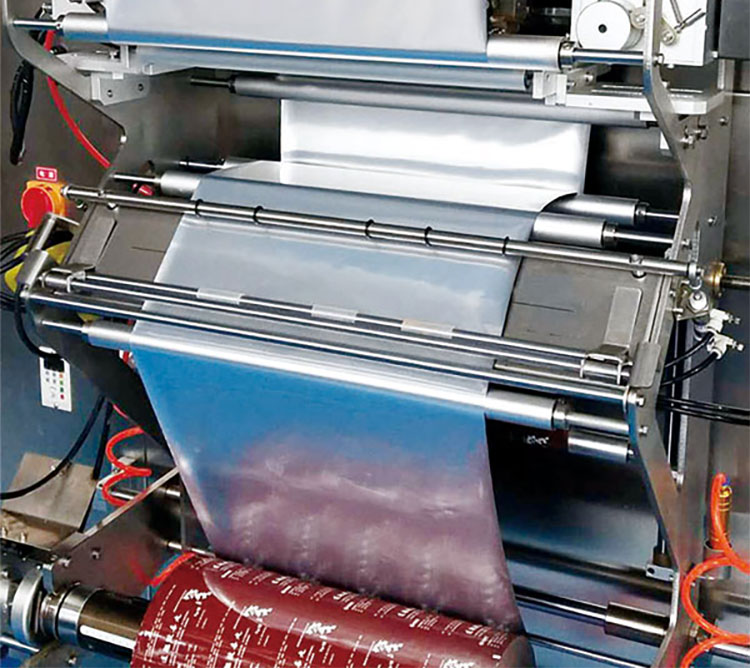

Stick Pack Forming

Stick pack formation- Picture Courtesy: Viking Masek

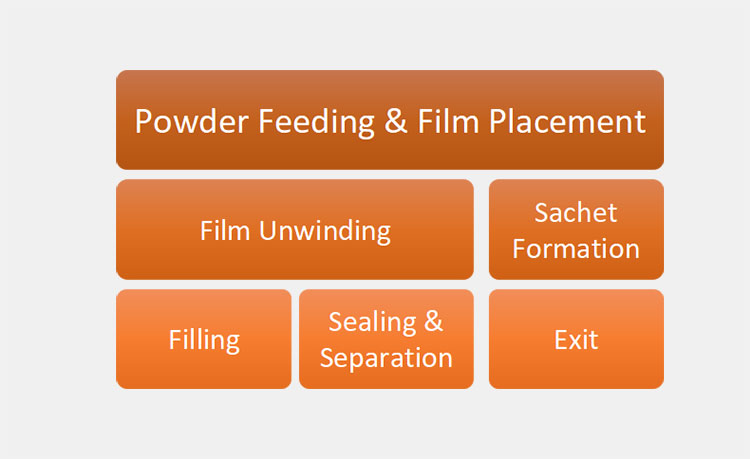

The actual process begins here with stick pack formation. The film is unwinded from reel through the nip of rollers which keep even pressure on film and guide it towards formation unit. After the film is reached to forming unit, it is divided into several layers through cutting and multiple stick packs are created through sealing.

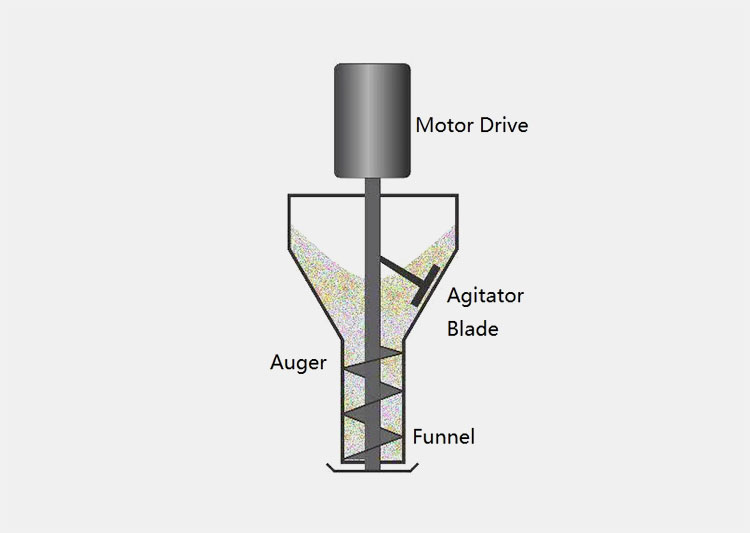

Material Weighing

Afterwards, the meal replacement powder laying in hopper is processed and weighed through auger filler. The constant rotation of auger leads to the weighing of powder, and it is moved downward.

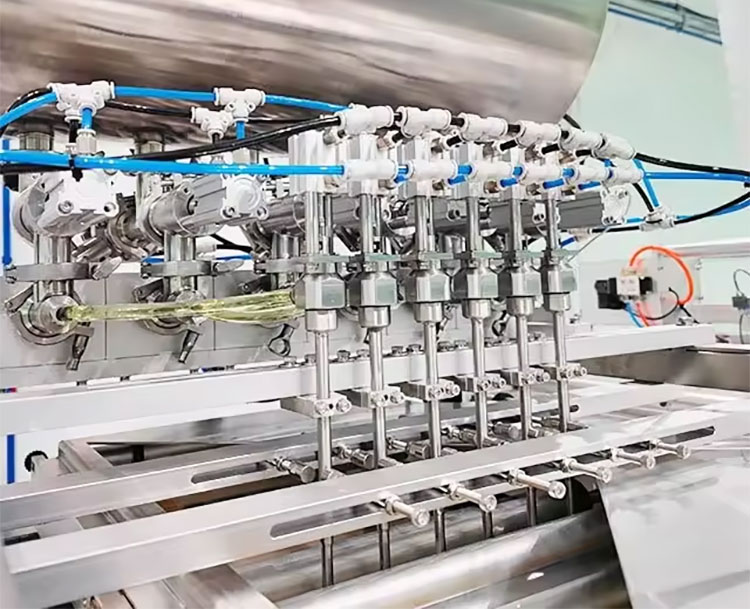

Material Filling

Meal replacement powder filling- Picture Courtesy: chengyipacking.com

Upon weighing, the powder is filled into awaited stick packs through filling heads. Here, special attention is paid to avoid any sort of material wastage by reducing over filling, under-filling, and wrong filling.

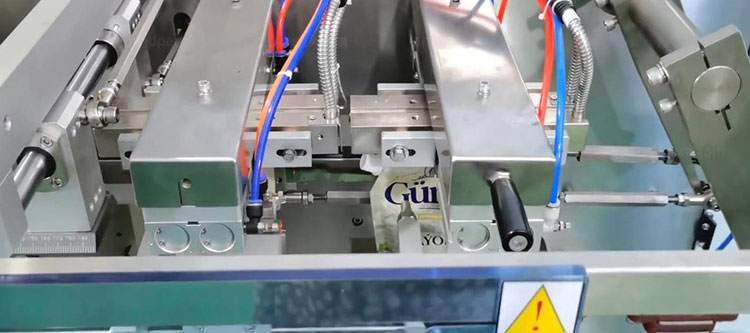

Stick Pack Sealing

Stick packs sealing process- Picture Courtesy: Great Pack

When stick packs are filled, they are supposed to be passed by the final stage of sealing where the opening of stick packs gets sealed through stringent heat sealing. In similar fashion, sealed connected stick packs are turned into individual stick packs by cutting.

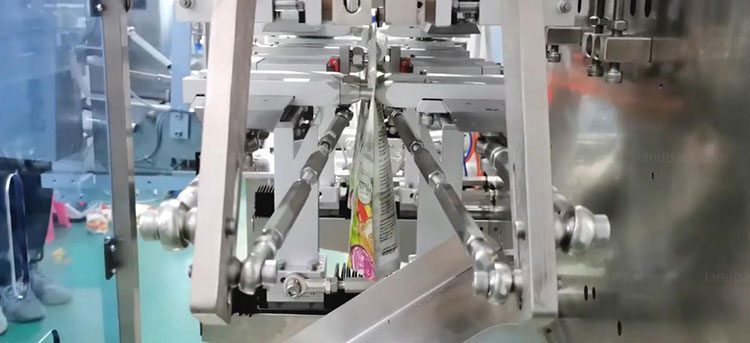

Stick Pack Discharging

Stick packs discharging- Picture Courtesy: Viking Masek

When stick packs are passed through all the essential steps of packaging, they are dropped over the conveyor belt which takes them towards final discharge or further mobilization for secondary packaging.

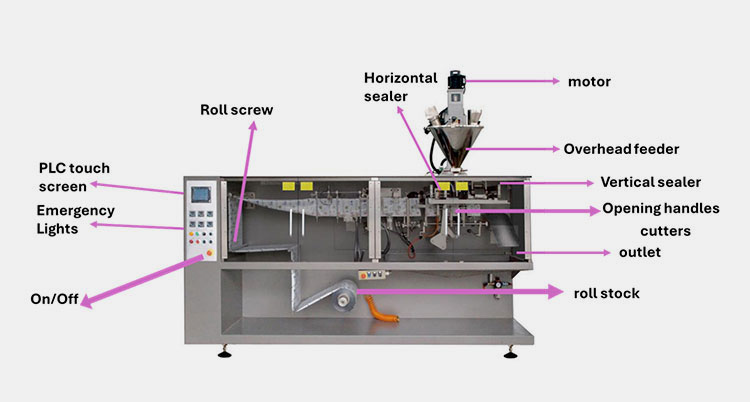

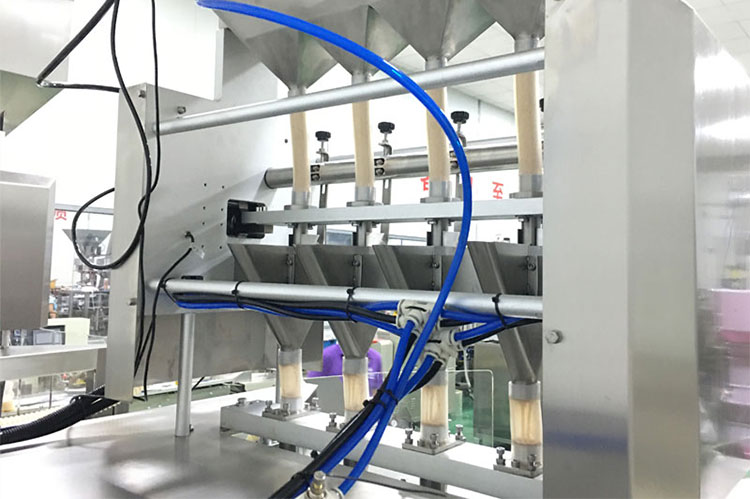

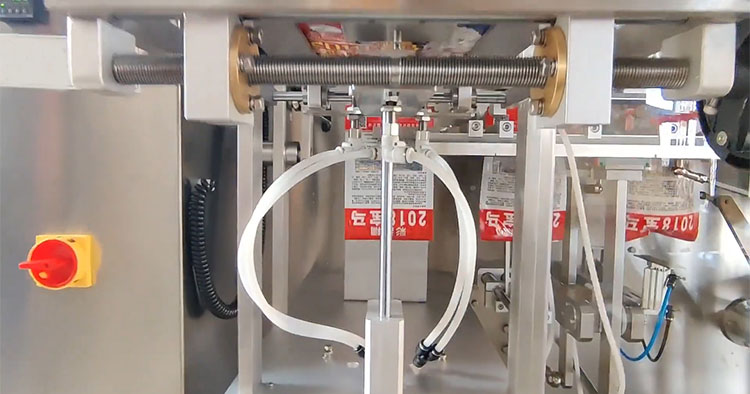

6.Describe The Components Of A Meal Replacement Powder Stick Packing Machine?

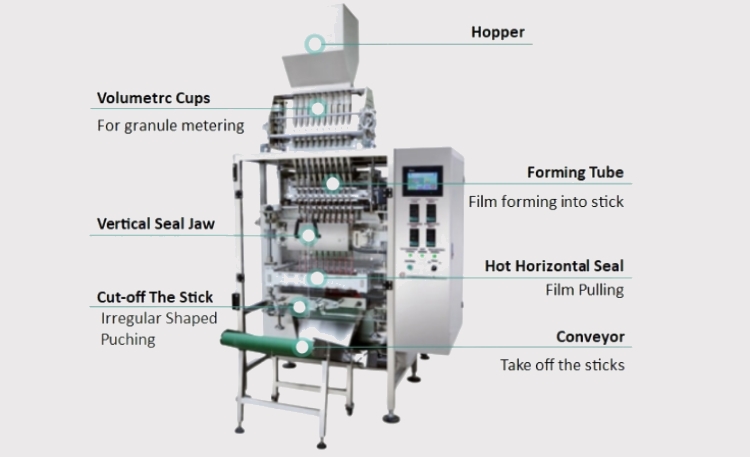

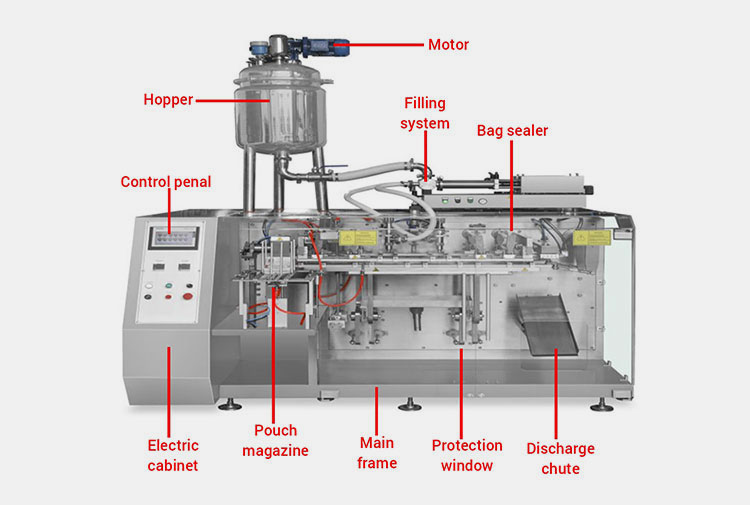

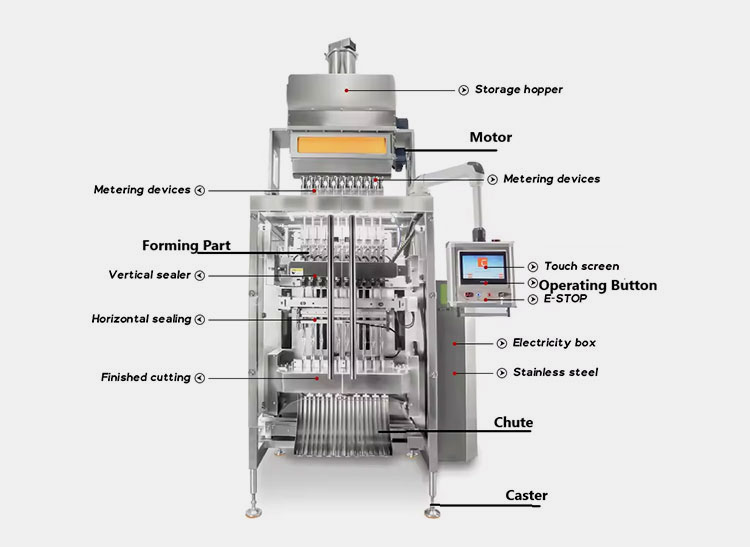

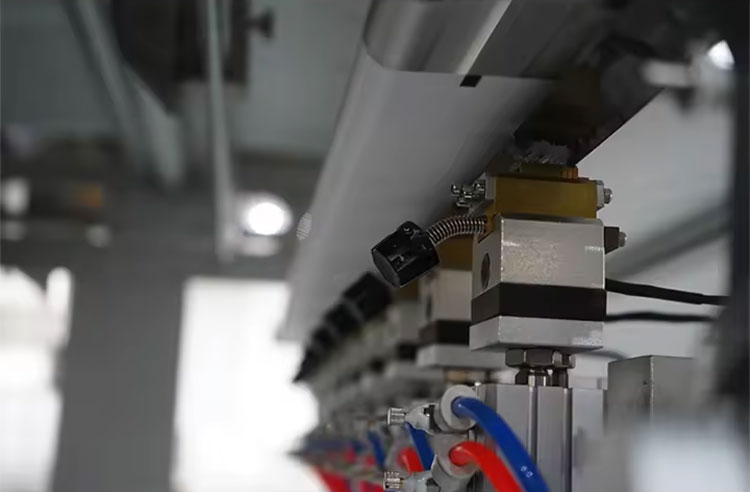

Meal replacement powder stick packing machine is composed of several components which are described below:

Components of Multi Line Powder Stick Packing Machine- Picture Courtesy: coretamp.com

| No | Components | Description |

| 1 | Hopper | Hopper is the storage tank of the machine which needs to be loaded with material such as meal replacement powder before starting the machine. It thus supplies the machine with powder during operation for non-stop functioning. |

| 2 | Motor | Motor is the power unit of machine which produces energy in other parts of the machine. |

| 3 | Protection Window | Meal replacement powder stick packing machine has an enclosed protection window which keeps the inside operation safe from external environment while at the same time allowing for convenient observation. |

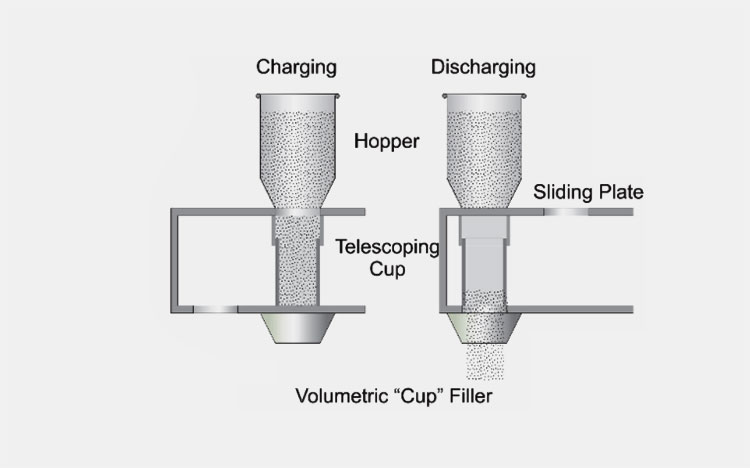

| 4 | Weighing Pump | Weighing pump is another crucial component of the machine whose function is to help weigh the exact amount of powder. Depending upon the material specifications, the machine may use different dosing techniques like volumetric cup weighing system for granulated products. |

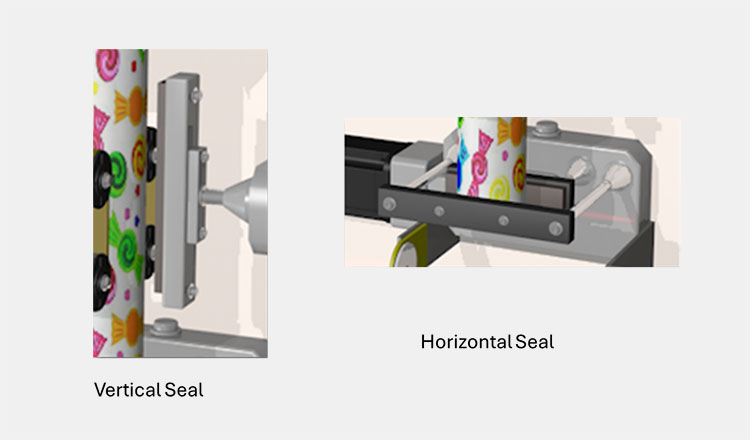

| 5 | Filling Heads | Filling heads are long narrow tubes used for dispensing the exact volume of meal replacement powder from hopper into the stick packs. |

| 6 | Horizontal Seal | It refers to the bottom and top seals; the former is added into stick packs during formation, while as, the latter is used for sealing stick packs opening after their filling. |

| 7 | Cutting Device | It is also known as cutting knife or blade which is employed to separate the continuous finished stick packs through uniform cutting. |

| 8 | Conveyor | Conveyor is an efficient mechanical handling apparatus attached to the main body of machine. It mobilizes the finished meal replacement powder stick packs for discharging or for further packaging into production line. |

| 9 | Main Frame | Main frame refers to the overall compact structure of the machine which is made from quality stainless steel. It is crucial for maintaining the structural stability of machine by supporting all the adjoined parts. |

| 10 | Stable Foot | Number of stable feet are attached to the machine for ensuring even placement of machine over surface or ground. |

| 11 | Electric Cabinet | It is an electric enclosure encasing all the electrical components of the machine including wires, fuses, switches, and terminals. |

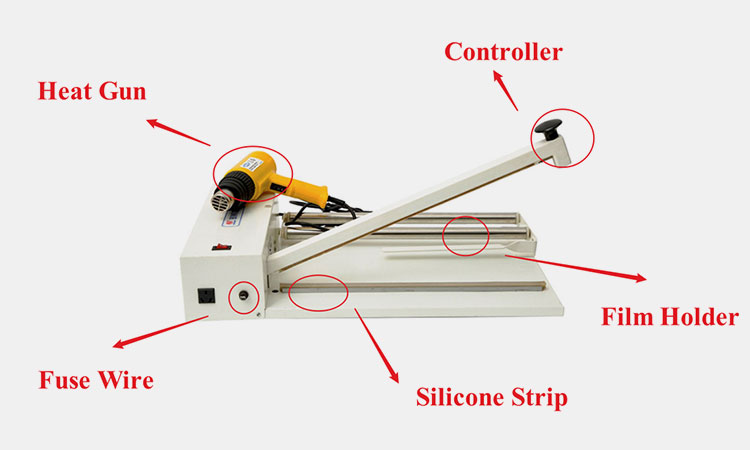

| 12 | Film Holder | Film holder is a device in the machine which is used to fix the film stock or film roll during operation. |

| 13 | Film Roll | Film roll is a stock of unbroken continuous film which is inevitable for running a meal replacement powder stick packing machine. |

| 14 | Touch Screen Interface | The machine has an advanced and intuitive tool known as touch screen interface. It holds over it multiple data in form of icons and enable the user to easily set commands in machine. |

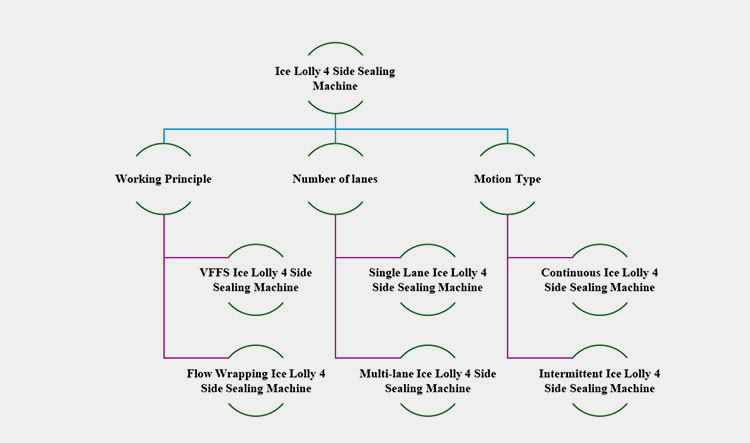

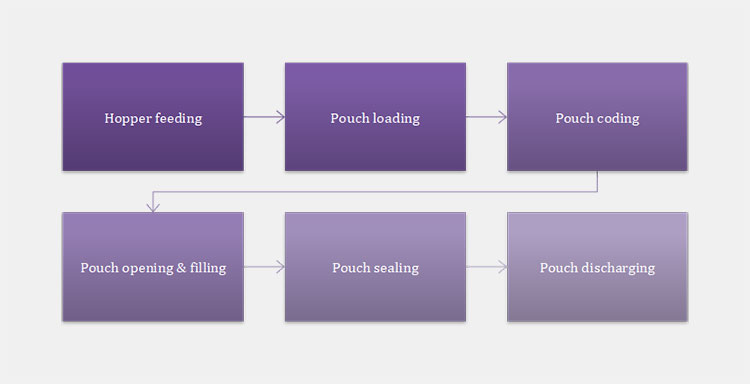

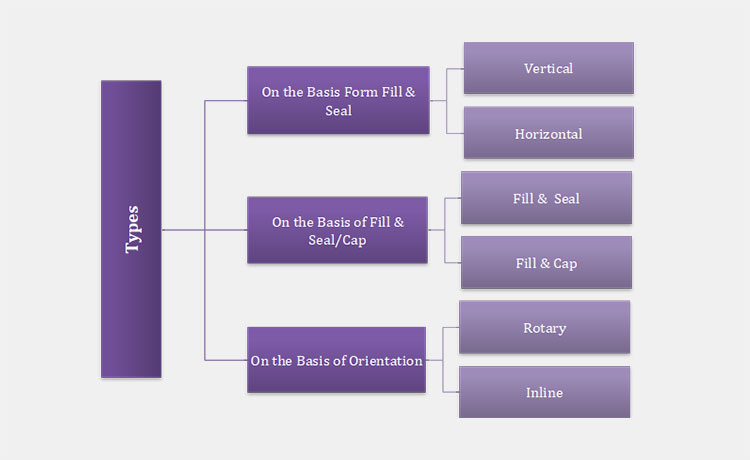

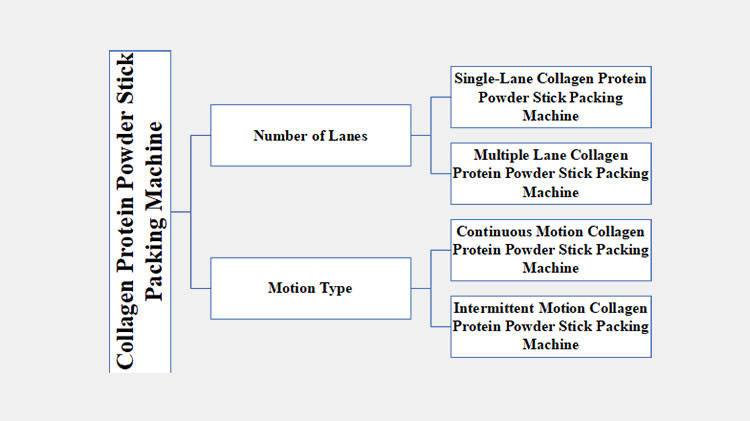

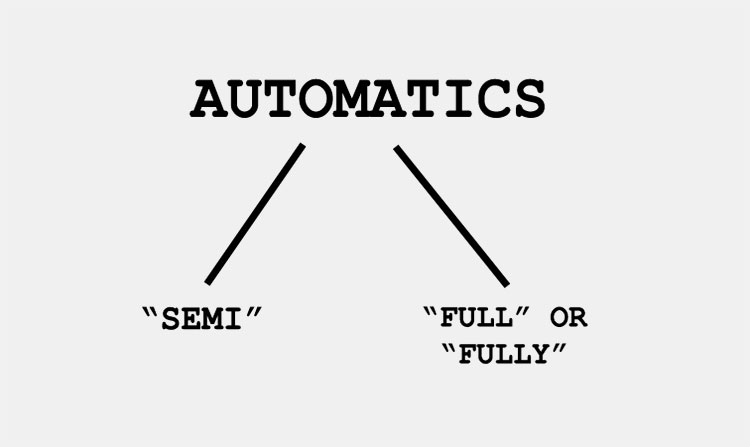

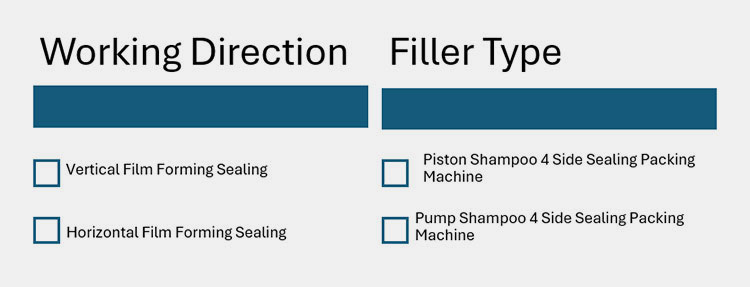

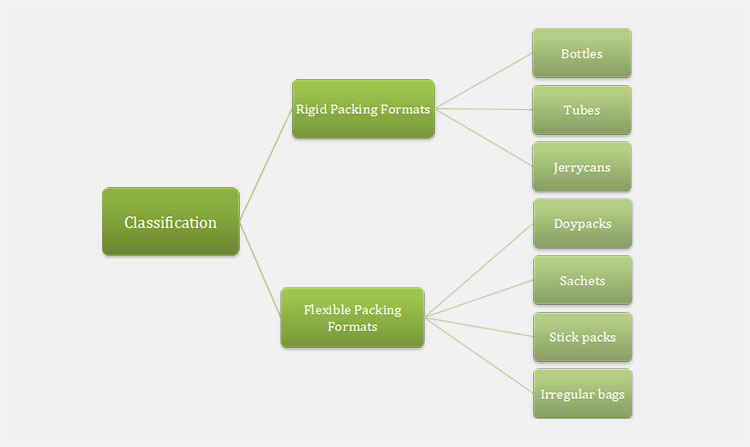

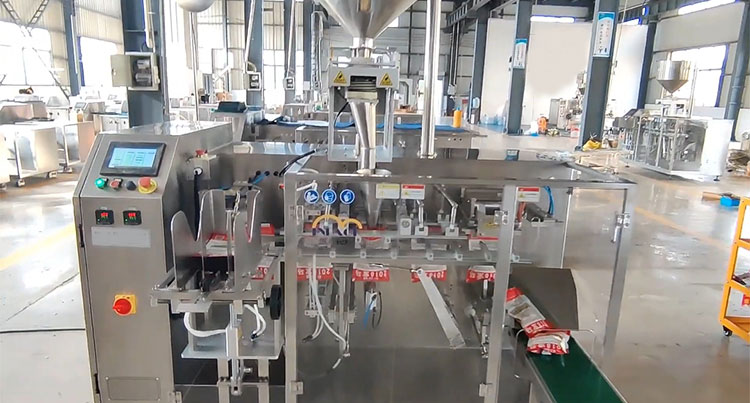

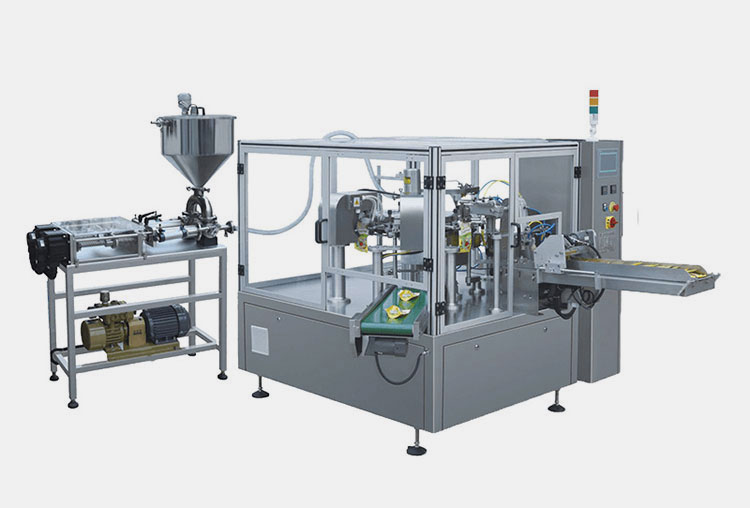

7.What Are The Types Of A Meal Replacement Powder Stick Packing Machine?

Meal replacement powder stick packing machine can be simply divided into two types depending upon their packaging capacity or lanes. These are explained below in detail:

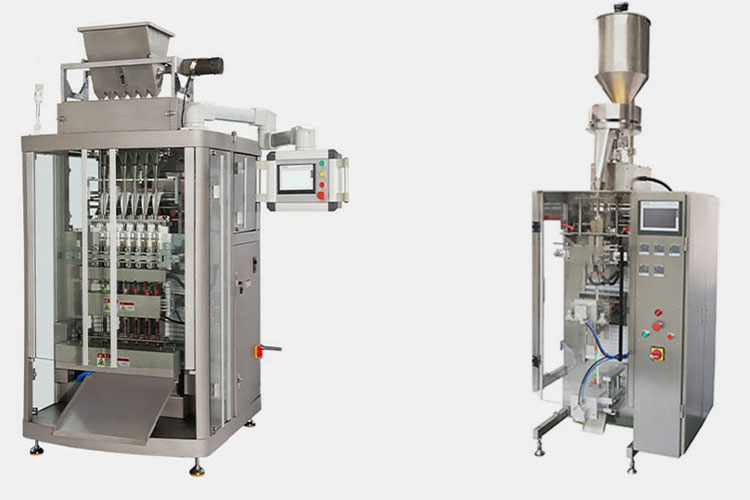

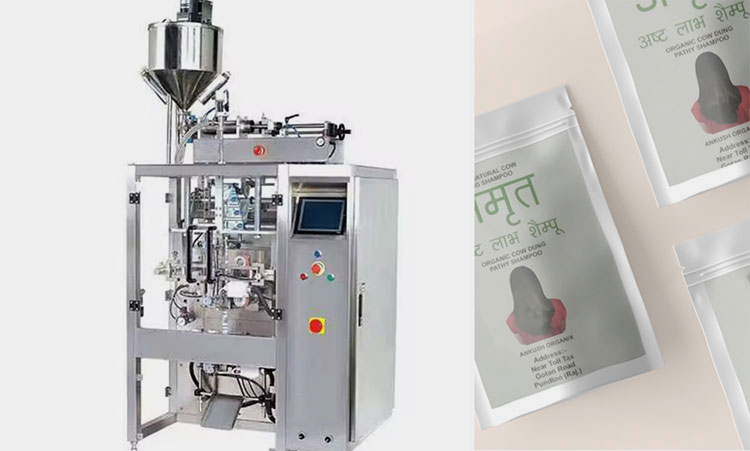

Single Lane Meal Replacement Powder Stick Packing Machine

Allpack- APK 2-220 Automatic Vertical Single Lane Powder Stick Packing Machine

This type of machine is characterized by its single lane for stick pack forming, filling, sealing, and cutting. Therefore, it is extremely compact and easily movable while covering less space. Although, the production efficiency of machine is a bit lower, it is fully automatic and is best suitable for small to medium size industries.

Structure

The structure of machine is small with main components including a hopper, film roll holder, control system, single filling nozzle, bag former, sealer, and a cutting device.

Working Principles

The machine follows straight forward way for meal replacement powder stick packing by taking start from unwinding film. As the film is unwinded, it is guided by rollers which brings it towards forming station. Here, the film is turned into a single stick pack and filled with pre-measured powder dosage. Afterwards, the stick pack is sealed, separated, and dropped for ejection.

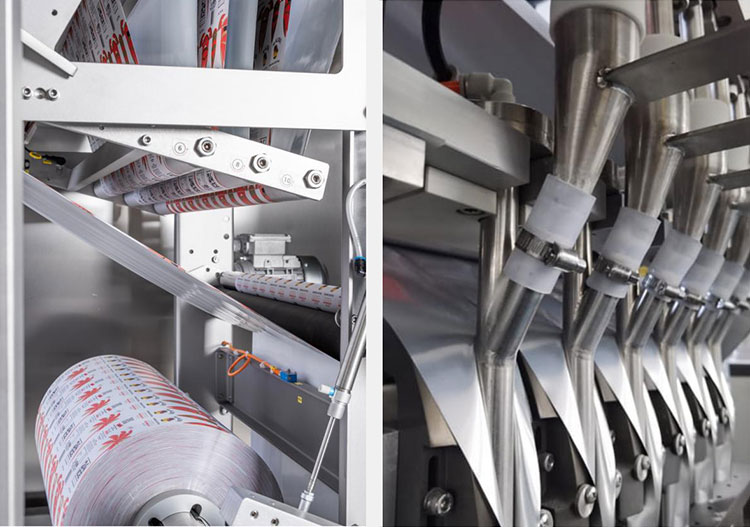

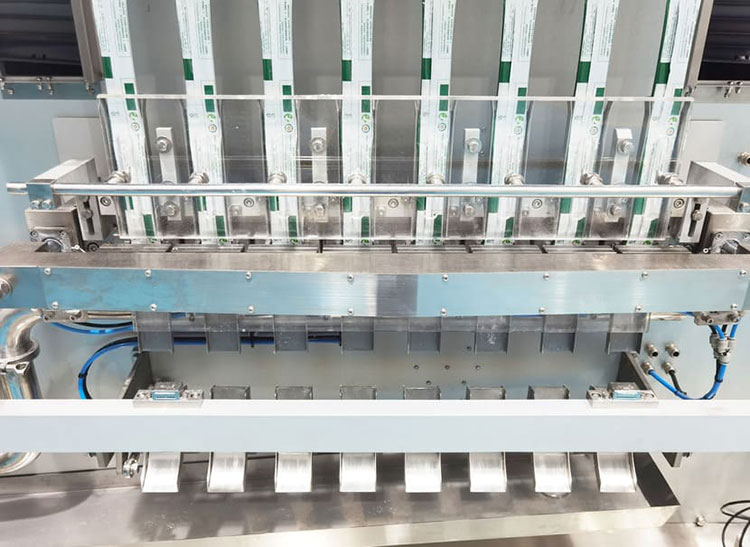

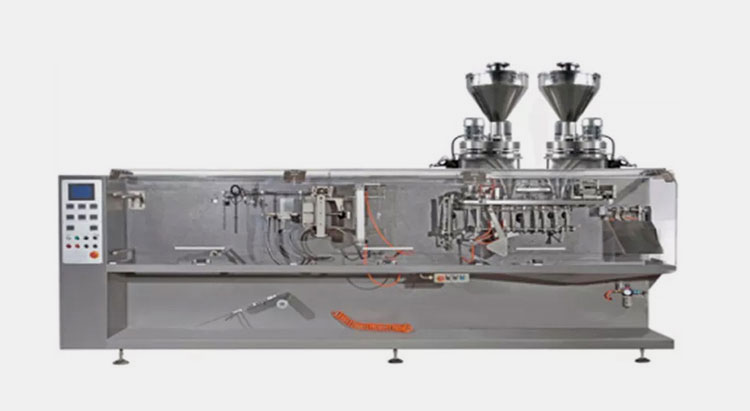

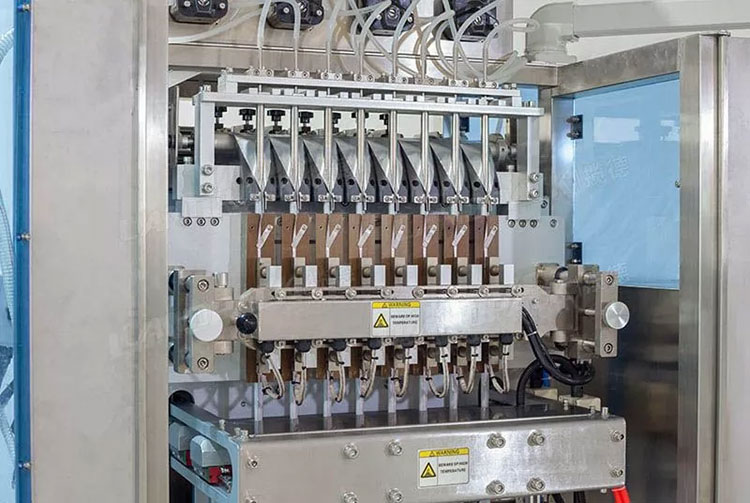

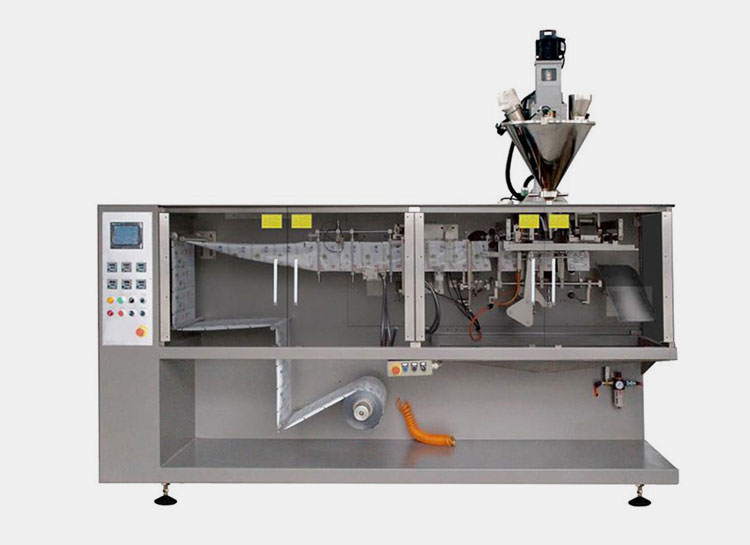

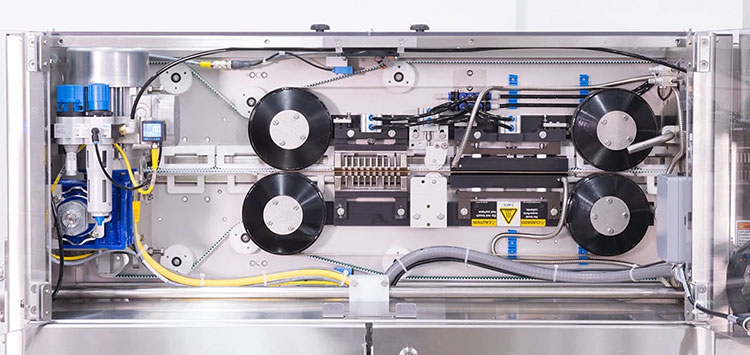

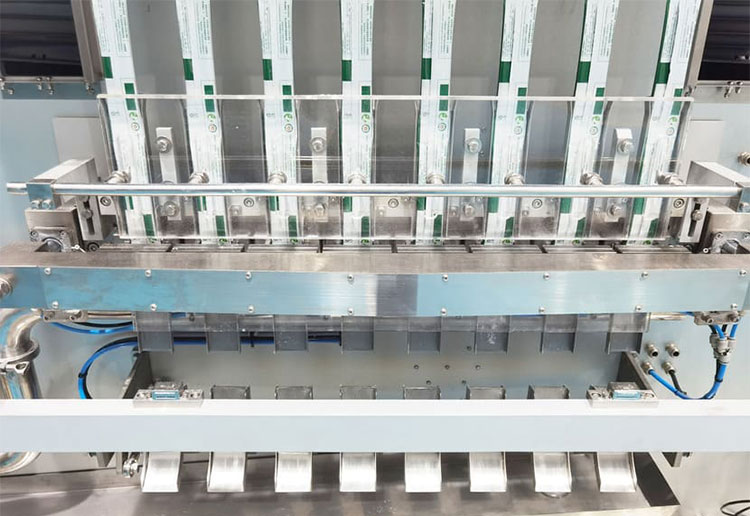

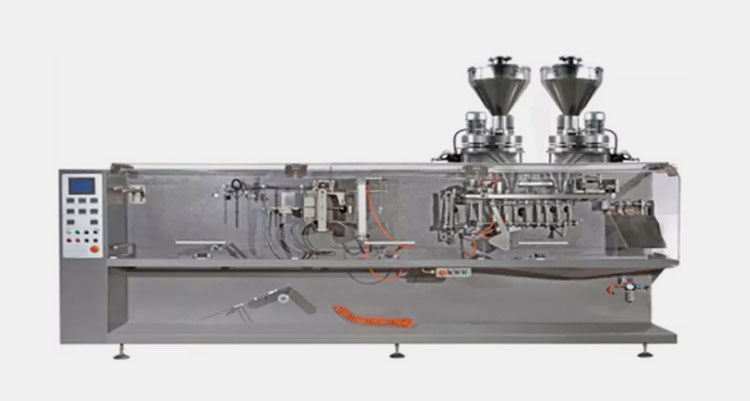

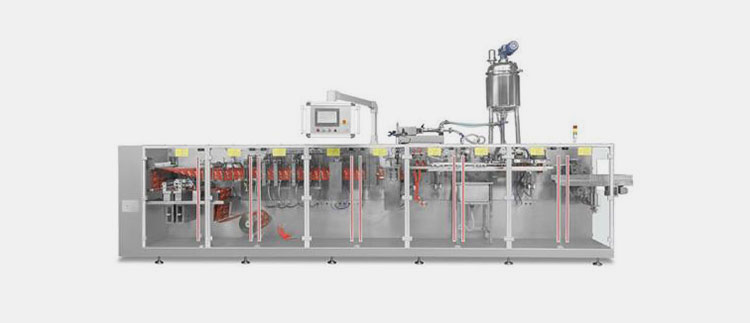

Multi-lane Meal Replacement Powder Stick Packing Machine

Allpack- APK 4-480 Multilane stick packing machine for powder

Multi-lane meal replacement powder stick packing machine is fully automatic, efficient, and advanced machine tailored with astonishing features to get the optimal production targets. The machine has extraordinary fast performance with wide applicability for different types of powders. Moreover, when adjusted, the machine can produce stick packs with range of beautiful sealing and cutting designs.

Structure

The machine has a complex structure with heavy-duty machinery and other major components. These include multiple channels as bag former, filling heads, sealing jaws, and cutting blade.

Working Principles

It works step-by-step to undertake meal replacement powder stick packing. Firstly, the machine unfurls the single layer of film and turn it into multiple stick packs through cutting and sealing. Secondly, it pours the measured amount of powder into formed stick packs, and at third stage, it seals these packs and discharged them out of the machine.

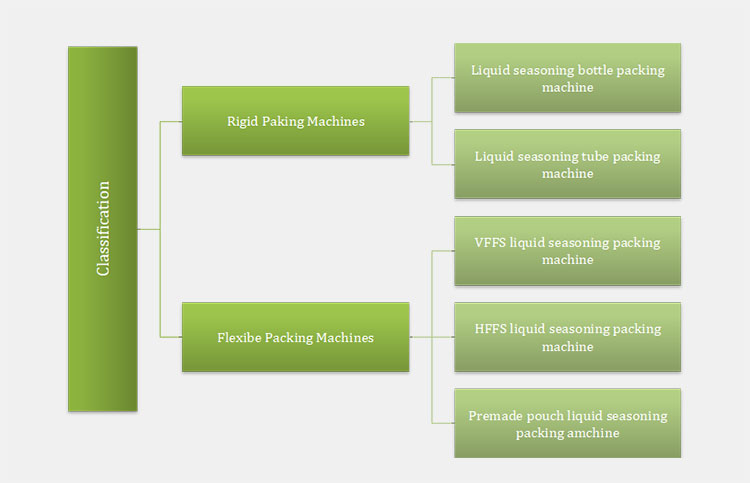

8.Highlight The Applications Of A Meal Replacement Powder Stick Packing Machine?

As meal replacement powder stick packing machine deals with powder processing, so, it can be easily used in every industry that is associated with powder. Some of the notable examples are given below:

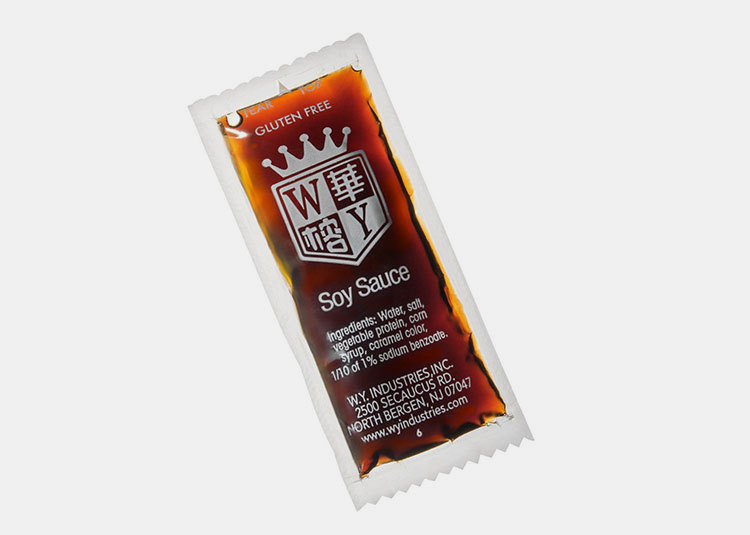

Seasoning Industry

Various seasonings in bottles- Picture Courtesy: sinfulkitchen.com

Seasoning industry is on the top when it comes to discuss the relevance of a meal replacement powder stick packing machine in food sector. The people's growing proclivities towards use of seasonings and spices in their soups, noodles, and other recipes has raised the importance of the single serving stick packs. Therefore, now seasonings like salt, pepper, and chilli powder are popularly enclosed and delivered in stick packs which are packed by this machine.

Dry Fruit Industry

Dry fruits in bowl- Picture Courtesy: momjunction.com

This machine can also be used in dry fruit industry where products like almonds, pistachio, walnut, and cashew are crushed and packed in powdered form. So, you can have the fun of dry fruit powders in small, beautiful stick packs with the help of a meal replacement powder stick packing machine.

Tea Processing Industry

Tea stick packs- Picture Courtesy: chengyipacking.com

Another notable application of a meal replacement powder stick packing machine is found in tea processing industry. As we are familiar with the fact that advancements in technology have greatly influenced our lifestyle. Similarly, we are moving towards convenience, and it becomes obligatory when the things in context are tea and coffee. So, this machine is best suitable for packing tea in individual stick packs.

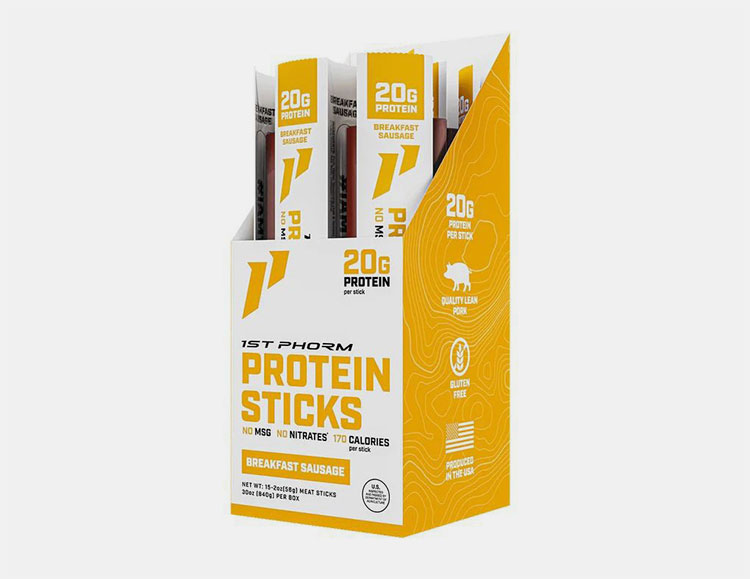

Healthcare Industry

Protein Powder Stick Packing- Picture Courtesy: 1st Phorm

Most of the supplements, protein powders, energy booster, and even medications are now delivered in form of powders to support swift action. Therefore, it is now a trend that these powders are packed in sachets or stick packs. So, a meal replacement powder stick packing machine is brought into use to securely carry out this function.

Chemical Industry

Detergent powder- Picture Courtesy: ohsospotless.com

Chemical industry is among other areas where the manufacturing and packaging of powders like detergent powder, adhesive powders, pigments, and pesticides powders are carried out. Since, these are deleterious to humans’ health, an enclosed protected machine is required which is no other than a meal replacement powder stick packing machine.

Cosmetic Industry

Hair color powder- Picture Courtesy: foreo.com

When the topic in discussion is about powder packaging, how can cosmetic industry be left behind! Well, this area revolves around the processing of materials needed for enhancing the external beauty of humans. Therefore, bleach powder, face powder, hair dye, and glitters are the common examples which can be packed in small stick packs by using a meal replacement powder stick packing machine.

9.How To Maintain A Meal Replacement Powder Stick Packing Machine?

Regular maintenance is the key to keep your machine in a good working condition. It helps you extend the working life of your machine and increase the production output. What is the right way for maintaining your meal replacement powder stick packing machine is a question we have tried to answer below:

Machine lubrication- Picture Courtesy: uesystems.com

Structural Adjustment

The very first step for maintaining your machine is the right structural adjustment. It simply includes locating all the parts of machine on right place and tightening the screws and nuts.

Regular Cleaning

Regular cleaning is also very essential for maintaining a meal replacement powder stick packing machine. For this, you need to follow the directions as recommended by the manufacturer. For instance, use the type of cleaning method and cleaning materials which are best suitable for the machine. During cleaning, make sure to remove all the residues and particulates from machine to ensure smooth functioning.

Parts Changeover

Timely parts changeover is also very necessary as negligence can cause further disruption. You just need to regularly inspect the seals, gaskets, and other parts of machine and their noise. In case of damage or any part is wearing, replace it quickly with the right and new one.

Lubrication

All the movable parts of machine play instrumental role in running machine. However, their friction can cause delays and damages to the machine. Therefore, to restrict these issues, it is crucial to lubricate your meal replacement powder stick packing machine with the right type of grease oil or lubricants.

10.What Is The Leak Test For A Meal Replacement Powder Stick Packing Machine?

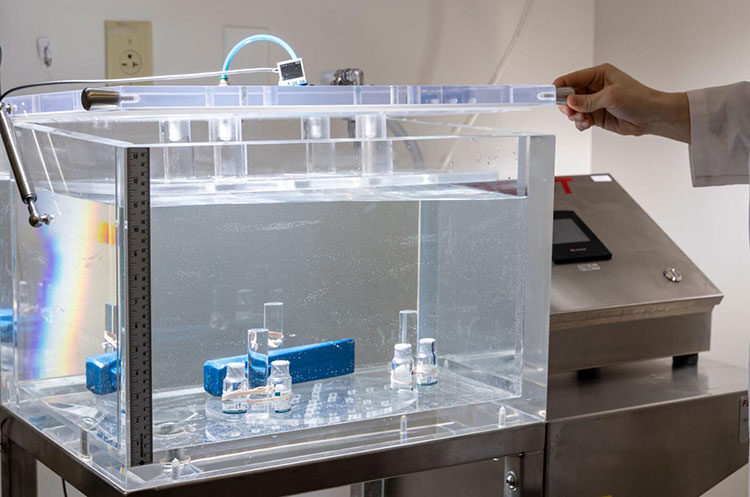

Leak test is one of the most important quality checking steps conducted for ensuring the quality of meal replacement powder stick packs produced by this machine. It thus validates the machine's performance for safety of materials. Although, there are number of leak tests being practiced by manufacturers, one such prominent test is the Vacuum Leak Test.

Vacuum leak tester- Picture Courtesy: sixt7ltd.com

During this test, a finished meal replacement powder stick pack is placed in a water filled chamber to check the presence of leak. Therefore, after its placement, the chamber is completely closed, and air is evacuated from it. Meanwhile, if small bubbles start appearing in the water filled chamber, it shows the existence of a leak.

Contrary to that, if the water remains calm with no generation of bubbles, then it is considered that the pack is free from leaks.

11.Explain The Troubleshooting Of A Meal Replacement Powder Stick Packing Machine?

Troubleshooting, countermeasures, and solutions are the terms which we often use in our daily life to make our lives easier and better. Similar is the case with this human created machine, a meal replacement powder stick packing machine, which we use for packing various powders. So, let's highlight some of its common issues along with possible causes and solutions!

False unwinding of film

Highlighting film unwinding issue- Picture Courtesy: chengyipacking.com

Causes

Intermittent film unwinding due to loose motor shaft rod.

Film reel is placed uneven on frame.

Unparallel tension on film.

Solutions

Tight the motor shaft rod for continuous film unwinding.

Place the film reel evenly and in center of the frame.

Equally release tension on film.

Incoherent filling of meal replacement powder

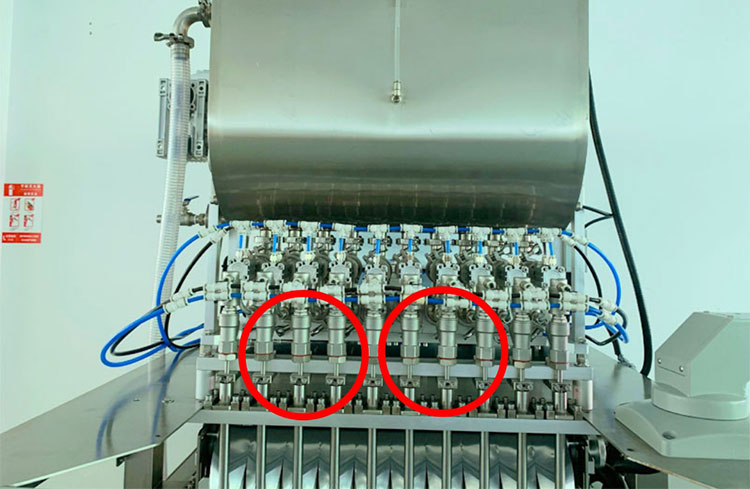

Encircled powder filling heads- Picture Courtesy: chengyipacking.com

Causes

The integrated filling system is incompatible with the properties of material being processed.

Low time duration for filling powder into stick packs.

The filling heads may be blocked due to inclusion of foreign objects.

Solutions

Make sure to use the right type of filling system. For instance, auger filler is suitable for adhesive powders and volumetric cup weighing system is desirable for granulated powders.

Increase the filling time for dispensing powder into stick packs.

Remove the foreign object and keep the hopper lid closed during operation to restrict environmental elements.

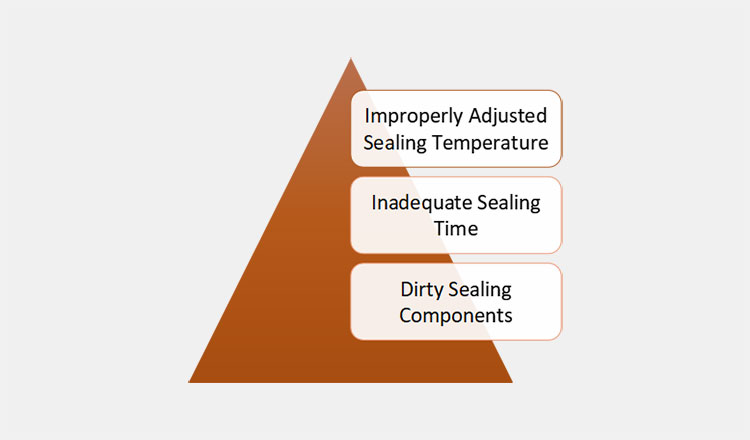

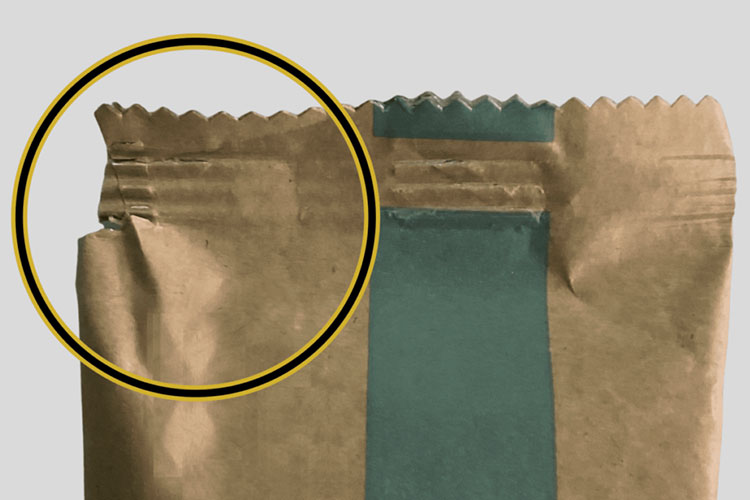

Improper Sealing

Highlighting erroneous sealing- Picture Courtesy: Behance

Causes

Low heated sealing jaws creates partial or weak sealing.

Temperature of heat-sealing jaws is not compatible to that of the film thickness.

Pressure applied by the sealing jaws is insufficient.

Solutions

Increase the temperature of sealing jaws to suitable level.

Make sure to set the temperature of sealing bars in accordance with film thickness.

Reset the sealing jaws for accurate pressure application.

Inconsistency in stick packs size

Displaying inconsistencies in stick pack sizes

Causes

The parameters fixed in machine setting as input are wrong.

There is a difference in the position of bag former and cutting device.

Worn out bag forming unit and cutting unit.

Solutions

Reset the machine by setting accurate parameters in accordance with your demands.

Replace the bag forming and cutting device in a way that both are parallel to each other.

Replace the damaged parts with new ones.

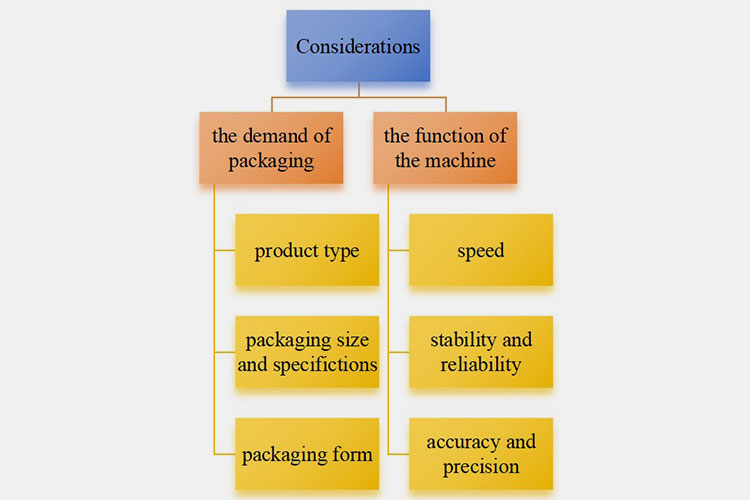

12.What Are The Top Considerations For A Meal Replacement Powder Stick Packing Machine?

Well, it is a question of great importance for every manufacturer that what factors will lead them to make a sound purchase! So, we have tried to solve this conundrum for you by enlisting simple but impressive tips. Consider these all:

Material Nature

Hemp protein powder- Picture Courtesy: thehempshop.co.uk

The very first thing to look for is knowing the material nature. It is very critical for choosing the right machine as it will determine the type of machine and associated filling system for it. In addition, you need to fix whether you are processing non-free-flowing adhesive powders or free-flowing and granulated powders. In such a case, the former will require an auger filler, while as, the latter will be perfectly processed by a volumetric cup weighing system.

Quantity

Another important consideration is to check your daily production targets. For instance, you can simply determine it by answering the question that whether you are running a small size, medium size, or large size industry. Therefore, considering it will assist you in choosing the machine that can produce desired output.

Expenditure

Expenses presentation idea- Picture Courtesy: business-standard.com

Expenditure is the inevitable factor you should pay attention to. It not only refers to the original price of the machine but also covers the overall cost of machine encompassing its installation and operational cost. Therefore, satisfy yourself by asking every possible question that comes in your mind regarding a meal replacement powder stick packing machine.

Quality

Quality icon- Picture Courtesy: gembaacademy.com

Last but not least, quality is indeed an undeniable facet of the machine which must be carefully checked when buying a meal replacement powder stick packing machine. For this, you should check the machine's quality certifications, warranty policy, and its manufacturers' reputation.

Conclusion

Let's wrap up this detailed buying guide about a Meal Replacement Powder Stick Packing Machine with a reminder that packaging machine can play pivotal role in your business. It can make or break your reputation, so, always try to get complete information about the machine, its features, working process, and types etc., as we have explained above. Besides this, it is very essential to have a trustable supplier with expertise in relevant field. In this way, Allpack is one such good example who has gained over 11 years of experience in packaging field. So, make sure to search our inventory for getting topnotch machine!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Meal Replacement Powder Stick Packing Machine: The Complete Buying Guide In 2025 Read More »

Powder- Sourced: eminenceorganics

Powder- Sourced: eminenceorganics