Jam Packaging: The Complete FAQ Guide In 2025

Jam Packaging: The Complete FAQ Guide In 2025

Whether is it a breakfast, supper meal, or a hunger knock, everyone loves to take jam with bread, in a roll, or with snacks. But, is it possible to have the precise amount of jam all time available in your bags without any fear of getting wasted and creating mess? Definitely it is! And that is due to the effective and resilient jam packaging.

Jam Packaging-Picture Courtesy: behance

Jam Packaging not only preserve the delight and quality of your delicious jams, but also help consumers in easy handling and convenient usage. Therefore, different techniques for jam packaging has been employed in the packaging market. These techniques along with other essential aspects such as jam packaging types, material used, process, and packaging machines will be explained in this FAQ guide. So, take start and go through this informative review!

1.What Do You Know About Jam Packaging?

Jam Packaging-Picture Courtesy: worldbranddesign

Fruits are preserved in several forms from drying to freezing. Among these methods, jam is one of the most popular means of storing the essence of fruits. It is formed by the crushing or slicing of fruits with mixed gelatin and sugar. This ultimately result in the creation of a consistent liquid formulation known as jam.

Various jam buckets-Picture Courtesy: worldbranddesign.com

Similarly, keeping this prepared jam in various types of bags, containers, and jars is referred as jam packaging. Jam packaging carries along with it diverse objectives such as prolonging the product shelf life, preserving its flavor, color, and aroma, and most importantly helping the manufacturers get recognition in market. Therefore, jam packaging is becoming an intensive topic of consideration for associated industries.

Besides that, jam packaging encompasses the different types of packaging material, labeling, and machines used for it. These all factors have been discussed in depth in the upcoming questions.

2.Why Jam Packaging Is Important? Also Explain Its Benefits?

The role of jam packaging is inevitable in retaining jam quality and keeping it fresh for longer period of time. Apart from this, jam packaging gives you multitude of benefits including the following:

Durability

Various jam bottles-Picture Courtesy: www.behance.net

Packing jam in bottles, jars, and containers ensures the durability that can easily withstand the rigors faced during transit. It thus helps manufacturers to deliver their quality made jams to consumers without any damage.

Charming Outlook

Strawberry jam bottle-Picture Courtesy: designerpeople.com

Jam packaging can be designed in different formats and innovative packaging bags and containers with multi faceted vibrant colors. This ultimately enhance the beautification and eye-catching appearance of jam packages which can be attractive for customers.

Boost Sales

Multiple jam bottles in trays-Picture Courtesy: www.behance.net

By delivering jam in effective packaging, can help you boost your sale. The one reason is that your jam is laying in safe packages which depicts the hygiene of your jam, and the other is information you provided over jam that validate your quality production. These factors are enough to increase the demand for your jam packs.

Provide Information

Jam bottle labeling idea-Picture Courtesy: vectorstock.com

Jam packaging is the best source that provide you an opportunity to convey all the necessary information about product ingredients, expiry date, usage, and nutritional value to consumers.

Increase Lifespan

Various Jam Jars-Picture Courtesy: therusticelk

Jam is a liquid and sugar rich substance which can easily attract insects and may also get deteriorated by the environmental elements. Therefore, jam packaging keeps the jam flavors, aroma, and texture intact from all these elements which ultimately increase its shelf life.

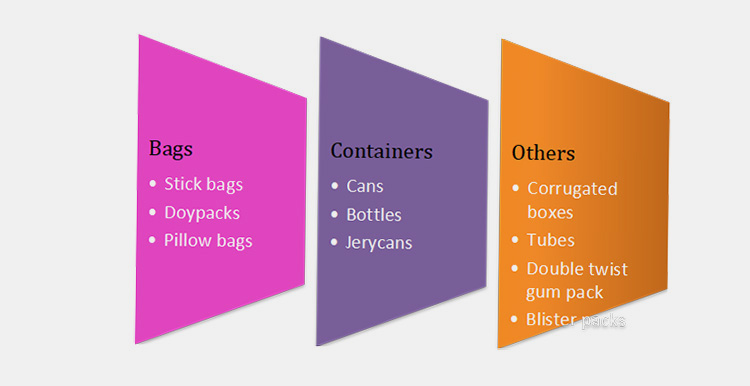

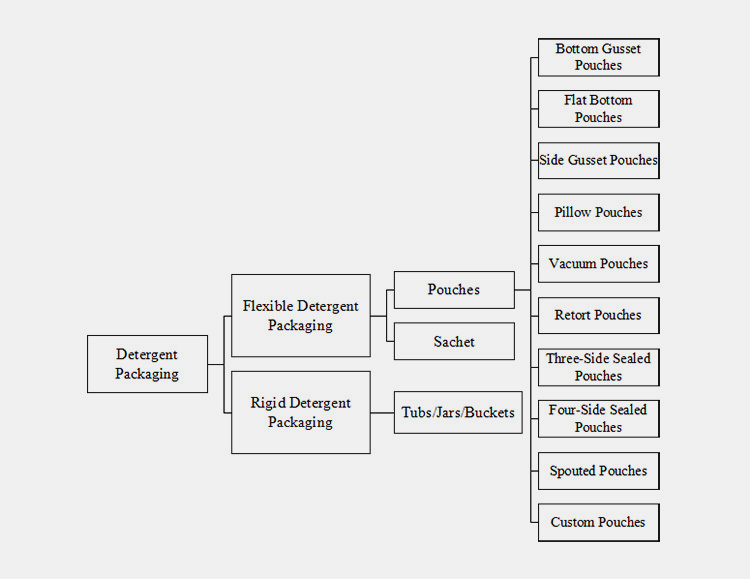

3.Enumerate The Vary Packaging Options Which Are Used For Jam Packaging?

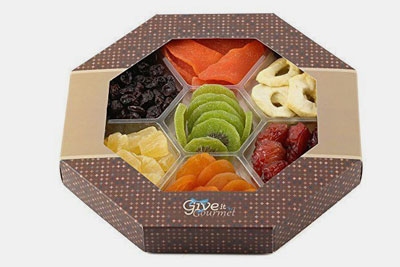

There are multiple types of packaging options which are utilized for packaging jams. Among them the popular packaging types are as follows:

Stick Packs

Various jam stick packs-Picture Courtesy: behance.net

Stick pack are the most convenient and flexible packaging bags used for jam packaging. They are long and narrow, often used for single serving purpose.

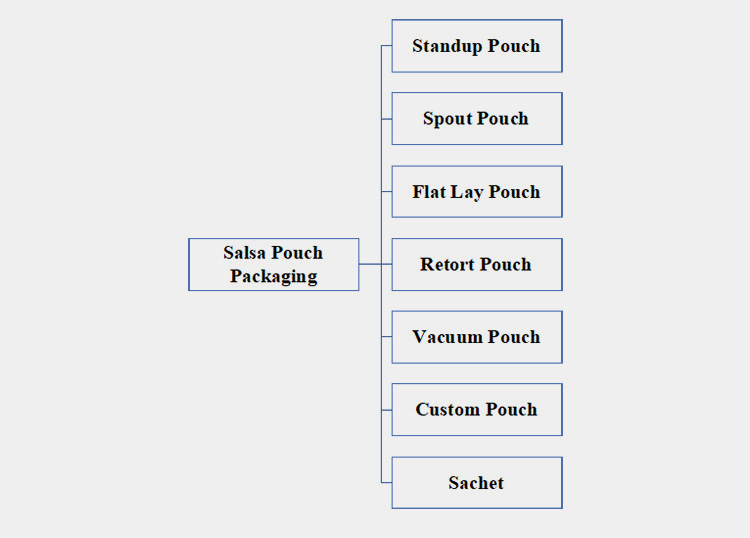

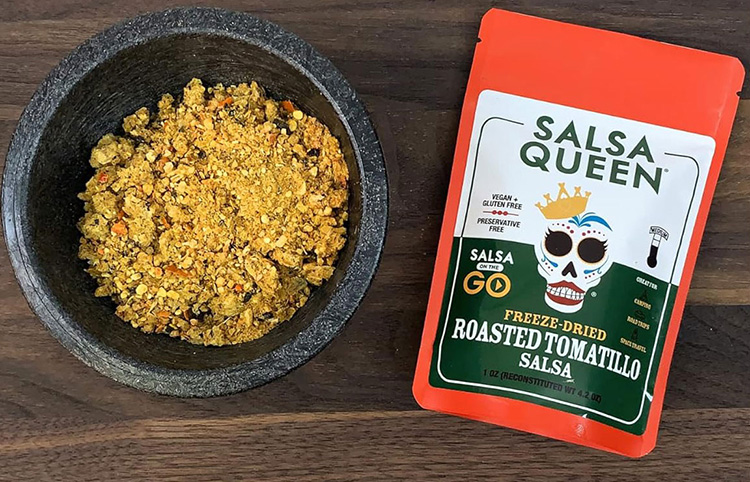

Pouches

Strawberry jam pouch-Picture Courtesy: eng.pg-branding.pl

Pouches are the flexible packaging bags popularly used for jam storing. They are also known as doypacks due to their ability to stand upright and hold enough amount of jam. These pouches have a spout for releasing jam which can be either screwed or push and pull.

Buckets

Smorodina jam bucket-Picture Courtesy: worldbranddesign.com

Buckets are large plastic containers with a lid over it and u shape holding hanger attached to the opposite side of bucket. It is used for packing large amount of jam and are capable of holding up to one kg of jam.

Blister Packs

Multiple jam blister packs-Picture Courtesy: webstaurantstore.com

Blister packs refers to the flexible and transparent plastic packages with a removable ALU film over them. These blister packs are used for delivering various products including jams. Mostly, blister packs are used for single serving jams such as in restaurants and hotels etc.

Tubes

Various fruit jam tubes-Picture Courtesy: marmetube.de

Another most alluring and convenient to use packaging option is tubes. These tubes are easily squeezable and can be resealed with a screwing cap.

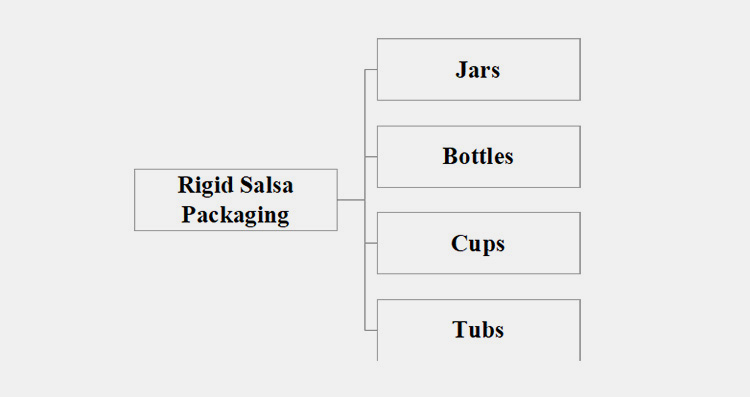

Bottles

Various jam bottles-Picture Courtesy: packagingoftheworld.com

Bottles are the most common type of packaging employed for jam packaging. They have narrow neck and a lid over them which creates a strong barrier against moisture, air, and temperature etc., to preserve the quality of jams.

Jars

Various jam jars-Picture Courtesy: vibekdesign.blogspot.com

Jars are smooth-sided glass containers which are often used for storing jams to keep their essence remains the same for a longer period. They are highly hygienic, durable, and transparent.

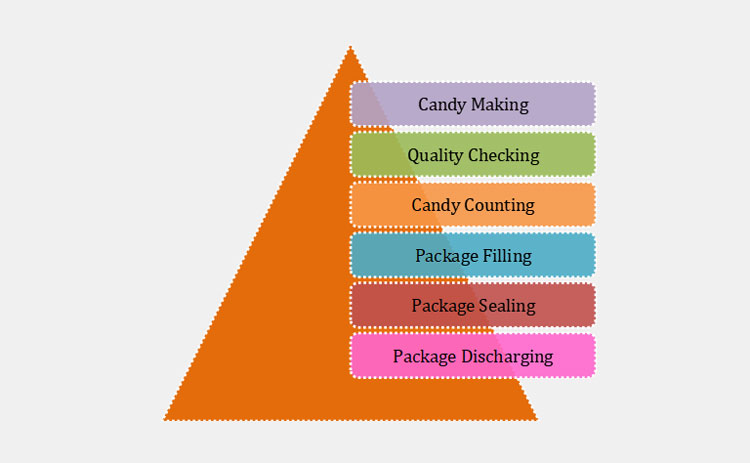

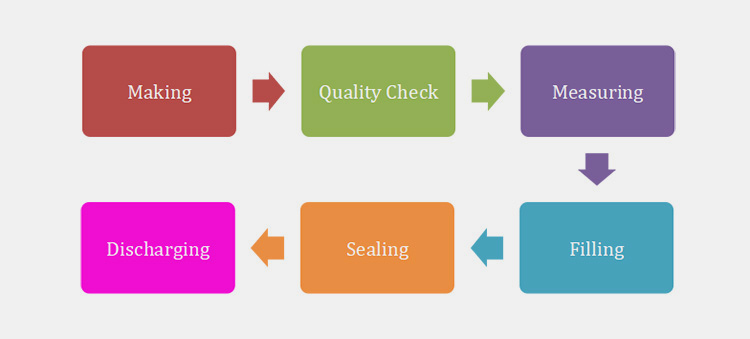

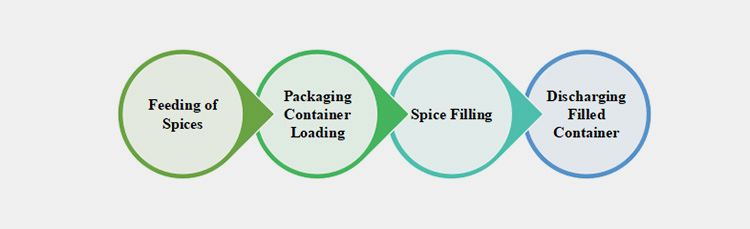

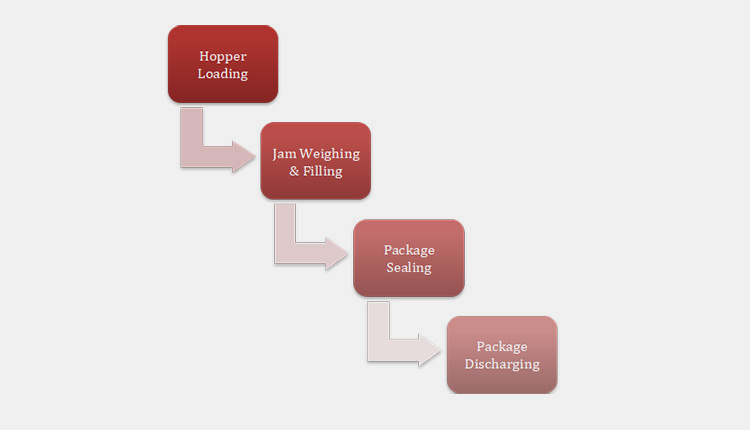

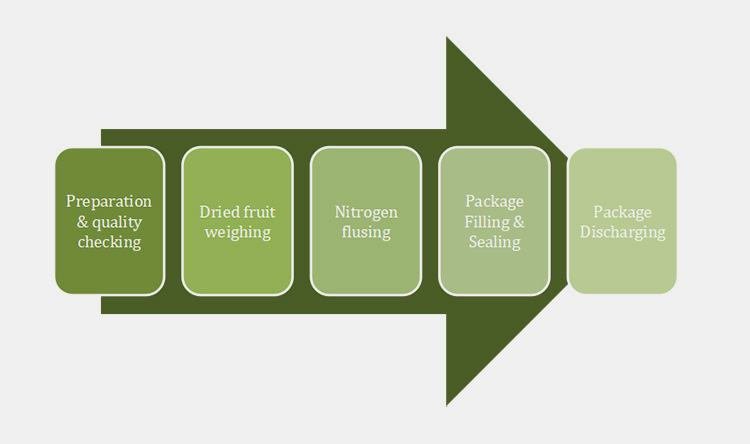

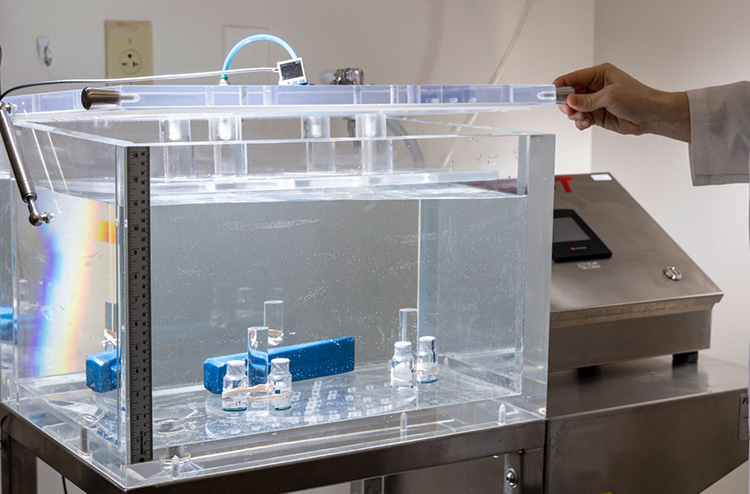

4.Explain The Working Procedure Of Jam Packaging?

The working procedure of jam packaging encompasses several steps which are highlighted below:

Hopper Loading

The process of jam packaging gets started by loading the hopper of jam packaging machine with enough volume of jam. After that, the basic functional parameters of the machine are fixed and machine is powered on.

Jam Weighing & Filling

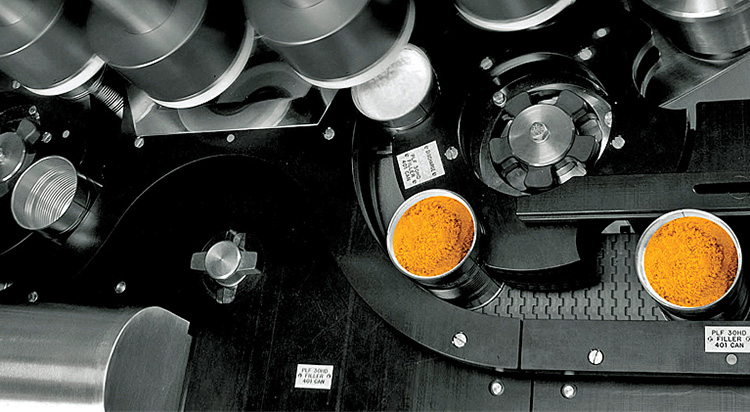

Jam jars filling process-Picture Courtesy: jdaprogress.com

From here start the actual process of jam packaging, when jam is measured by the machine through various methods such as piston filling, volumetric filling, and pump filling etc. At the same time, the weighed jam is delivered into bottles, jars, and pouches via filling nozzles.

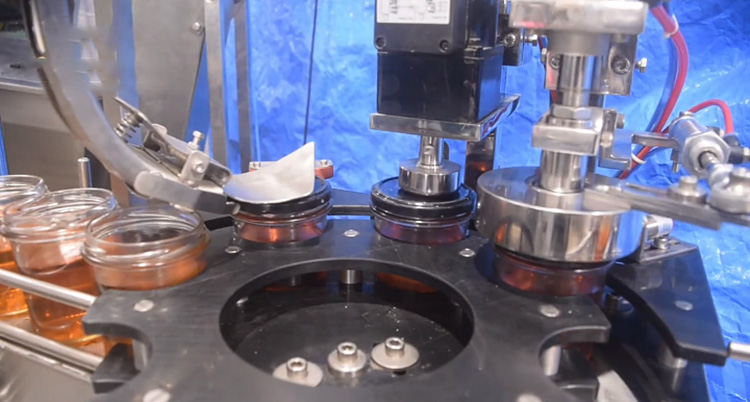

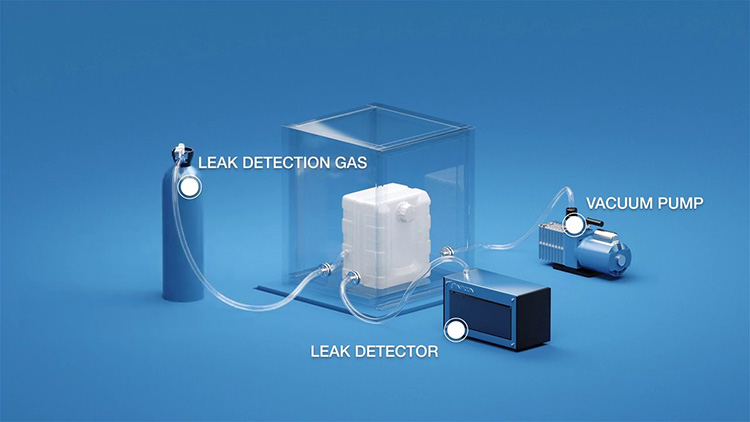

Package Sealing

Jam bottle sealing-Picture Courtesy: trumarkindia.com

Once the packages get filled, they undergo sealing phase where these containers are covered with lids and well screwed. Along with that, the method of induction sealing is also employed here to form a hermetic sealing.

Package Discharging

Jam bottles discharging-Picture Courtesy: Parle Global Technology

Finally, the filled and packed jam pouches and containers are discharged by the machine towards secondary packaging.

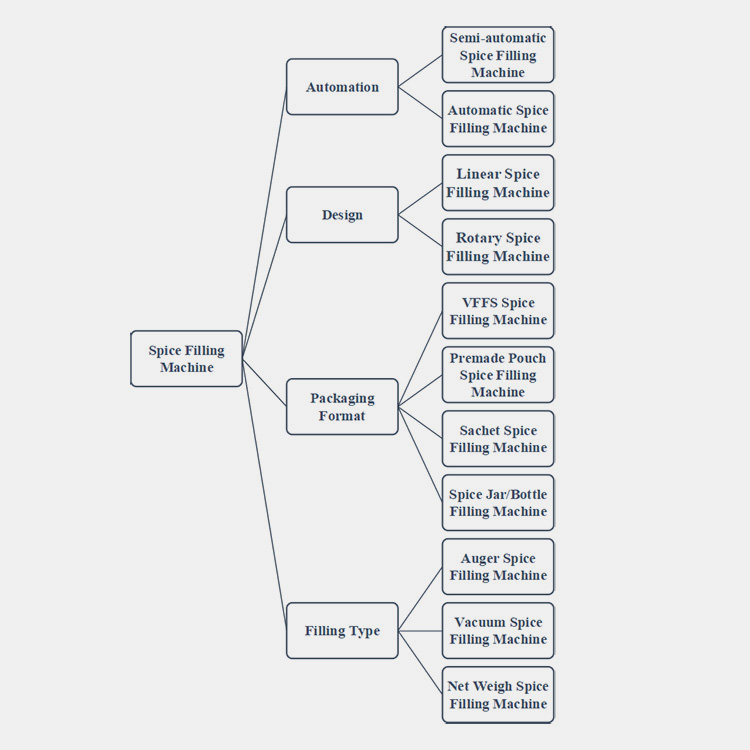

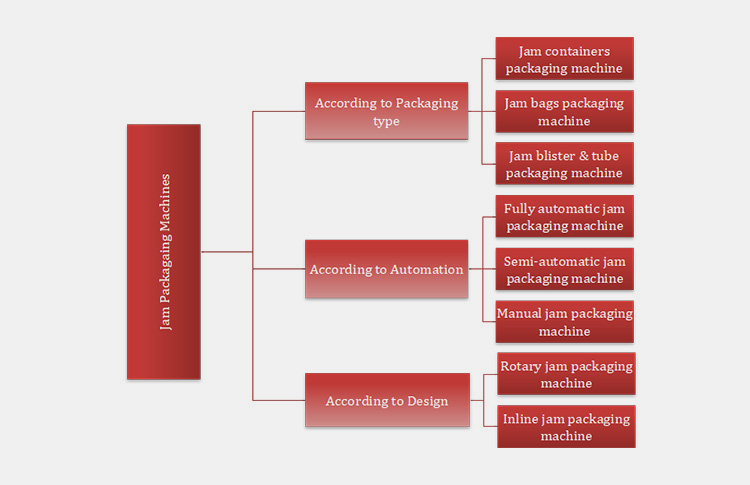

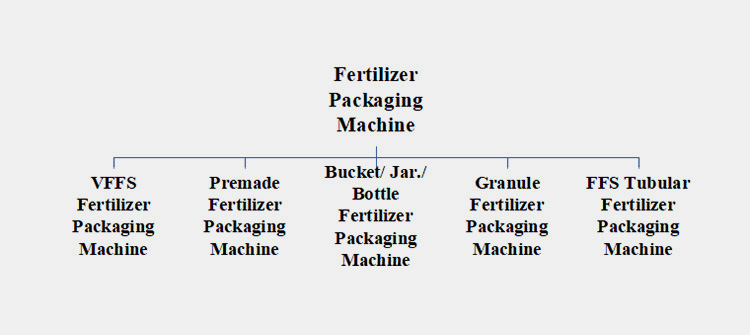

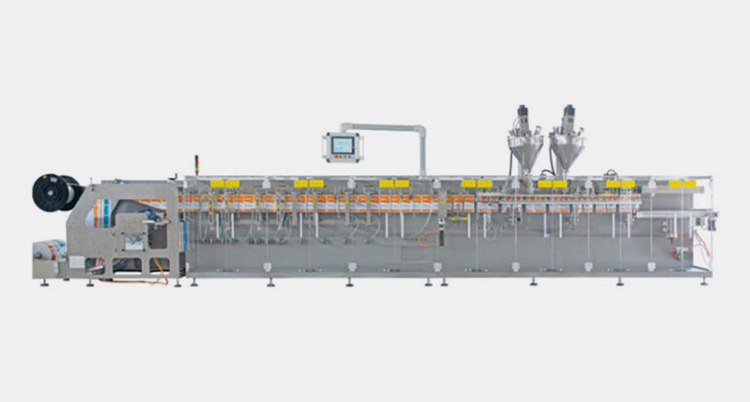

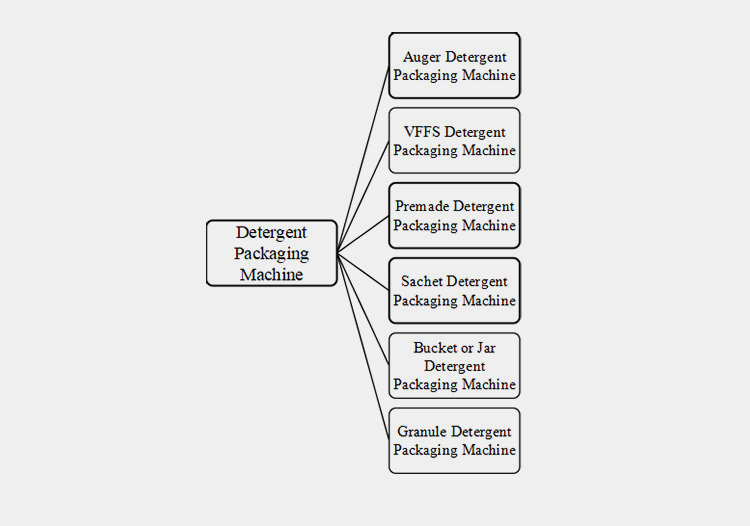

5.Which Machines Are Used For Jam Packaging?

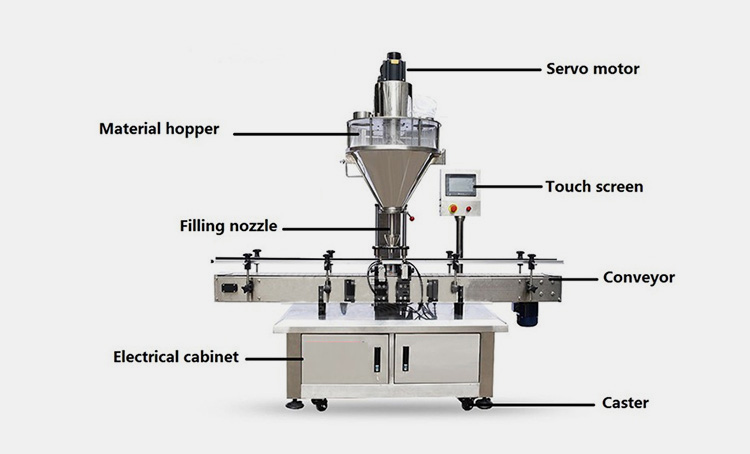

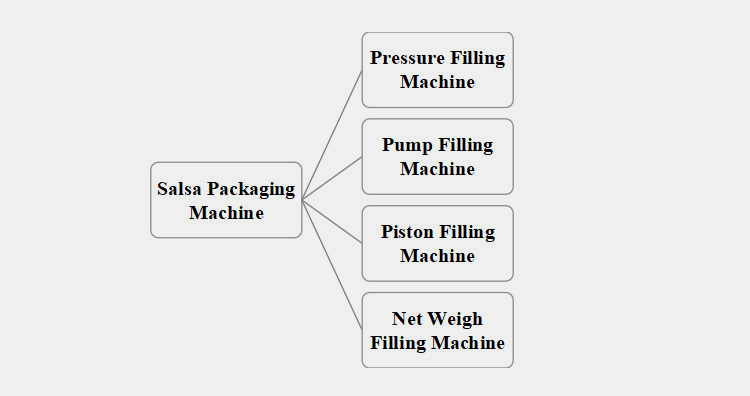

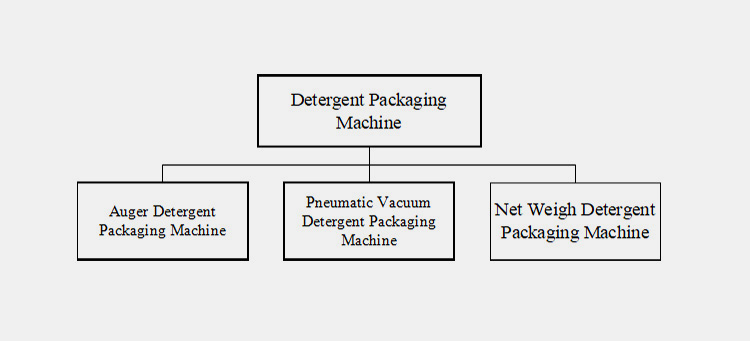

Generally, jam packaging requires different machines for achieving its primary as well as secondary packaging. However, there are certain machines which are inevitable for jam packaging in particular. Therefore, below paragraphs will disclose these machines:

According to packaging type

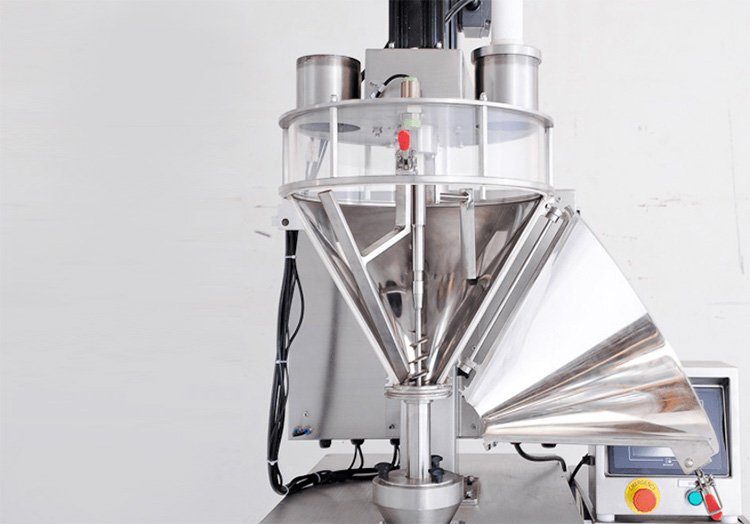

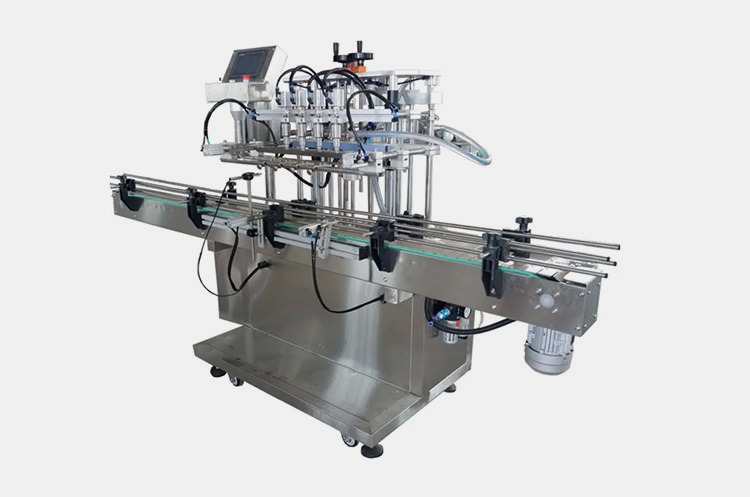

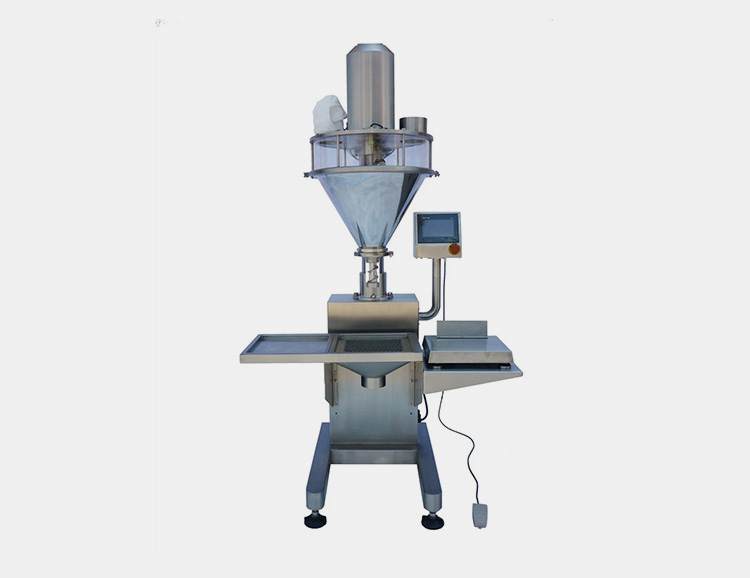

Jam Containers Packaging Machine

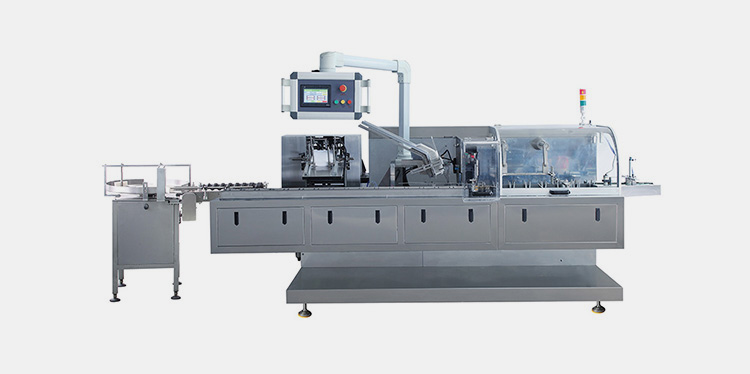

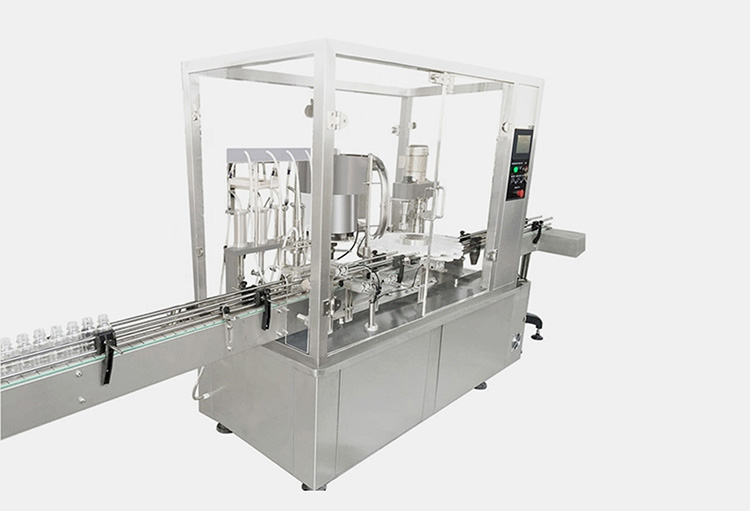

Jam Container Packaging machine-Allpack

Jam container Packaging machine is a pneumatic machine employed to fill jam in range of containers such as bottles, buckets, and jars etc. It is designed with automatic features to perform jam packaging. The machine consists of a hopper, control unit, stainless steel body, a piston filler, and filling nozzle. It comes into operation when the piston retract and pull jam from hopper towards piston cylinder. Once, the piston cylinder gets loaded, the piston will return to its original place which ultimately result into the filling of containers via nozzles. The containers are then automatically discharged by machine or pick up by the operator in case of semi-automatic machine.

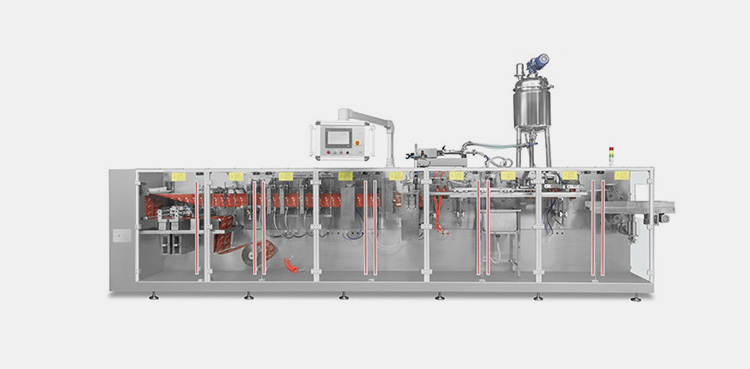

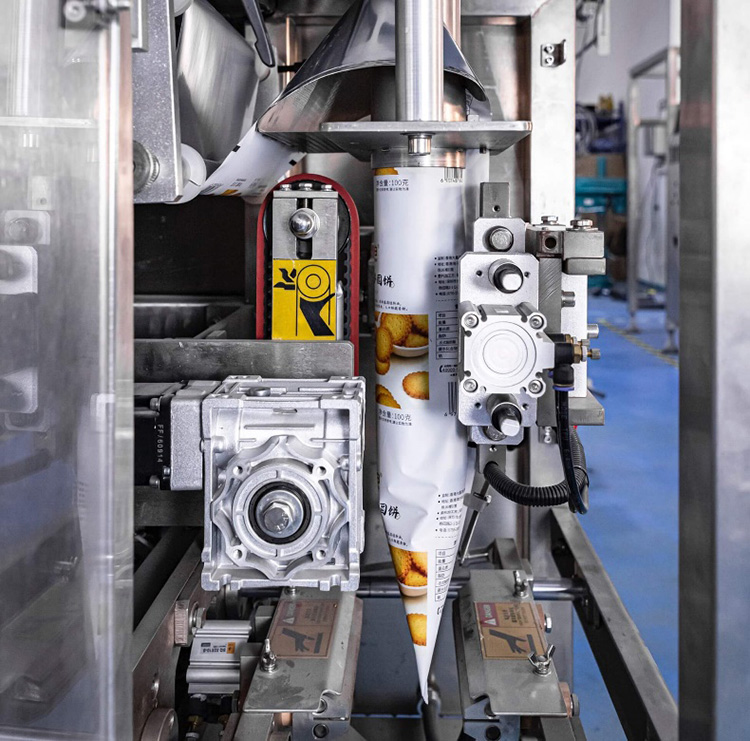

Jam Bags Packaging Machine

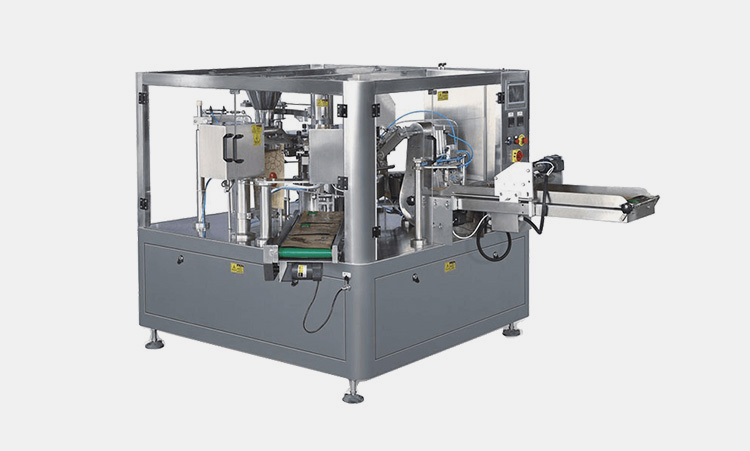

Jam Pre-made Pouch Filling Machine

Jam Pre-made Pouch Filling Machine-Allpack

This type of jam packaging machine is designed to fill pre-made pouches with precise amount of jam. It has a complex structure made up of stainless steel body with multiple components. It functions by forming pouches and taking these pre-made pouches from filling them with accurate amount of jam. At last, the pouch the hermetically sealed and discharged by the machine.

Jam Stick Packaging Machine

Jam Stick Packaging Machine-Allpack

Jam stick packaging machine is one of the popular and most flexible machines employed to pack the free flowing to viscous jams in multiple stick packs simultaneously. The machine is made up of quality stainless steel complying GMP's standard. Moreover, its advance system of forming and filling multiple stick packs at the same time makes the machine more lucrative for large scale industries.

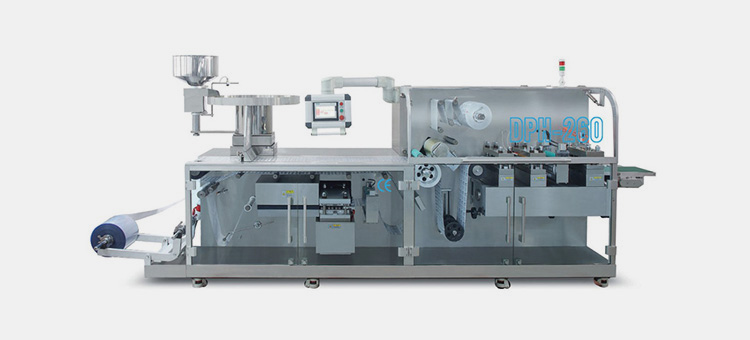

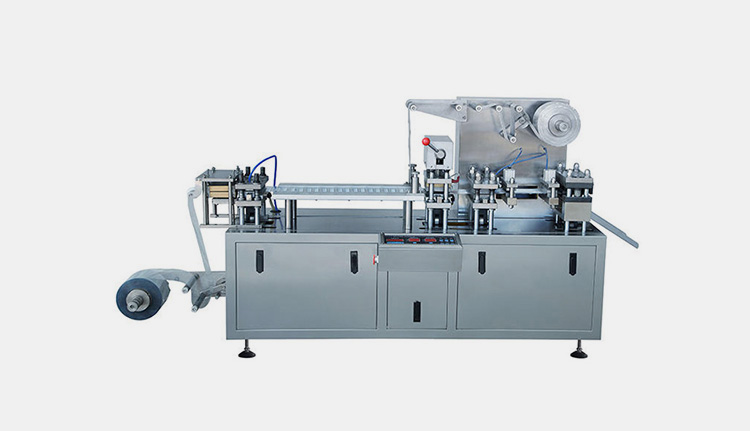

Jam Blister & Tube Packaging Machine

Jam Blister Packaging Machine

Jam Blister Packaging Machine-Allpack

Jam blister packaging machine is innovative equipment brought into the field to facilitate manufacturers in the accomplishment of packing their jams in blister packs. Its assembly comprised of main frame, plastic film roller, aluminum foil roller, heating system, a hopper, conveyor, cutters, and control system. The machine start its process by pulling flat plastic film from roller and molding it into blister through heating. Once, the blisters are formed, jam is filled into these blisters and a strong layer of aluminum foil is laid over the filled blisters which are then tightly sealed. Thus, the blisters are discharged by conveyor after their cutting ended.

Jam Packaging Tube Filling Machine

Jam Packaging Tube Filling Machine-Allpack

Jam packaging tube filling machine is yet another type of jam packaging equipment popularly used for filling jam into plastic or metal tubes. It is made with multi function capabilities such as a unit for keeping tubes, a hopper for holding jam, and turntable to process tubes. Its working procedure is quite simple with machine delivering tubes in a sequential order to turntable via conveyor belt. These tubes are then filled by the filling nozzles and at the same time sealed, embossed and discharged by the machine. Hence, the process ends in a few minutes.

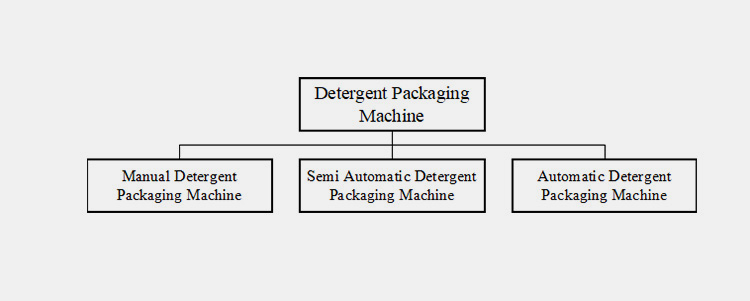

According to Automation

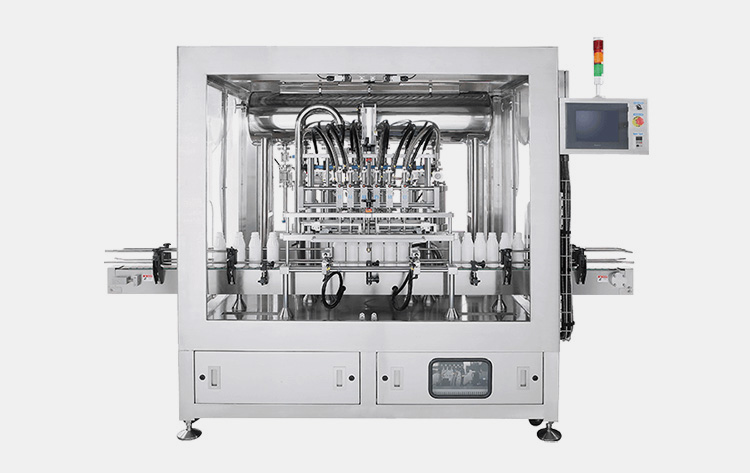

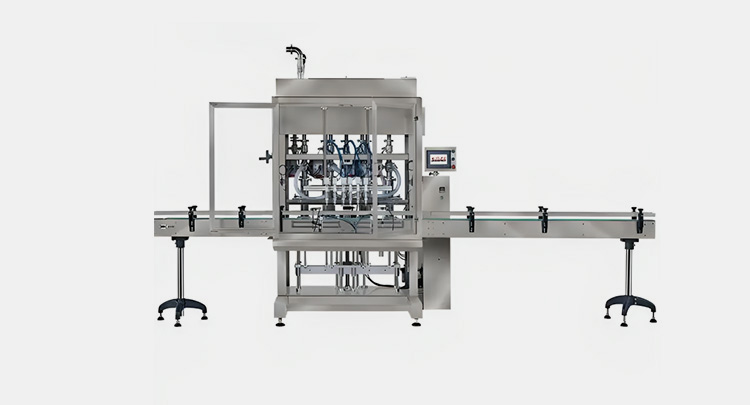

Fully Automatic Jam Packaging Machine

Fully Automatic Jam Packaging Machine- indiamart.com

Fully automatic jam packaging machine is the most innovative equipment designed with advance features of automatic processing from jam weighing till container discharging. The machine is equipped with PLC touch screen panel, adjustable filling nozzles, stainless steel hopper, control cabinet among prominent components. As the structure of machine is complex and fully automated, it carries out the core function of jam packaging into various bottle, jars, and containers automatically. Therefore, large industries with excessive overload can better take advantage of this machine.

Semi-Automatic Jam Packaging Machine

Semi-Automatic Jam Packaging Machine-Allpack

Semi-automatic jam packaging machine is an advance machine made with the combination of automatic and manual features. The machine has small footprint with a hopper, stainless steel mainframe, control system, foot peddle, and motor etc.

It can be operated by manual loading of bulk jam into hopper. Similarly, the machine automatically starts dispensing jam into containers when the operator press foot peddle. Once, the desired volume of jam is filled in container, the machine stops automatically, and operator pick up the filled jam container. This machine is best suitable for medium level jam manufacturing business.

Manual Jam Packaging Machine

Manual Jam Packaging Machine-Allpack

Manual jam packaging machine is cheaper and having simple design compared to fully and semi-automatic jam packaging machines. Therefore, it is a good option for small scale businesses. It mainly consists of a hopper, pressing handle, and a filling nozzle.

To bring the machine into operation, the user must supply hopper with jam, keep the container or pouch under filling nozzle, and press the handle till the package get filed.

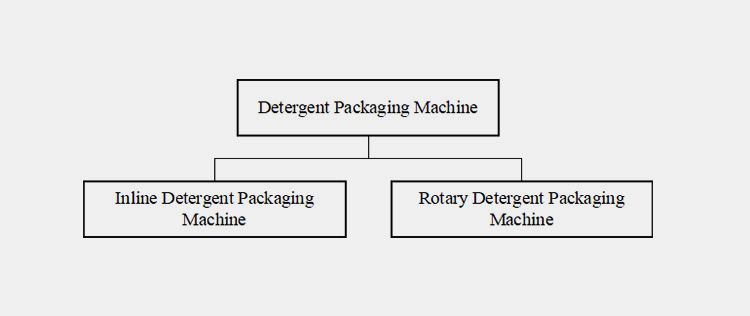

According to Design

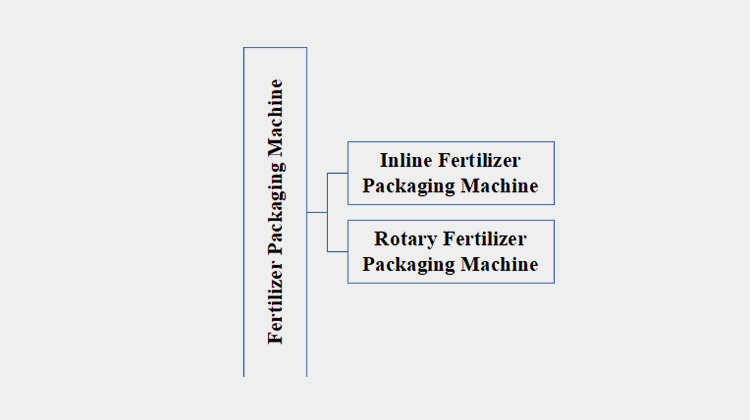

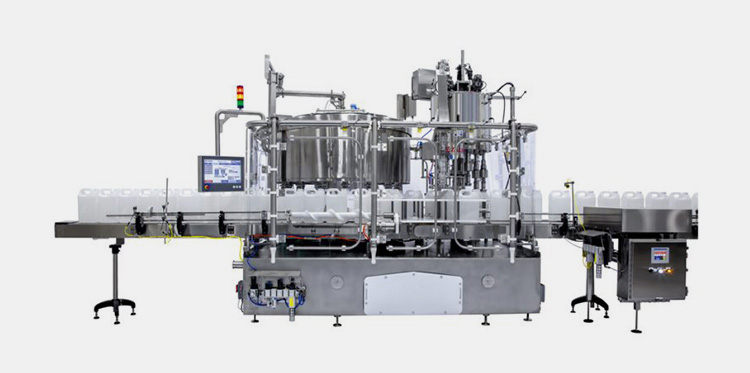

Rotary Jam Packaging Machine

Rotary Jam Packaging Machine-Allpack

Rotary jam packaging machine is known for its circular packaging stations which together contribute to the perfect jam packaging. It has a simple operational mechanism where the machine picks empty packages, fill them with jam, seal the opening, and discharge finished jam packages in one go through a rotary packaging system. This type of jam packaging machine is ideal for large production facilities where multiple jam packages can be packed simultaneously.

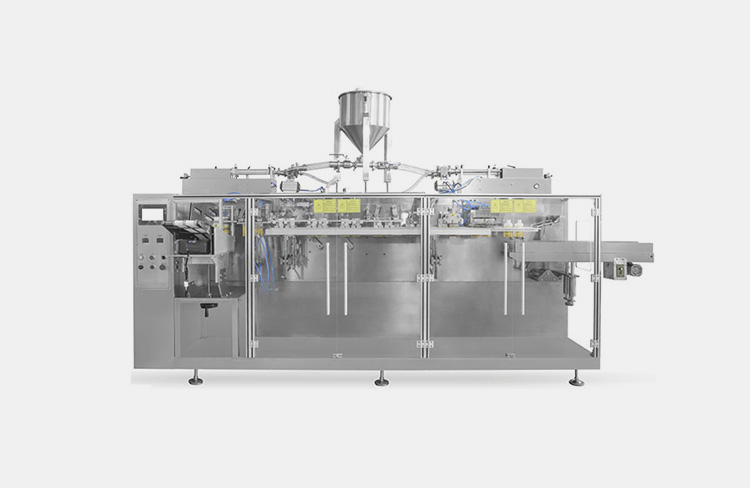

Inline Jam Packaging Machine

Inline Jam Packaging Machine-Allpack

Inline jam packaging machine has a simple and straight forward structure which can process jam packaging in linear way. Unlike rotary jam packaging machine, it can be integrated with other machines to achieve high throughput. Besides that, the machine is typically more compact and accomplish the jam packaging task in a sequential order by package detection, filling, and discharging etc.

6.What Are The Crucial Aspects Of Jam Packaging?

Packaging play a key role in the preservation, handling, and branding of your safely produced delicious jams. Hence, several aspects which are associated with jam packaging must be considered such as:

Preservation

Berries jam-Picture Courtesy: lifeisfullofgoodies.com

When the question arises how to preserve the quality, taste, and texture of jams, the answer is always through effective packaging. This implies, that jam packaging is the sole protector of all types of jams. Moreover, using corrosion resistant and antibacterial packaging material such as glass and plastic create high barrier against moisture, air, and damage throughout their shelf life.

Sustainable Packaging

Eco-friendly packaging display-Picture Courtesy: meyers

The growing environmental awareness has given the sustainable packaging prime importance. Therefore, bringing in use reusable, recyclable, and eco-friendly packaging options can not only reduce the negative impact of jam packaging but also resonate with the users who proposes environmental sustainability.

Convenience

Kiwi easy to open container-Picture Courtesy: www.behance.net

Jam storing and handling are the other facets of jam packaging which involves the type of sealing a jam package is holding. For instance, using resealable lids and twist-off spouts encourage the convenient product handling for consumers.

Branding

Jam bottle labeling idea-Picture Courtesy: www.behance.net

Jam packaging is also very significant for your business success as it enables you to get recognition in the market by displaying your logo, company information, and certification etc. Along with that, employing innovative labeling design, providing precise precise information, and enhance the visibility of your jam packaging with vibrant colors can add more into it.

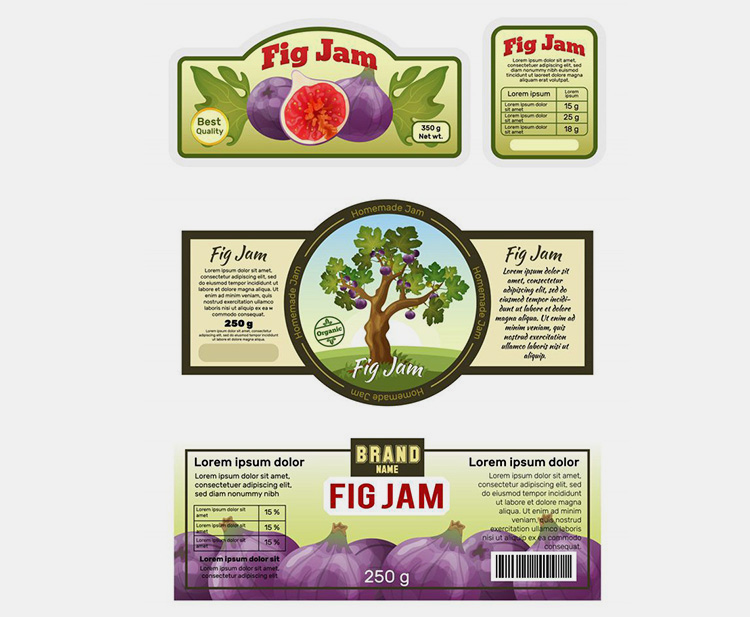

7.Describe The Role Of Labeling In Jam Packaging?

Labeling play an instrumental role in jam packaging by providing range of information to consumers such as:

Jam label idea-Picture Courtesy: Freepik

Product & Brand Name

The main role of labeling is to let the manufacturers publicize their brand name and product name among buyers. Labeling thus make it easier for both the producer and consumers by displaying the company brand logo and type of jam on the front of bottles.

Ingredients Used

It is the labeling through which ingredients used in jam preparation and preservation can be communicated to the customers.

Batch No & Bar Code

Batch.no is a designation given to the vary products such as jam bottle through which the products can be traced easily. Similarly, barcode is a machine-readable code which consists of parallel lines. Large super-markets use machines which reads these barcodes for convenient selling.

Expiry Date

Jam package labeling also holds on it the date of manufacturing and expiration. It simply allows users to use the jam under fixed period of time after that, it will lose the essence and may have a negative effect.

Allergens

Food and Drugs Administration has fixed the eight food allergens which are often used during preparation of jam packaging as well including gelatin, wheat, fish, and soybean etc. Therefore, it is necessary to mention the allergens present in jams which is done through labeling.

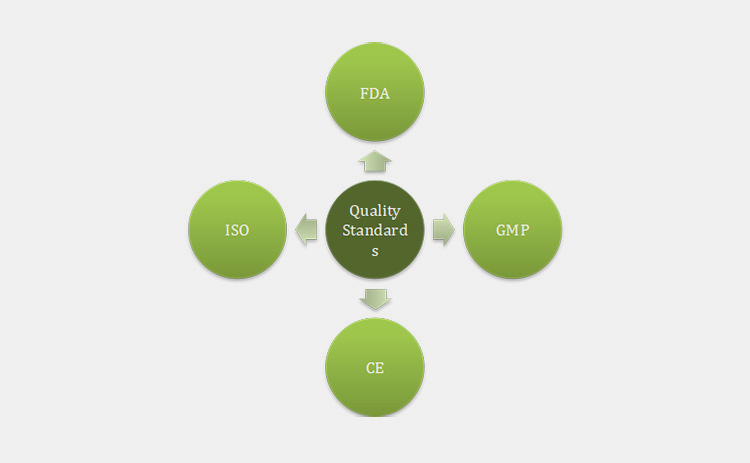

8.What Quality Standards Should Jam Packaging Meat With?

Quality standard icon-Picture Courtesy: fluxmin.com

There are four major quality standards available on international level which have established the rules and regulations for safe packaging. Any jam package meeting with these standards will show that the jam packaging is made up of safe material and the jam itself has been processed by using 304 stainless steel packaging machines. These standards include:

- FDA (Food & Drugs Administration)

- ISO(International Organization for Standardization)

- CE (Conformite Europeenne)

- GMP (Good Manufacturing Practices)

9.Factors Responsible For Making Instrumental Jam Packaging?

Shaping your jam packaging in right direction can be lucrative for your business. Hence, you can adopt distinct means to achieve this aim by understanding the underlying points:

Attractive Labeling

Raspberry jam labels-Picture Courtesy: www.behance.net

By employing innovative labeling techniques for your jam packaging such as beautiful color combination and stylish fonts can make your packaging more attractive and mesmerizing. Ultimately, every customer will stop their eyes on your jam packs and would just move to pick it up from the shelf.

Packaging Material

Eco-friendly packaging idea-Picture Courtesy: refinepackaging.com

Using environmental friendly packaging material such as metal, aluminum, and paper can also be a determining factor for most of the consumers who respect environmental sustainability.

Resilient Packaging

Small jam bottles presentation idea-Picture Courtesy: backbonebranding.com

Another crucial factor you should consider is opting for resilient jam packaging. For instance, you may use jam packaging bottles, buckets, stick packs, and even spouted pouches to expand the accessibility of your jams for all types of consumers.

Conclusion

To summarize, jam packaging is becoming a bone of contention both on the part of manufacturers and consumers. It implies that eco-friendly, hygienic, and quality packaging are the major concerns for consumers to look for. Similarly, producers are obliged to take these prerequisites in mind and mold their jam packaging towards greater customization, using environmentally safe packaging material and also inculcate in their production such packaging machines which can better fulfill these aims. In this way, you can also consider Allpack, which is providing all sorts of quality jam packaging machines with one-year warranty and installation support. So, what are you waiting for!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Jam Packaging: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours