Shampoo Manufacturing: The Complete FAQ Guide 2025

Shampoo Manufacturing: The Complete FAQ Guide 2025

Are you curios about Manufacturing of shampoo? Do you know shampoo manufacturing comprises of specialized set of manufacturing protocol?

Shampoo is an essential hair care product purposely created for hair cleansing. They are used to remove extra sebum (natural oil) from hair without damaging hair. Shampoo manufacturing is not just about mixing and blending different ingredients. It comprises of precise blend of ingredient, advance equipment and series of testing measures to meet the consumer demand and expectation for safety.

Shampoo Manufacturing: The Complete FAQ Guide

This FAQ guide about shampoo manufacturing is created to educate manufacturer as well as general public about science and innovation behind this process. Let’s start this topic.

1.What is shampoo manufacturing?

Shampoo Manufacturing

Shampoo is specialized cleansing agent in which water is mixed with surfactant and other additive that will bind with water insoluble substance in scalp and rinse off without leaving residue which is not easily washed by water only.

Shampoo manufacturing compasses of several steps that transforms high quality raw material to final product which you see in super markets. It includes batch mixing quality assessment and final packaging in bottles. Each and every step require precise attention to meet the required quality and consistency in shampoo manufacturing.

There are different kinds of shampoo manufactured like medicated, anti- dandruff, dry shampoo, shampoo bar and many more with the evaluation of market trend and consumer demand.

2.How shampoo manufacturing is beneficial to manufacturer?

Shampoo manufacturing is beneficial in many ways to manufacturer. It shows promising fast pace production and filling of shampoo in record time. Now without further delay look into remarkable benefit of shampoo manufacturing.

Product quality

Product Quality-Picture Courtesy: Health

Shampoo manufacturing is automated process which means very less number of people required for monitoring and controlling the process that reduces chances of contamination. This way it increases quality and efficacy of final product.

Maintaining consistency

Maintaining Consistency-Picture Courtesy: Health

Maintaining consistency is crucial step for any manufacturer to retain its market presence. Shampoo manufacturing is automated process and high accuracy equipment are used which ensure perfect mixing and blending resulting in consistent texture and accuracy in each batch.

Reduce labor cost

Reduces Labor Cost-Picture Courtesy: Levapack

Shampoo manufacturing is highly efficient process and use of automated machine which result in labor cost. Due to automation, very less number of are required in process and high tech machine perform task repetitively with greater speed. This way need of manual labor reduces.

Increase production efficiency

Increase Production Efficiency

Shampoo manufacturing continuously produce large quantities at high speed due to automated machine with minimal use of manual labor. This process reduces production time and allows manufacturer to meet increasing demands of customer.

Minimal wastage product

Minimal Wastage of Product

Shampoo manufacturing follows automatic principle so every bottle gets adequate amount and no bottle is missed or overfilled. Accurate amount of ingredient mixed, blend and filled without any error. Shampoo manufacturing greatly reduces waste.

3.What are the primary ingredients used in shampoo manufacturing?

Shampoo manufacturing is a complex process in which various ingredients are carefully mixed together to create an effective product which can cleanse scalp with nourishing and conditioning catering specific hair concern. Let’s look into each ingredient that you find in typical shampoo.

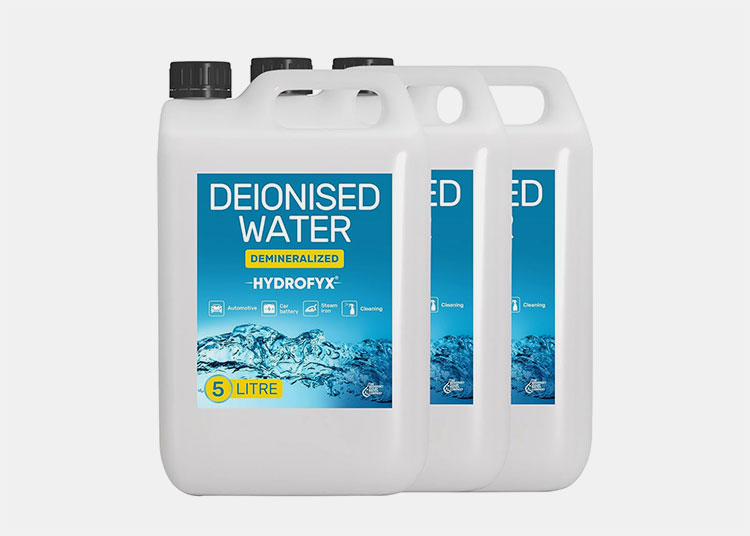

Deionized water

Deionized Water

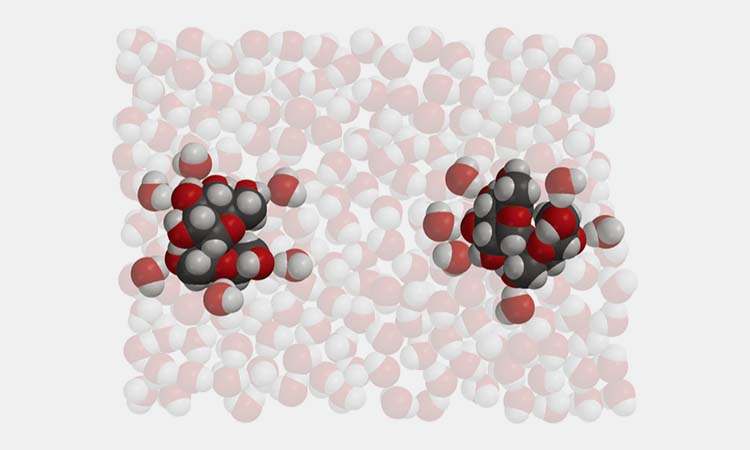

Most important ingredient in shampoo manufacturing is water as it is 70-80% of total shampoo and act as transport medium for blending and mixing of other additives. But the water used in shampoo manufacturing is not an ordinary tap water, it is deionized water.

Deionized water, is the water from which all mineral like calcium, sodium and magnesium, and other impurities are removed through deionization process. Why it is important to use deionize water? Because it free from all minerals, increasing its compatibility with other ingredients and all impurities are removed which reduce chances of microbial contamination and enhances its performance.

Surfactant

Surfactant in Shampoo Manufacturing

Surfactant are major cleaning agent in shampoo. It is added to aid foaming in shampoo manufacturing resulting in washing of dirt, oil and residue of hair care product on scalp. There are two different types of surfactant used in shampoo manufacturing

- Primary surfactant

- Secondary surfactant

Let’s discuss in detail function of each surfactant and how they are different from each other?

Primary surfactant

Primary Surfactant- Picture Courtesy: Pharma Excipients

Primary surfactant is main cleaning agent and they are mainly responsible for removing dirt, sebum and debris from scalp. They exert best foaming property and easily rinse off from hair without leaving residue. They easily mix with oil so remove dirt that are not washable with water.

Most commonly used primary surfactant are sodium lauryl sulphate (SLS) and sodium laureth sulphate(SLES) due to their lathering ability and, easy mixing of oil in water.

Seconadary surfactant

Secondary Surfactant –Picture Courtesy: Formula Botanica

Secondary surfactant is also known as co-surfactant. They are added to enhance overall performance of shampoo and other properties like mildness, conditioning, nourishing content and viscosity depending on customer demand. These effects are restored by combined effect of both or by only secondary surfactant properties.

Some of secondary surfactant used depending on manufacturer requirement are, cocamidopropyl betaine(CAPB) used for milder preparation and gives conditioning effects to hair, cocamidopropylamine oxide(CAO) added for stabilizing and enhancing foaming property, and alkyl polyglycoside are used as eco-friendly choice because it is easily biodegradable, and still gives good foaming and cleaning effect.

Thickeners

Thickener – Picture Courtesy: Cosmetic Ingredient

Thickeners are added in shampoo for various reason, although thickeners do not impart any role in cleaning and foaming properties of shampoo. Thickeners are added to enhance product stability hence providing even distribution of other ingredient.

Thickeners also facilitate in maintaining viscosity of shampoo. If shampoo is too thin it will run down from your hair and if it is too thick it will not easily spread or penetrate in hair. Appropriate thickness also gives product luxurious feel and enjoyable to use for consumer.

Shampoo manufacturing with desired viscosity provide consumer better overall experience and effectiveness. There are so many options available for thickeners used in shampoo manufacturing like xanthan gum, guar gum, hydroxyethyl cellulose, carbomer and many more depending on manufacturer requirement.

Conditioning agent

Conditioning Agent- Picture Courtesy: Radici Hair Studio

We all know that main function of shampoo is to clean and remove dirt oil. But due to evolving market trend and consumer demand of shampoo with other additional benefit like conditioning, nourishing and repairing of hair are gaining popularity.

Incorporating conditioning agent in shampoo enhances overall performance by providing protection, nourishment and give smooth texture to hair. It makes hair silky and detangle which are easily manageable and give smooth look to hairs.

There is some common conditioning agent which you find in most of commercial shampoo manufacturing are silicones which include dimethicone, natural oils like coconut oil and argan oil and fatty alcohols like stearyl and cetyl alcohol.

Preservatives

Preservative

Preservatives are crucial component in shampoo manufacturing. Preservative are added in formulation to extend shelf life and prevent contamination from microbial growth like mould and fungi. It is also needed to make sure the product is equally effective and safe to use till mentioned expiry.

Few examples that are frequently use are potassium sorbate and sodium benzoate etc. You have to keep in mind few factors while selecting preservative like pH level, composition of product and desired shelf life.

Fragrance and colorant

Fragrance and Colorant-Picture Courtesy: On Line Hair Depot

Fragrance and colorant doesn’t add any advantage to product performance. It is added to give eye appealing look for user experience. fragrance help to build customer loyalty and enhances product market demand. Fragrance and colorant used may be derived for natural resources or synthetic.

It is also considered while adding colorant that it is evenly dispersed in formulation which is achieved by different dispersion technique and advance equipment.

pH adjuster

pH Adjuster- Picture Courtesy: Cosmetic Formulator

pH is an important factor in maintaining stability and performance of shampoo. Desirable pH for shampoo is 4.5-6.5.

What pH adjuster do? It can increase and decrease pH of shampoo. If pH is too high it makes hair dry and brittle, while very low pH can irritate scalp.

In most of shampoo manufacturing, citric acid and lactic acid and sodium hydroxide is used as pH adjuster. It is also critical that pH adjuster is also compatible with other ingredient and do not cause any adverse effect

Humectant

Humectant- Picture Courtesy: Gisou

Humectant is essential ingredient in shampoo that retain moisture and prevent over dryness in hair. It also restores hydration level in hair which is damage from over stripping of natural oil by surfactants.

Most shampoo manufacturer add glycerin, sorbitol and propylene glycol as humectant in their formulation to make hair soft and manageable.

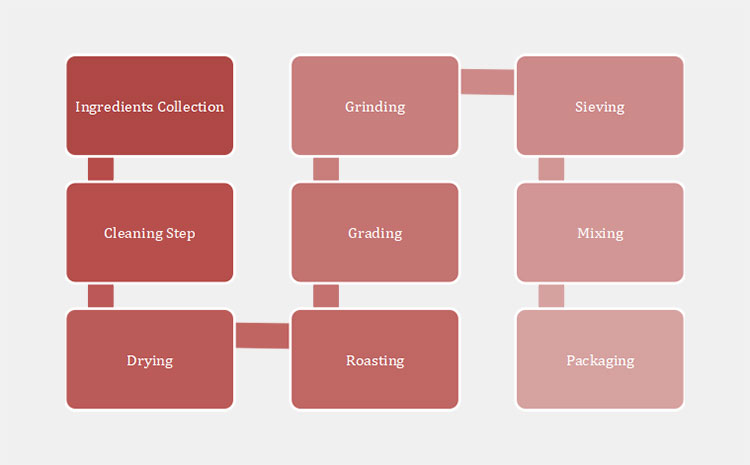

4.What is the step by step process in shampoo manufacturing?

Shampoo manufacturing is a time taken process involve multiple steps which you need to strictly monitor so you get consistent and quality product every time. Here is the more detailed breakdown of each steps.

Selecting and preparing raw ingredient

Selecting and preparing Raw ingredients- Picture Courtesy: Roam and Thrive

Selecting raw ingredient is crucial step in manufacturing consistent and quality product. Selecting ingredients starts from choosing right surfactant which is important for cleansing to other additive ingredient which is added for specific hair benefits.

After selecting perfect ingredients process start by preparing and pre dissolving solid ingredient like some surfactant and thickener that are solid are dissolve in deionized water to ease incorporation in mixture.

Other ingredients are added in specific sequence like secondary ingredient and conditioning agent are added after base is prepared. This step avoids any premature reaction.

Mixing and blending

Mixing and Blending in Shampoo Manufacturing-Picture Courtesy: TY Cosmetic

In second phase, ingredients are mixed in large mixing tank in a specific manner. Mixing and blending is critical step in shampoo manufacturing because it ensures that you will get perfect consistency in every batch.

This purpose is served by using different agitators and high-shear mixer which ensure thoroughly mixing of ingredients. The duration and speed of mixing is also play important role in achieving uniformity in mixture.

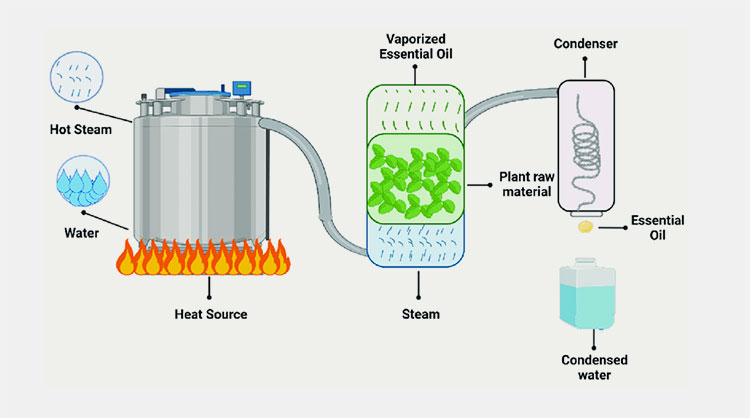

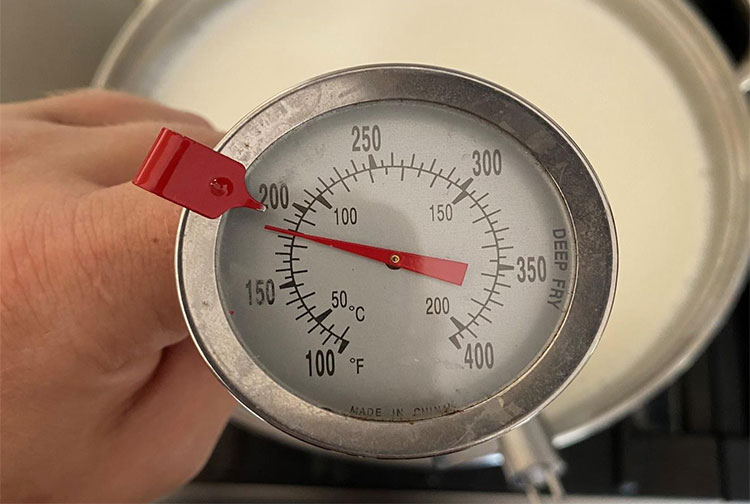

Heating and cooling

Heating and Cooling

This process is incorporated because certain ingredient required specific temperature to dissolve or activate. Heating assist dissolution of certain ingredients like thickeners and it also facilitate emulsification.

After that temperature is cooled down to introduce heat-sensitive ingredients like fragrance, preservative and coloring agent without affecting its performance.

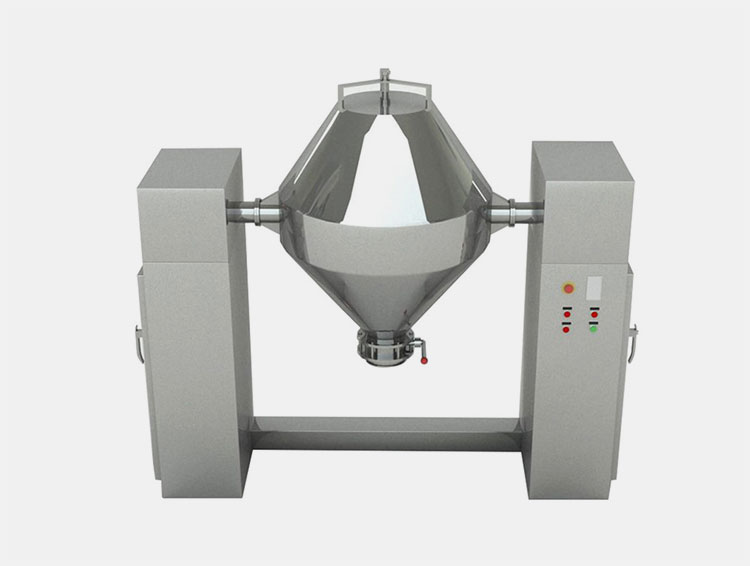

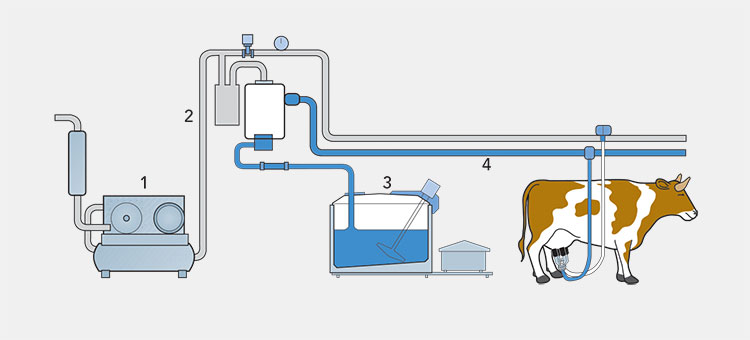

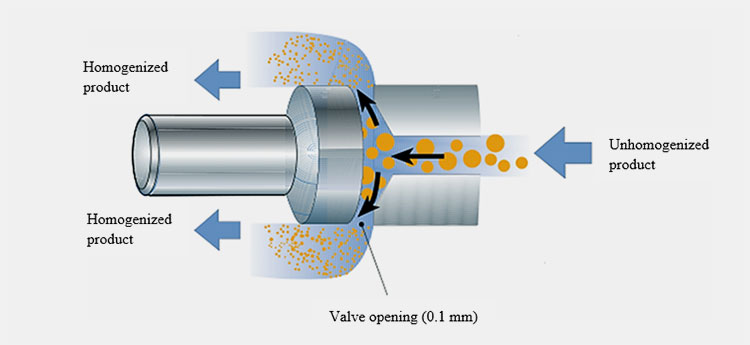

Homogenization

Homogenization

Finally, mixture is passed through homogenization process to ensure uniformity throughout the mixtures. This purpose is best served by homogenizer. In this step mixture is mixed at high speed which lead to reduced particle size creating consistent and smooth texture of shampoo.

Homogenization is most important step in shampoo manufacturing for achieving desired texture and all ingredients are evenly distributed throughout the mixture.

Quality checking

Quality Checking- Picture courtesy: Jochamp

Quality testing is done for different parameters to check whether the product up to desired quality and competency. Each batch undergoes rigorous testing for pH, stability and viscosity. pH range which is considered ideal for shampoo that does not irritate scalp is 5-7. This initial testing process determine how much pH need to adjust

Same goes with other parameters like viscosity is determined and adjust according to requirement. Batch is also checked for product stability and this step ensure shelf life of shampoo after packaging and reduced chances of layering and separation.

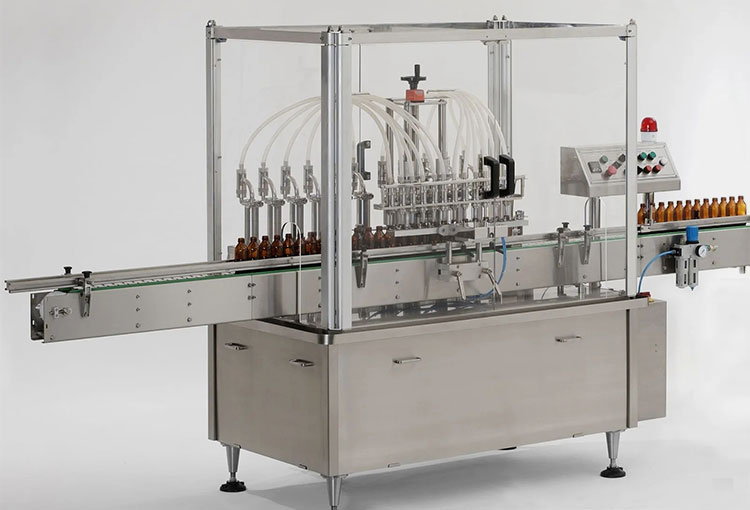

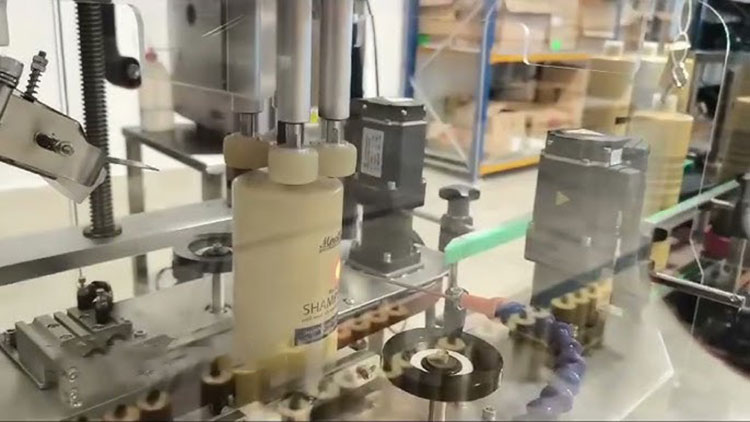

Filling and packaging

Filling and packaging- Picture Courtesy: Makwell

After batch is thoroughly checked for quality, the shampoo mixture is moved to filling area. First appropriate container is selected for filling then bottles are placed in automated filling machine which fill bottles with precise quantity of shampoo. These machine are calibrated to fill each bottle with exact amount.

After filling, bottles are closed and sealed to prevent leakage and contamination. Seals may vary from simple screw cap to pump dispenser. These automated machine reduce labor cost and make production faster.

5.What kind of machinery frequently used in shampoo manufacturing?

In production line of shampoo manufacturing some of important equipment are used to make process effortless, faster and cost effective without compromising quality and efficacy of final product. Some major machinery which can see in every shampoo manufacturing are described below.

Mixing Tanks

Mixing tanks are large stainless steel container which are used to mix large batches of surfactant and other ingredient in water to make uniform mixtures. These tanks usually include agitator and high-shear mixer that ensure even mixing and stirring. Let’s describe each mixer individually.

Agitator

Agitator Mixer –Picture Courtesy: Haosh

Agitator are specialized equipment placed in mixing tank which ensure uniformity in shampoo mixture inside the tank. This equipment is frequently used in shampoo manufacturing.

The basic principle of agitator based on rotating impeller induce flow and shear force imparting homogenization of one or two ingredients. This equipment ensures uniformity throughout the mixture and maintain consistency in shampoo manufacturing.

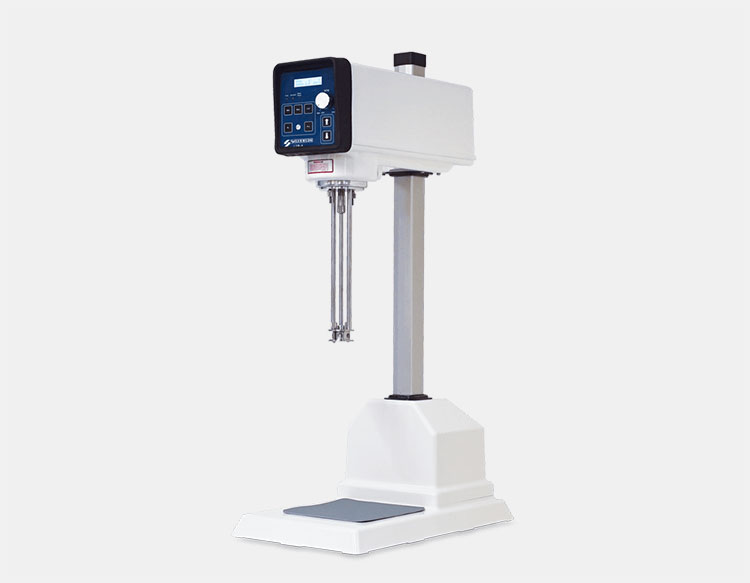

High-shear mixer

High-Shear Mixer-Picture Courtesy: Tetra Pak

High shear mixers can break up clumps and used to emulsify, homogenize, disperse and dissolve immiscible mixture. Tighter particle size ensures consistency, uniformity and optimal performance of your final product.

High shear mixer revolves around the concept of shear force. The mixer consists of a rotor that rotates at high speed within a stationary stator. The constantly moving rotor create centrifugal force while the stator remain stationary creating shear force resulting in reduced particle size and leading to evenly dispersed mixture.

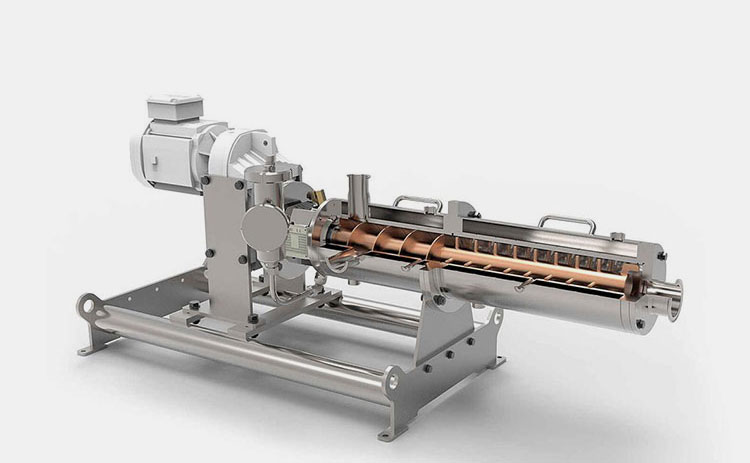

Vaccuum emulsifier mixer

Vacuum Emulsifier Mixer- Picture Courtesy: Pharmaceutical Machinery

The vacuum emulsifier mixer tends to mix immiscible liquid by reducing surface tension between liquid. It also disperses, homogenize, aspirate very viscous ingredients making them easier to blend and mix.

Vacuum emulsifier work on basic principle shear disperse force. It worked by heating water or oil based in separate container then they are suck into emulsifying pot, where they quickly dispersed and emulsified by high shear impeller blade making mixture homogenized. As emulsifier is in vacuum condition it removes all air bubble which are produced during mixing liquid making your shampoo shinier and homogenized.

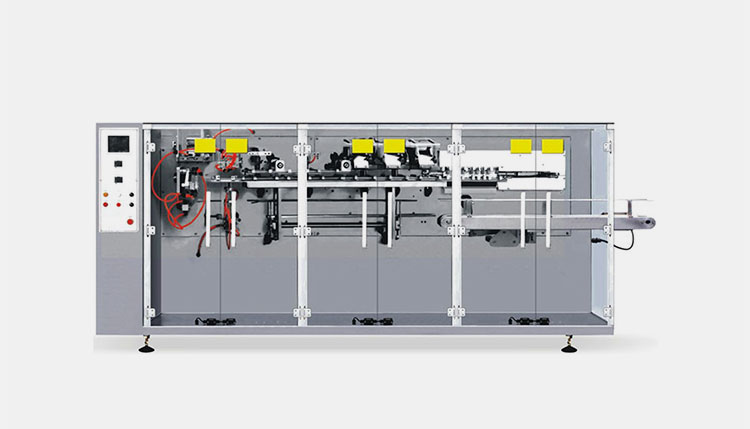

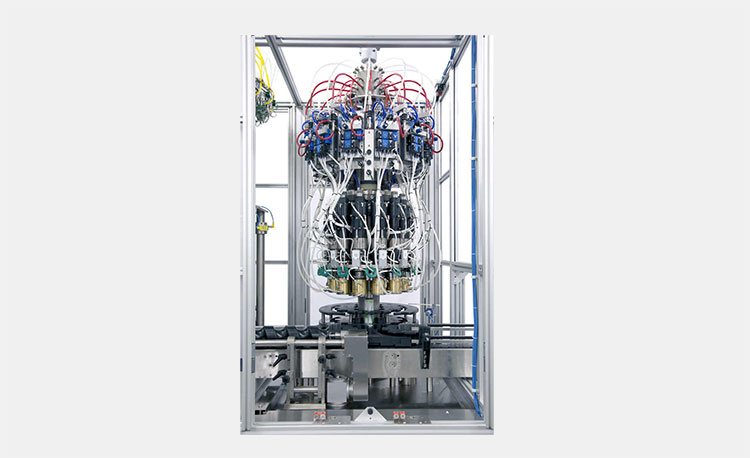

Filling machine

The filling machine is used to fill accurate amount in tubes. There are so many filling machines. Let’s talk about them in detail.

Automatic shampoo filling machine

Automatic Filling Machine

Filling machine is integrated automated machine which used to fill shampoo bottles with precision and accurate consistency minimizing wastage and spilling of shampoo.

The basic principle of filling machine is consisting of conveyer belt which automatically hold bottles by itself and carrying it to filling nozzles that fill each bottle with desired amount which was pre-set in the filling machine. The correct integration and speed is crucial in filling machine for accurate filling and increase production rate.

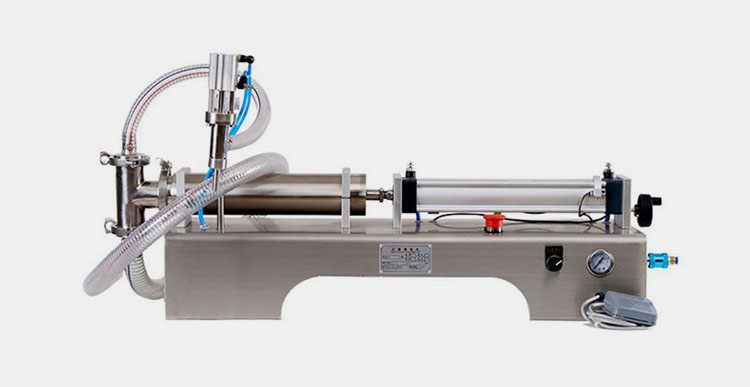

Semi-automatic shampoo filling machine

Semi-Automatic Shampoo Filling Machine

Semi-automatic machine is another type of machine used in shampoo filling process. It is cheaper and convenient to use.

The main principle of semi-automatic machine is you need to place bottles on holder and machine fills in automatically. It has multiple heads you fill number of bottles at a time. It is good low scale production because of cheaper value as compared to automatic machine.

Manual shampoo filling machine

Manual Shampoo Filling Machine

Manual filling machine work on simple process you need to put bottle below nozzle and pulls the lever but you need to adjust volume by close monitoring. This equipment needed undivided attention to overcome spilling and wastage. It is cheaper version easy to use and clean.

Capping machine

Capping Machine

After completion of shampoo filling process, bottles are tightly closed by caps to avoid spilling and contamination of product.

Capping are also done by automated machine in which bottle is sent from filling unit to sealing or capping unit through conveyer belt where automated machines sealed the mouth of bottles with caps and preserving its efficacy and freshness. These machine reduces manual labor as well increasing production rate.

6.How different industries incorporating shampoo manufacturing in their practices?

Nowadays shampoo manufacturing is greatly expanded and used in various larger industries in formation of different product such as:

Pharmaceutical industry

Pharmaceutical Industry-Picture Courtesy: EZO

In pharmaceutical industries various ointment, medicated cream and lotions are also prepared through same process of shampoo manufacturing. Such as mixing and blending of solid in liquid phase, homogenizing the mixture, heating and cooling etc., all above mention procedure are also used in manufacturing pharmaceutical grade product.

Food industry

Food Industry-Picture Courtesy: The Sun

There is huge application of shampoo manufacturing process in food industry. Nowadays you used different sauces like ketchup, mayonnaise and different seasoning; they are also produced with same process. Shampoo blending, mixing, filling and packaging machines are used in food industry as well.

Chemical industry

Chemical Industry-Picture Courtesy: Royal Talens

In chemical industry product like hair dyes, paint, cleaner, polishes, water and oil colors are prepared through same process used in shampoo manufacturing. Some related equipment is also used for effective production in chemical industry.

Veterinary Industry

Veterinary Industry-Picture Courtesy: The Independent

In previous time there is no proper hygiene product available for pets so it quite difficult to treat take care of them. Now due to emerging demand we see lots of veterinary grooming products. There we see another application of shampoo manufacturing process; pets shampoo and body wash are formed with same process.

Cosmetic industry

Cosmetic Industry

Cosmetic industry is a diverse field in which many products are manufactured through same process which are used in shampoo manufacturing. Like BB creams, foundation and lip product used same process and even some equipment are also same.

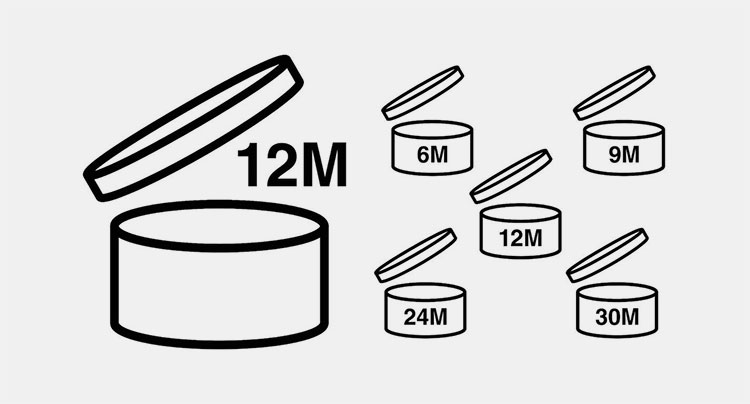

7.What is the expiration of shampoo manufacturing product?

Shelf Life of Shampoo-Picture Courtesy: Function

After manufacturing, Shampoo may last up to 2 to four year if unopened. But if opened it may not last more than 6months to 2 years. This extended shelf life is achieved by adding preservative and stabilizer in formulation.

It helps in inhibiting microbial growth, balance pH under desired range and preserving integrity of ingredient. But natural shampoo has shorter shelf life as compared synthetic shampoo. Because natural preservative is less potent than man made.

In cosmetic product expiry date are not mentioned they are calculated on the basis manufacturing or either from opening container mention I above picture.

8.What are the common challenges manufacturer faces in shampoo manufacturing?

Some of common challenges in shampoo manufacturing and provide solution to overcome the challenges

Inappropriate mixing

Inappropriate Mixing-Picture Courtesy: TY Cosmetic

Inappropriate mixing challenge occur due to many factors. Mixer may not be properly design to mixing the shampoo ingredients this may lead to inconsistencies in shampoo formulation.

Solution

Manufacturer may follow the proper mixing protocols. Sensor monitoring to enable proper mixing and calibrate different parameters to stable the accuracy of shampoo.

Foaming during shampoo manufacturing

Foam Formation

Another major challenge face in shampoo manufacturing is formation of foam during manufacturing. Due to this filling operation inaccuracy may occur which may lead to effect the product foaming.

Solution

Use of anti-foaming agent may control the foaming formation. Stable mixing speed and thermal control may also control the excess foam formation

Disintegration of Equipment

Equipment Disintegration

Ingredients of shampoo is erosive in nature like detergent and surfactant due to this it can damage the equipment.

Solution

To control the equipment disintegration, use of stainless steel and some protecting material or maintenance of equipment may increase the life span of equipment

Leakage

Leakage-Picture courtesy: PhotoDune

Leakage in shampoo manufacturing plant may lead wastage of product and increase the chances of contamination. It also greatly impacts production rate of shampoo manufacturing plant.

Solution

Sealed all the machinery part in which shampoo manufacture this may control the leakage and hence decrease wastage of product.

Machine Sterilization

Sterilization of shampoo machine may control contamination. Cleaning of equipment all parts may further enhance the hygiene and reduce contamination

Conclusion

Shampoo is an essential product for hair care hygiene. In this article we have deeply learned science and innovation behind this unique process. Understanding the complex process of shampoo manufacturing equips business people with insight to produce high quality shampoo product. This guide gives you strong in depth knowledge to excel in manufacturing and ensuring product meet both set standard and customer satisfaction. For more business seeker advice, you can contact our expert team of customer services. Our dedicated team will give solution to your problem.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Shampoo Manufacturing: The Complete FAQ Guide 2025 Read More »

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours