Chicken Seasoning Powder Packaging: The Complete FAQ Guide in 2025

Chicken Seasoning Powder Packaging: The Complete FAQ Guide in 2025

When a company decides to launch or scale a food product, most of the attention is given to flavor, sourcing, and pricing. However, one element that is often overlooked that has an impact on success is packaging. Especially, chicken seasoning powder packaging isn’t just about filling the spice into a pouch, sachet, or jar; it’s a blend of science, design, and machinery.

Every step in the packaging process has a direct impact on your product’s shelf life, safety, and sales. If you are starting the manufacturing of chicken seasoning powder, examining the process of packaging is not optional but crucial. In this guide, we will disclose everything you need to be familiar with to make an informed decision.

1.What is meant by chicken seasoning powder packaging?

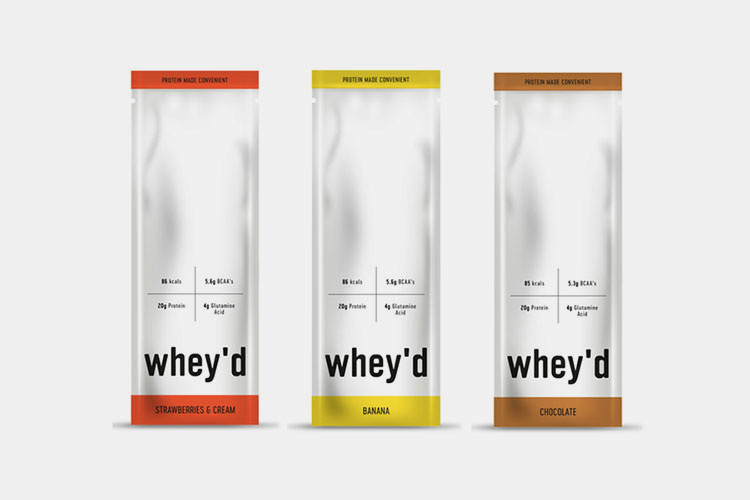

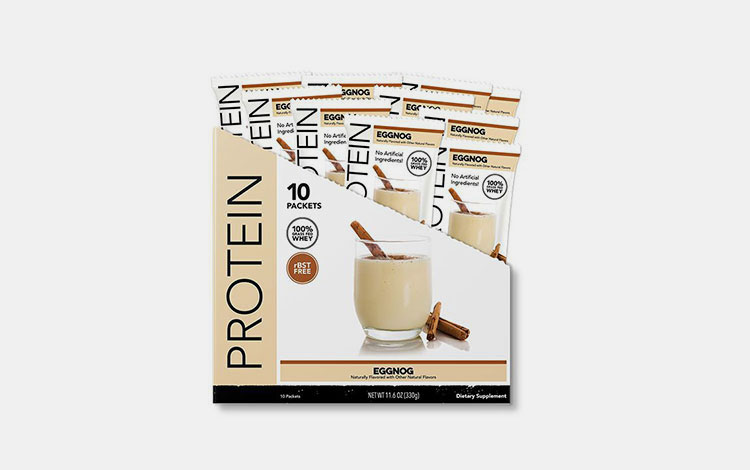

Chicken Seasoning Powder Packaging

The chicken seasoning powder packaging is a process and materials used to pack and preserve chicken-flavored seasoning. The chicken seasoning powder is a blend of spices to enhance the flavor of food with a chicken-like taste.

According to Food Packaging: Principles and Practice by Gordon L. Robertson, proper packaging is responsible for protecting the seasoning from environmental factors and ensures consumer compliance.

2.Why is chicken seasoning powder packaging important?

Benefits of Packaging- Picture Courtesy: Unilever Food Solutions

The chicken seasoning powder packaging provides benefits to the food sector and consumers. Let’s reveal them:

Preserves Aroma and Flavor

Chicken Seasoning Enhances the food's aroma.

Proper packaging protects powder from deterioration, preserving the taste and aroma of the product.

Prolonged shelf Life

Prolong Stability

When you use packaging material with barrier properties, it protects the product against microbial contamination, maintaining the stability for a long time (extending shelf life).

Customer compliance

Resealable Packaging

It offers easy-to-use packaging solutions, such as resealable pouches and sachets, to improve usability and portion control.

Safety of the Product

Sealed Packaging Necessary During Transportation

Hygienic and properly sealed packaging minimizes the risk of contamination and maintains product integrity during transit and storage.

Identification

Packaging Gives Attractive Appearance.

Attractive packaging helps the product to capture the consumer's attention on shelves, providing a distinct identity in the market.

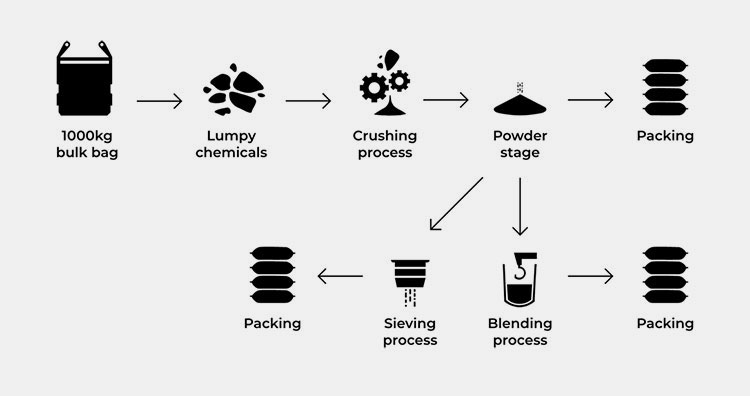

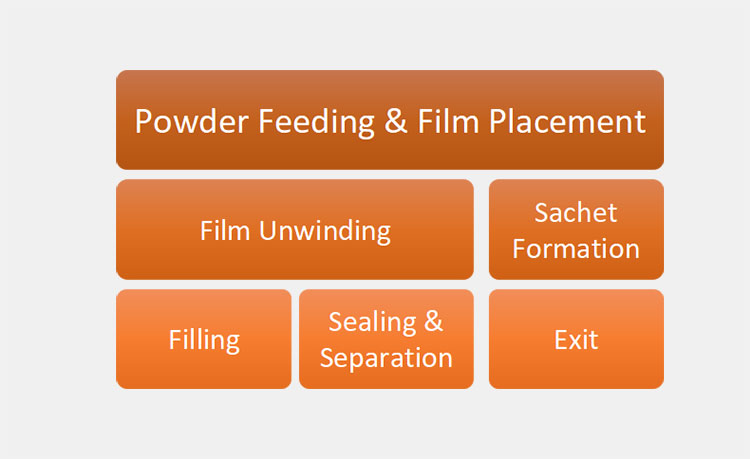

3.Do you know the step-by-step process for chicken seasoning powder packaging?

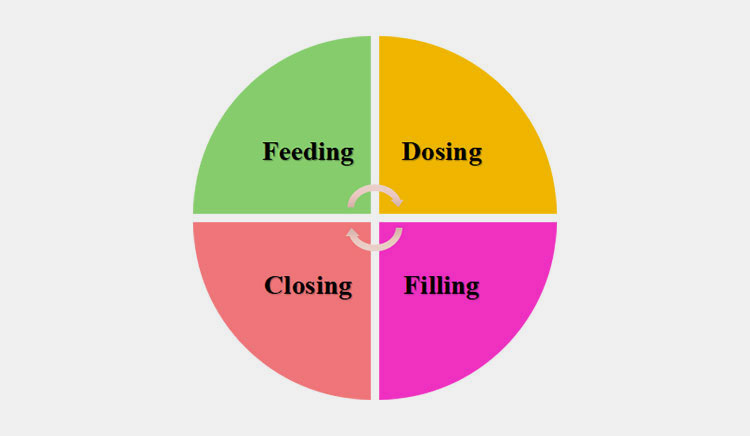

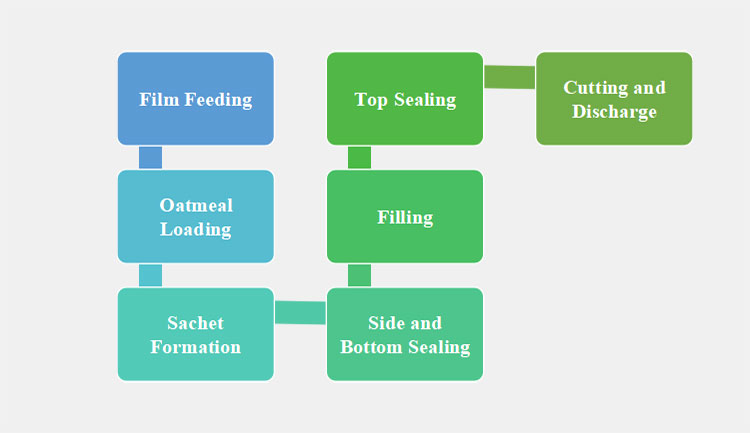

The chicken seasoning powder packaging involves a standardized procedure in the food sector. Here is the step-by-step procedure to understand how it takes place:

Step # 1: Cleaning and Sieving of Raw Materials

Raw Material for Chicken Seasoning Powder- Picture Courtesy: Choco Coorg Spice

The received raw materials first pass through a sieving machine to achieve uniform particle size and to remove any impurities.

Step# 2: Grinding, Blending, and Sieving

Weighing of Raw Material- Picture Courtesy: Pacific Spice Company

In the case of whole spices, milling or pulverization is performed to convert raw spices into fine powder. This step involves accurately measuring and thoroughly mixing all the spices and flavors to create a uniform blend of chicken seasoning powder. After that, they are passed through a sieving machine to remove lumps and any foreign particles.

Step # 3: Quality Inspection

Quality Checks- Picture Courtesy: Merieux NutriScience

Quality control testing is performed to check for particle size, microbiological contamination, taste, aroma, and uniformity

Step # 4: Dehumidification

Drying of Chicken Seasoning Powder- Picture Courtesy: Humiscope

Drying is required if high moisture content is found. This step improves shelf life.

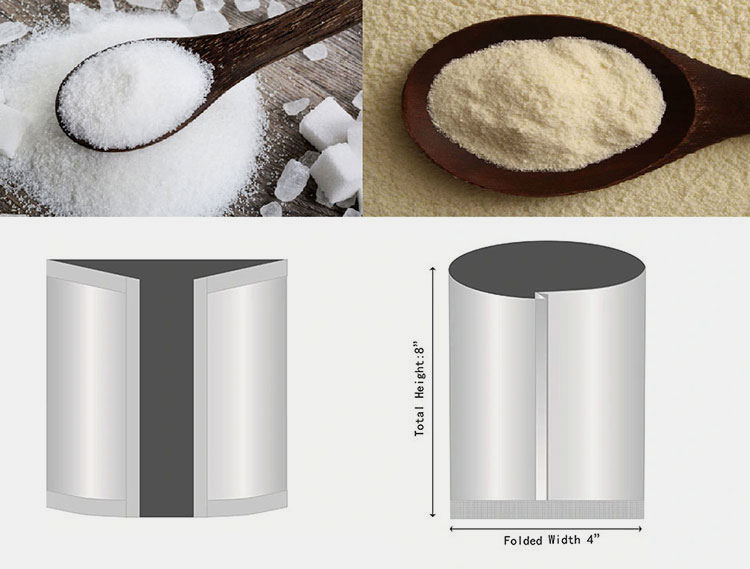

Step# 5: Filling into Containers

Filling of Weighed Powder into Containers

The formulated powder is precisely measured according to the desired packaging size. Then it’s filled through an automatic filling machine. The weighed powder is dispensed into pre-formed packaging, which may be sachets, pouches, or bottles.

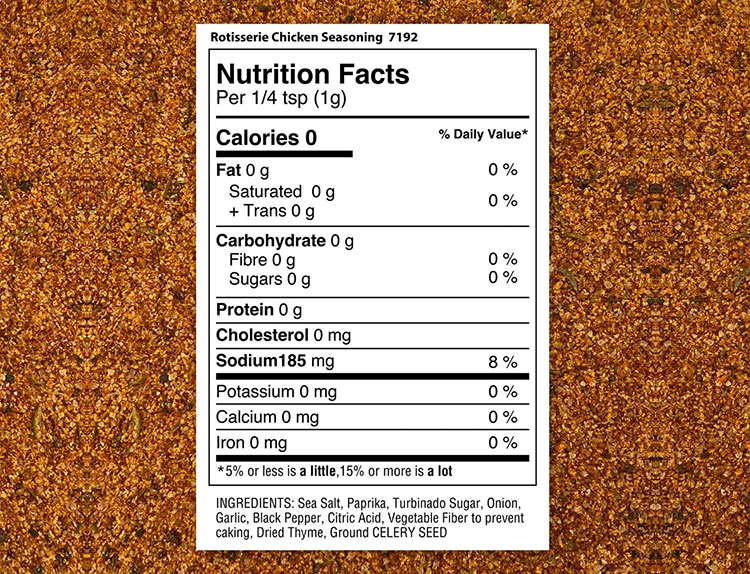

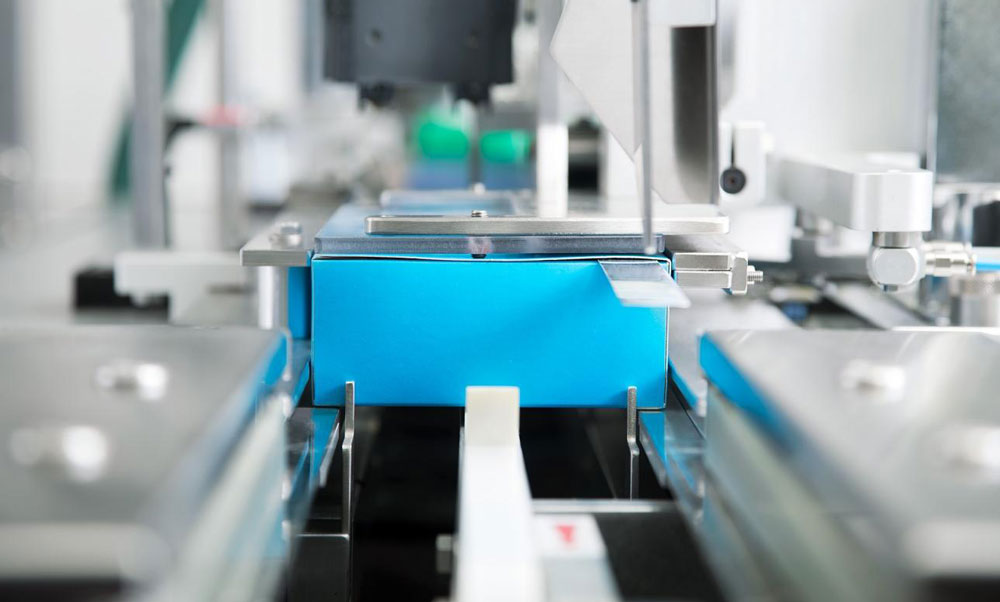

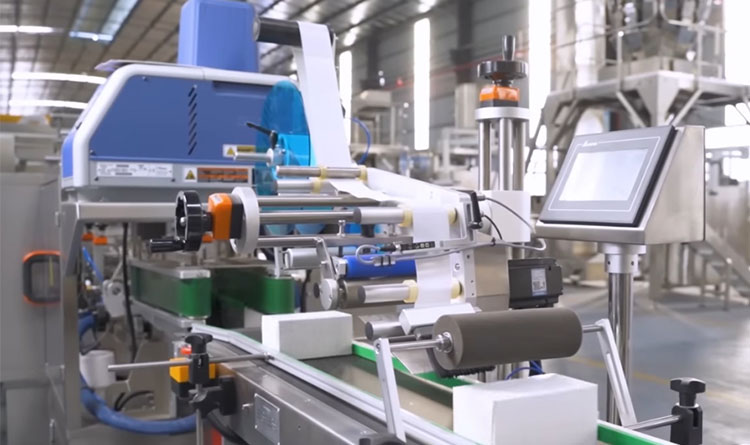

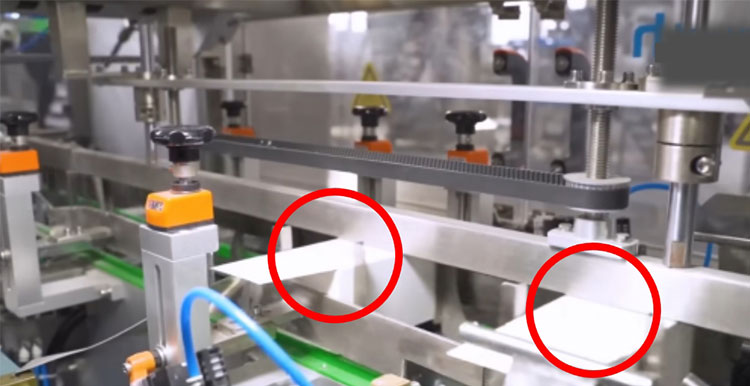

Step# 6: Sealing and Labeling

Labeling Includes Nutritional Facts- Picture Courtesy: The Spice Lab

Then, the filled packs are sealed properly via heat-sealing or vacuum-sealing machines. The packaging is then labeled with the names of ingredients, nutritional facts, expiry date, and storage conditions.

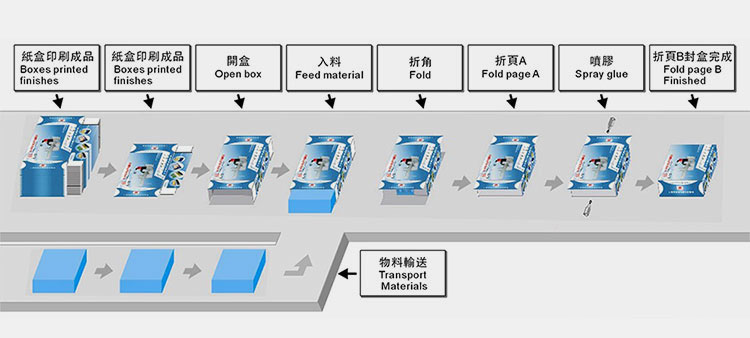

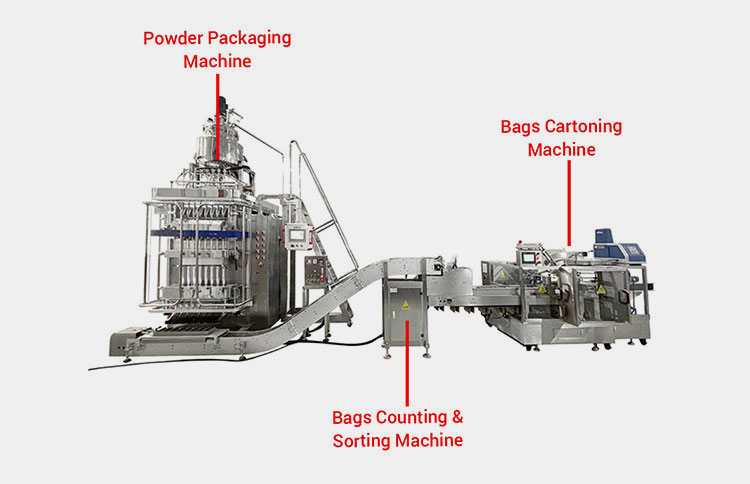

Step# 7: Secondary Packaging

Packed into Boxes- Picture Courtesy: Red Stick Spice

These final sealed and labeled packs are packed into cartons or boxes for bulk handling and distribution.

Step # 8: Final Inspection

Quality Inspection- Picture Courtesy: Pacific Spice Company

This step involves a visual test for proper sealing, weight, and correct labeling. Random sampling is done for final product testing.

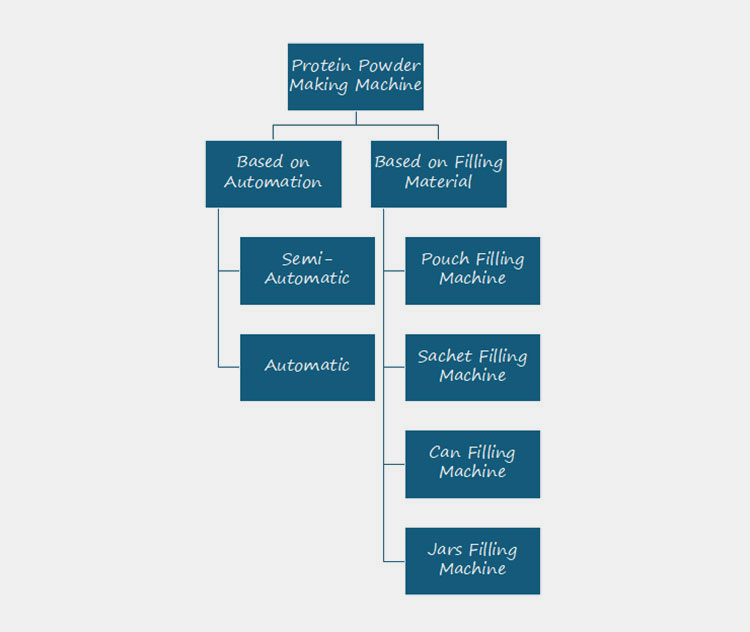

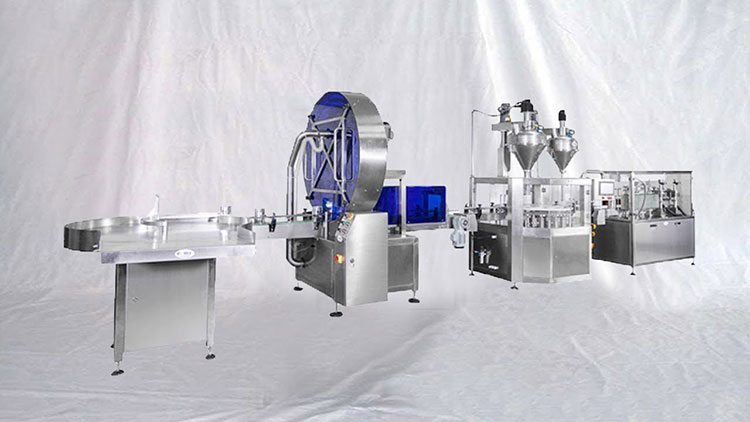

4.What machines are commonly used for chicken seasoning powder packaging?

Packaging Equipment

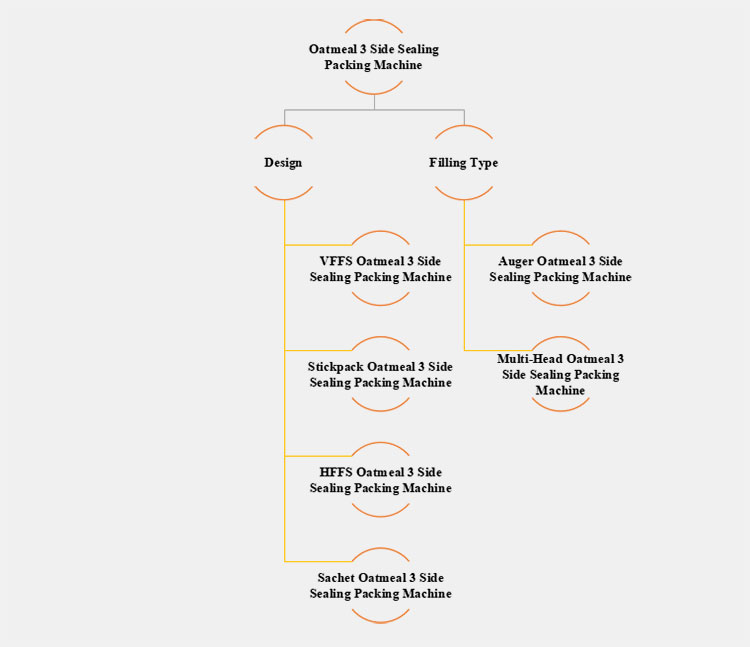

In the food sector, hygienic and efficient chicken seasoning powder packaging is achieved by employing multiple types of machinery at different stages of the packaging process. The selection of machines is dependent upon the flow properties of the chicken seasoning powder, the required packaging format, and the production scale.

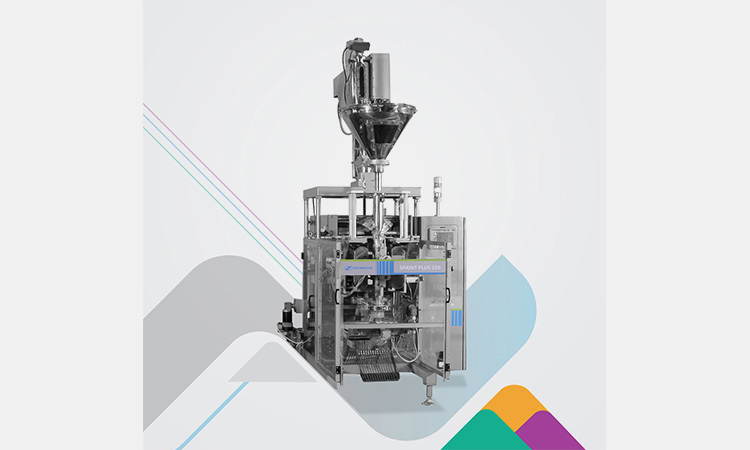

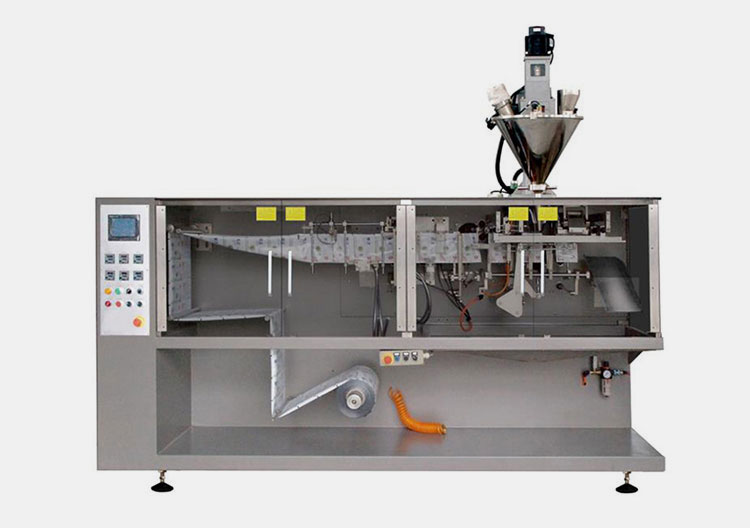

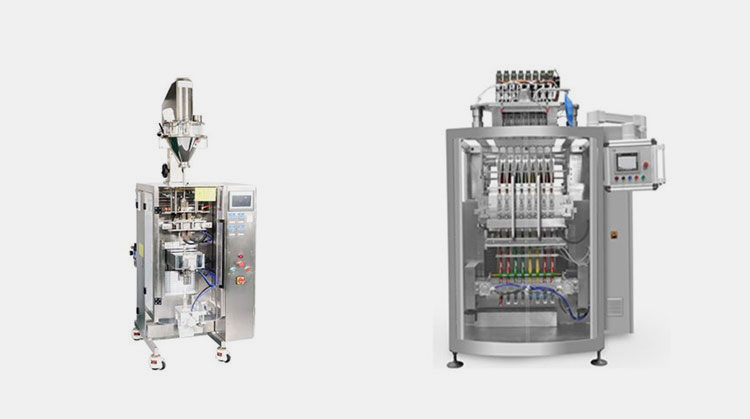

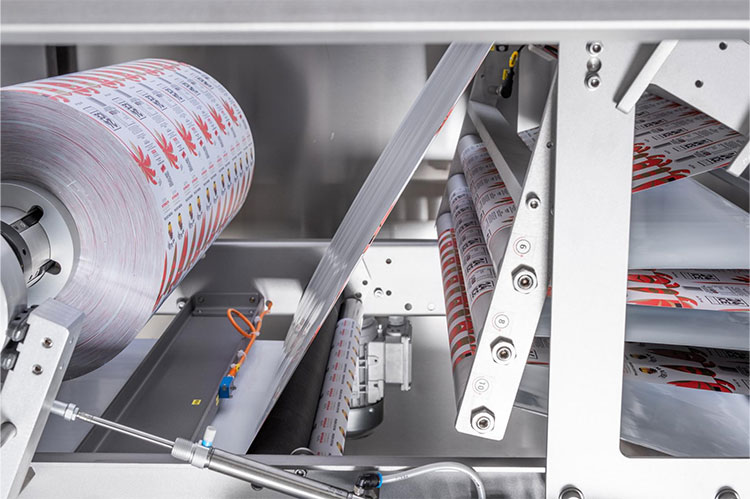

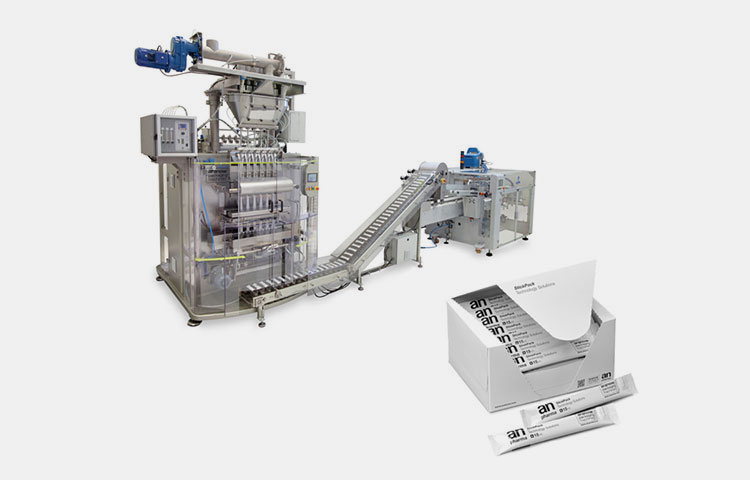

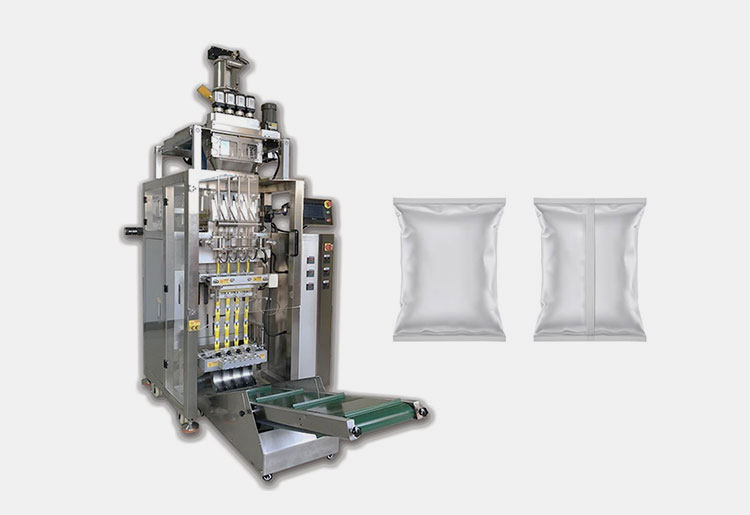

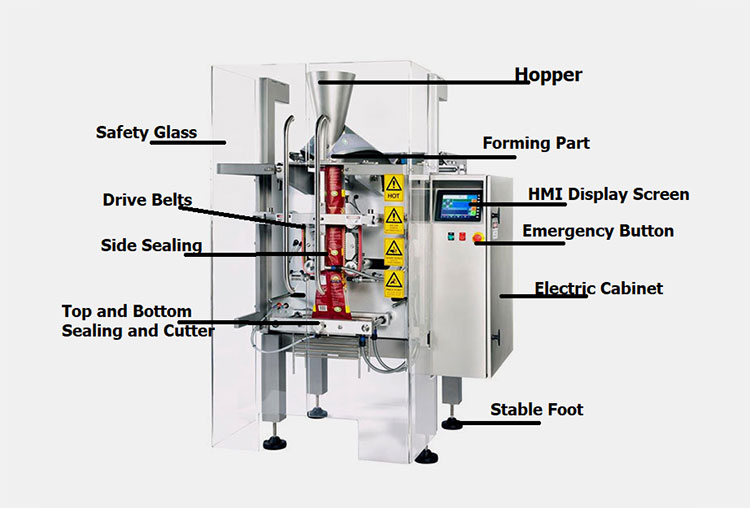

Vertical Form Fill Seal (VFFS) Machine

VFFS for Filling- Picture Courtesy: Propac Industrial

In these machines, bags are formed from a roll of film and then filled with product. The bags are sealed vertically. All steps are done in one continuous process.

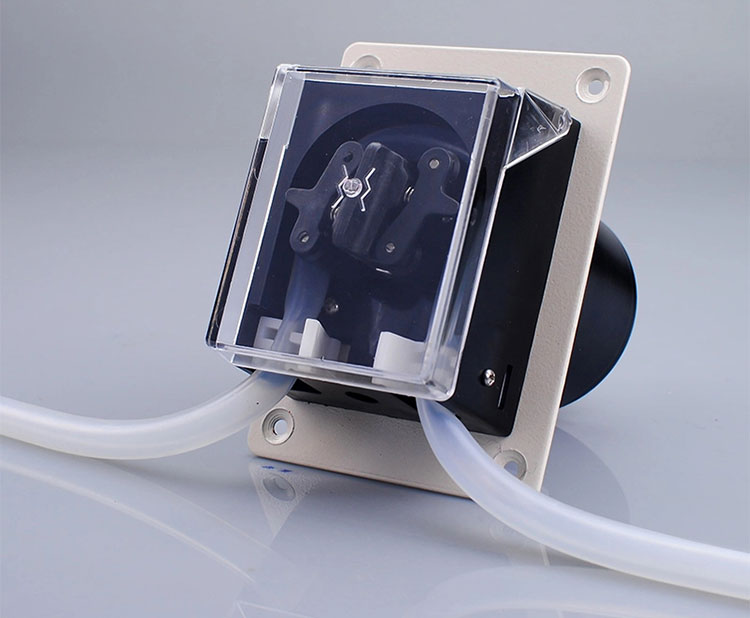

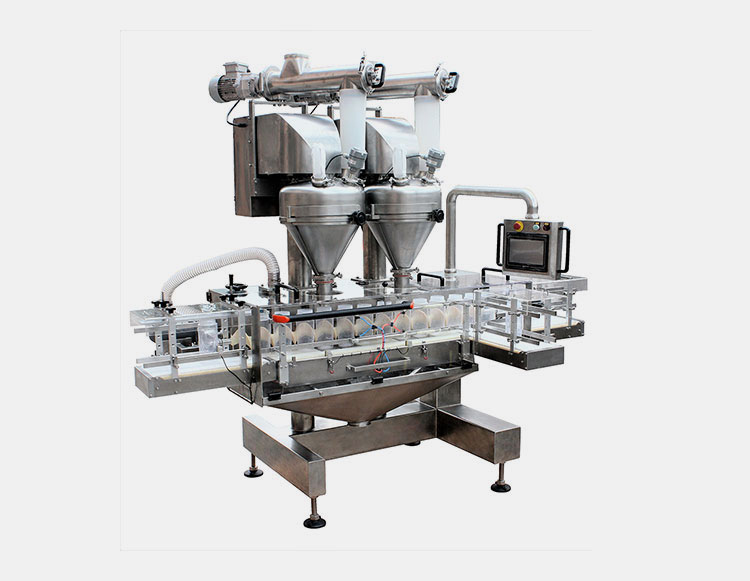

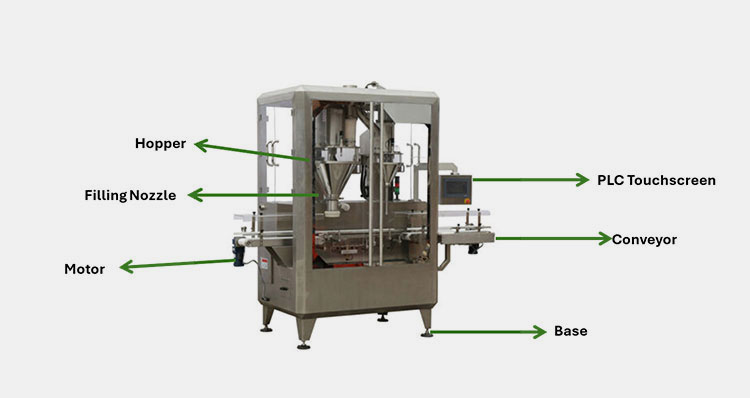

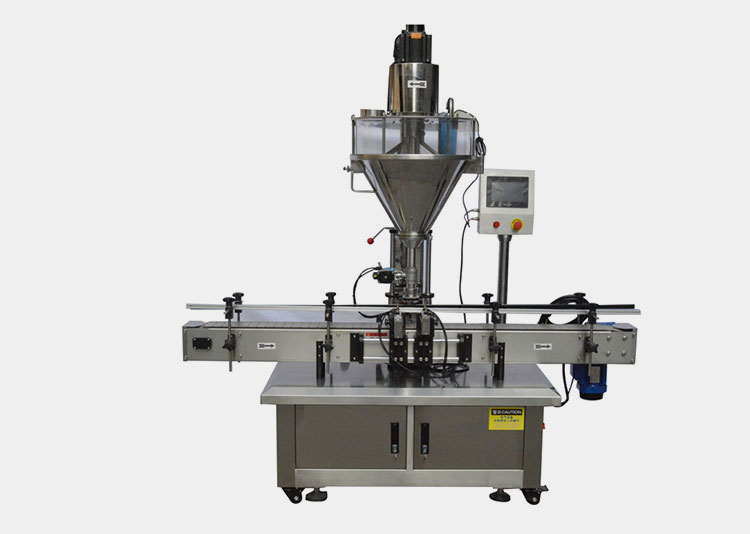

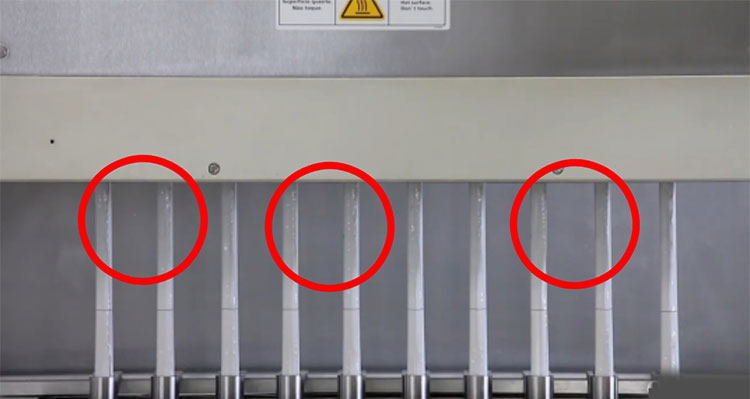

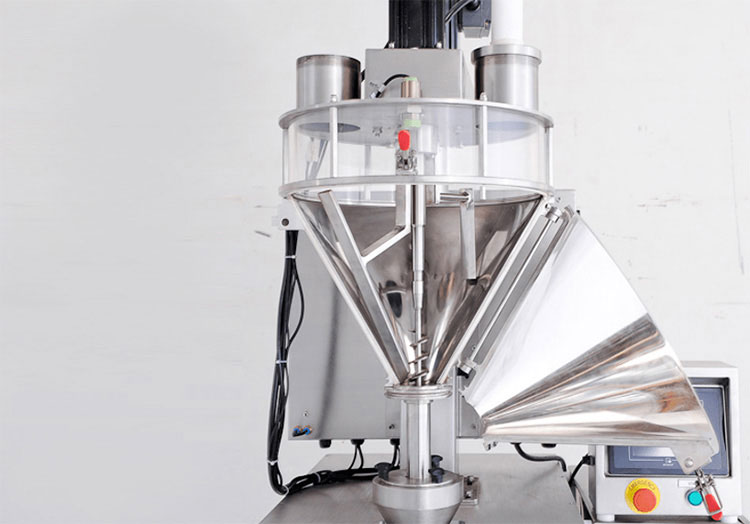

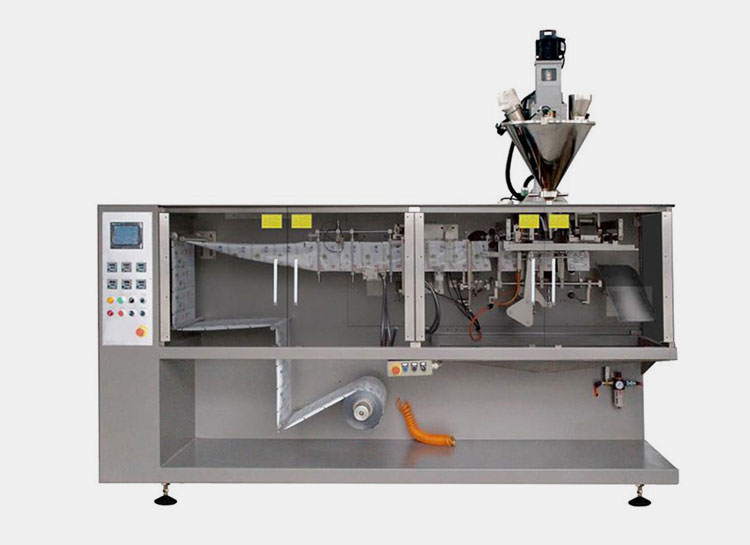

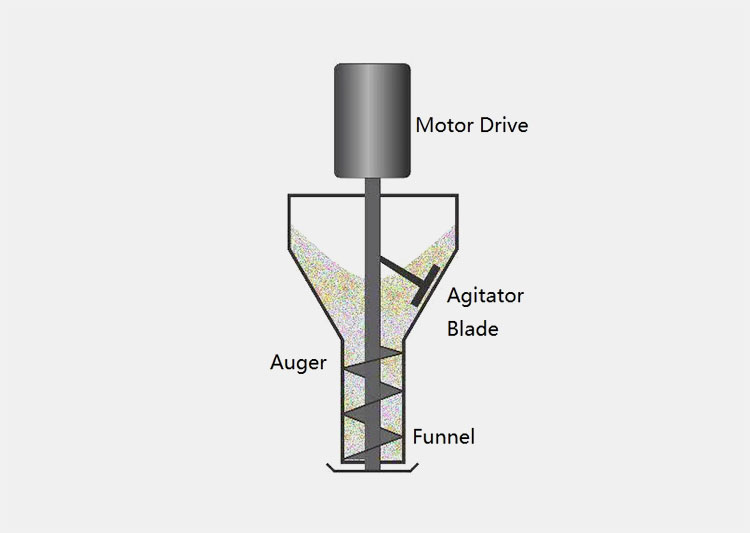

Auger Filers Machine

High-Speed Chicken Seasoning Powder Packaging

These machines filled the powder precisely by using a rotating screw mechanism. They are ideal for chicken seasoning powder as they facilitate the filling of non-free-flowing powders.

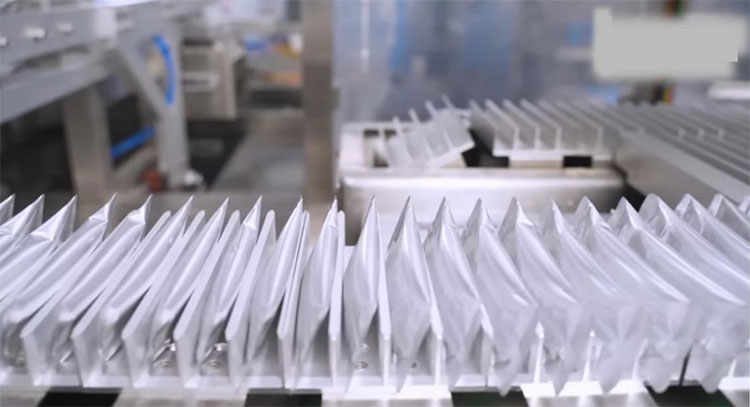

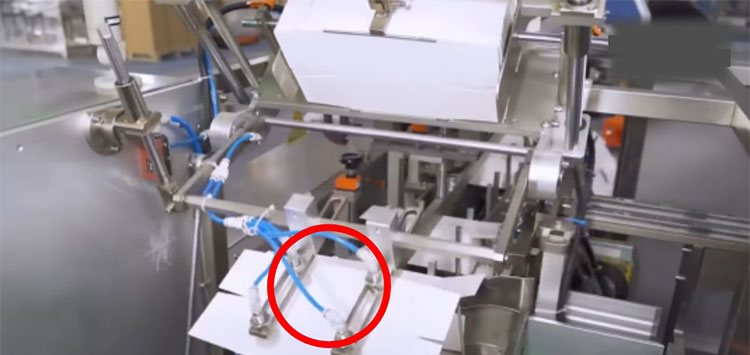

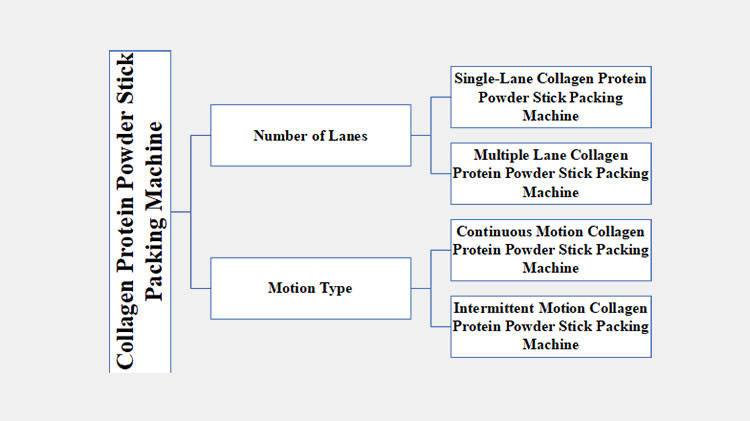

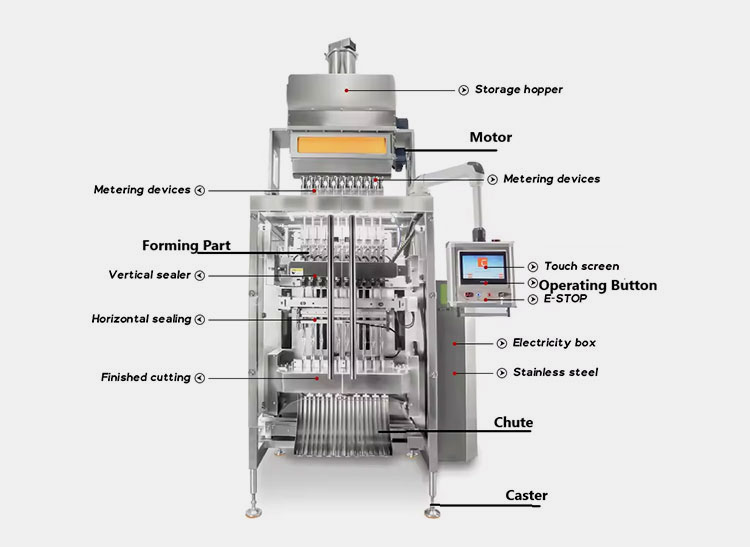

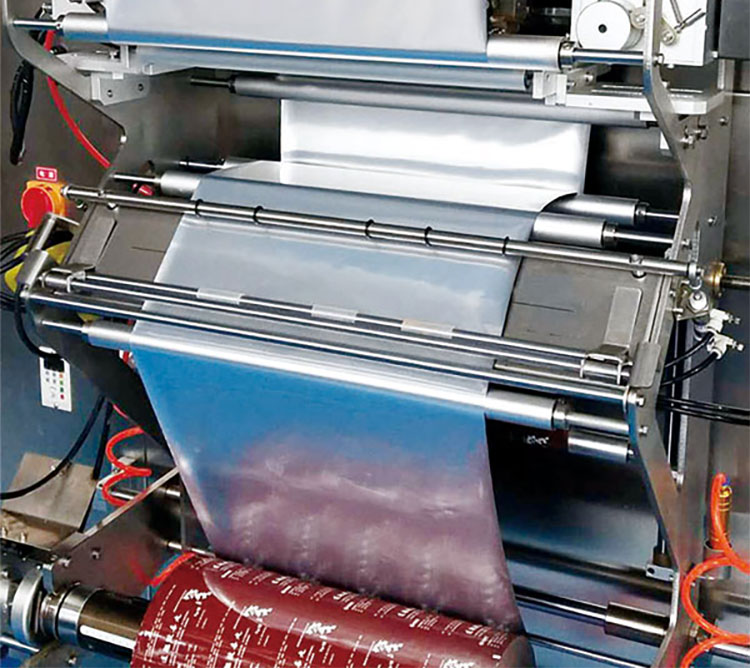

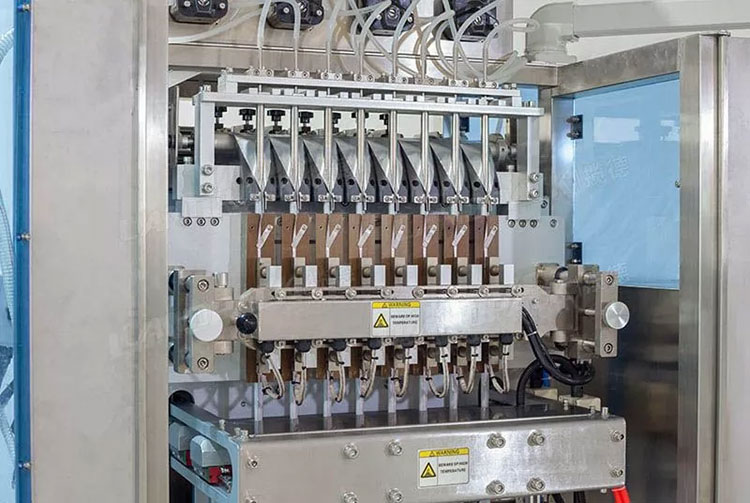

Stick Packs and Sachet Machine

Stick Pack Machine- Picture Courtesy: Suthar Pack Tech

These machines are commonly used for producing single-time use stick packs or sachets. They are suitable for both free-flowing and non-free-flowing powders. They cut and seal the film into small stick packs or sachets while simultaneously filling the powder.

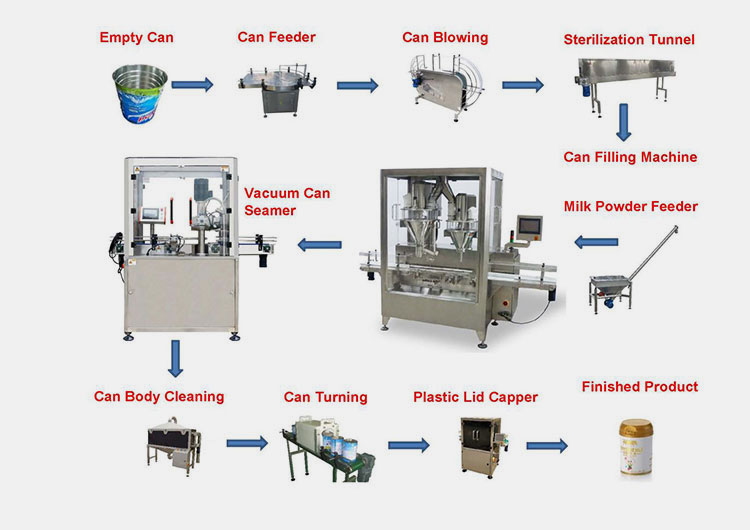

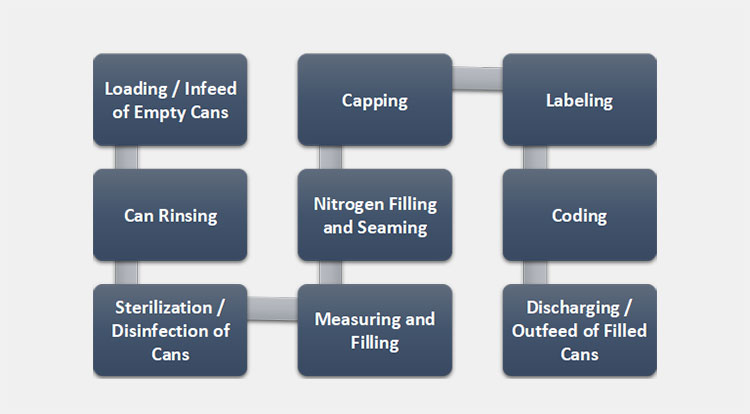

Bottle and Jar Filling Machine

Jar Filling Equipment for Chicken Seasoning Powder Packaging

These automatic filling lines efficiently handle filling, capping, and labeling of powders packaged in rigid containers. The system is adaptable to various container sizes.

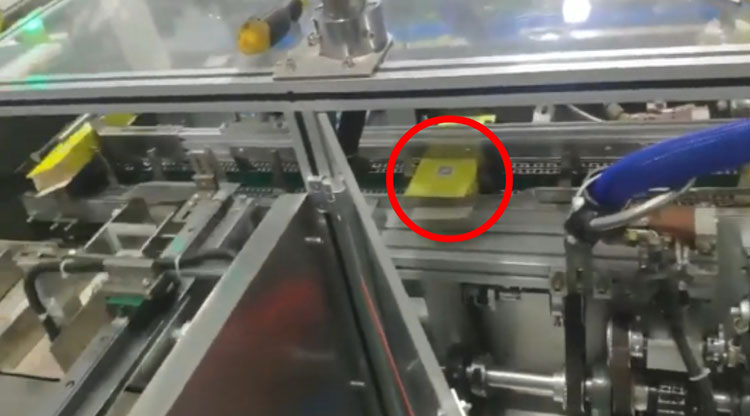

Rotary Premade Pouch Packaging Machine

Filling Equipment for Preformed Pouches

These machines fill the chicken seasoning powder into preformed pouches. They support a wide range of packaging formats and sizes according to products and market needs.

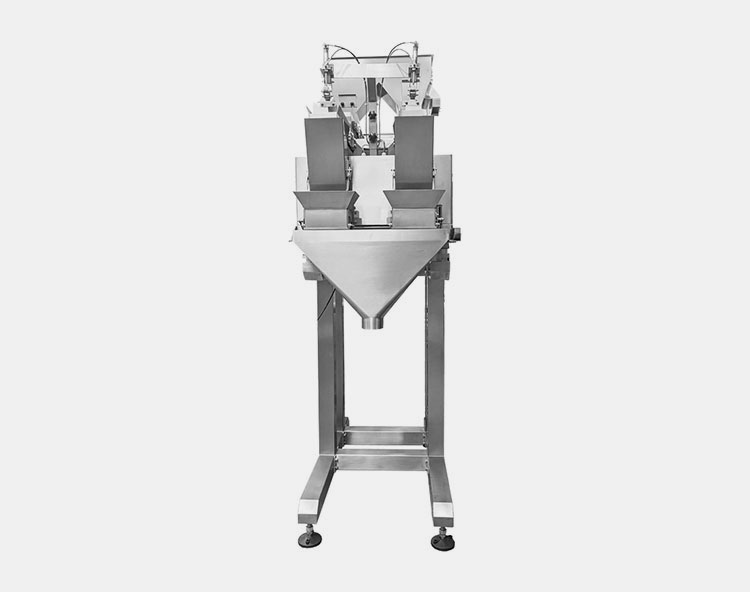

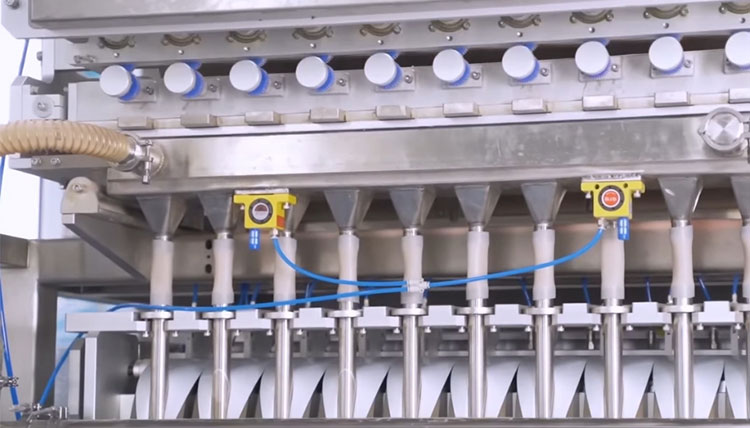

Multihead Weighers

The Multiple Head Features Offer Quick Operations

These machines are used to accurately and quickly weigh chicken seasoning powder before packaging. Multiple weigh heads ensure a consistent and uniform filling, even during high-speed operations.

Check Weighers

Check Weigher System- Picture Courtesy: E.G. Kantawalla

These machines are part of the post-packaging operation. They verify the weight of each package, ensuring that the packaging meets the specified weight ranges. They reject those packages that don’t meet the required weight range.

5.Is it possible for one machine to handle different formats (sachets, pouches, and jars) for chicken seasoning powder packaging?

Jar Packaging

Modern packaging machines are designed with adaptability, enabling users to fill chicken seasoning powder in different packaging sizes and shapes with one machine. The following are the features that enable multiple-format packaging in machines:

The machine must contain a modular design that allows quick changeovers, hence minimizing downtime and improving productivity.

The machine should be equipped with an advanced control system like PLC, allowing real-time monitoring and easy adjustments according to the desired format.

Some machines offer customized parts for different container shapes and sizes.

6.What are the most suitable materials for chicken seasoning powder packaging?

Packaging Material Types

The following are the most suitable materials for chicken seasoning powder packaging based on industry insights and general practices. Let’s explore these options:

Aluminum Foil Laminates

Laminated Packaging

This is the most renowned choice as it has barrier properties against moisture, light, and oxygen. It is most commonly used in multilayer composite packaging, often combined with polyethylene or propylene to improve durability and provide secure sealing.

Biaxially Oriented Polypropylene (BOPP), Oriented Polypropylene (OPP), and Polyethylene Terephthalate (PET) Films

Transparent Chicken Seasoning Powder Packaging- Picture Courtesy: PEPPER & Me

These films are transparent, durable, and moisture-resistant, which makes them ideal for chicken seasoning powder packaging. They are also used in multi-layer laminates to improve barrier properties. PET is specifically preferred for those packaging that demands visibility with protection.

Kraft Paper with Inner Linings

Kraft Packaging

These types of product packaging are the best option when consumers are environmentally conscious. Since these are eco-friendly and offer biodegradability and recyclability. These papers are combined with the inner lining of aluminum foil or PE to provide sufficient barrier properties when packaged chicken seasoning.

Glass and Metal Packaging

Glass Jar Premium Packaging- Picture Courtesy: The Oil Tree

These are the most traditional packaging options available in the market. Glass jars and metal tins both provide adequate protection against moisture and air. Glass jars are chemically inert and provide a premium appearance, while metal tins are durable and offer superior barrier properties. Their weight and high transportation costs are the limiting factors.

Plastic Shaker Jars

Shaker Jars- Picture Courtesy: The Spice Lab

These packages use BPA-free plastic containers with shaker lids. The packaging allows controlled dispensing of chicken seasoning powder.

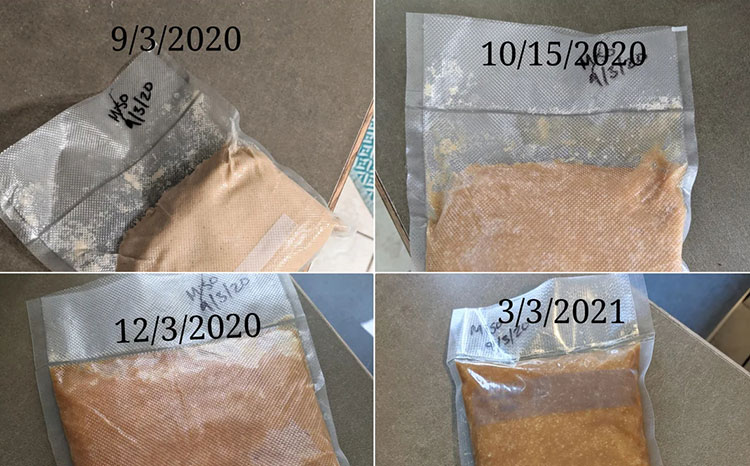

7.Is vacuum packaging suitable for chicken seasoning powder packaging?

Vacuum Sealed Packaging

The answer is, yes! It’s particularly useful in extending the shelf life and preserving the flavor of chicken seasoning powder. According to Robertson (Food Packaging: Principles and Practice) and Han (Innovations in Food Packaging), excludes air from packaging, especially oxygen, significantly reduces the chances of oxidation, moisture uptake, and microbial growth.

This advantage of vacuum packaging is particularly important for the spice products like chicken seasoning powder, which can cause loss of aroma, color, and flavor. Additionally, it improves barrier properties, which maintains product freshness and prolongs its shelf life proving it an effective option for spice packaging.

8.How do you ensure accurate weighing in chicken seasoning powder packaging?

In-line Check Weigher- Picture Courtesy: Wedderburn

Accurate weighing of the product is important to maintain product consistency, meet labeling regulations, and minimize material waste. The following steps taken during the packaging can ensure accurate filling of the product:

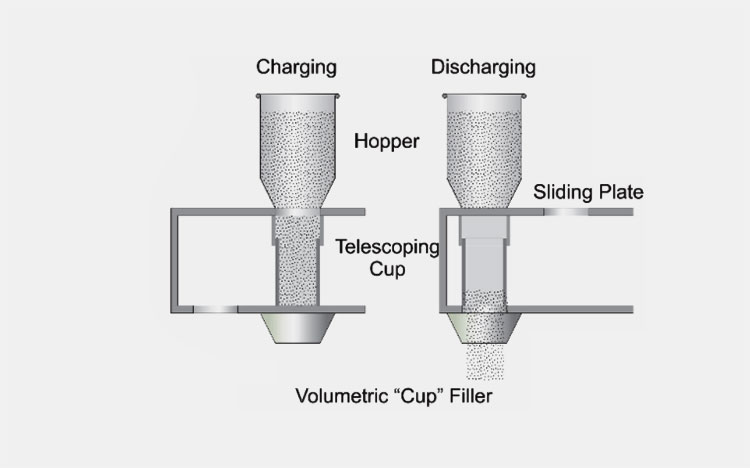

| Use multi-head or auger filling machines for precise weighing and filling of the powder. These machines dispense the accurate amount of powder automatically without human error. |

| The manufacturer must ensure regular calibration of the weighing system with a certified test weight to ensure accuracy. |

| The in-line check weighers are integrated into the packaging line to inspect the weight of each package. These weighers automatically reject overweight and underweight items. |

| Make sure temperature and humidity levels are controlled during the process, which prevents powder clumping and fluctuations in weight reading. |

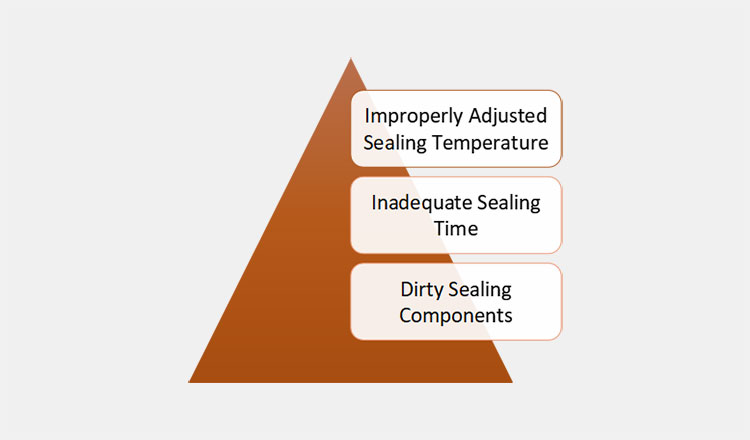

9.How do you ensure leak-proof chicken seasoning powder packaging?

Leak-Proof Packaging

The following measures should be taken to ensure leak-proof packaging for the sake of product integrity, preventing contamination, and enhancing shelf life.

High-Barrier Packaging Materials

Laminated Film Packaging

Use laminated films such as PET, aluminum foil, which provides an excellent barrier against moisture and oxygen.

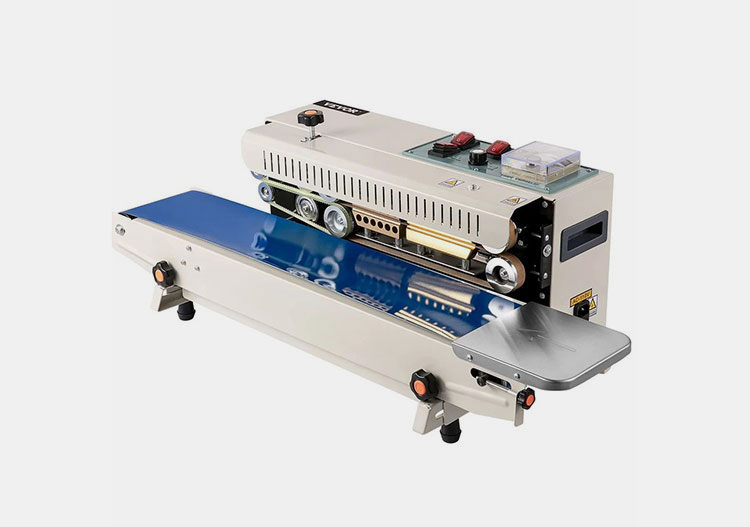

Heat Sealing Technology

Heat-Sealing Machine

Used automated heat-sealing machines. These machines ensure strong airtight sealing on sachets and pouches for leak-proof packaging.

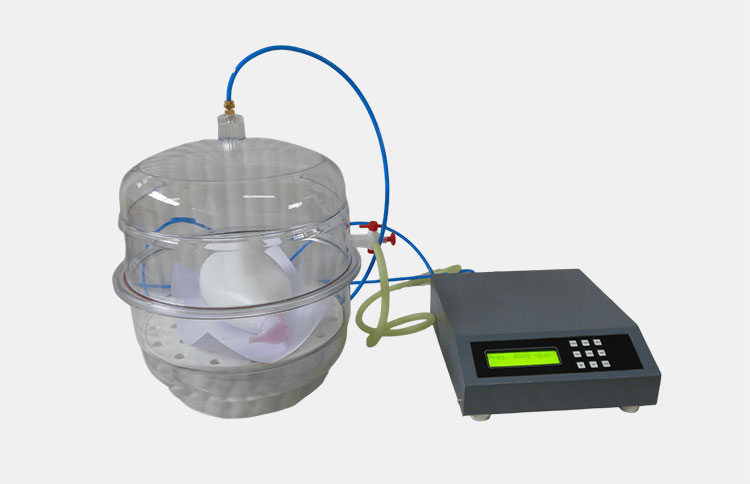

Seal Integrity Inspection

Vacuum Leakage Tester- Picture Courtesy: Pack Test

Some of the quality tests, such as vacuum leak tests, bubble emission tests, or dye penetration methods, are used to inspect any weak or compromised seals.

Proper Filling

Accurate Filling- Picture Courtesy: Serenity Kids

Ensure proper filling system since overfilling or improper alignment during filling can affect seal integrity.

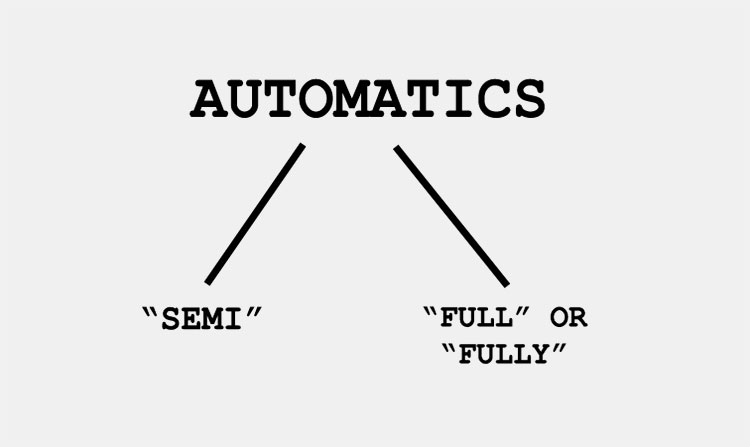

10.What is the best option for small-scale chicken seasoning powder packaging?

Small-Scale Packaging Equipment

The best option for small packaging is to use semi-automatic machines, which are user-friendly, affordable. These are ideal for small-scale production. For small settings, use an impulse or foot-operated sealer for tight, leak-proof sealing. Small-scale setup allows adjustment of pack sizes according to different market demands.

11.How is air expelled from pouches during chicken seasoning powder packaging?

Methods to Expel Air from the Pouches

The expulsion of air from chicken seasoning powder packages is necessary to ensure the product remains dry, flavorful, and fresh throughout its shelf life. The following measures can be taken to expel air from a chicken seasoning powder packaging:

Vacuum Packaging

Vacuum Pouches- Picture Courtesy: Kinderway Packaging

As discussed earlier, vacuum packaging is the most effective method to remove air from the pouch before sealing. It prevents oxidation and maintains the freshness of the product.

Modified Atmosphere Packaging (MAP)

MAP Machine

This method, also known as nitrogen flushing. It involves replacing of air with inert nitrogen gas.

Manual Air Pressing

Air Expulsion preserves the freshness of chicken seasoning powder- Picture Courtesy: Elephantrunk

This method applies to small-scale operations. Air is removed by manual pressing or a simple roller before heat sealing, although it’s the least efficient and reliable method.

Secure Sealing with Barrier Films

Sealing Along with Barrier Films

Air can be removed even without a complete vacuuming, by using high-barrier films with tight sealing helps to reduce residual air and extend the product’s shelf life.

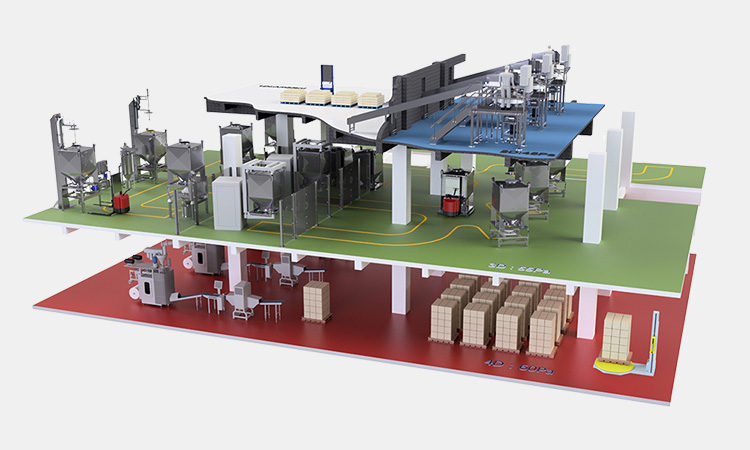

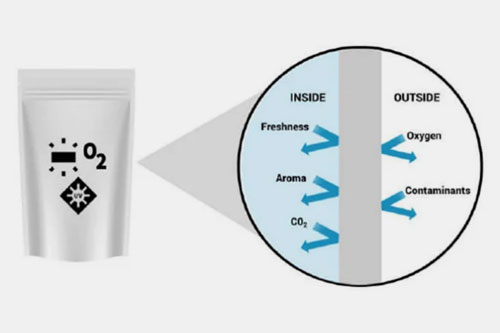

12.How do barrier properties affect the packaging performance in chicken seasoning powder packaging?

Properties of Barrier Packaging- Picture Courtesy: Nichrome India Ltd.

Let’s discuss the importance of barrier properties on packaging performance:

- It provides moisture resistance by preventing the absorption of humidity. Thus, minimize clumping of the powder.

- It provides an oxidation barrier, preserving the strong aroma, flavor, color, and nutritional value.

- Opaque or UV-resistant materials help protect the light-sensitive ingredients from light-induced degradation.

- It reduces microbial growth and enhances food safety.

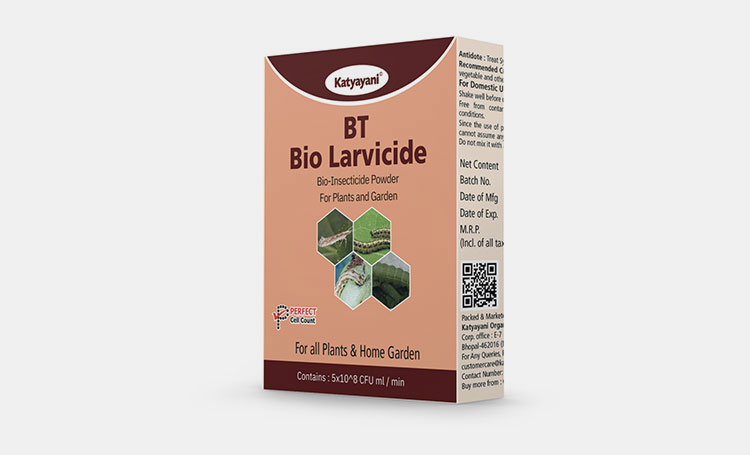

13.What do you know about ideal labeling information for chicken seasoning powder packaging?

Labeling of Chicken Seasoning Powder Packaging- Picture Courtesy: Graphic Design Australia

Labeling information and storage conditions are important for consumer and product safety. Below is some key information that should be mentioned on chicken seasoning powder packaging:

Name of the Product

Product Name on Packaging- Picture Courtesy: Graphic Design Australia

The packaging should mention “chicken seasoning powder” and include a more specific name if it contains a blend like “spicy chicken seasoning powder.”

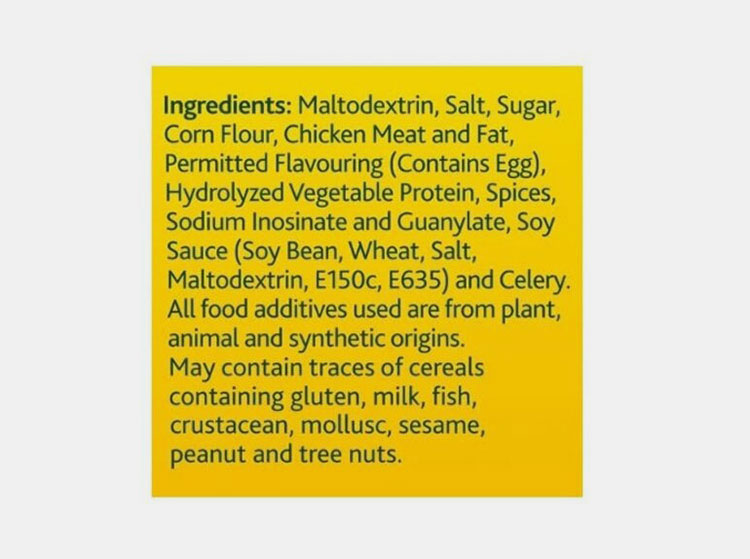

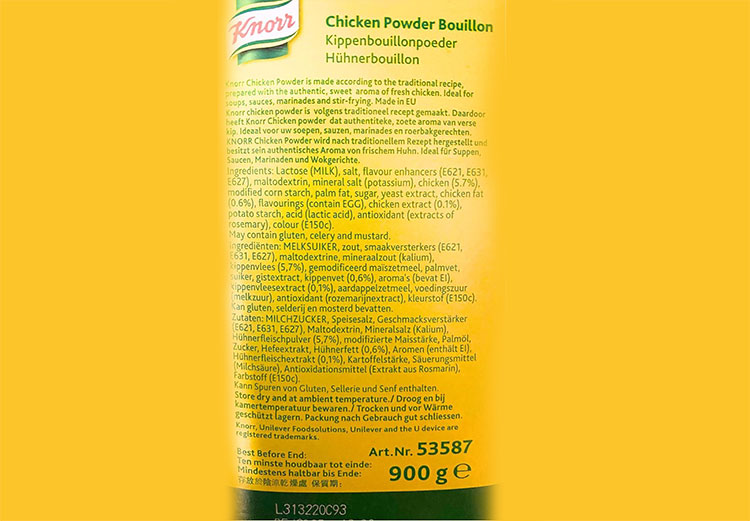

Ingredient List

Mention Ingredients- Picture Courtesy: Chef’s Play

It should contain a list of all ingredients in descending order by weight. Such as spices (e.g., salt, onion powder, garlic), flavor enhancers (such as MSG), and preservatives.

Net weight

Net Weight of the Product

Accurately mention the amount of product in grams or ounces.

Manufacturer name

Manufacturer Name of Chicken Seasoning Powder

Labeling must include the name and address of the manufacturer or distributor.

Shelf Life and Batch Information

Shelf Life of Chicken Seasoning Powder

It includes the manufacturing date and the best-before date. It should contain a batch number for traceability in case of quality control or recall.

Storage Conditions

Storage Instruction- Picture Courtesy: GoSupps

It includes clear information about temperature, protection from humidity, light, and oxygen.

Allergen Warning

Declaration of Allergens- Picture Courtesy: Asetena Pa

Mention if the product contains any allergens or is manufactured in premises that handle allergens such as soy, wheat, or milk.

Regulatory Symbols

Include Regulatory Information

It includes regulatory symbols to indicate halal, organic, or kosher on the basis of certification.

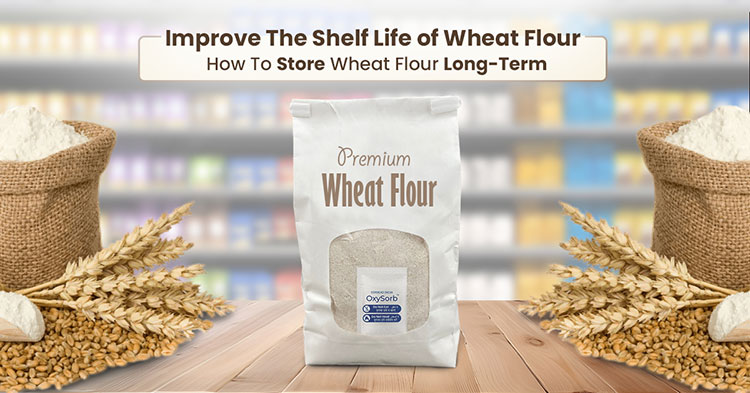

14.How does chicken seasoning powder packaging impact shelf life?

Prolonged Freshness- Picture Courtesy: LIKEHOTKETO

The proper packaging plays an important role in extending the shelf life of chicken seasoning powder. Let’s discuss how it works:

| Moisture Barrier | |

| Good packaging prevents moisture from entering the pack, thus stopping clumping, spoilage, and microbial contamination. |

Aluminum Foil Pack |

| Protection from Oxygen | |

| When the product is exposed to oxygen, it causes fat oxidation and loss of flavor. The secure packaging extends the freshness. |

Packaging Prevents Oxidation- Picture Courtesy: SAC Herbal |

| Light Resistance | |

| UV-resistant packaging is used to protect the product from damage caused by light. |

Packaging Resists Light- Picture Courtesy: My Electric Bites |

| Aroma Retention | |

| Proper sealing of the product locked the strong aroma of the seasoning, preserving its sensory appeal. |

Strong Aroma- Picture Courtesy: Epicurious |

| Prevents Physical Damage | |

| Durable packaging keeps the product intact, prevents damage like crushing or tearing. |

Durable Packaging |

| Quality Material | |

| High-barrier materials like foil laminates of multi-layered plastic instead of basic plastic or paper greatly improve shelf stability. |

Multi-Layered Plastic Packaging |

| Packaging Atmosphere | |

| Modified atmosphere packaging, such as nitrogen flushing, removes oxygen and further helps extend shelf life. |

Nitrogen Flushing- Picture Courtesy: Solos Polymers |

| Storage Instructions | |

| Labeling details about storage on the packaging instructs the user to preserve the product longer. |

Clear Storage Instructions- Picture Courtesy: TedPack |

Conclusion

The choice of the right packaging material and technique for chicken seasoning powder packaging directly affects the product freshness, customer satisfaction, and brand reputation. ALLPACK offers you advanced, high-quality machines like automatic powder filling machines, vertical form-fill-seal (VFFS) machines, and auger fillers for a smooth packaging process. With their innovative packaging solutions, companies can meet the industry standards.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Chicken Seasoning Powder Packaging: The Complete FAQ Guide in 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours