Spice Manufacturing Process: The Complete FAQ Guide In 2025

Spice Manufacturing Process: The Complete FAQ Guide In 2025

From Asia to the world who is unfamiliar with the term "Spices"? Of course, no one! Where spices are known for pungent flavors and vibrant colors, their manufacturing process is often taken for granted. This is the reason why quality of spices is compromised. To solve this issue, we have explained in detail about Spice Manufacturing Process in this FAQ guide.

Before starting a business, it is always important to take a look into the Spice Manufacturing Process which involves several steps. Similarly, these steps are carried out with the help of sophisticated technology in the form of machines on an industrial level. Thus, knowing about these areas can help you to become a successful manufacturer in the Spice market. For clear understanding just go through this piece of writing!

1.What Is Meant By Spice?

Various powder spices in bowls- Picture Courtesy: allrecipes.com

Spice can be simply described as a substance used to add flavor, color, and aroma to food. Spices are of various types and there are different numbers of spices available today. The common examples include pepper, chilli, cinnamon, and ginger etc.

Spices are also termed as seasonings or condiments due to their specific use in cuisine and other foods like pasta, noodles, and salads. Spices may also be used for the preservation of food and that's the reason why people across the globe are using their favorite condiments for making their dishes tastier and appetizing.

Apart from this, you may find spices in different forms such as granules, powder, and in whole and liquid form. These forms are helpful in the use of spices on a daily basis.

2.Spice Manufacturing Process- A Brief History?

Globe made with spices- Picture Courtesy: foodinsight.org

The history of spices show an exciting journey from their unfamiliar discovery in ancient times to the known variety in modern age. Its beginning has been noted 6 million years ago when early humans used to wrap meat in leaves. Gradually, they found the taste of food more pleasant and aromatic.

Early Egyptian, Chinese, and Mesopotamian civilizations played instrumental role in documenting the medicinal benefits and other uses of leaves, however, unable to distinguish between herbs and spices. With passing time, spices became famous for their advantages especially after the discovery of Indian spices.

Similar to spices exploration, its manufacturing process also evolves from using as fresh leaves and flowers to drying, crushing, and roasting. The same method is now followed on industrial level with the use of machines and advanced technology for enhanced efficiency.

3.Spice Manufacturing Process- Is It Worth It?

Well, the answer to asked question is not straight forward rather requires one to first deeply look into the importance of spices itself. Although, we may take spices as ingredients used in food only, however, its benefits falls beyond the area.

Various spices in bottles mccormickscienceinstitute.com

Firstly, the use of spices in food is rising on global level due to internet which is helping people in the promotion of their local cuisine. This in turn generate a demand for spices manufacturing which is an opportunity for entrepreneurs and businesspersons.

Secondly, spices such as turmeric, ginger, and cinnamon are popularly used for medicinal and beauty related products. It directly shows the expansion of spices benefits in fields beyond food industry.

Thirdly and lastly, being spiritual beings humans cannot avoid the religious practices which also involves use of certain spices. So, what we get from these facts is the rapidly growing significance of spices which is creating a room for economic development through cultivation, manufacturing, and packaging of spices.

Overall, spice manufacturing process is as necessary as other products manufacturing. However, it is always important to pay special attention to market trends, quality

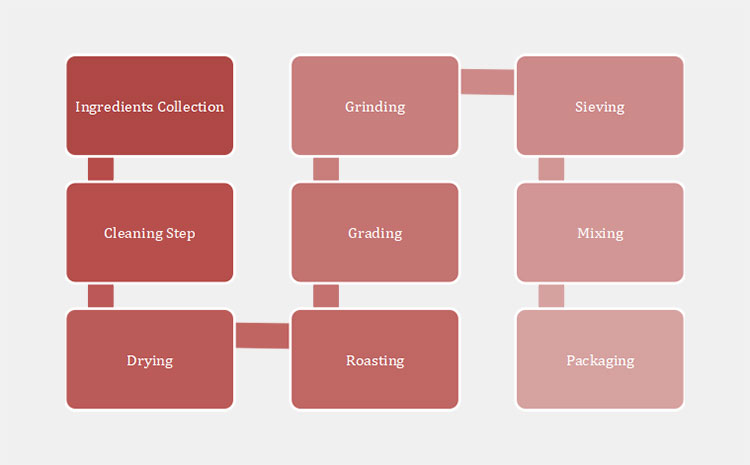

4.Spice Manufacturing Process- The Major Steps Involved?

Spice manufacturing process involves several steps which is obligatory for the production of high quality spices. Let's explore these steps one by one!

Ingredients Collection

Whole spices- Picture Courtesy: thegardenrecipe.com

Before starting spice manufacturing process, it is important to know that spices are of different types which depends upon their usage. For instance some spices are mixture of multiple ingredients like curry powder, chilli powder, and parika while others are only composed of single ingredient like fennel seeds, turmeric, and cumin.

Now, it is clear that during spice manufacturing you will need to have these ingredients at your hand which is available in raw form. So, make sure to aquire all the necessary ingredients for your specific spice mixture.

Cleaning Step

Ginger washing in machine

Once you have gathered all the required ingredients, undergo them through cleaning step to remove out impurities. For this, you can use automatic washing machine for plants and herbs.

Drying

Chili drying- Picture Courtesy: dryingplant.com

After cleaning comes the drying phase which is one of the crucial steps during spice manufacturing process. The reason for its importance is that the essence of spices gets increased with drying it also prevents bacteria from poisoning spices. Therefore, sophisticated machines should be used to reduce the moisture content while taking care of temperature as different spices require different level of moisture. For instance, mace needs 6% of moisture and chillies need 12%.

Roasting

Coriander seeds roasting- Picture Courtesy: Excell Packs

Moving forward, the dried ingredients are roasted to bring out the color and aroma. However, it is crucial to carry out this step in controlled environment with required temperature and limited heat, so, that the originality of substances could be well retained.

Grading

Upon roasting, your next task will be to grade the ingredients on the basis of their size, weight, and volume. It can help you deal with the grinding process or else the process may get messy.

Grinding

Spices grinding- Picture Courtesy: holar.com.

After grading, spices are grinded by using heavy-duty industrial grade grinding machines. Depending upon the hardness of ingredients, different machines are available with sharp blades which can effectively and efficiently break down whole spices into powder form.

Sieving

Turmeric sieving- Picture Courtesy: dahanmachine.com

Another step is sieving during which grinded spices are passed through a sieving machine. It helps ensure the segregation of particles based upon their size thereby maintaining consistency during production which is key for quality manufacturing.

Mixing

Spices blending process-Picture Courtesy: sampackindia.com

Mixing is the final step of spice manufacturing process where intended spices are thoroughly blended to get the desired spice mixture. For large scale production, industrial mixers are used which automatically carry out mixing in an enclosed ad hygienic environment.

Packaging

Spices bottling- Picture Courtesy: JDA Progress Canada

Packaging is the last but most eminent phase which must be done carefully. For this purpose, spices are loaded in packaging machines which then precisely deposit accurate volume into desired packages such as bottles, jars, and bags.

5.Spice Manufacturing Process- Equipment Needed?

With advancements in technology, now it is quite easy to conduct spice manufacturing process without any human harm and product loss. This is possible with innovative machines produced for carrying out every single step of spice manufacturing. These machines are listed below:

Spice Washing Machine

Auto Fresh Ginger/Turmeric Washing Machine Stainless Steel- Picture Courtesy: juiceprocessline.com

Spice washing machine is an efficacious machine employed to wash out different types of whole spices such as turmeric, ginger, and chillies. It is made up of corrosion resistant stainless steel with washing and tumbling system. The machine effectively clean out spices by passing them through clean water and tumbling to remove out all the impurities.

Drying Machine

Tray Dryer Stainless Steel Spice Drying Machine

Drying machine is another equipment you will need to conduct spice manufacturing process. It is an electric machine with heat system that can effectively reduce the moisture content of your spices to desired level. The machine has trays over which spices are spread. It has adjustable heat system to support customized drying as different spices have diverse drying needs.

Roasting Machine

Spices roasting machine DCCZ7-15 roaster- Picture Courtesy: chchike.com

Roasting machine is an excellent machine designed with advanced feature to facilitate pollution free roasting of various spices. The machine has robust structure with sustainable electromagnetic source for heat generation. The main body of machine is made up of 304 stainless steel followed by other components including a removable feeding hopper, electric cabinet, control unit, cover, and roasting chamber.

Grinding Machine

Allpack Herb Grinding Machine DLF-70S

Grinding machine is another important machine needed for spice manufacturing process. It has fully automatic system to process whole spices and turn into into fine powder or coarse particles as intended. The machine is made up of several components including main frame, control panel, feeding station, outlet, and grinding unit. It can be simply operated by fixing the speed of grinding and time for each cycle after which it automatically finish the processing.

Screening Machine

Allpack- ZS Series High Efficient Screening Machine

Screening machine is also known as grading or sieving machine which is designed to process powders and granules. It is essential for the sieving and grading of spices. This multifunctional equipment has a precise structure with quality stainless steel. It consists of multiple perforated plates through which spices are passed for sieving. It works automatically through the principle of vibration.

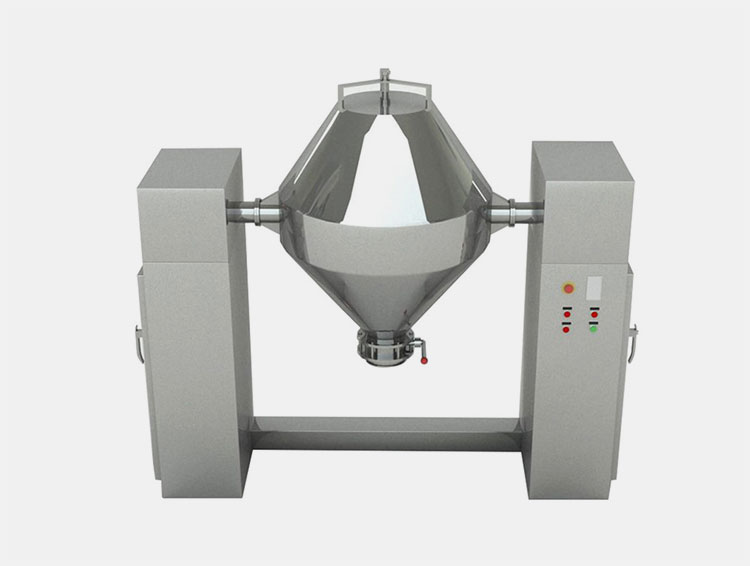

Powder Mixer

Allpack- Model CH-V Series High Efficiency Mixer

Powder mixer is inevitable for spice manufacturing process. This powder mixer by Allpack has special V shape structure which is fully automatic in its functioning. The machine has stainless steel bin with dual feeding inlets on upper side followed by separate discharge unit in lower side. The bin rotate in 90° which helps in the homogeneous mixing of different powder spices.

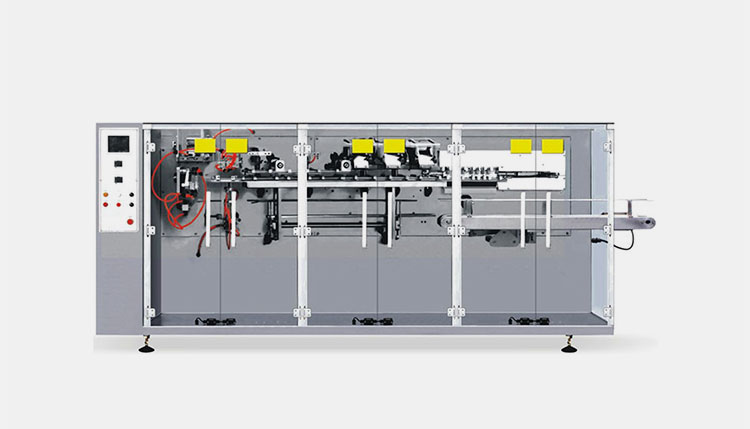

Pouch Packaging Machine

Allpack APK-210Z series premade pouch filling machine

Pouch packaging machine is designed for packing spices into various flexible packages such as sachets, stick packs, and doypacks. This premade pouch filling machine by Allpack is a wonderful solution that can process different types of flexible packages. The machine offers convenient operation where packages are formed from flat film, filled with precise volume of spice, and then tightly sealed.

Powder Filling Machine

Allpack- Single Head Automatic Powder Filling Machine

Powder filling machine is a specialized equipment tailored with astonishing features to fulfill the packaging of powder spices. It has auger filling mechanism for the accurate measurement of spices and stainless steel nozzles to discharge the weighed spices into bottles and jars. The process simply involves loading hopper with bulk powder spices and feeding bottles into machine. Similarly, it pours the spices into bottles which are then discharge from another end.

6.Spice Manufacturing Process- Various Packaging Options?

Packaging is the most important phase during spice manufacturing process which helps in the preservation of their quality, aroma, and taste. Thus, various options are now available to secure the richness of spices and help them reach to the awaited consumers. Let's know some of the popularly used packaging types!

Bottle Packaging

Various bottles of spices- Picture Courtesy: colaveco.com

Bottles are frequently used for storing various types of spices due to their enhanced protection and safety. These bottles vary from plastic to glass bottles and are often transparent to clearly display for the customers which is laying inside. Bottle packaging is best option for spices as they attract consumers.

Pouch Packaging

Various pouches of spices- Picture Courtesy: fiverr.com

Pouch packaging refers to the packaging of spices in flexible bags like stand-up pouches and doypacks. They are cost-effective and easy-to-use therapy deducting packaging costs.

Carton Packaging

Tumeric powder carton pack- Picture Courtesy: designsagar.com

Carton packaging is also popularly used to deliver spices. For such packaging, firstly spices are packed in aluminum or plastic pouches which are then enclosed in cartons. In this way, both the security of spices and marketing of brand are easily achieved.

Sachet Packaging

Various sachets of spices- Picture Courtesy: designsagar.com

Spices can also be delivered in flat bags like sachets which are usually used for delivering single serving and small amount of spices. These sachets have three or four sides sealed which also looks beautiful when laying on the shelves of market.

Jar Packaging

Various jars of spices- Picture Courtesy: glassnow.com

Traditionally, jars were famous for their use of storing spices as they have exceptional safety against moisture and bacteria. Today, many reputable suppliers used to deliver spices in glass jars.

Tin Packaging

Various spices in tins- Picture Courtesy: tropicasem.sn

Although tin packaging is rarely used for spices, however, it is still practiced in some Western countries. Steel tins are effective to preserve the freshness of spices and they are also recyclable.

7.Spice Manufacturing Process- What Is The Importance Of Quality Control?

The importance of quality control can never be denied when it comes to spice manufacturing process. In fact, the growing demand for spices has also raised the concerns regarding their quality. Thus, international community has brought up certain rules for spices manufacturing whose adherence show the reliability of companies. Let's know these guidelines in a bit detail!

Quality inspection in spice manufacturing process- Picture Courtesy: hudsontraders.com

International Organization for Standardization (ISO)

ISO has different standards for maintaining the quality of spices and the preservatives used. For instance, ISO 67.220 deals with spices, condiments, and food additives, while as, ISO 948:1980 covers sampling of spices.

Good Manufacturing Practices (GMP)

GMP has special guidelines for safe production of spices which were renewed in 2023. Some of the notable rules include use of GMP certified machines and conducting spices manufacturing in hygienic environment.

Conformate European (CE)

CE represents the collective will of European Union regarding food and non-food products manufacturing which also include spices production.

Food and Drugs Administration (FDA)

Food and Drugs Administration is United States's agency for the production and processing of medicinal and food products. For this reason, it is essential to follow the established guidelines by FDA.

8.Spice Manufacturing Process- Factors To Consider?

Spice manufacturing process revolves around several aspects each requiring full attention. So, you must be careful in paying attention to these important factors which are provided as under:

Source of Raw Material

Various raw spices- Picture Courtesy: amazingfoodanddrink.com

The foremost thing to look for is the source of raw material. It is crucial to confirm whether the raw ingredients taken are fresh and obtained from safe sources. For this, you should have trustable supplier with proper certification.

Machines Used

Allpack- Model W Series Double Taper-shaped Mixer

Spice manufacturing process is almost impossible without machines. Therefore, make sure you have adequate knowledge about each machine required for it and select machines by keeping in mind their automation level, energy consumption, and automation level.

Production Methods

Although, spices are produced through the use of machines, however, it is you who determine which step should be done prior and which one should be later. So, be careful in adopting globally recognized and accepted methods.

Packaging

Chili powder bottle- Picture Courtesy: designsagar.com

Packaging is essential in retaining the originality of spices, therefore, you need to be very careful in selecting the most suitable option. For this, you may look towards your budget and market trends.

Quality Compliance

Quality icon- Picture Courtesy: mddionline.com

Your products are known by their quality which is itself dependent upon the marks issued by quality standards. So, make sure to comply international as well as local quality standards for getting global recognition.

Conclusion

To put in a nutshell, Spice Manufacturing Process is a long lasting procedure where multiple machines are needed to carry out each step. Along with this, right method also play a significant role in getting all the things done. In addition to it, packaging is considered important for the quality retention of produced spices. So, overall we may summarize that this complicated phenomenon require thorough consideration of several aspects. Besides, we hope you have got the desired information about spice manufacturing process. If you have any query or you are interested in purchasing necessary equipment then you can simply contact us through our website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Spice Manufacturing Process: The Complete FAQ Guide In 2025 Read More »