Windshield Washer Water Bottling Line: The Complete Buying Guide In 2025

Windshield Washer Water Bottling Line: The Complete Buying Guide In 2025

Have you ever wondered how is windshield washer water or fluid produced and bottled? What procedures guarantee its efficacy and safety? How can investing in the windshield washer water bottling line benefit and grow your business?

With the increase in demand for windshield washer fluids due to their efficient cleaning and removing the dirt from the windshields to maintain driver visibility and safety. The windshield washer water bottling line is made to produce and bottle windshield washer fluid effectively. It is an essential part of the vehicle care sector.

Selecting the right equipment for integration into your production line can be crucial for streamlined operation and business success.

This article 'windshield washer water bottling line' explores the essential elements, operating procedures, and technical advancements that characterize a contemporary windshield washer water bottling line, emphasizing the significance of this line to the automobile sector.

1.How do you describe a windshield washer water bottling line?

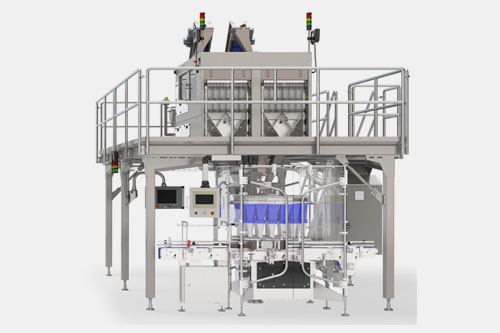

Allpack Windshield Washer Water Bottling Line

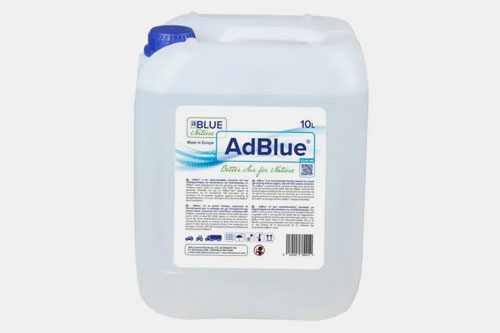

A windshield washer water bottling line is an advanced set of automated machinery designed to fill and pack windshield washer fluids into various containers in an effective manner.

The windshield washer fluid is a liquid used to clean the windshield of cars, trucks, and other types of vehicles. It is a necessary automobile care item that aids in keeping sight when driving, particularly in bad weather.

2.Why should you invest in the windshield washer water bottling line?

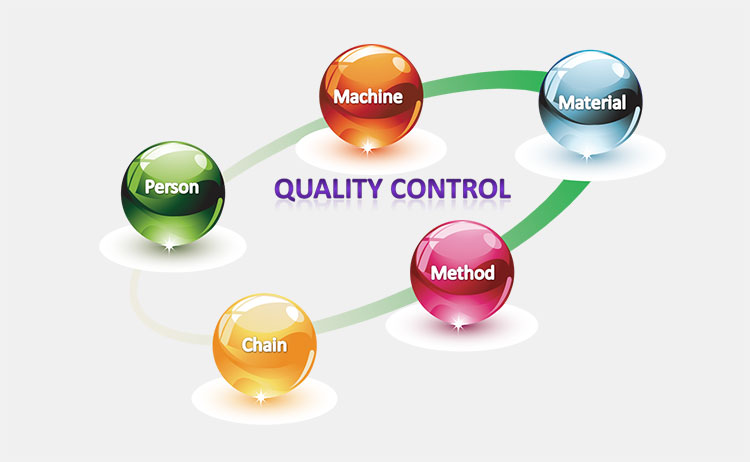

Safety and efficacy have evolved from objectives to necessities in the automotive care industry. The windshield washer water bottling line offers several key benefits, primarily efficiency, speed, quality assurance, and cost-effectiveness.

Here are some of the notable benefits highlighted as under:

Enhanced Efficiency

Enhanced Efficiency

The automated windshield washer water bottling line accelerates the packaging, saving time and labor. Here, every motion and movement is precisely timed to provide the greatest possible output, resulting in a fluid combination of efficiency, precision, and rapidity.

Consistency

Consistent Results

The windshield washer water bottling line is an essential component within the intricate framework of supply chain management. It guarantees everlasting dependability and consistency which are critical for preserving brand integrity and winning over customers.

Cost Benefits

Cost Benefits

Installing a windshield washer water bottling line requires a significant investment but the savings it brings in the long run to your business in terms of the costs is substantial. Automation in the packing process lowers human intervention resulting in labor cost reductions. Additionally, precise and automated filling mechanism preserves resources by ignoring human mistakes and product loss.

Improved Product Quality

Improved Product Quality

The integrated modern filling devices ensure that the pre-determined volume of the liquid product is dispensed into each container, reducing spills and enhancing consistency. Maintaining the product's quality is made possible by the airtight capping, which shields it from outside contaminants.

Versatility

Versatility & Adaptability

Advanced windshield washer water bottling lines can handle various liquid products and bottle types, allowing for product diversity without requiring expensive retooling.

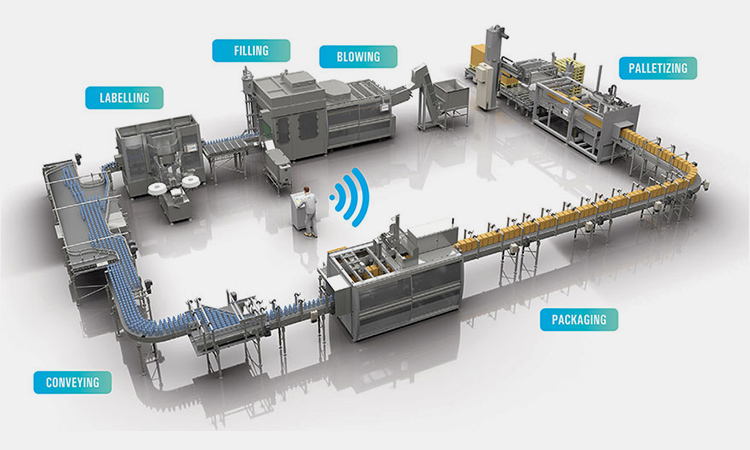

Streamlined Operation

Streamlined Operation – Picture Courtesy: Process Model

The windshield washer water bottling line comprises advanced equipment, providing greater compatibility. These devices ensure the entire process is streamlined and automatic without requiring manual connection.

3.What industries can adopt the windshield washer water bottling line?

Picture Courtesy: Prosino

The windshield washer water bottling line is an indispensable assembly of various industries, including automobile, beverage, and chemical sectors. The line ensures the safe and efficient packaging of several liquid products into multiple containers, preserving the product’s quality.

Some of the major industries utilizing the windshield washer water bottling line are:

Automotive Care Industry

Use of the Windshield Washer Water Bottling Line in the Automotive Care Industry

The automotive care industry is the primary sector where the windshield washer water bottling line has gained importance and popularity. The line enables the manufacturers to package distinct formulated windshield washer fluids and other automobile fluids into containers of various forms and sizes efficiently.

Dairy Industry

Use of the Windshield Washer Water Bottling Line in the Dairy Industry

In the dairy industry, the windshield washer water bottling line packages milk and other liquid dairy products into bottles and other containers rapidly and effectively.

Beverage Industry

Use of the Windshield Washer Water Bottling Line in the Beverage Industry

The beverage industry is another popular sector where the windshield washer water bottling line is widely used for packaging various liquid beverages, such as juices, soft drinks, energy drinks, wines, and malted drinks, in multiple containers.

Food Industry

Use of the Windshield Washer Water Bottling Line in the Food Industry – Picture Courtesy: Source Good Food

In the food sector, the windshield washer water bottling line is used to bottle and securely cap various liquids such as pastes, sauces, ketchup, and vinegar.

Water Supply Industry

Use of the Windshield Washer Water Bottling Line in the Water Supply Industry

The windshield washer water bottling line is also used in the water supply sector where treated water is efficiently bottled and supplied to households.

Pharmaceutical Industry

Use of the Windshield Washer Water Bottling Line in the Pharmaceutical Industry

In the pharmaceutical sector, multiple liquid drugs, such as anesthetics, methanol, ethanol, infusions, ethers, and benzene, are securely bottled using a windshield washer water bottling line.

Chemical Industry

Use of the Windshield Washer Water Bottling Line in the Chemical Industry – Picture Courtesy: SKS Bottle

Due to its streamlined and efficient operation, the windshield washer water bottling line is used in the chemical industry for bottling various liquid chemicals, such as laundry detergents, phenyls, acids, oils, glass cleaners, and dishwashers.

Cosmetics Industry

Use of the Windshield Washer Water Bottling Line in the Cosmetics Industry

Several liquid beauty and personal care products are packaged and labeled via the windshield washer water bottling line. These products include lotions, creams, sera, moisturizers, toners, body washers, etc.

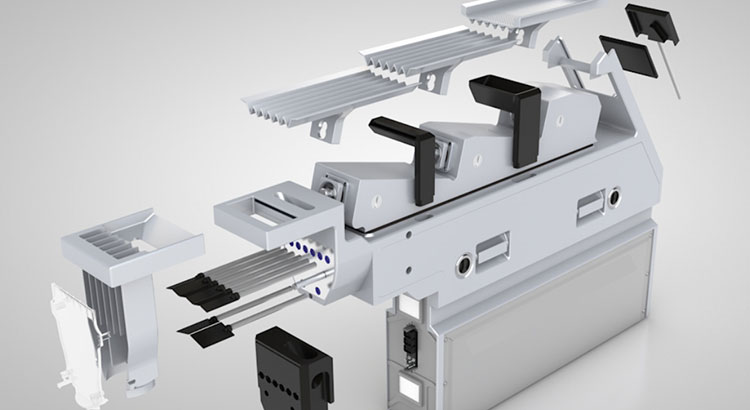

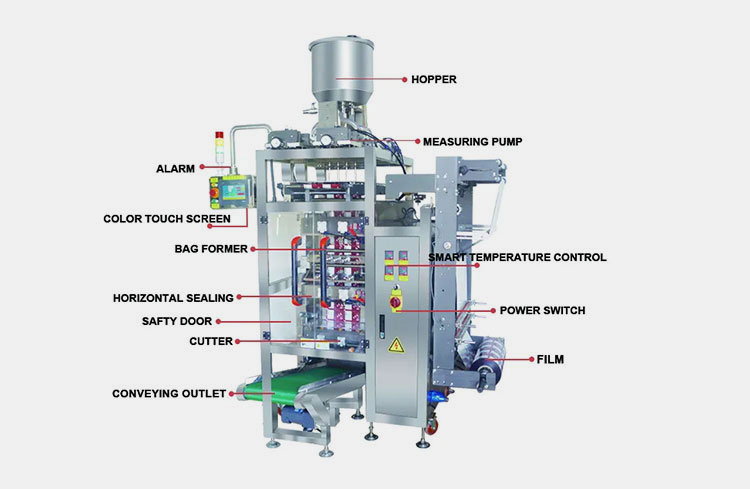

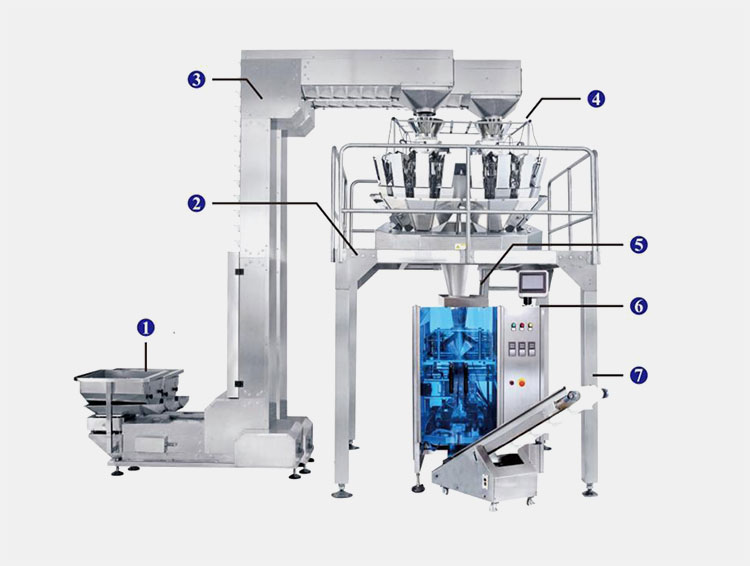

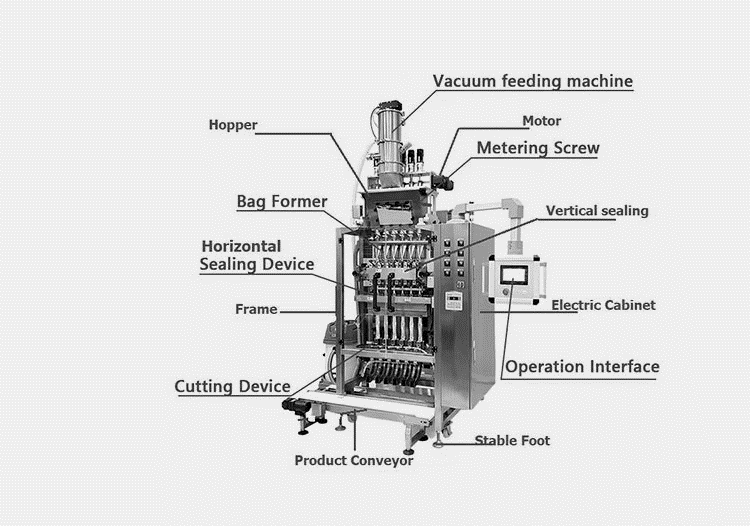

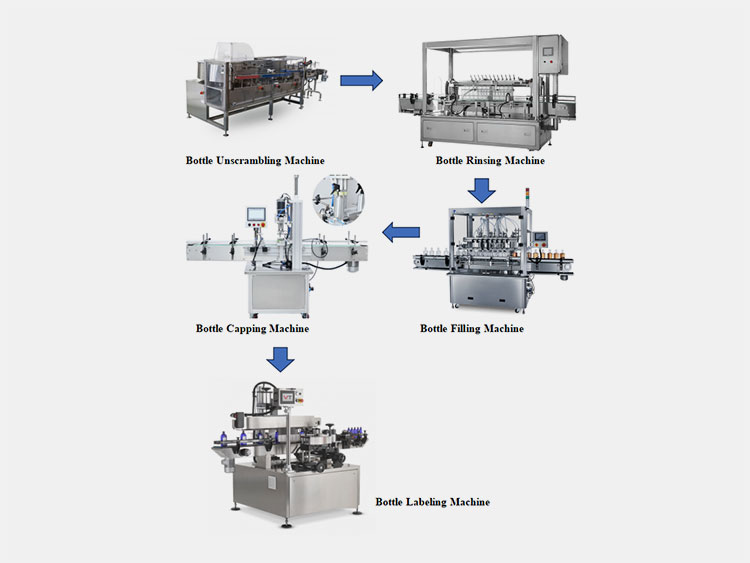

4.What devices comprise a windshield washer water bottling line?

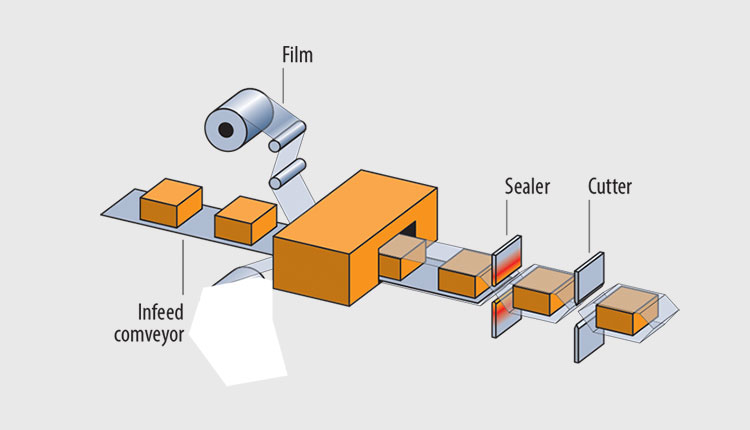

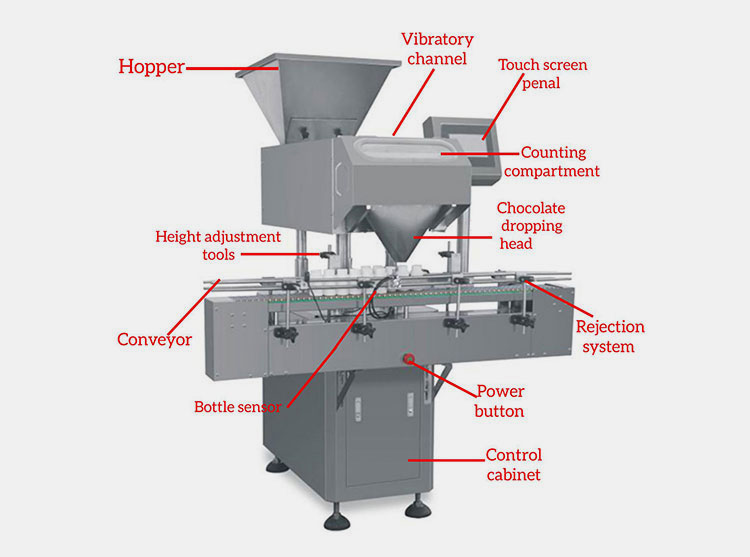

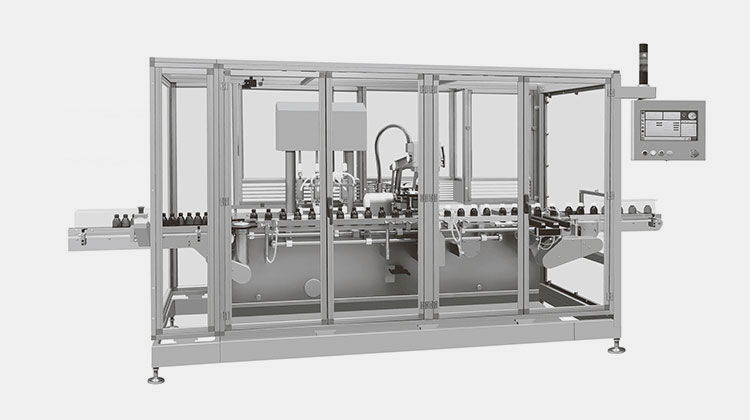

The windshield washer water bottling line has several machines, each expertly built to perform a specific function throughout the packing process. The principle integrated devices in the line and their corresponding functions are described below:

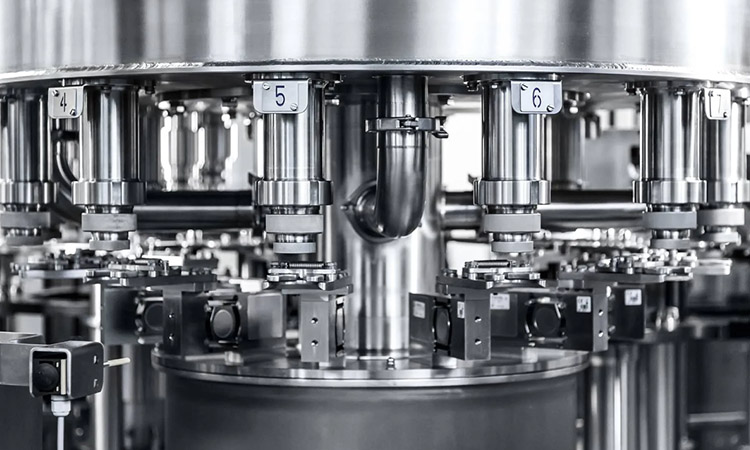

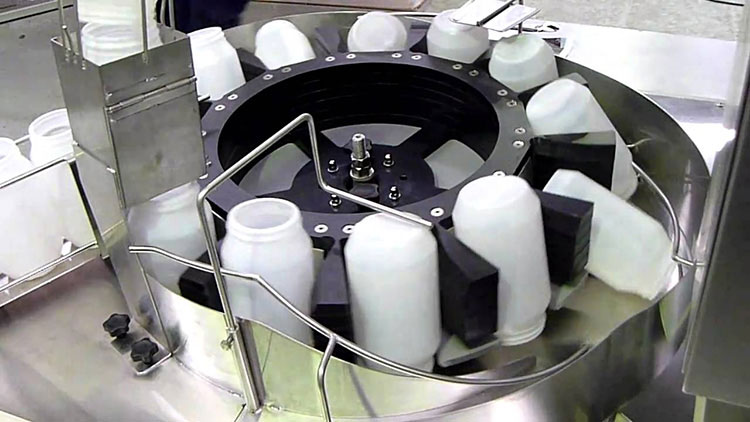

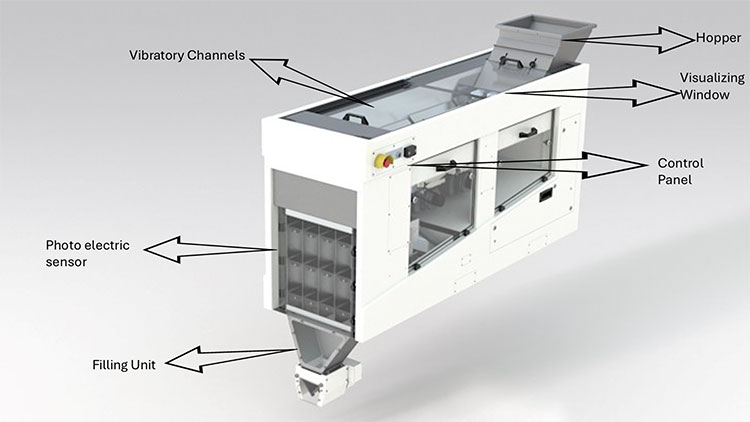

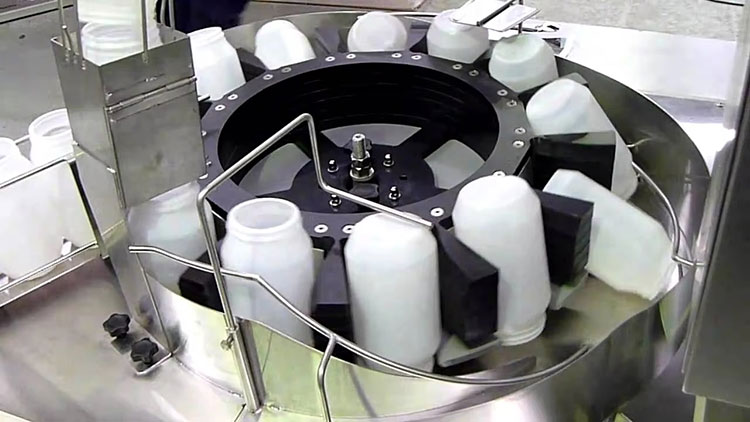

Bottle Unscrambler (Infeed)

Automatic Bottle Unscrambler Machine (Infeed)

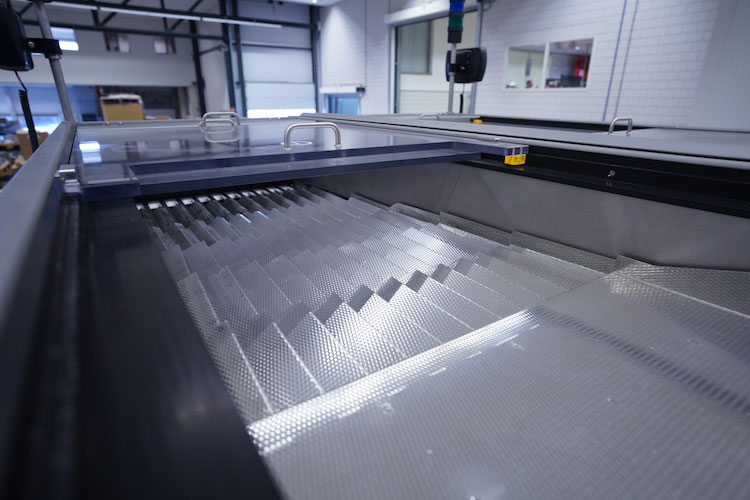

The infeed bottle unscrambler is an automated piece of equipment that consists of a rotating table and guides the empty bottles to the conveyor station precisely and efficiently. It ensures an uninterrupted supply of bottles while maintaining a certain distance between them.

Bottle Rinsing Machine

Automatic Bottle Rinsing Machine – Picture Courtesy: KWT Machine Systems

Automatic bottle rinsing machines are a staple in the packaging sector. These cutting-edge tools are made to completely clean the containers with water before using them to package products. The containers are susceptible to dust accumulation during packaging, therefore, it is essential to clean them thoroughly to maintain the product’s integrity and guarantee that standard regulations are followed.

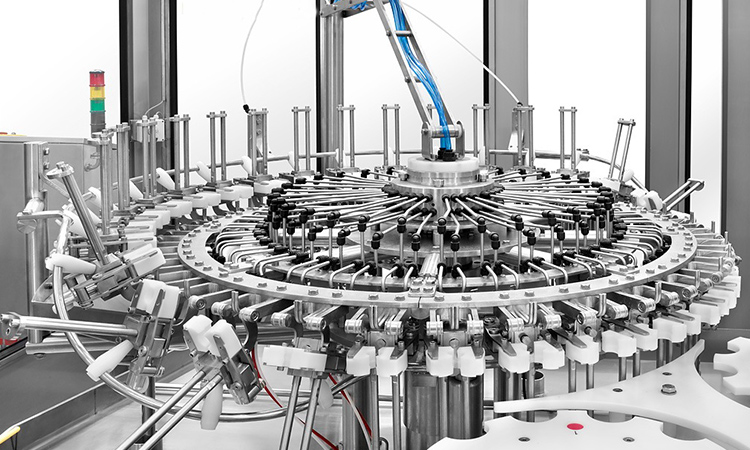

Liquid Filling Machine

Automatic Liquid Filling Machine – Picture Courtesy: iPharmachine

An automatic liquid-filling machine is a key component of the windshield washer water bottling line. You can choose among various liquid filling machine models based on your product characteristics (viscosity and density) and operational speed.

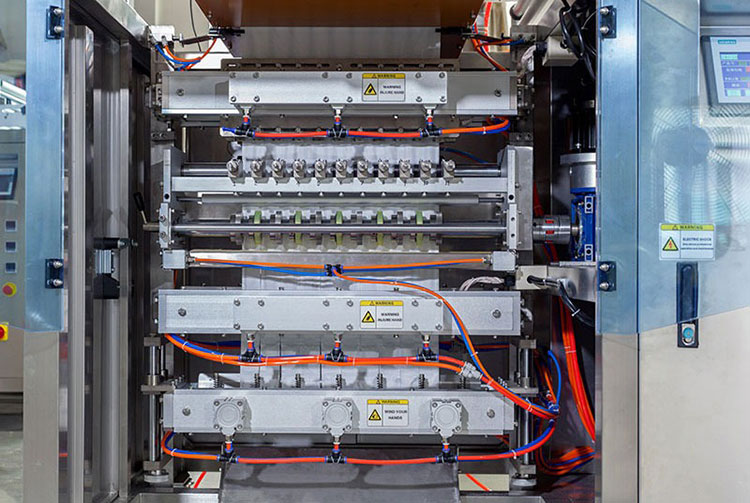

Bottle Capping Machine

Automatic Bottle Capping Machine

An automatic capping machine guarantees the airtight leak-proof closure of the receptacles. It is done by applying numerous sophisticated closures, including plastic and metallic caps.

Three sets of traction pedals, a simple PLC operating panel, a mechanism for removing and putting on caps, a stepper motor, a photoelectric detector, and other parts make up the machine. The capper devices come in a wide variety, with the primary ones being ‘screw-on cappers’.

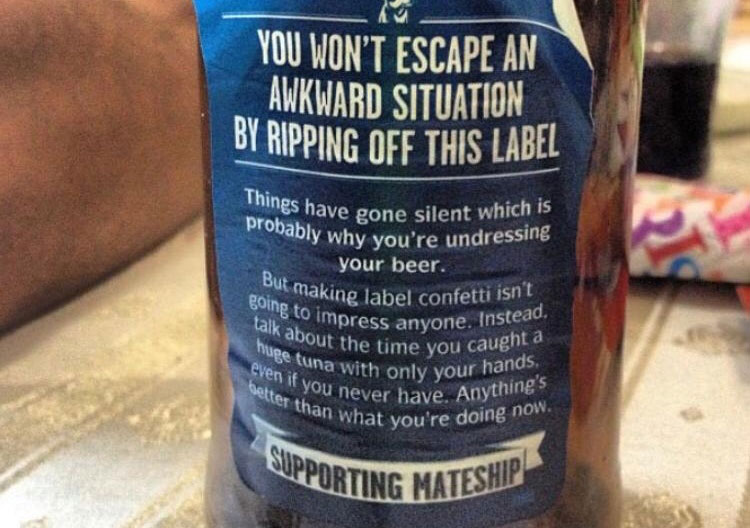

Bottle Labeling Machine

Automatic Bottle Labeling Machine – Picture Courtesy: Herma

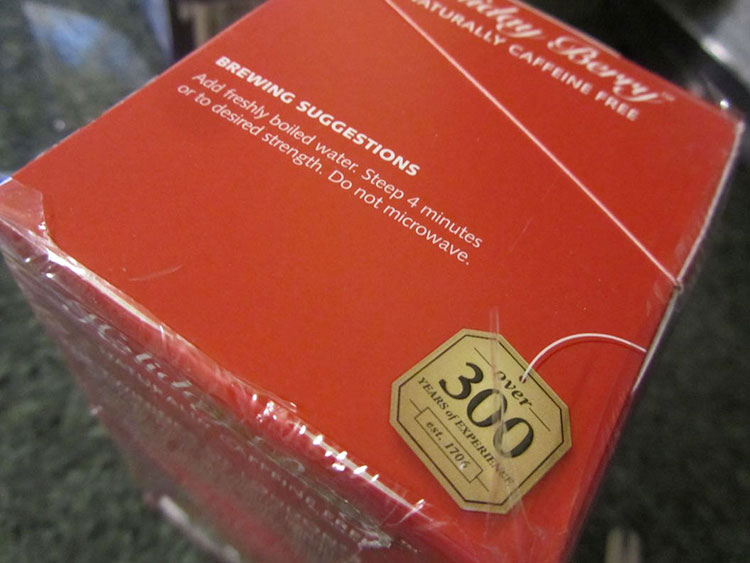

The bottle labeling machine can be positioned either before the filling machine or after the capping machine in the windshield washer water bottling line.

The device is used to affix labels onto the containers, either applying pre-made labels/stickers via pressure-sensitive mechanisms or directly applying labels on the bottle’s surface using printers (laser-jet or ink-jet).

The labels contain essential information regarding the product along with the expiry dates and brand name. Efficient labeling is necessary for proper product inscription, branding, distinct identity, and compliance with standard labeling procedures

Bottle Unscrambler (Outfeed)

Automatic Bottle Unscrambler Machine (Outfeed)

The outfeed bottle unscrambler is located at the end of the windshield washer water bottling line, facilitating the packed goods to be easily taken off the conveyor.

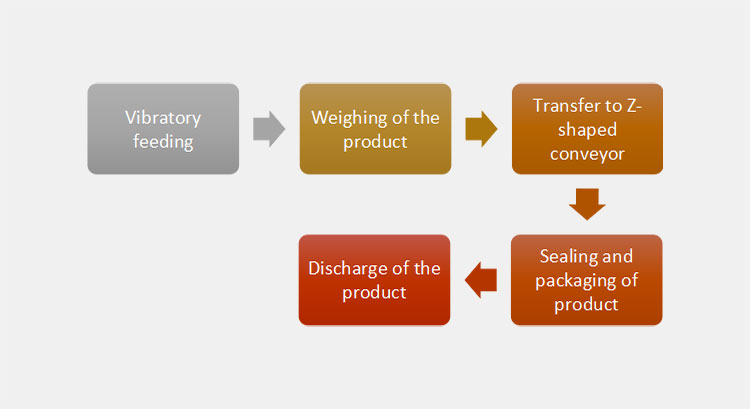

5.Explain the working procedure of the windshield washer water bottling line.

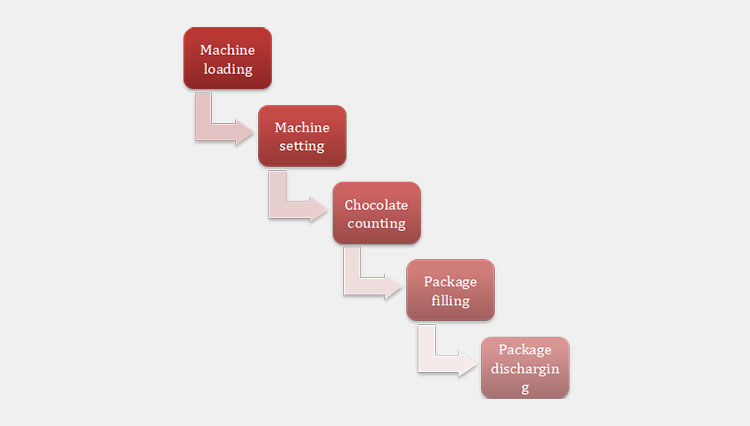

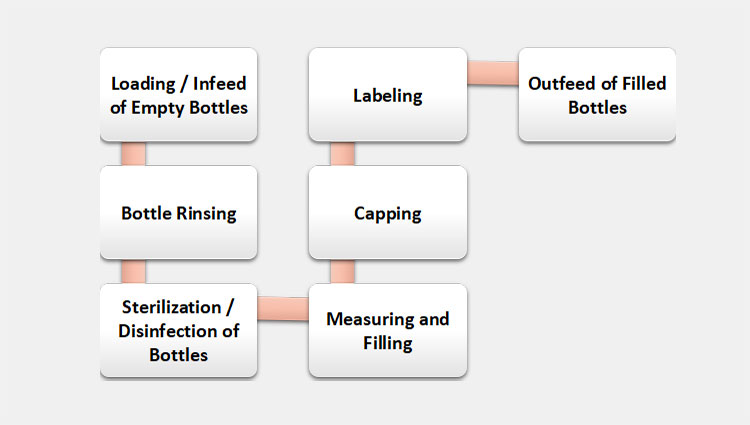

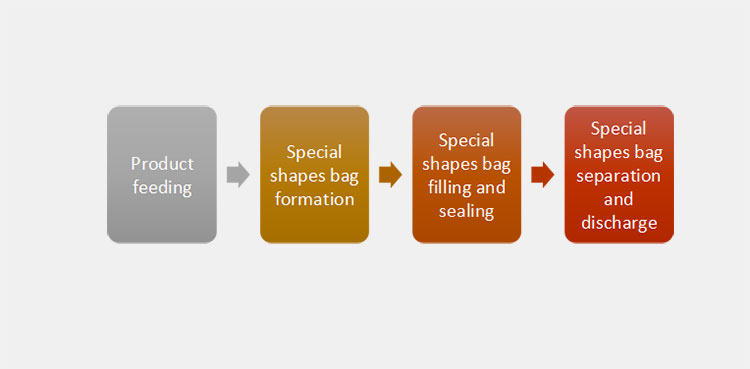

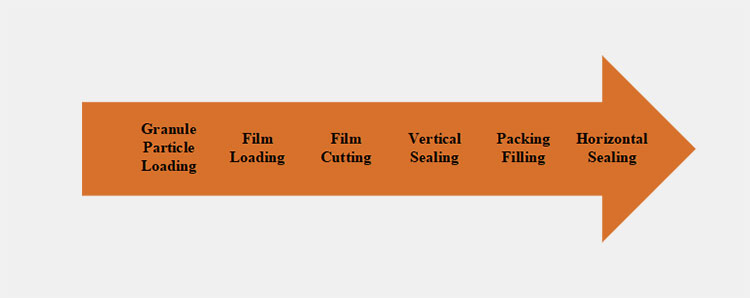

There are various operational steps for the windshield washer water bottling line, each performed by the respective device. These steps are described below:

Working Steps of the Windshield Washer Water Bottling Line

Loading / Infeed of Empty Bottles

The process begins by placing the empty bottles on the bottle unscrambler (infeed), which rotates, arranges, and directs the bottles to the conveyor belt individually.

Bottle Rinsing

The bottle rinsing machine will blow and rinse the bottles to eliminate dust and impurities and ensure a clean container.

Sterilization / Disinfection of Bottles

It is an optional step and only be employed for certain products, such as food and medicinal items. The bottles after rinsing are directed toward the drying and sterilization tunnel of the sterilizer.

The bottles are dried and sterilized through several mechanisms, including ionized or high-pressure heated air. Opting for a particular sterilizer is entirely dependent on the unique requirements.

Measuring and Filling

The liquid product is precisely measured and filled into the cleaned bottles using an automatic liquid-filling machine. The device's construction allows it to fill one or more bottles simultaneously.

Capping

The appropriately filled bottles are securely capped using a bottle-capping machine. It ensures a leak-proof tightened capping using torque sensors.

Labeling

After capping, the bottles are labeled with the desired or essential information through a bottle-labeling machine.

Outfeed of Filled Bottles

Following the process, an automated rotating bottle unscrambler (outfeed) safely releases the completed bottles off the conveyor for further processing.

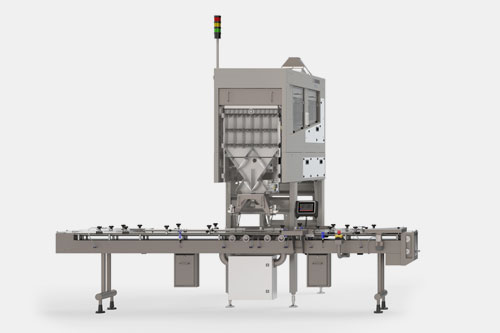

6.How much automation would you like for your windshield washer water bottling line?

The level of automation required for a windshield washer water bottling line entirely depends on the scale of the company and its production volume. The production rate varies with the respective form of the line (automation-based) and is determined as bottles produced per minute (BPM)

Semi-Automatic Windshield Washer Water Bottling Line

Investing in a more manual windshield washer water bottling line (production rate of around 1-10 BPM) would be ideal for a small business or home brewer. It may not, however, be able to satisfy the needs of a big or expanding business.

A semi-automatic windshield washer water bottling line is recommended for medium-scale or small businesses. It consists of semi-automatic devices integrated, requiring more labor for certain operations while providing higher productivity (25-50 BPM) than manual lines.

Fully Automatic Windshield Washer Water Bottling Line – Picture Courtesy: Universal Filling

Large-scale industries having higher production demands should invest in a fully automatic bottling line for an efficient and robust manufacturing process with minimal human intervention and errors. The automatic line utilizes advanced equipment for the process and offers numerous benefits. The production rate of such lines is more than 50 BPM.

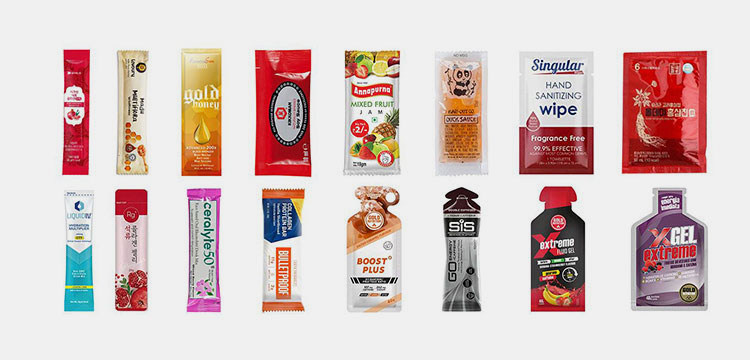

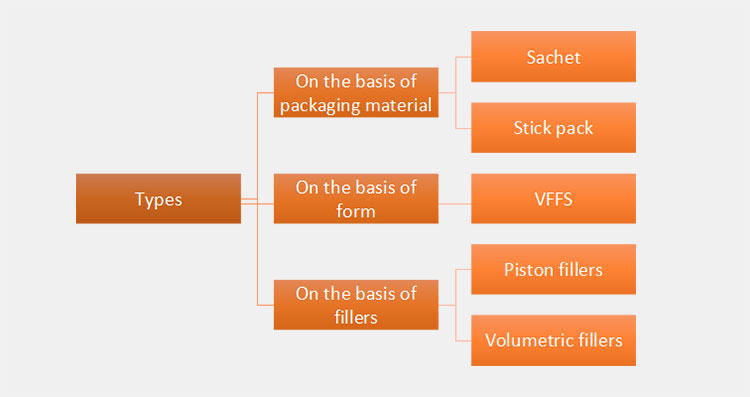

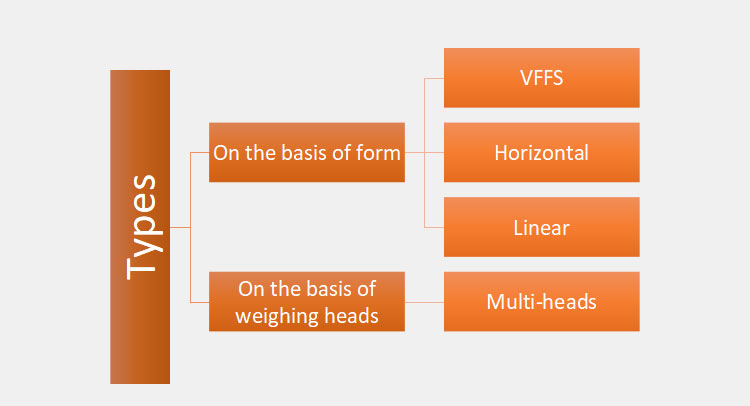

7.What distinct filling machines are available for integration into the windshield washer water bottling line?

Various liquid filling machines are integrated into the windshield washer water bottling line per the product properties and specific needs. These devices fill liquids of different viscosities into multiple containers. They are categorized based on several aspects.

Here is an overview of the categories of the liquid filling machines:

Automatic Liquid Filling Machine

Automatic Liquid Filling Machine – Picture Courtesy: Packleader

It is an advanced piece of equipment that can handle large production volumes at quick rates. Courtesy of the advanced degree in automation, it requires limited human involvement.

It is created to process in a linear orientation. It is usually provided with a conveyor which feeds vacant bottles to the filling section and guides filled bottles forward for further processing.

Gravity Filling Machine

Gravity Filling Machine

In this system, the liquids flow from the storage vessel into bottles by gravity. There is a time-dependent regulation on this equipment. It permits an identical amount of fluid to be dispensed into bottles.

Pump Filling Machine

Pump Filling Machine

It utilizes a roller or gyral pump to dispense specified liquid volume into bottles. It may be partially automatic or fully automatic.

Overflow Filling Machine

Overflow Filling Machine – Picture Courtesy: KWT Machine Systems

These devices are created to fill bottles with liquids to the brim, usually via dipping spouts/nozzles. The spouts plunge into bottles and form an enclosure to avoid spills. After making it to a predefined proportion, the spouts are revoked, and surplus liquids are spilled back into the storage vessel.

Vacuum Filling Machine

Vacuum Filling Machine

It utilizes a suction method to extract fluids into bottles. When the process is finished, the suction is released. This mechanism prevents the degradation of viscous liquids.

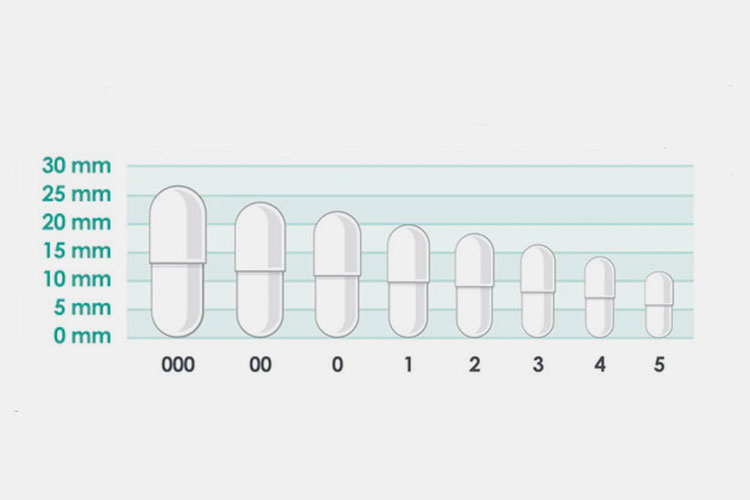

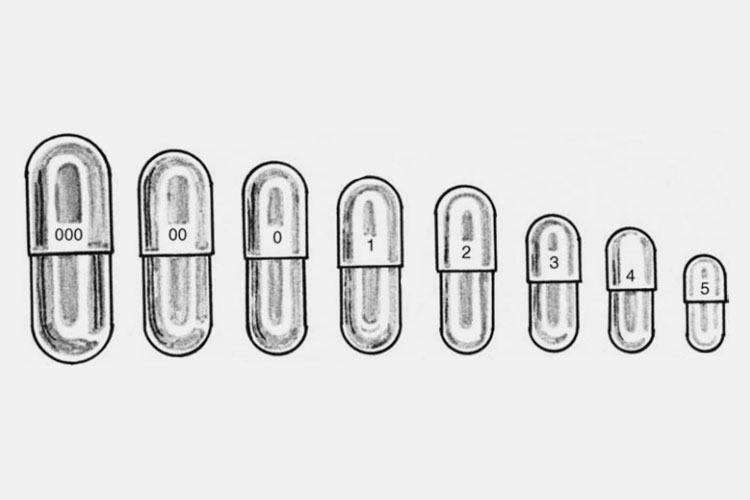

8.What bottle types and sizes can be used with the windshield washer water bottling line?

Typically, the windshield washer water bottling line is designed to handle a range of bottle sizes and types to satisfy various market demands. The following are typical bottle sizes and types that are processed through the line:

| Bottle Types | |

| High Density Polyethylene (HDPE) Bottles

HDPE is a thermoplastic polymer. They are the most commonly used plastic bottles due to their durability and chemical-resistant properties. |

|

| Polyethylene Terephthalate (PET) Bottles

They are recyclable bottles and are sometimes used for smaller bottles as they are clear and offer good barrier properties. |

|

| Bottle Shapes | |

| Round Bottles

They are the most commonly shaped bottles. They are easy to handle and pick and therefore are most popular. |

|

| F-Style Jugs/Bottles

They are rectangular-shaped bottles with handles. They are efficient for storage and shipping goods, as they maximize space. |

|

| Square Jugs

They are also used for bulk storage but are typically less used than rectangular ones. |

|

| Jerry Cans

Its name refers to German origin. They are versatile containers designed for safe and secure storage and shipping of liquids. |

|

| Bottle Sizes | |

| Small Size

They range from 1 to 2 liters (33.8 oz. to 66.7 oz.) bottles. They are convenient for small vehicles. They are easy to carry. |

|

| Medium Size

They range from 3 to 5 liters (101.4 oz. to 169 oz.) bottles or jugs. They are usually used for household or small business use. They are popular among users requiring a moderate volume of fluids. |

|

| Large Size

They typically range from 1-gallon (3.785 liters) to 5-gallon (18.93 liters) bottles. They are widely used for commercial usage and professional settings. They provide bulk storage of items. |

|

9.How to maintain the windshield washer water bottling line?

Every device in your windshield washer water bottling line has to be maintained and cleaned, to ensure their longevity and optimal working condition. The machinery may sustain damage if you neglect to conduct routine maintenance, resulting in lowered efficiency and production.

The following are essential guidelines to guarantee the efficient operation of your bottling line.

Cleaning

Equipment Cleaning – Picture Courtesy: G3 Enterprises

Once a week, scrub down the external surfaces of all components to remove dust and debris. Use a gentle fabric with water or a suitable cleanser.

Perform a thorough cleaning of each element regularly. Dismantle the devices and clean them to prevent the collection of filth and remnants. When done with cleaning, air-dry all the parts.

Lubrication

Lubricating the Equipment – Picture Courtesy: Miller Stephenson

Lubricate all the moving parts of every component of the windshield washer water bottling line using a proper lubricant. It reduces friction and ensures efficient and silent functioning.

Inspection & Assessment

Inspection of the Equipment

Periodically examine all the components for wear and tear. Contemplate prompt repair or substitution to ensure smooth functioning and avoid malfunctions.

Software Updating

Software Updating – Picture Courtesy: Packaging World

Regularly update the software to the latest available version to access the advanced features, improving the device functionality.

10.What are the common problems encountered during the operation of a windshield washer water bottling line and how to resolve them?

Even the most sophisticated equipment encounters problems, therefore, you must be aware to tackle them on time and avoid a breakdown. Some commonly encountered issues while using a windshield washer water bottling line and their respective solutions are described below:

Unscrambling Disc Jamming

Unscrambling Disc Jamming – Picture Courtesy: Micoope

The infeed bottle unscrambler disc can be jammed, resulting in interrupted feeding or incorrect sorting of bottles. It may be caused due to the malfunctioning of the friction plate and transmission gear.

Solution: replace the friction plate. Modify the specs of the transmission gear.

Conveyor Jamming

Conveyor Jamming

The conveyor station jamming can be caused by the impaired conveyor belt and high-speed operation, resulting in the bottles slipping and lowered efficiency.

Solution: replace the conveyor belt. Adjust the speed of operation.

Inconsistent Filling

Filling Inconsistency

The liquid filling devices precisely measure and dispense the liquids into containers. If there is non-uniformity in the filling volume, it may be due to improper calibration, incorrectly adjusted process settings, or damaged/clogged filling nozzles.

Solution: properly calibrate the equipment, especially after the maintenance. Validate the process settings. Replace the damaged nozzles or clean the clogged ones.

Loose Capping

Loose Capping – Picture Courtesy: Automate & Control

If the caps of bottles are loose, it may result in the product’s loss and spills. It may occur due to a damaged spindle screw or a wrong capping technique applied for a particular container.

Solution: replace the spindle screw. Use the capping machine with a mechanism compatible with the processed containers.

Creased Label

Creased Label – Picture Courtesy: Label & Litho

It may be caused by the over-speeding of the label supply disc or incorrectly adjusted pressure for affixing labels, creating wrinkles on the label.

Solution: adjust the speed of the label supply disc. Regulate the exerted pressure properly.

11.What things to consider when choosing a windshield washer water bottling line?

Picture Courtesy: Mashvisor

An effective windshield washer water bottling line is essential in the product packing. This system has a complex layout and includes several important steps, such as label imprinting with precise information coding, meticulous capping, precise filling, and bottle sterilizing.

The objective is to guarantee effective processing and adherence to stringent safety criteria, preserving the product's inherent quality, rather than merely storing them within bottles. Understanding the factors influencing the cost and performance of the devices is crucial for making the right decisions as per your needs.

Here we will discuss some major factors influencing the decision to invest in a particular windshield washer water bottling line:

Production Scale

Production Scale

Determining the production scale is crucial when investing in the windshield washer water bottling line. For the line to operate at higher efficiency, you must be aware of your production demands and then opt for the devices that can effectively satisfy your present needs and future objectives.

Degree of Automation

Degree of Automation

The level of automation is another critical factor. Select the line (manual, semi-automatic, or automatic) as per your requirements and budget. Don’t go above or below your production scale. For example, investing in an automatic line for small-scale businesses is a budget waste unless you are willing to expand the production line.

Budget

Budget – Picture Courtesy: Business Today

The investment required for a windshield washer water bottling line depends on several factors, including the level of automation. The automation required for your production line will determine the overall cost of the line. It is recommended for smaller and medium-level enterprises to invest in manual or semi-automatic bottling lines.

The automatic windshield washer water bottling line requires huge investment plus the operational and maintenance costs, therefore, an industry with high production demands should invest in it for better outcomes.

Compatible Integration

Compatible Integration – Picture Courtesy: Sainty Tec

Buying a single device might be easy while shopping for multiple devices for a production line is complicated. You will have to choose devices that are compatible with each other to achieve optimal performance outcomes consistently.

Conclusion

Ensuring precise and effective processing and packaging is always crucial whether you have already established or intend to launch a liquid production company. All these tasks can be achieved with the appropriate and efficient devices in your windshield washer water bottling line. You can quickly choose the ideal pieces of equipment for your production requirements if you have a thorough grasp of the many varieties of these machines. We hope the details in this buying guide will enable you to make an informed purchase decision. So without any delay and hesitation, contact Allpack and save your precious time and money and grow your business!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Windshield Washer Water Bottling Line: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours