Glass Bottling Machine: The Complete FAQ Guide in 2025

Glass Bottling Machine: The Complete FAQ Guide in 2025

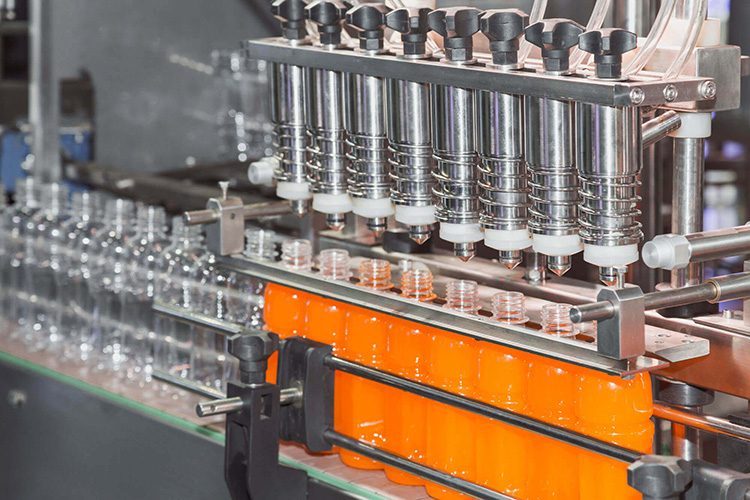

In today's fast-paced consumer market, the demand for efficiently and precisely packaging products in glass bottles has never been higher. Glass bottling machines are the unsung heroes behind the scenes, ensuring that everything from beverages to sauces, oils, and cosmetics is packaged flawlessly.

In this blog post, we will explore the ins and outs of glass bottling machines, shedding light on their working mechanisms, capabilities, and the benefits they offer to businesses. Whether you're a manufacturer looking to streamline your production line or a curious enthusiast interested in the intricacies of bottle packaging, we've got you covered.

Join us as we unravel the secrets behind these remarkable machines and discover why they are indispensable in the realm of modern packaging.

1.What Is A Glass Bottling Machine?

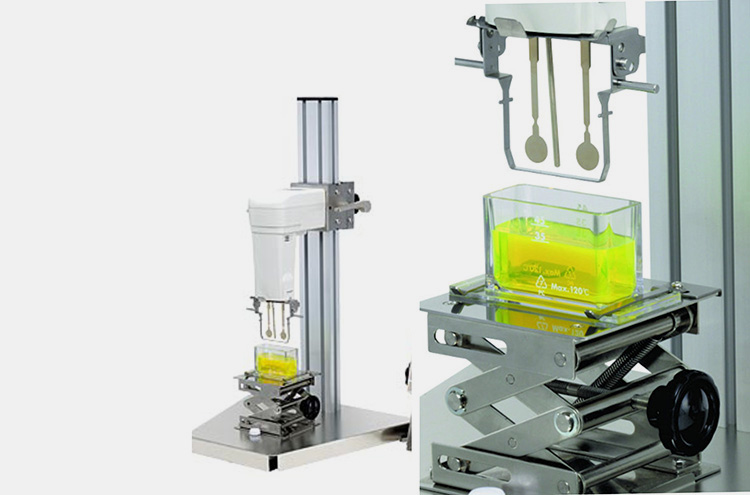

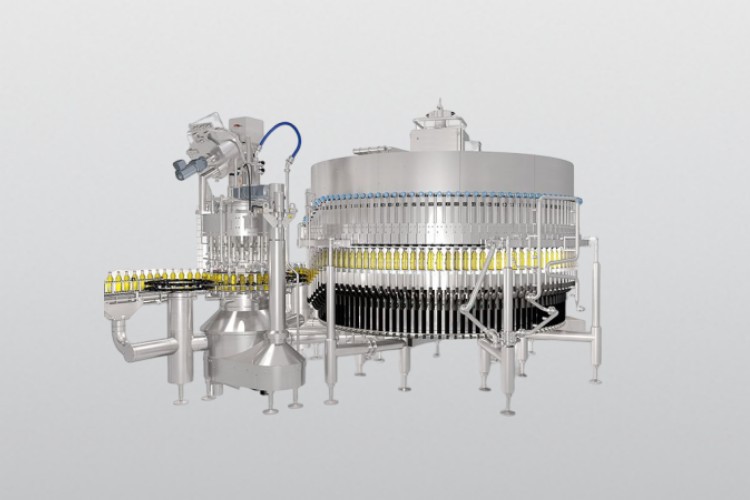

A glass bottling machine is a device that is used to package beverages into bottles made of glasses. Normally, the machine is automated and uses a range of technologies or processes such as filling, capping, labeling, and packaging for efficiency in production.

Glass bottling machines are used in many food and beverage processing facilities to bottle beer, spirits, soda, juice, and other beverages into glass bottles. This system of machines is designed to handle a variety of bottle sizes and shapes with minimal operator interaction, making it an easy-to-use choice for many production lines. In addition, the machine often incorporates safety features such as guards for operators and conveyor belts that stop when necessary.

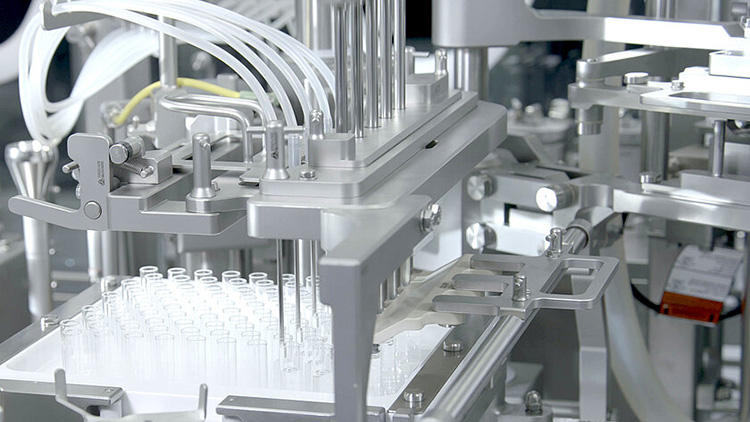

2.What Are The Key Components Of A Glass Bottling Machine?

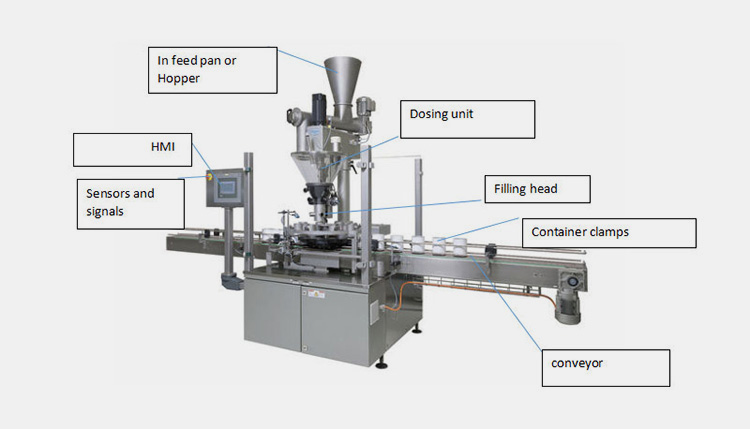

A glass bottling machine is technically composed of several components that work together to package liquids into bottles. The main systems of a glass bottling machine are:

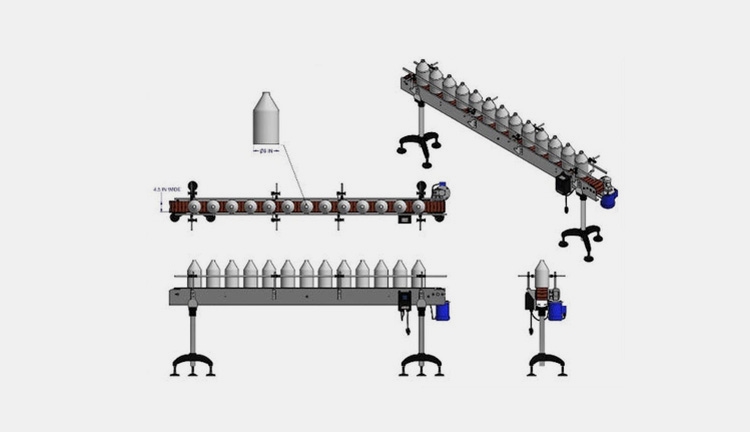

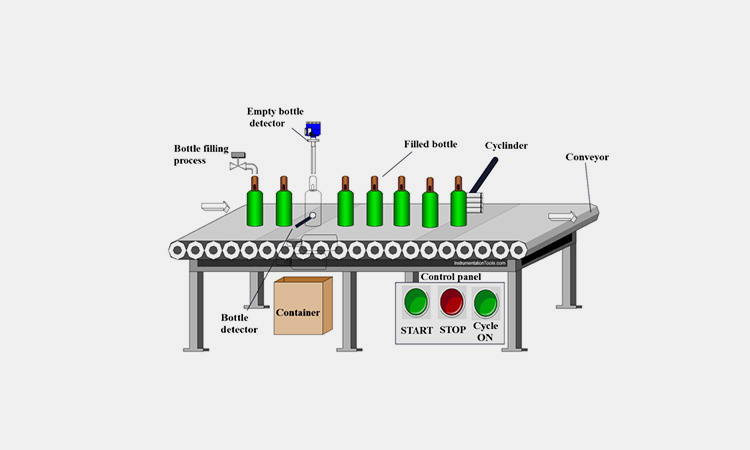

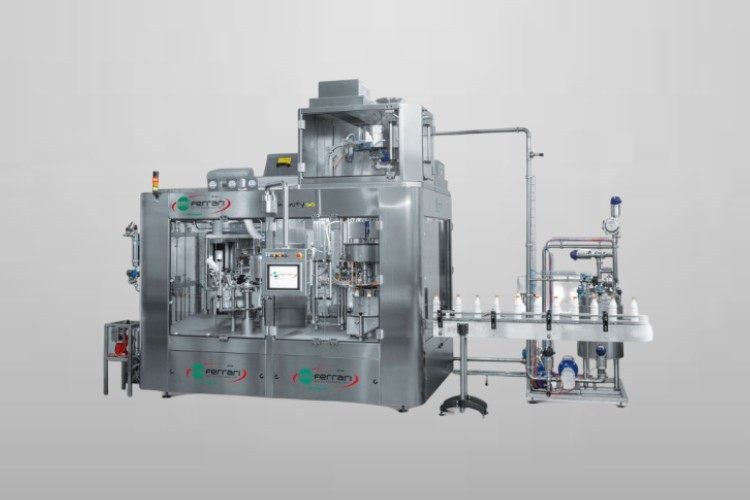

Conveying System

The conveying system is responsible for moving the bottles through various stages in the bottling process. It typically consists of a roller conveyor or a belt system designed to transport the glass bottles from one station to another.

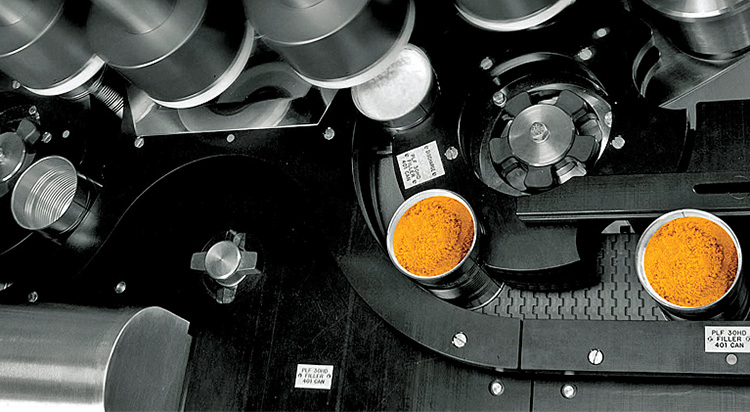

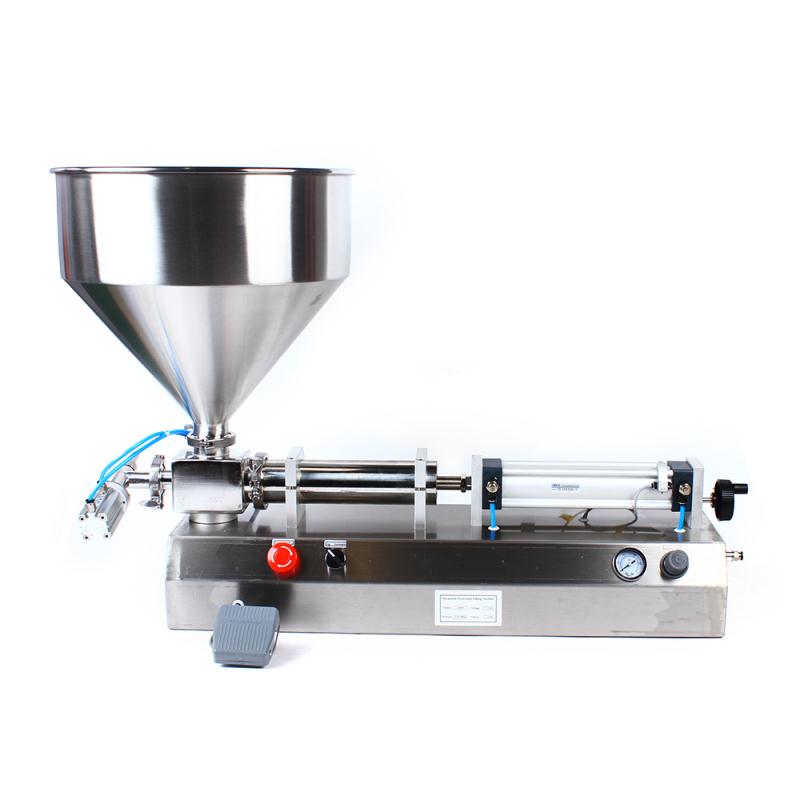

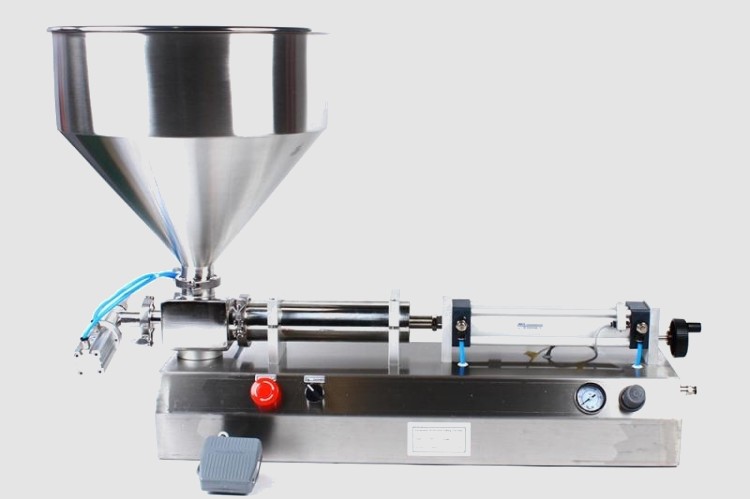

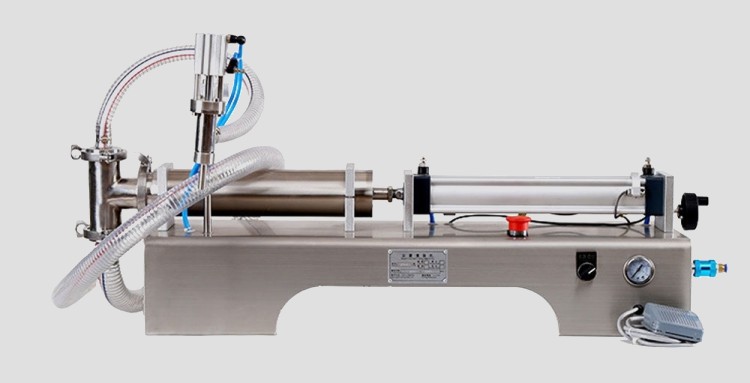

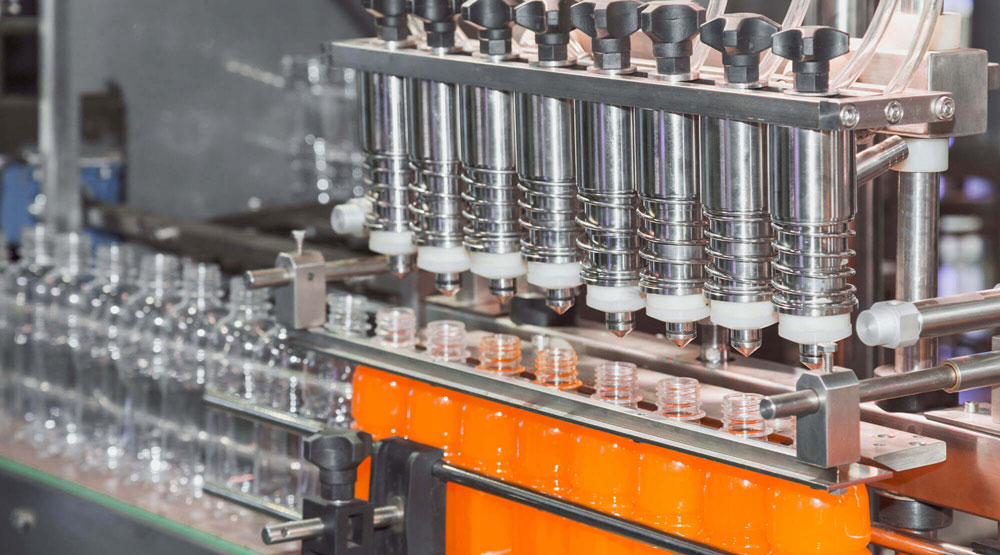

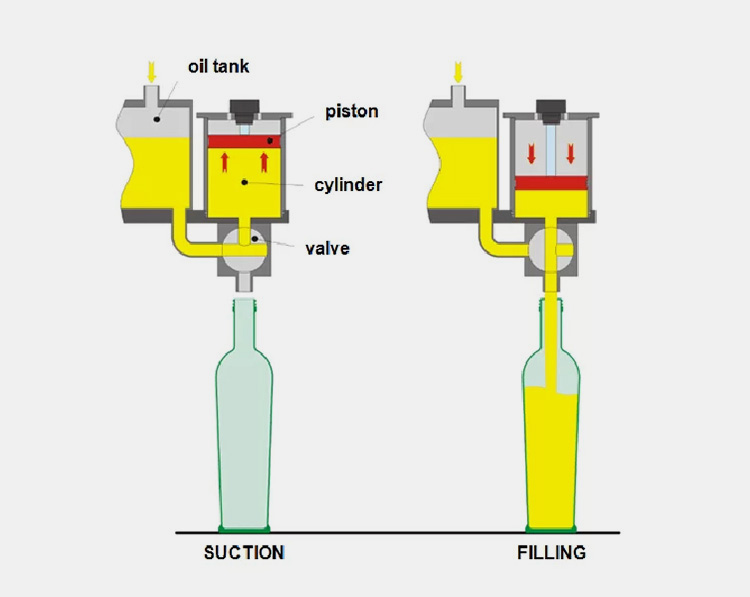

Filling system

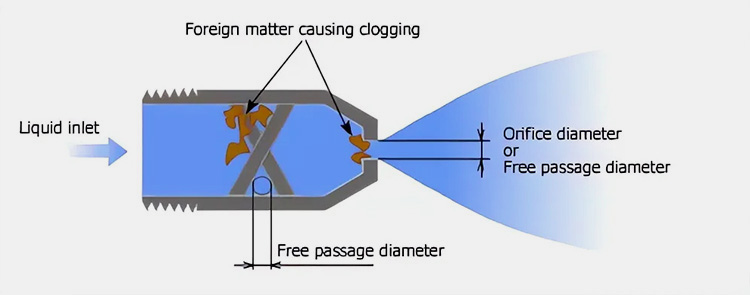

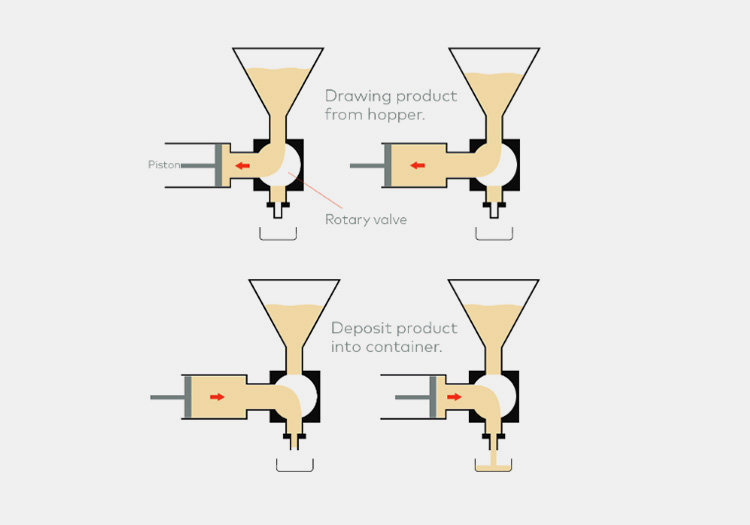

This component is responsible for filling each bottle with a specific volume of materials or liquids. It usually consists of a cylinder, a piston, and valves to control the dispensing of the liquid or materials.

Sealing/capping System

This component does the sealing of each bottle with the desired type of caps or closures. They can range from manual capping machines to fully automated systems that use a variety of methods such as heat-sealing, crimping, and induction sealing.

Labeling System

This is the component that is responsible for printing labels onto the bottles before they are packaged and shipped. Typically, it consists of a printer or an inkjet system that prints labels or codes directly onto the glass bottles.

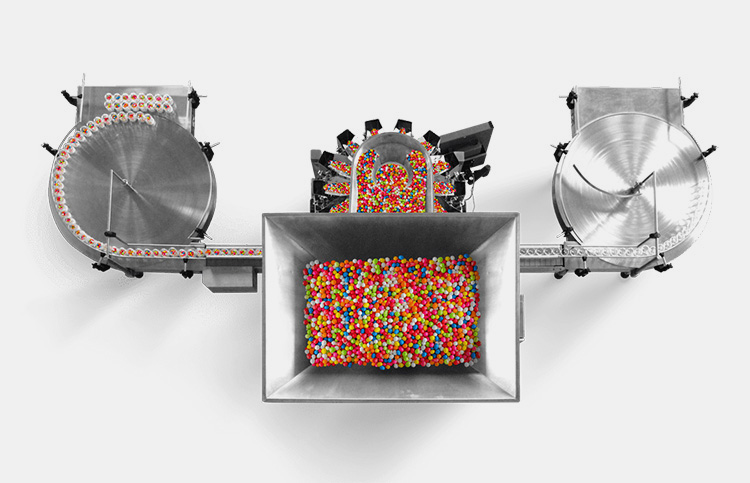

Packaging System

This component is responsible for packaging and boxing the glass bottles after they are filled, sealed, and labeled. It generally consists of an automated system that arranges the bottles into boxes, cases, or pallets and seals them before shipping.

3.How Does A Glass Bottling Machine Work?

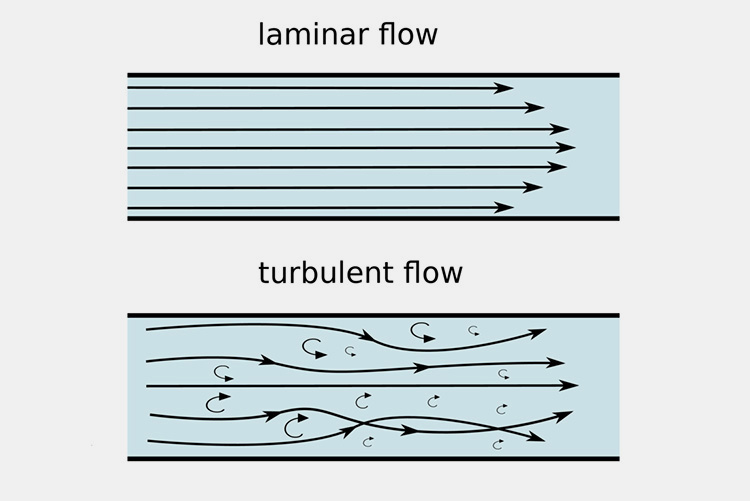

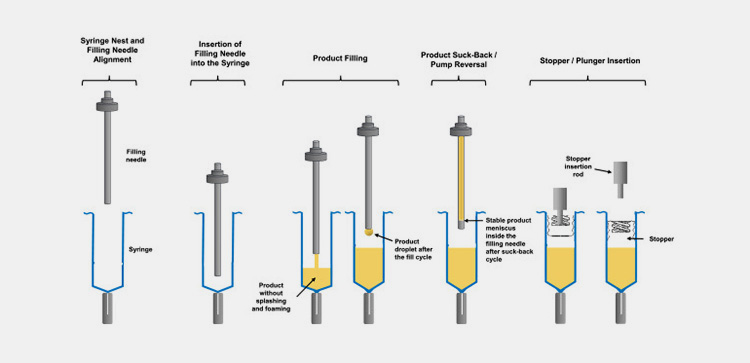

The first step in this cycle is the infeed conveyor, which transports empty glass bottles from storage to the rest of the machine. The bottles are then moved into a cleaning station where they are sanitized with water and air before filling is done.

After the bottles are clean they are then moved at the filling station, the products are dispensed into each bottle at a precise rate according to predetermined levels or volumes. Then, a vacuum filler suctions out any air that may be present in the bottle before filling.

The next step is sealing the bottles using capping machines. These machines attach lids or screw caps to the tops of the now filled glass bottles. The capping machine also inspects each lid for proper fit and seals it onto the bottle precisely.

Once these glass bottles are sealed, they move to the outfeed conveyor where the finished product is carried away from the machine for packaging and shipping. The glass bottling machine then repeats the entire process for each new batch of product that needs to be packaged and filled.

This automated system has made it easier for businesses to quickly fill large quantities of bottles in a very short period of time. Glass bottling machines are very efficient and reliable, making them a popular choice for industrial applications

4.What Are Some Of The Applications Of A Glass Bottling Machine?

Beverage bottling

A glass bottling machine is used to fill and package beverages such as soft drinks, beer, wine, juice, and water into bottles made of glass. The machine ensures accurate filling levels and delivers consistent quality output. It can also be used for carbonated beverages with its special settings.

Pharmaceuticals

A glass bottling machine can be used to package pharmaceuticals such as creams and ointments into bottles made of glass. The machine is designed to provide accurate filling levels, ensure the contents remain sterile, and deliver better-quality results.

Foods

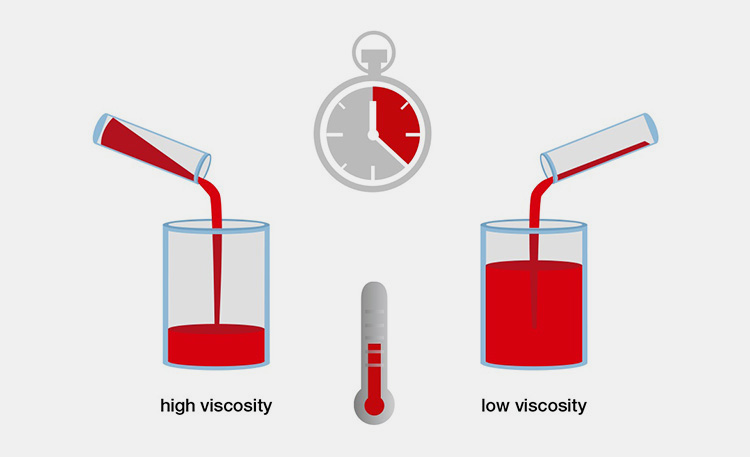

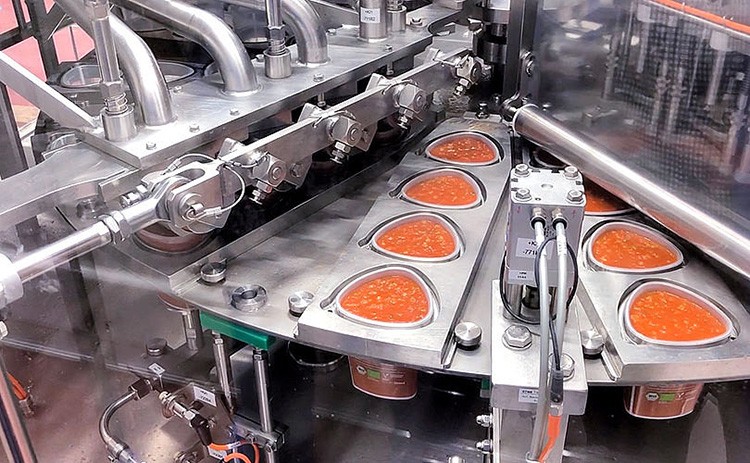

Glass bottling machines are also used for packaging food items such as sauces, jams, pickles, and other condiments. This device ensures filling desired levels and can be used to package products with different viscosity levels.

Perfumes

This equipment is also suitable for packaging perfumes into glass bottles

Cosmetics

Glass bottling machines are also used in packaging different cosmetics such as lotions, creams, and gels into different glass bottles. Its special nature with its settings ensures accurate filling levels and consistent quality output that makes it a good tool in the cosmetic industry production line.

5.What Are The Advantages Of Using A Glass Bottling Machine?

Glass bottling machines offer a variety of advantages for any business that uses them. Here are some of the benefits;

Cost-Effective

Glass bottling machines are incredibly cost-efficient and require less labor, as the process is automated it reduces the overall cost of glass bottling production.

Adaptability

A glass bottling machine can be adapted to fill and seal different types of bottles with varying sizes and shapes precisely allowing manufacturers to meet the demands of their consumers.

Flexibility

Different types of bottle shapes and sizes can easily be filled and sealed with a glass bottling machine, allowing for versatility in production.

Quality Assurance

Glass bottles produced by machines are more consistent in shape and quality than those made manually; this ensures that the product is of the highest quality.

Correctness

The automated cycles of this machine result in more precise daily production outcomes. This ensures that there is uniformity in the overall production process as well as high-quality output results.

6.What Types Of Glass Bottling Machines Are Available?

There are two types of glass bottling machines available that can suit your range of needs and budgets. Some may be used for producing single bottles, while others are designed for mass production. Most glass bottling machines consist of a combination of automated machinery that can fill, label, cap, and package the product. Depending on the product being bottled, some machines may also be equipped with additional features such as conveyor belts.

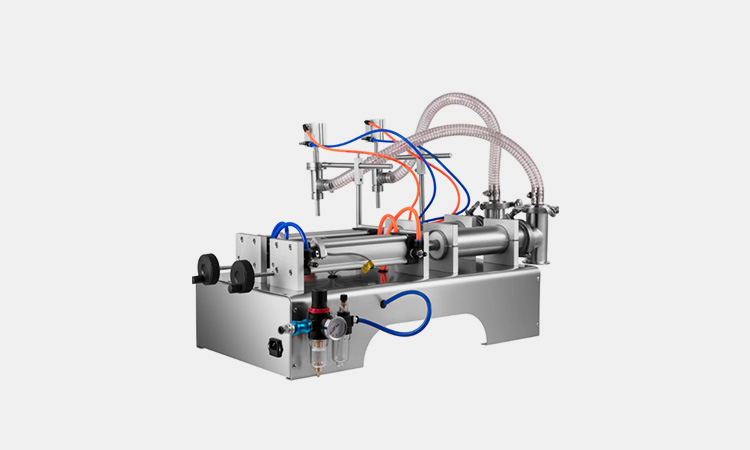

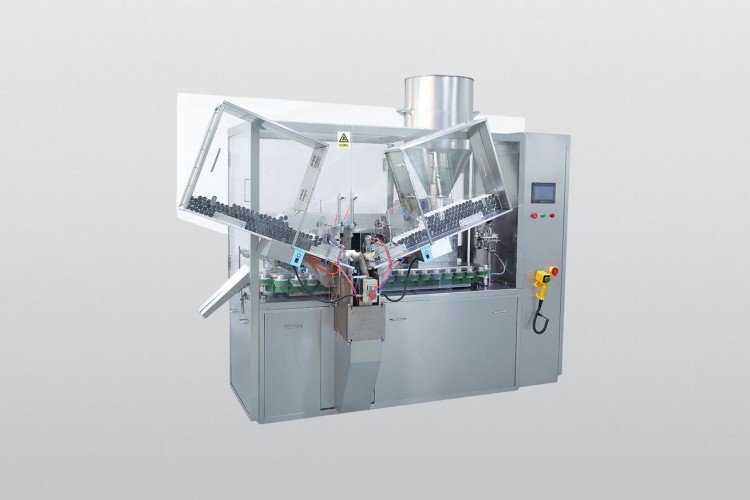

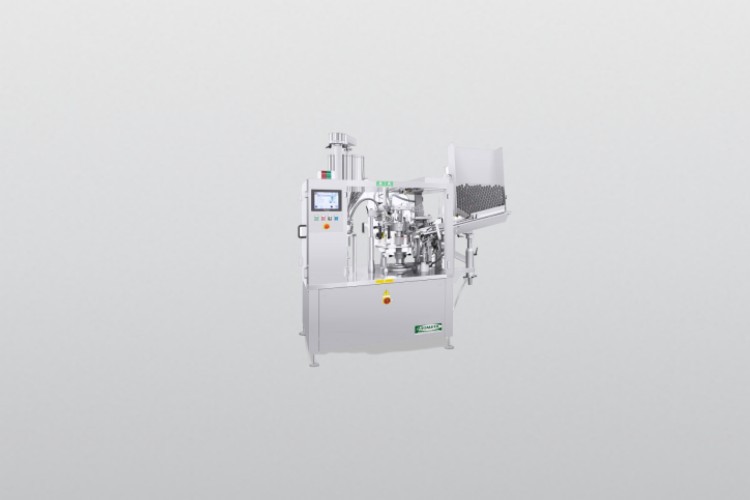

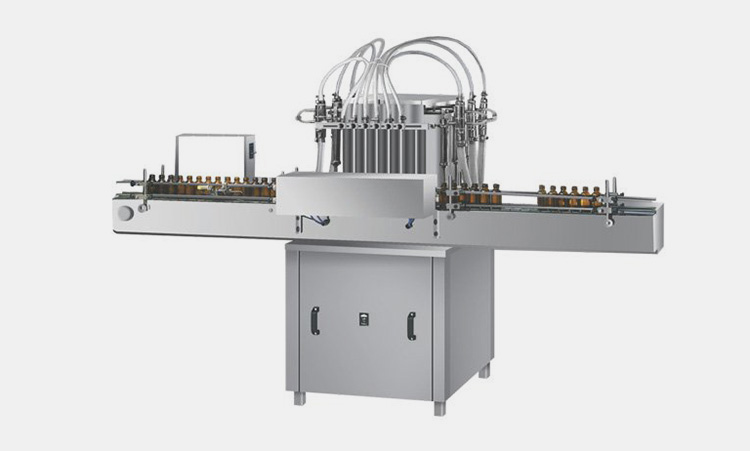

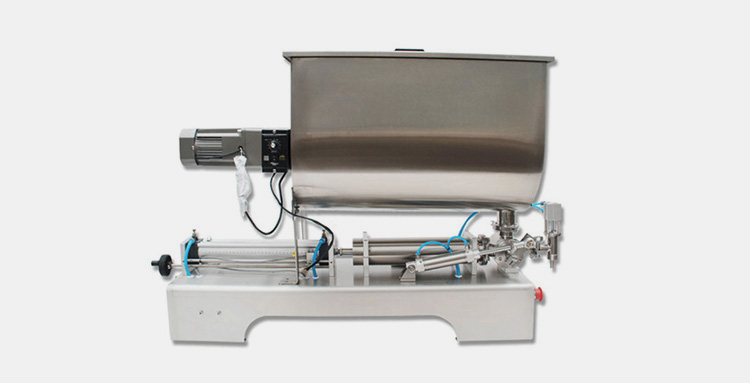

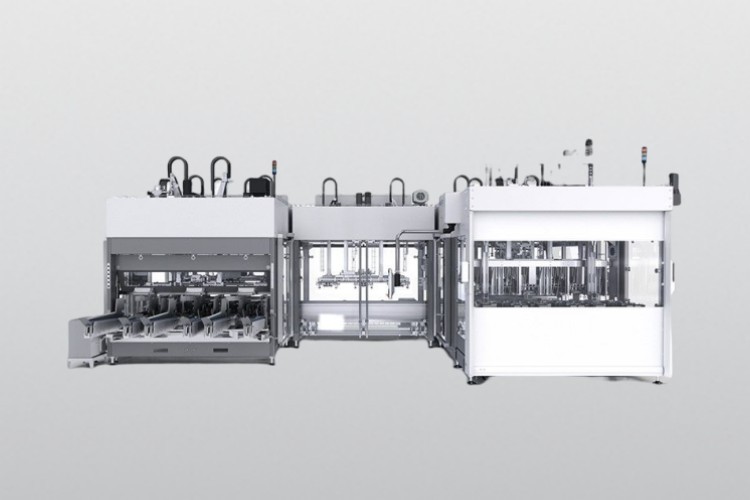

Semi-Automatic Glass Bottling Machine

For those looking for an economical option, semi-automatic glass bottling machines are available. This type of machine uses manual labor to fill the bottles but still has automatic filling, labelers, and cappers.

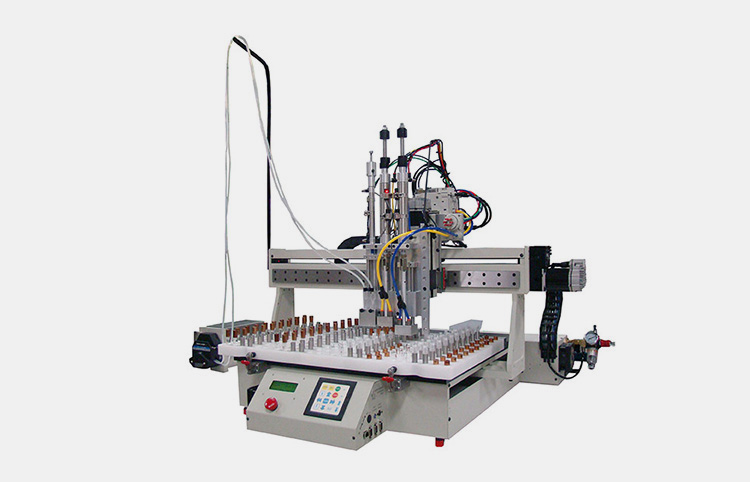

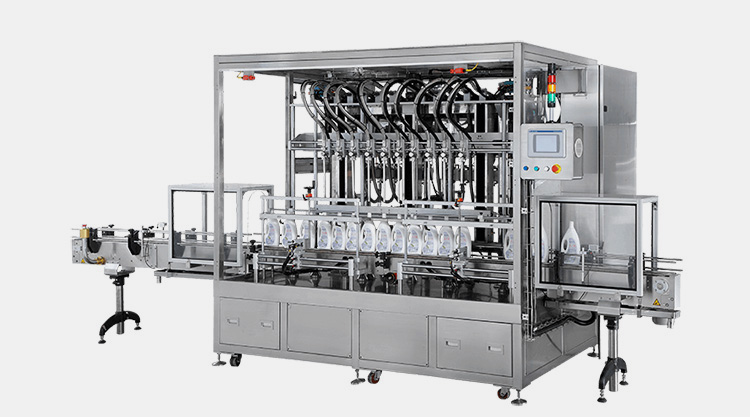

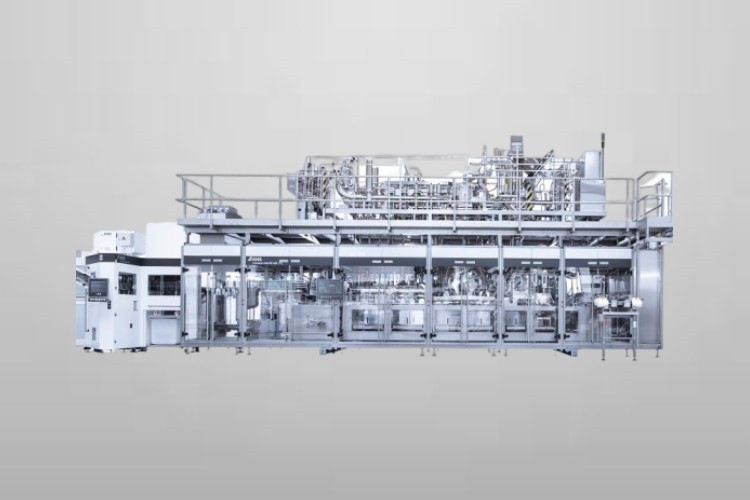

Fully-Automatic Glass Bottling Machines

For larger operations, fully-automatic glass bottling machines may be the best solution. These machines can process thousands of bottles per hour and are able to fill, label, cap, and package with minimal manual labor required. They often contain additional features such as a conveyor belt for transporting bottles and a shrink-wrap system for securing them during transport.

7.What Types Of Products Can Be Bottled Using A Glass Bottling Machine?

Many commercial operations use glass bottling machines to quickly fill bottles with the desired product. The machine is designed to ensure that each bottle contains the correct amount of product as well as meets any other specifications.

Since glass is considered a safe and reliable packaging material, bottling machines can be used with foods and drinks that have high acidity levels or require refrigeration. It also helps to protect the product from light, oxygen, and moisture damage that can occur over time. Additionally, glass bottles are often preferred for their aesthetic appeal, making them ideal for products that are meant to be displayed on shelves or in refrigerators.

Beverage liquids

Beverage liquids are the most common products bottled with glass bottling machines due to the high levels of carbonation in many drinks that require a heavy-duty machine to seal the bottle shut.

Food grade liquid sauces and dressings

Food grade liquid sauces and dressings are also commonly bottled using a glass bottling machine as these items require a high level of sanitation during the process.

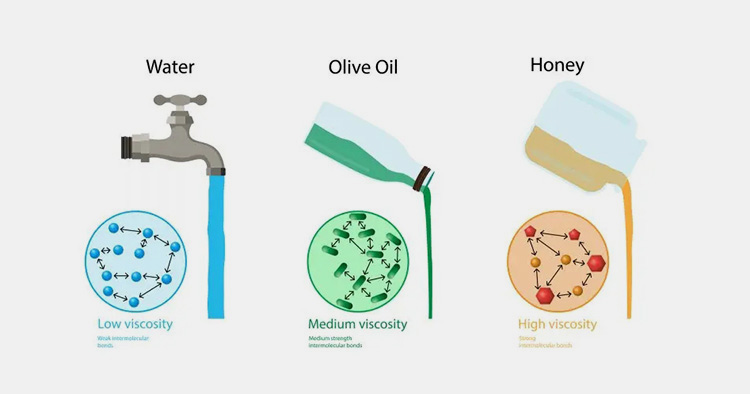

Viscous products

Viscous liquids such as honey, molasses, and ketchup can also be bottled in glass containers using a glass bottling machine due to their thickness which requires more pressure than liquid beverages to seal the bottle shut.

Pharmaceutical-grade liquids

Pharmaceutical-grade liquids such as vitamins, supplements, and lotions can also be bottled using a glass bottling machine since these products must maintain their integrity during the process.

Chemical and petroleum-based liquids

Chemical and petroleum-based liquids can also be packaged in glass containers with a glass bottling machine as long as they meet the safety requirements of the machinery.

8.Can A Glass Bottling Machine Handle Different Bottle Sizes And Shapes?

Yes, a glass bottling machine can handle different bottle sizes and shapes. This is due to their adjustable filling heads and spouts that help accommodate bottles of varying heights and widths. Many glass bottling machines are equipped with multiple nozzles that allow precise control over the amount of liquid they dispense into each container.

These machines can also be used to fill glass bottles of different shapes and sizes with the right adjustments. As a result, these machines are well-suited for bottling operations that require flexibility in their production processes.

9.Can A Glass Bottling Machine Handle Hot-Filled Or Cold-Filled Products?

The answer is yes. Glass bottling machines are designed to handle hot and cold products, depending on the specific model. Hot filling involves heating up the product before it is poured into bottles, while cold filling involves cooling down the product to a lower temperature than room temperature before being bottled.

In either case, industrial-grade glass bottling machines can efficiently and accurately handle both processes. The precise details of the operation, such as temperature control and liquid transfer speed, are typically customizable, allowing you to adjust the parameters according to your needs.

10.What Types Of Bottles Can Be Used By Glass Bottling Machines?

Glass bottling machines can be used to fill a variety of bottles, including beer and wine bottles, soda bottles, food jars, and many more. Depending on the specific machine design and capabilities, it is possible for glass bottling machines to accommodate different bottle sizes and shapes.

Generally speaking, these types of machines are designed to fill single-serve sizes, but larger capacities can be achieved by linking multiple machines together. Additionally, glass bottles with special features like caps and other closures may require additional parts or adjustments to the machine in order to handle them properly.

Customization of machines is also possible to accommodate specific bottle types and provide higher production speeds. In any case, the best way to determine which types of bottles can be used with your glass bottling machine is to consult with a qualified specialist. They will be able to provide expert advice, as well as suggest additional features or modifications that may be necessary for optimal performance.

It is advisable to consult with a specialist before making any decisions regarding which types of bottles should be used, as they can provide the necessary advice and suggest modifications or additional features that may be necessary for optimal performance.

11.What Maintenance Is Required For A Glass Bottling Machine?

To ensure the smooth operation of a glass bottling machine, regular maintenance is crucial. Here are some key maintenance tasks for a glass bottling machine:

Sanitization

Regularly clean the machine to remove any dirt or leftovers or glass particles that may accumulate. Use appropriate cleaning detergents and follow the manufacturer's cleaning guidelines.

Lubrication

Apply lubricants to moving parts as recommended by the manufacturer. This helps reduce friction, prevent wear and tear, and maintain optimal performance.

Inspections

Conduct routine inspections to identify any signs of damage, loose components, or malfunctioning parts. Inspect conveyor belts, guides, seals, and sensors for wear or misalignment.

Calibration

Periodically calibrate the machine to ensure accurate filling levels, sealing pressure, temperature control, and other critical parameters. Follow the manufacturer's instructions for calibration procedures.

Replacement of worn parts

Replace any worn or damaged parts promptly to prevent further damage or breakdown. This may include belts, gears, seals, valves, or electrical components.

Electrical system checkups

Inspect the electrical connections, wires, and control panels for any loose connections, frayed wires, or signs of overheating. Address any electrical issues immediately to prevent hazards that might result.

Preventive maintenance

Implement a preventive maintenance schedule, including regular servicing by qualified technicians. This includes thorough cleaning, lubrication, inspection, and testing of the machine's components.

Operator training

Ensure operators are trained in the proper operation, maintenance, and troubleshooting of the glass bottling machine. Educate them on best practices to prevent common issues and promote safe working conditions.

12.How Do You Choose The Right Bottling Machine For Your Needs?

When it comes to bottling your products, the most important decision you will make is choosing the right bottling machine. There are a variety of machines available for different types of bottles and applications. Here are some key points to consider when selecting a machine for your needs:

First, look at the types of bottles you will be using the bottle filling and capping machine for – whether they are glass or plastic bottles. If you plan on filling glass bottles, then an appropriate glass bottling machine should be chosen, as this type of bottle requires specific machinery.

consider the speed requirements of your production line; different machines offer different output capabilities and can handle varying fill volumes per hour.

Other factors to take into account include the size of bottles you will be utilizing – making sure that the equipment is able to accommodate them appropriately – as well as the type of closure you will be using. It is also important to consider the overall cost of investing in a bottling machine, and whether it is within your budget.

Conclusion

The glass bottling machine has revolutionized the packaging process by efficiently and precisely filling and sealing glass bottles. Its advanced technology has ensured consistent quality and reduced the risk of contamination in the overall production process. With its versatility and adaptability nature, the machine can accommodate various bottle sizes and shapes, making it suitable for a wide range of industries. Automating the bottling process has significantly increased production capacity while minimizing labor costs attached. Moreover, its eco-friendly design will promote sustainability by using recyclable glass bottles. At Allpack we offer precise glass bottling machines that can be a game-changer in your packaging industries that will also guarantee you reliable and efficient solutions for your bottling needs.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Glass Bottling Machine: The Complete FAQ Guide in 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Company Background & Information

Company Background & Information

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

ACF-L Liquid Packaging Machine

ACF-L Liquid Packaging Machine

Mercury Liquid Packaging Machine

Mercury Liquid Packaging Machine

PHS-100 Liquid Packaging Machine

PHS-100 Liquid Packaging Machine

LINEA Liquid Packaging Machine

LINEA Liquid Packaging Machine