Stick-Pack vs Sachet — Which Flexible Packaging Format Fits Your Product?

Stick-Pack vs Sachet — Which Flexible Packaging Format Fits Your Product?

When it comes to highlighting the best packaging formats for food products, flexible packaging is always on the top. Manufacturers and producers often get confused when choosing between stick pack vs sachet. As both of these flexible packaging formats are popular for various reasons. Stick-pack vs Sachet--- Which Flexible Packaging Format Fits Your Product?

In this review, you will learn about stick packs and sachets. Information about each packaging format, including definition, advantages, potential drawback and most importantly, comparison between the two will be provided as under. After going through this review, you will be able to choose the right one between the two. So, let's begin to explore more about stick pack vs sachet!

1.Why do manufacturers often struggle choosing between stick-pack and sachet formats?

Although, stick-pack and sachet are two popular formats of flexible packaging, manufacturers often struggle to choose between the two. This challenge of deciding the best between stick packs and sachet is caused by various reasons which are enumerated below:

Product Compatibility

Various stick-packs and sachets- Picture Courtesy: fodapack.com

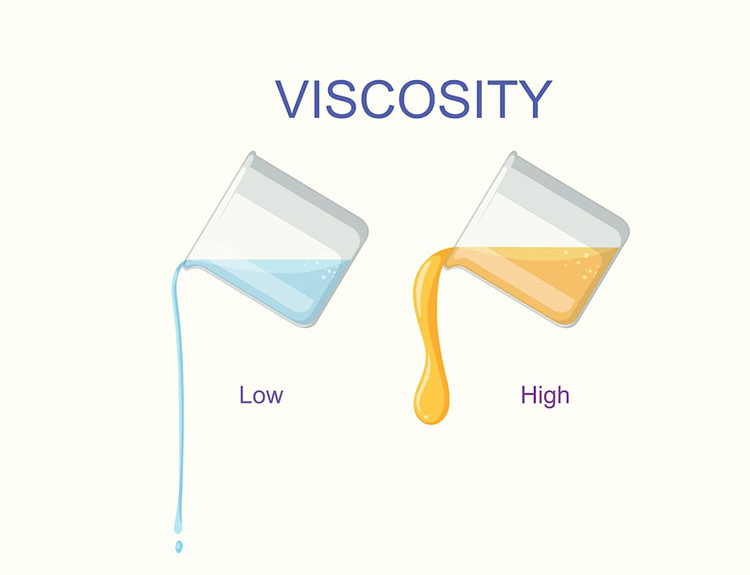

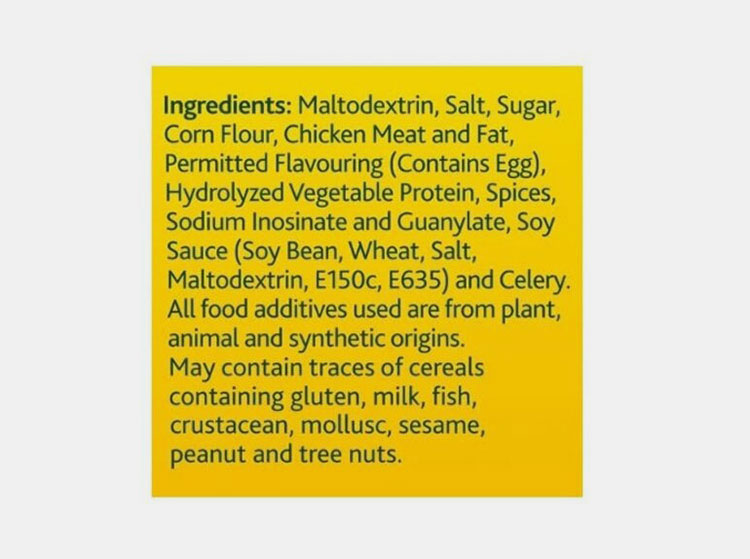

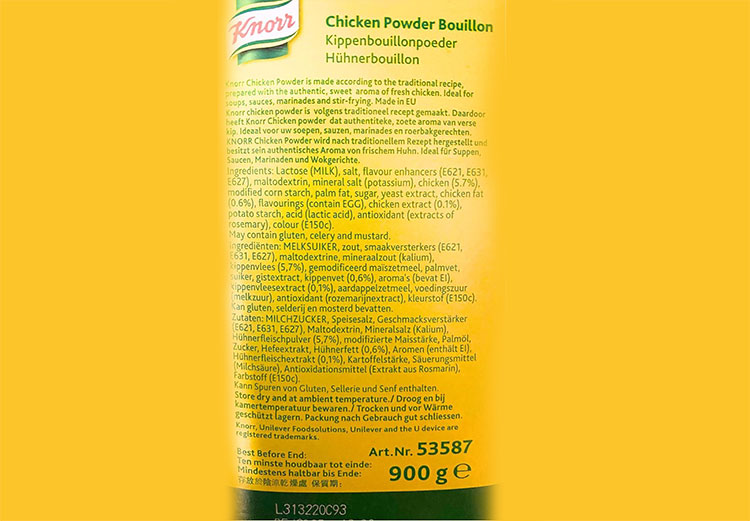

One of the reasons why manufacturers find it difficult to opt for stick-pack or sachet is the product compatibility. Food products such as powders, granules, and liquids have different characteristics. These products are available in different forms, requiring special storage, temperature, and strength against environmental factors. All these aspects, makes it challenging for manufacturers to choose between stick-pack and sachet.

Current Market Trends

Stick pack labeling- Picture Courtesy: foodpack.com

Manufacturers encounter constantly changing market trends which is another significant factor contributing to their struggle in choosing between the two packaging formats. These trends include consumer preferences in using convenient packaging that vary from region to region. Keeping in view these factors producers should opt for the best option.

Production Cost

Packaging cost illustration- Picture Courtesy: howtobuypackaging.com

In many cases, manufacturers need to balance their packaging costs that goes side by side with packaging material, production speed as well as the machines used, which are different for stick pack and sachet. Thus, it becomes a hurdle to select each packaging type to be on the safe side.

Brand Image

Brand image- Picture Courtesy: marketingdonut.co.uk

It is a matter of fact that the type of packaging format manufacturers choose is detrimental for branding. It is greatly influenced by factors like surface space and labeling etc. Hence, it becomes a major reason why entrepreneurs often strive to choose between stick-pack and sachet formats.

2.What are the common products packaged in stick-packs or sachet pack?

When it comes to discuss the common products packaged in stick-packs or sachet packs, there is a long list. Some of the prominent products are enlisted below:

Powders

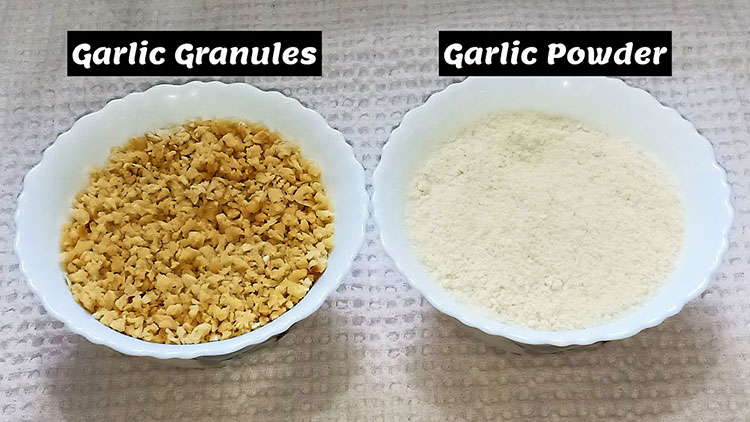

Various powders- Picture Courtesy: Freepik

Both stick packs and sachet packs are used for packing powders. These powders contain fine particulates that flow freely. Common examples include instant coffee, milk powder, salt, black pepper, and other spices.

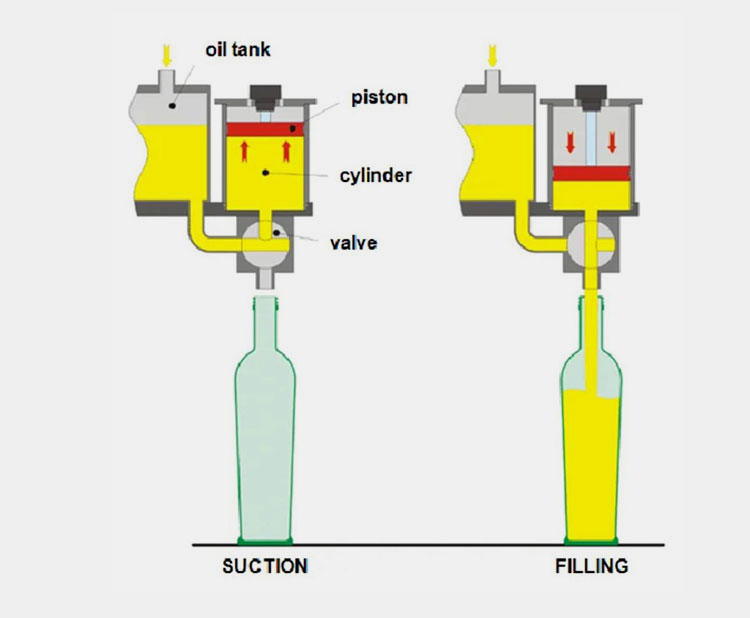

Liquids

Whole apple and apple juice- Picture Courtesy: elephango.com

In addition to powders, liquids may also be packed in stick packs and sachet packs. These liquids vary according to flow properties and thickness such as viscous liquids and free flowing liquids. Few common examples include ketchup, honey, mayonnaise, and jelly etc.

Supplements

Supplements- Picture Courtesy: recreation.ucsd.edu

Apart from powders and liquids, stick-pack and sachet is popularly used for supplements packaging. These supplements include tablets, pills, and other forms of medication in form of ointment or energy drink powder etc.

3.What exactly is a stick-pack?

Stick-packs- Picture Courtesy: elkpackaging.com

Stick-pack is a single serving bag characterized by elongated body. It is made up of one folded strip of laminate film sealed on three sides. The types of stick-pack may include shaped, pillow, strip, and side fin as explained below:

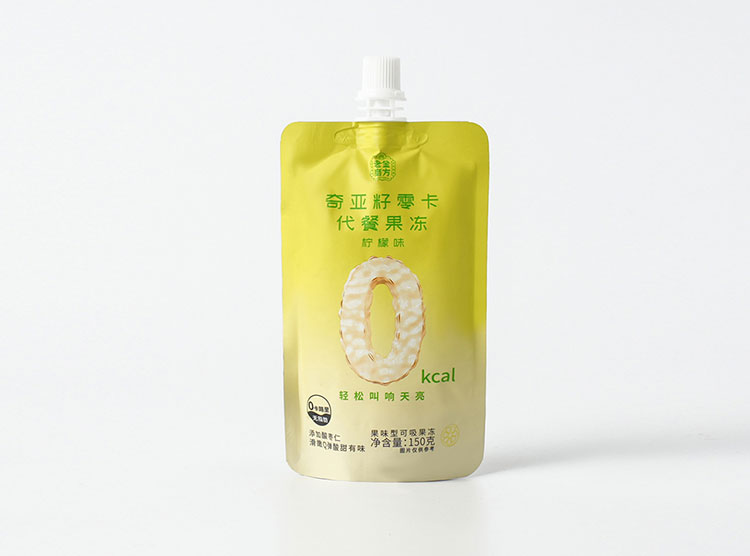

Shaped:Shaped stick-pack is special type which is created to suit consumer needs. The common example include stick-pack for liquid with bottle neck to ease discharge.

Pillow:Such type of stick-pack resembles pillow. They are suitable for comparatively large volume of single serving product like powders and granules.

Strip:Strip stick-packs are interconnected to each other through perforation. They are good for consumers who like to have multiple bags attached to each other.

Side Fin:It is a specialized type of stick-pack with a sealed fin on one side. It offers convenience in opening.

4.What are the main advantages of stick-pack packaging?

Stick-pack packaging offers multiple advantages which are enumerated as under:

Enhanced User Experience

User pouring liquid from stick-pack onto a spoon- Picture Courtesy: kaatimex.bg

Stick-packs are convenient in opening, usage, and product dispensing. Their slim body makes it very easy to carry it and store it. All these attributes enhance the user experience as they start carrying them for travel and sports etc.

Improved Protection

Stick-packs- Picture Courtesy: elkpackaging.com

It is one of the benefits of stick-packs that they are designed to protect the product from external environmental factors such as moisture, contaminants, and air. It's secure seal is crucial in maintaining the originality of sensitive products like pharmaceuticals and nutritional supplements.

Cost-effectiveness

Another significant advantage of stick-packs is their cost-effectiveness for both the manufacturer and the consumers. The reason is use of less packaging material which ultimately reduce waste. Moreover, it also reduces the shipping cost as more units of stick-packs can be transported at once.

Portion Control

Precise dosage given to a child from stick-pack- Picture Courtesy: unither-pharma.com

Stick-pack offers exact amount of product which is necessary for maintaining the quality and taste. In this way, it eliminates the hassle of overdose, especially in case of medication, coffee, of supplements etc.

Environmentally Friendly

Environmentally friendly icon- Picture Courtesy: mcrsafety.com

The material used for making stick-packs is less than that of other flexible packaging including sachet. This minimum consumption of packaging material makes it sustainable and environmentally friendly.

Versatility

Stick-packs offer versatility by allowing multiple types of products to be packed in them including powders, granules, and liquids. Similarly, their design flexibility is also very crucial for branding and marketing.

5.What are the potential limitations of stick-pack formats?

While stick-packs come with wide range of benefits they also have potential limitations which we will explore in the upcoming paragraphs:

Limited Volume

Torn stick-pack with powder- Picture Courtesy: Freepik

The primary limitation of stick-pack formats is limited volume that allows very small amount of product to be stored in it and is not suitable for larger quantities.

Limited Space for Branding

Unlabeled stick-pack- Picture Courtesy: Freepik

Stick-packs are quite narrow that they allow little space for labeling as a result branding opportunity is not enough. There is only little space for displaying information about the product.

6.What defines a sachet packaging format?

Sachet- Picture Courtesy: universalpack.it

Sachet packaging format may be defined as a versatile square or rectangular shape pack. It has flat structure with usually four or three sides sealing. Sachets are used for multiple types of products such as powders, liquids and pastes etc. Some of the common types of sachets include:

Standard:Standard sachet is the common example of sachet packaging format. It is flexible enough to be used for range of products.

Flat:Flat sachet is rectangular shape small pouch that is used to hold single-serving amount of any product.

Twin:Two interconnected sachets are known as twin sachets which are ideal for storing products separately.

Strip:Strip sachets are number of sachets joined together via perforation and can be simply torn-off.

7.Which industries commonly use sachets?

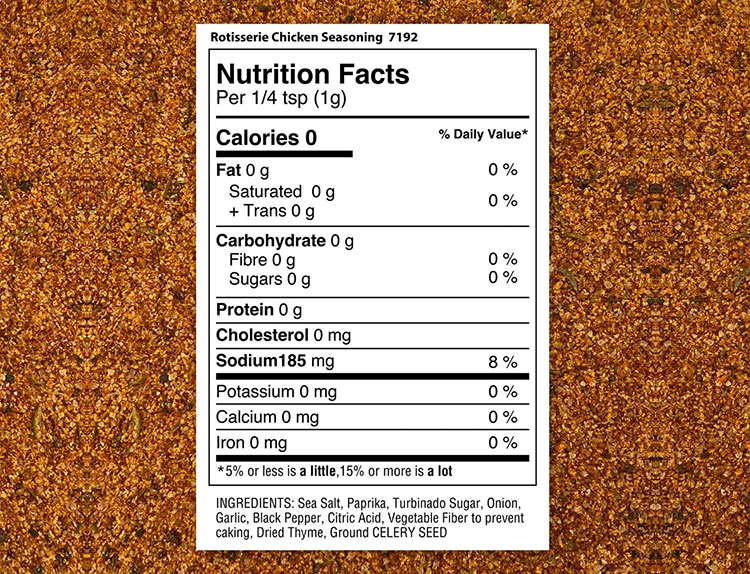

Sachets are considered the most convenient form of flexible packaging due to their precise size, easy-to-open design, and capacity to carry accurate dose of various products. Some of the major industries using sachets are listed as under:

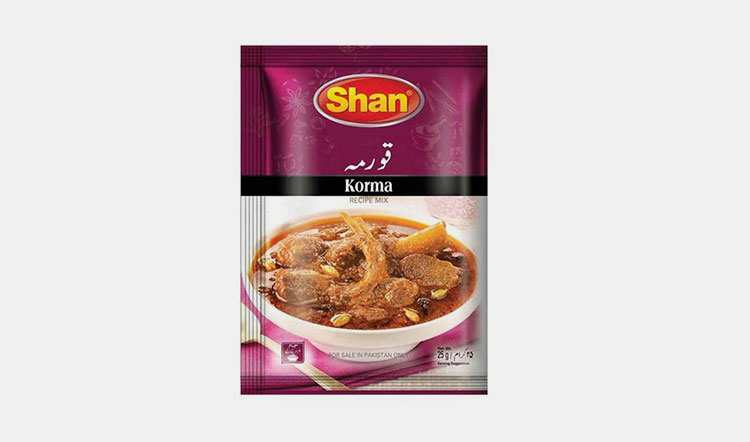

Food Industry

Powder spice sachet- Picture Courtesy: lgdapnamart.com

Food industry is one of the top beneficiary of using sachets. Wide range of products including condiments, sweeteners, and instant beverages are stored in sachets in order to preserve their essence.

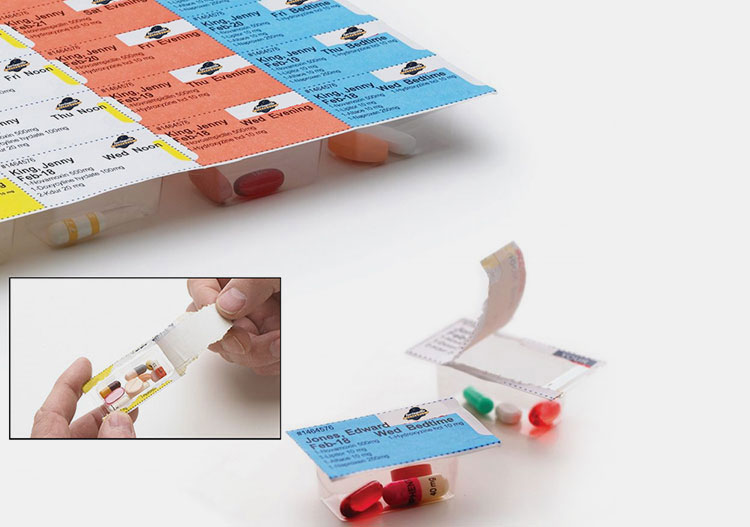

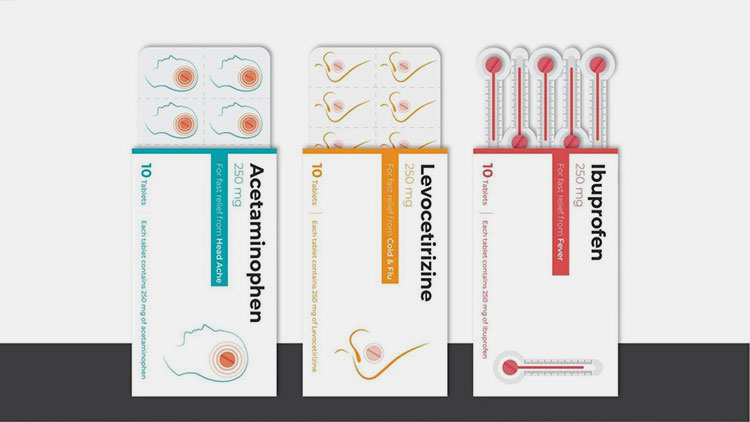

Pharmaceutical Industry

Cranberry sachets- Picture Courtesy: herbiotics.com.pk

Sachets are widely used in pharmaceutical industry due to their enhanced barrier properties against environmental factors. The common examples include tablets, pills and ointments etc.

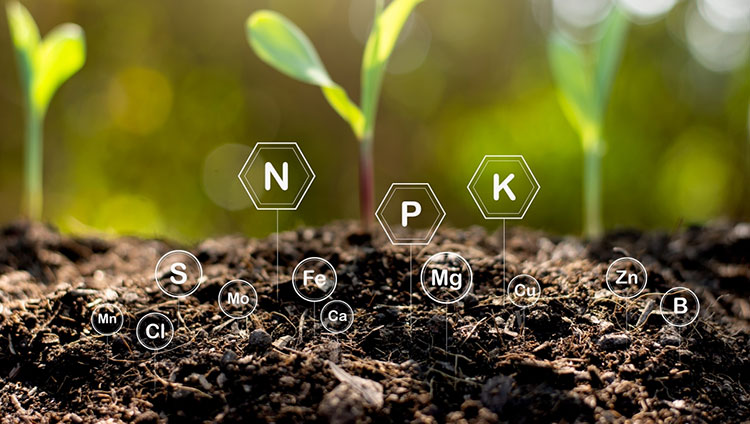

Nutraceutical Industry

Nutraceuticals- Picture Courtesy: qualityze.com

In addition to pharmaceuticals, nutraceuticals, supplements beyond basic medications, are also delivered in small quantities. Thus, sachets are used for protein powder, energy drinks and magnesium powders.

Herbal Industry

Tea sachets- Picture Courtesy: dorsettea.co.uk

Herbal industry is also among the applications of sachets where herbal extracts and herbs are commonly stored. The examples include dried tea, creams, and collagen powder etc.

8.What are the key benefits of sachet packaging?

Some of the crucial advantages of sachet packaging are as follows:

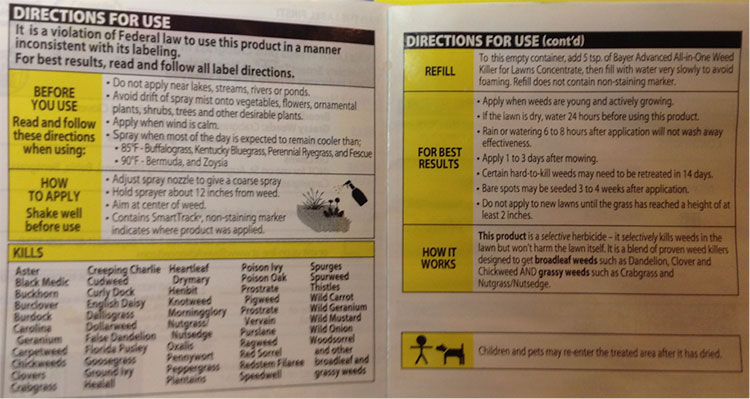

Marketing Potential

Sachet labeling- Picture Courtesy: carepac.com

Sachet packaging is considered best for marketing potential as the packages allow sufficient room for labeling and designs are also customizable. It makes them appealing for customers.

Cost-Efficiency

Sachet packaging significantly minimizes the cost of packaging by using fixed material and the production cost is also low.

Portability

Strip sachets- Picture Courtesy: breakfreefromplastic.org

Sachet packs are light-weighted, precisely structured and easy-to-use. These features make sachet packaging portable and convenient especially in terms of transportation.

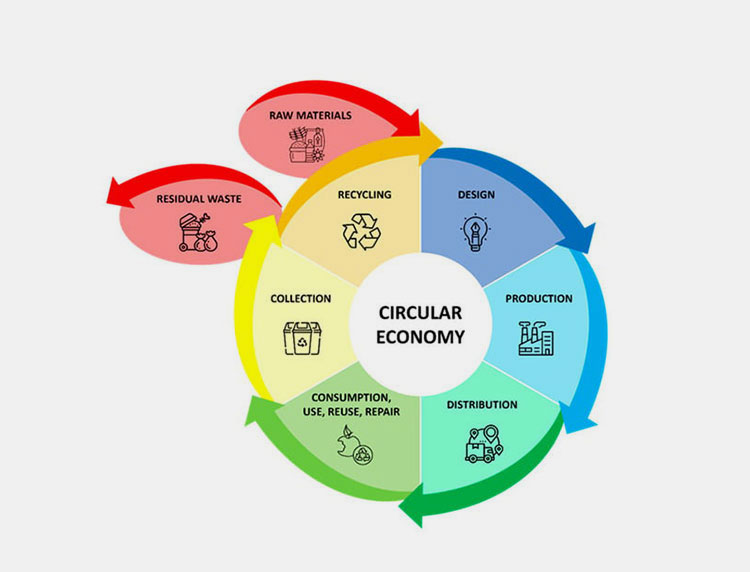

Eco-friendly

Eco-friendly icon- Picture Courtesy: rolleatusa.com

There are extensive packaging options now available for sachet packaging which are biodegradable. Sachets made from such materials are recyclable and have lower environmental impact.

Flexibility

Various sachets- Picture Courtesy: stanleypackage.com

Sachet packaging offers flexibility in terms of designs as well as the products to be stored inside. For instance, flat, twin, and strip is the example of former while powders, granules, and liquids are the examples of latter.

9.What are the potential drawbacks or limitations of sachets?

There are certain drawbacks of sachets which impose limitations over its usage. These are as follows:

Environmental Impact

Environmental impact- Picture Courtesy: inform.tmforum.org

Sachets are often made from multiple layers of plastic, paper, and aluminum. It makes the recycling difficult as a result of which environmental issues are created. In addition, the non-recyclability leads to high carbon footprint which can also harm ecosystem.

Design Limitations

Sachet- Picture Courtesy: Freepik

Although, sachets offer variation in designs and labeling yet it has potential drawback on part of user experience. For example, in the absence of tear notch, consumers find difficulty in opening sachets.

10.How Do Stick-Packs and Sachets Compare?

Stick-pack and sachets differ in various aspects. From their shapes to the production cost and applications, you will find each against other. Let's explore the explanation below!

| Aspects | Stick-Packs | Sachets |

| Definition | Stick-pack is a type of flexible packaging with limited capacity for single serving products. | Sachets are flexible packages which offers adequate space for products storage. |

| Shape | Stick-packs are tubular in shape that is long and narrow. | Sachets come in square or rectangular shape. |

| Cost | Stick-packs have a comparatively higher cost due to material waste and production cost. | On the other hand, sachets are produced with little material waste and production cost is also low. |

| Design Flexibility | Stick-pack offers minimum chances for customization of design. | While as, sachets are more flexible and can be made in different shapes. |

| Application | Stick-packs are widely used for powder and granules such as tea, coffee, and condiments etc. | In contrast, sachets are applicable to pack multiple products including powder, liquids, and supplements. |

| Picture |

Coffee stick-pack- Picture Courtesy: Nehonorpack.com |

Various sachets- Picture Courtesy: graphicpkg.com |

11.How to Choose the Right Packaging Format for Your Product?

Choosing the right packaging format between stick-pack and sachet depends upon your requirements. Both have unique features therefore, you must choose by looking into your priorities. Some of the essential factors to consider include:

Form of Packaging

Sachet and stick-pack- Picture Courtesy: hyflexpack.com

Both packs have a distinction in their form. Stick-packs are long, narrow and tubular shape made up of single layer of film. While as, sachets are wide and rectangular or square shape pouches made up of multi layer films.

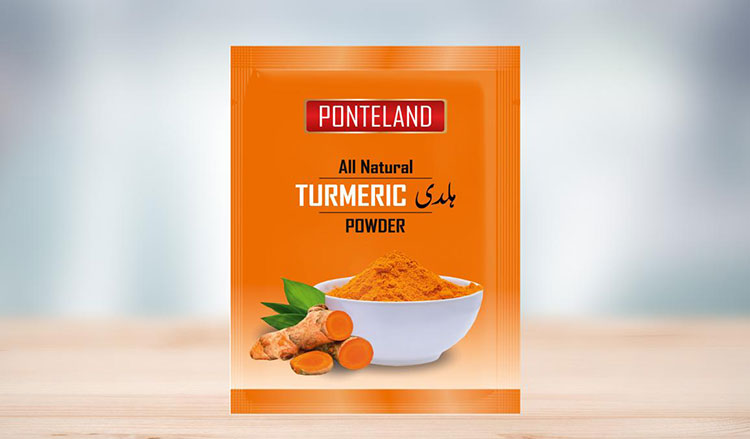

Capacity

Turmeric sachet- Picture Courtesy: ponteland.pk

Stick-packs have fixed capacity for holding limited amount of product such as 1 to 60 ml of liquid and several grams for powder or granules. On the other hand, sachets are designed to hold large amount of powders as well as liquids up to 10 ml.

Cost

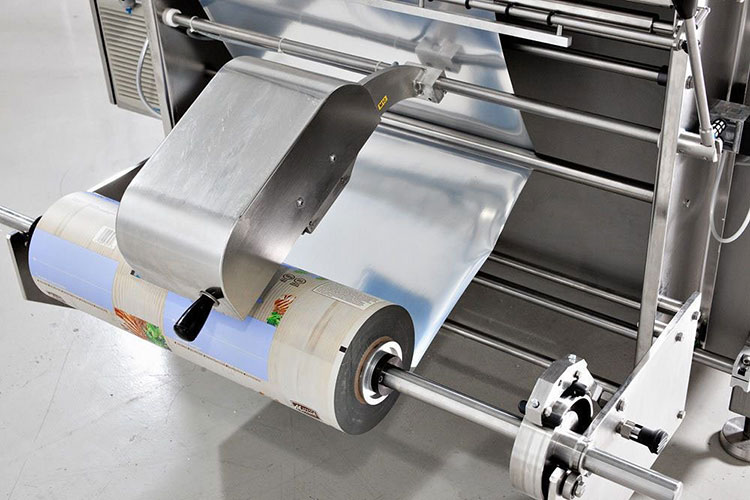

Sachet packing process- Picture Courtesy: recordpackaging.com

Stick-packs are bit expensive due to the production cost and separate machines required for their manufacturing. Compared to stick-packs, sachets are cheaper and more accessible to produce.

Industries

Various flexible packaging in food industry- Picture Courtesy: Landpack

Although, both forms of packaging, stick-packs and sachets are used in food and medicine industry yet, they differ in some applications. For instance, stick-packs are suitable for to store dietary supplements and instant drinks like coffee of various types. While as, sachets can be used to pack cosmetics and condiments.

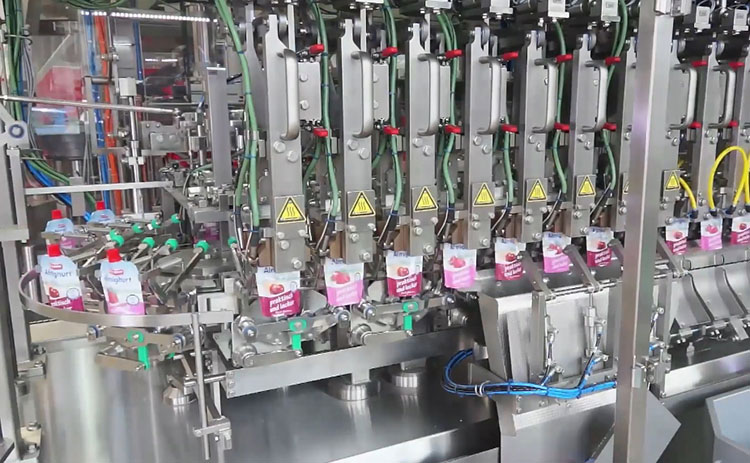

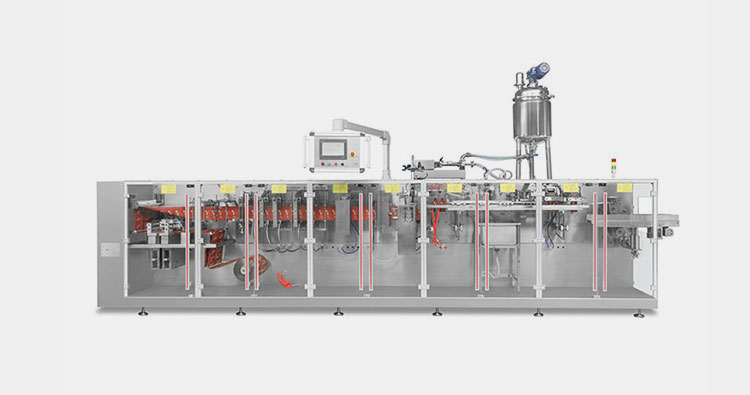

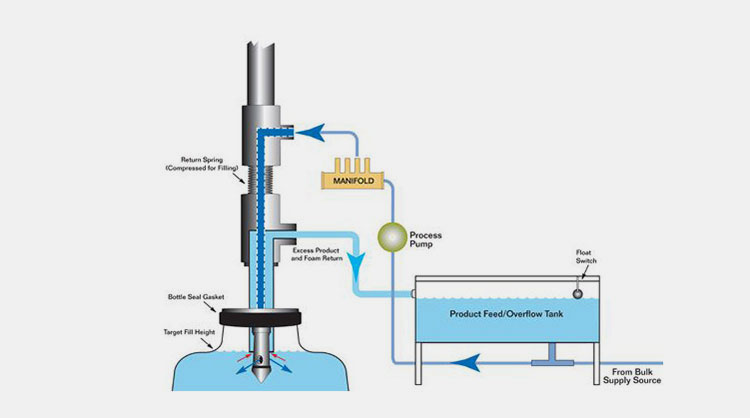

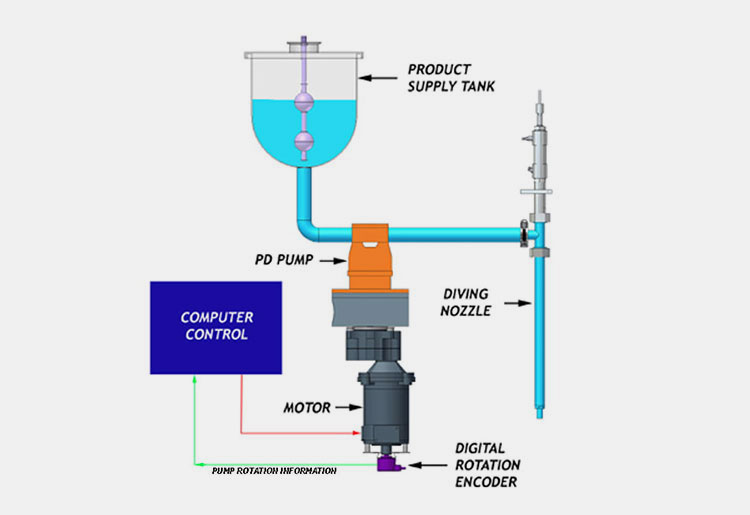

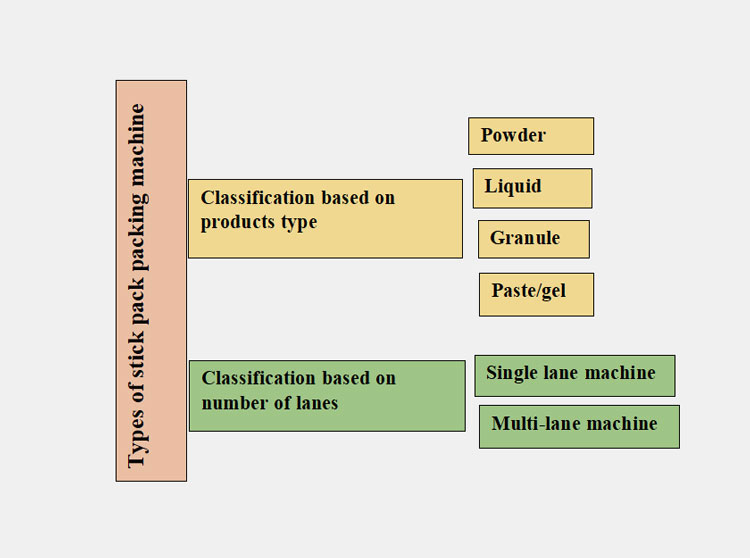

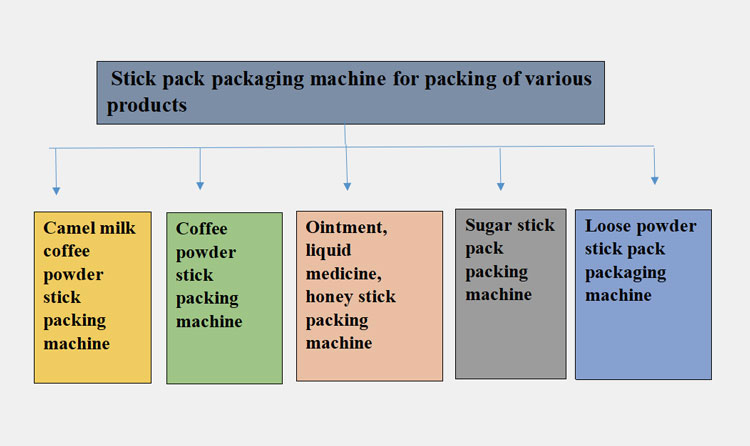

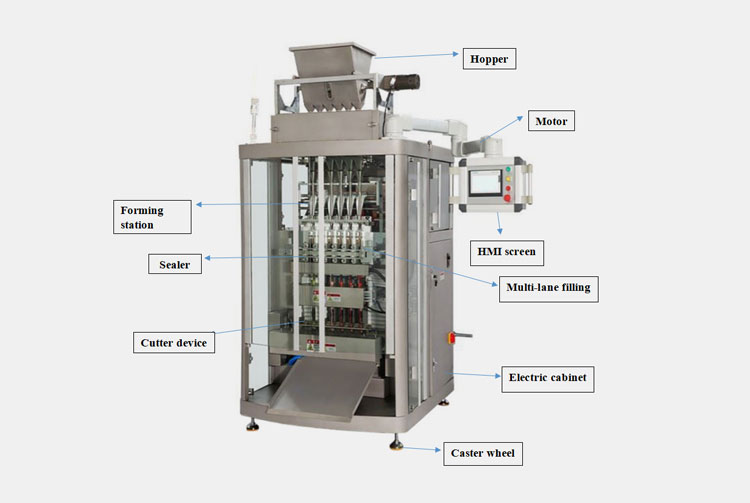

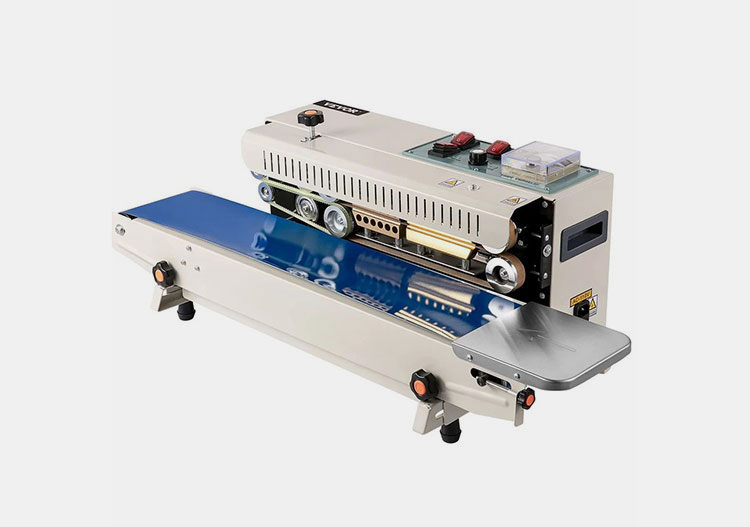

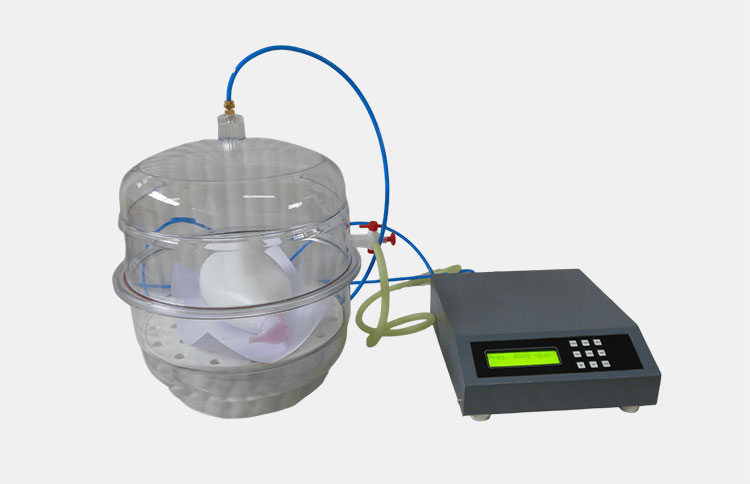

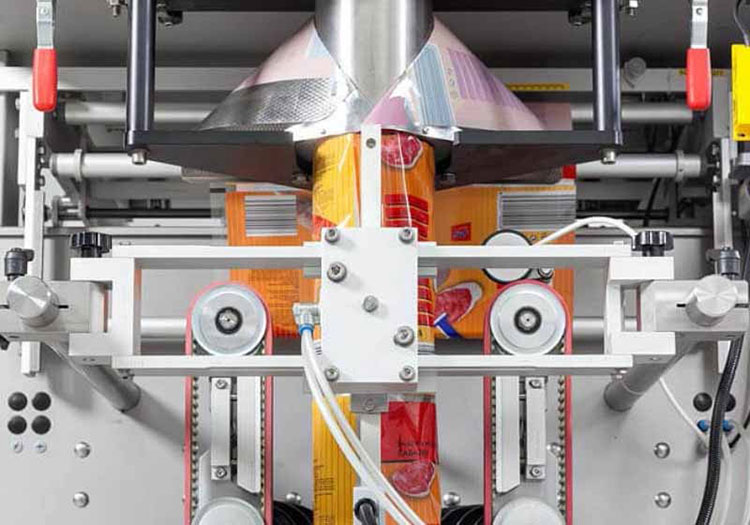

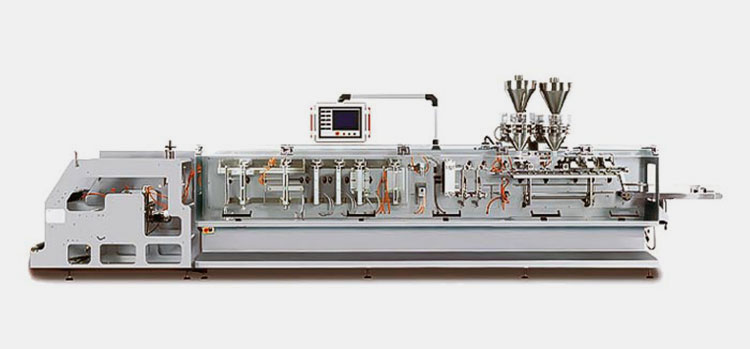

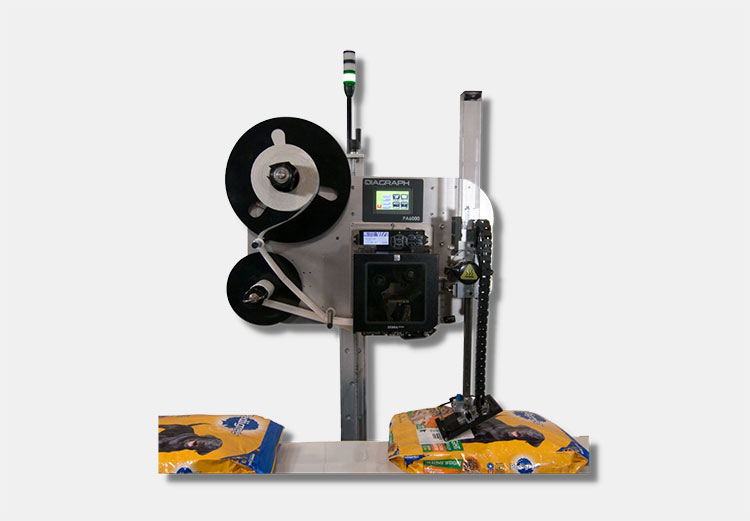

Required Machines

The machines used for stick-pack and sachets also differ. In addition, stick-packs are made using sophisticated machines including single lane stick packaging machine and multi-lane stick packaging machine. While as, the machines required for sachets include vertical sachet packaging machine and horizontal packaging machine.

12.What Are Emerging Trends in Flexible Packaging?

There are certain trends emerging in flexible packaging. These are also relevant to stick-packs and sachets. Therefore, exploring these trends are crucial when choosing between the two. Some of the popular emerging trends are as follows:

Sustainability

Sustainability- Picture Courtesy: news.sap.com

There is increased proclivity towards environmental protection which has led to the new trend of sustainability. Now, mono-material structures are used instead of multi layer films. It can contribute to easy recycling.

Source Reduction

The use of abundant resources has increased the production cost. In order to manage the resources required for flexible packaging, such as less use of material, the focus is now on making small packages. In this way, the best examples we have are stick-packs and sachets.

Functional Packaging

Recyclable sachets- Picture Courtesy: avrasiyabaku.az

Simple packaging is no more applicable in contemporary time as consumers look for convenience. For this reason, the functionality of flexible packages is now improved with the addition of resealable zippers, spouts and tear notches.

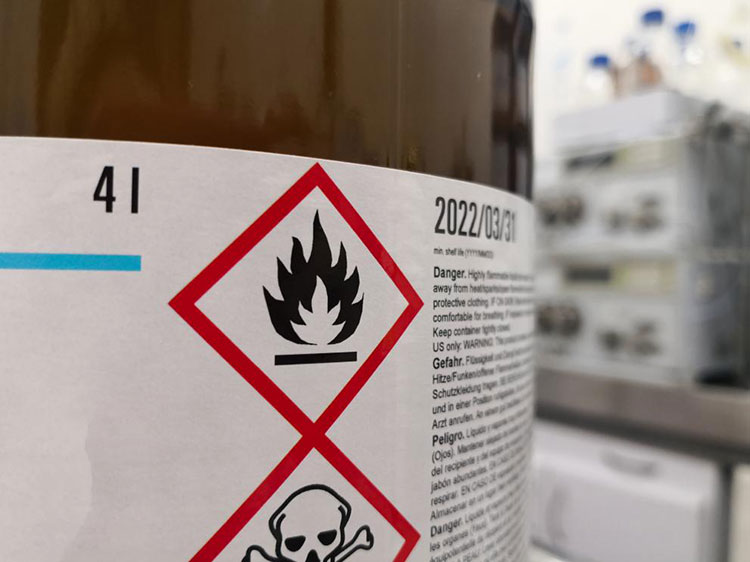

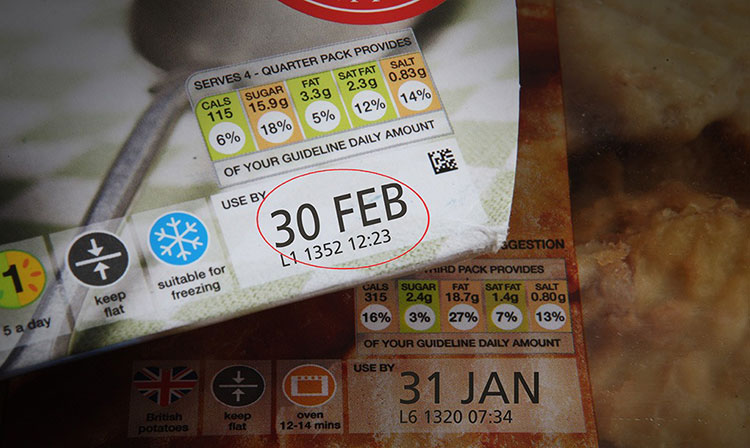

Use of Technology

Smart labels

Technology has greatly influenced the field of flexible packaging. Its use is now prevalent in form of digital labeling and Internet of packaging. Smart labels and customized labels are the common examples for enhanced transparency and updated designs respectively.

Conclusion

To put in a nutshell, the answer for Stick-pack and Sachet- Which Flexible Packaging Format Fits Your Product? lies in thorough analysis of understanding both forms of flexible packaging. It is necessary to look into your priorities and preference while choosing between both, the stick-packs and sachets, including production cost, flexibility and applications. Keeping in view the emerging trends such as sustainability factor, functional packaging and technology, it becomes more convenient to select for your business the compatible packaging format for which stick-packs and sachets qualify. To explore more about flexible packaging or related machinery visit our website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Stick-Pack vs Sachet — Which Flexible Packaging Format Fits Your Product? Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours