Container Filling Machine: The Complete FAQ Guide In 2025

Facing the labor shortage and high cost of manual packaging, container filling machines have become an increasingly popular solution for manufacturers looking to increase efficiency while reducing costs.

The use of container filling machines can help reduce errors, improve worker safety and streamline production line operations. Not only are these machines more affordable than labor resources, they also offer higher levels of accuracy as well as a greater degree of flexibility. If you’re looking for a way to optimize your packaging process, this is the perfect time to invest in a container filling machine that meets your exact needs.

Here is the journey of the great benefits and features you are looking for in a reliable container filling machine for your needs.

1.What Is A Container Filling Machine?

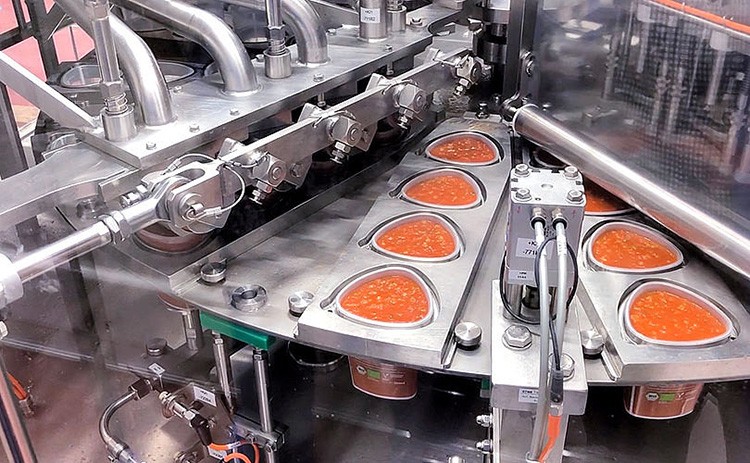

A container filling machine is an equipment that is worth investing in. They are used to fill containers with different materials such as liquids, granules, pastes and many more. They come up in a different shapes and sizes depending on your requirements. They range from manual to fully automated systems.

The biggest reasons for their preference in many industries such as the pharmaceutical, chemical, cosmetic, beverage and the food industries; is their ability to fill and package containers in a quick and precise way. These machines are quite a critical component in any production line.

2.What Are The Components Of A Container Filling Machine?

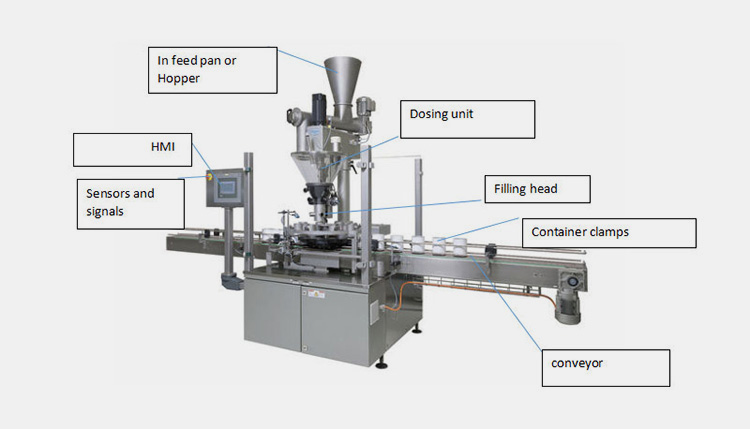

The components that make up the container filling machines include:

In feed Pan Or Hopper:This component is used to store the product that needs to be filled.

Dosing Unit:The dosing unit dispenses precise amounts of product into containers. It consists of a hopper, auger, feed wheel, and fill head.

Filling Head:The filling head is the device that dispenses product into containers. It can be a hand-held device, piston filler, or another type of automated system.

Mechanical Drive Systems:These systems provide power and movement to the container filling machine. They can include conveyors, belts, drives, motors, and other components.

Sensors And Signals:Sensors and signals are used to monitor the filling process and ensure accuracy. They can include fill level sensors, weight sensors, and other types of feedback devices.

Plc Control Panel: The plc control panel can be used to monitor the filling process, change settings, and troubleshoot issues. It is also used to set parameters and control it.

Conveyors and Container Clamps: Containers are placed on conveyors or clamps, which move them through the machine.

HMI Control Systems:These components are used to operate the machine and monitor its performance which can include touchscreens, displays, and other types of user interfaces.

3.How Does A Container Filling Machine Work?

A container filling machine works in different ways depending on the type being used. However, here are the general steps involved in each type:

Step One: Preparation

In this stage this device is set up by adjusting settings to the preferred ones.

Step Two: Container Positioning

The containers to be filled are manually or automatically positioned under the filling nozzles to help in avoiding wastage in case of any spills due to misalignments of containers.

Step Three: Product Supply

The product or material that is supposed to be filled is supplied to the filling machine from the main tank, it is typically filtered to remove any contaminants and for easy dispensation to the containers for packaging.

Step Four: Filling

In this stage, the filling process is done. Material dispensation is done into the containers through one or more nozzles through different methods in regard to the type of equipment being used.

Step Five: Container Indexing

This involves the movement of the containers in each step consistently.

Step Six: Capping

In this step the containers are moved to a capping station where they are automatically or manually capped or sealed if need be.

Step Seven: Quality Control

Inspection for accuracy and quality is done after capping to ensure the desired results are met or achieved.

Step Eight: Packaging And Labeling

In this final stage, the filled and capped containers can now be labeled where they are packaged for shipping.

These steps are just a simple and general mapping on how container filling machines work.

4.What Are The Benefits Of Using A Container Filling Machine?

Container filling machines make the process of packing products more efficient and provide several benefits for businesses such as increased accuracy, speed, cost savings, and safety. This machine can be of great support to your production requirements.

Accuracy

Container filling machines are of standard designs that fill containers consistently and accurately. This ensures that the product is sealed and packaged correctly, with precise measurements.

Efficiency

Their configuration enables for quick and accuracy in measuring, filling, and sealing containers with a wide variety of liquid products. This allows for fast packaging production speeds resulting in very efficient operation.

Versatility

A container filling machine can be modified or customized to work with a wide range of different container sizes, shapes, and liquid kinds, including water, oils, and beverages. This gives the production of packaging more freedom.

Safety

These machines' automated nature contributes to ensuring compliance with all health and safety laws and error-free packaging. In addition to preserving product quality assurance, this can shield workers from various workplace dangers. Their safety nature during operational time is highly enhanced.

Cost-Effectiveness

By reducing manual labor costs and increasing operational efficiency by saving time, using this equipment can help to lower overall production costs.

5.In Which Industries Do Container Filling Machines Apply?

Container filling machines have applications across many different industries, including:

Beverage Production

Beer, soft drinks, juices, milk, honey, water and many other liquids are mostly filled or packaged by the container filling machines in the beverage industries. They ensure accurate volume and speed when filling each liquid product.

Pharmaceuticals

In the pharmaceutical industry these machines are greatly and specially designed to fill containers with precise doses of medication, using careful measurements and calibration.

Cosmetics

Machines used for cosmetics container filling are often employed in the makeup and skincare industries. These devices can quickly and accurately fill a variety of bottles and jars with cosmetics in desirable designs.

Chemicals

Many industrial and commercial chemicals require container filling machines to ensure accuracy when handling the product and due to the dangers related to manual filling operations. These machines are designed to work with a range of containers, including drums and totes.

Food Processing

Container filling machines designed specifically for food processing industries can quickly and accurately fill containers with food products such fruits, cereals and many more.

6.What Are The Different Types Of Container Filling Machines?

There is a wide range of container filling machines that are used to fill containers with different materials such as liquids, powders, and granules. There availability depends on what kind of production line or in form of automation. They include:

Based on the production line.

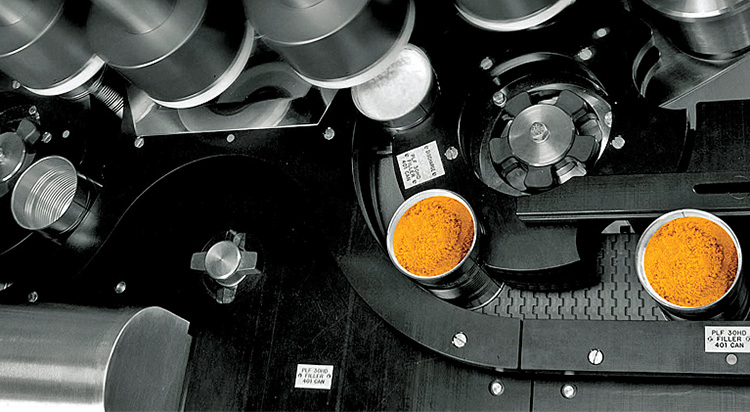

1.Liquid Fillers

Liquid fillers are designed to fill containers with liquids such as water, wine, and oil. These machines can be either volumetric or net weight depending upon the type of product that needs to be filled.

Working principles of liquid fillers.

Liquid container filling machines are designed to fill containers with clearly expressed volumes of liquid. They typically use volumetric, gravity or pressure-based filling principles that are explained below.

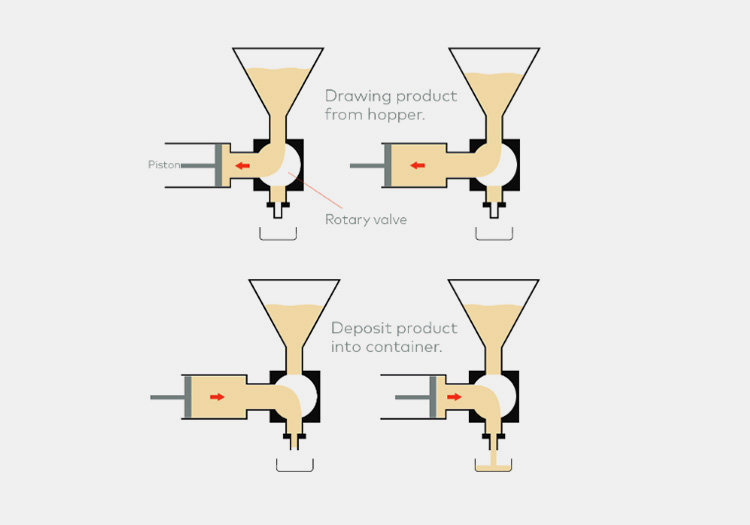

Volumetric filling machinesuse a piston and cylinder system to accurately dispense the fluid into each container. The piston is calibrated for each product size, then as it moves up in the cylinder, it pumps a specific volume of liquid into the container below. The volume is calculated by counting the cycles of piston movement.

Gravity filling machineswork by gravity force to fill different containers with liquid. Containers are placed below the fillers for gravity to dispense the desirable volume of liquid set up. This method of filling relies on natural gravity to feed the liquid into the containers.

Pressure fillersuse the principle of positive or negative pressure to dispense liquids into containers. Positive pressure filling machines work by forcing a predetermined amount of liquid into containers, negative pressure filling machines use suction and technology to draw liquid from a reservoir tank into each container.

All these machines are the best but it will depend on the product being filled or the volume of work that is available for your needs. Choosing the right machine, can guarantee you precise levels of accuracy, speed up production lines, reduced waste and an improve in overall efficiency.

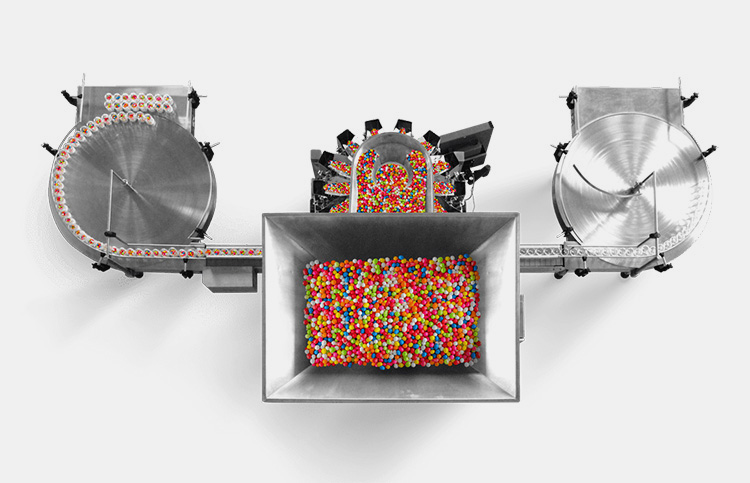

2.Vibratory Weight Filling Machines

These types of container filling machines are designed to accurately fill containers with a wide variety of granular or palletized products such as spices, grains, and nuts. The vibratory weight filling machine uses an oscillating system to ensure that the product is filled to the correct weight every time.

Working principles of vibratory weight filling machines.

The working principles of vibratory weight filling machines involve using vibration and gyratory force to move product from a hopper into a container in a controlled manner or according to the operators’ settings. The hopper holds the product that needs to be dispensed and is usually mounted onto the machine's base. As the vibration begins, it causes the product to move in a downward motion, where it is then forced or slowly dispensed into the container by a combination of gravity and vacuum.

The motors in these machines control the process's speed, making sure that it remains constant regardless of the size or weight of the product being filled. The product can also be regularly turned or sifted to make sure that it is uniformly distributed in the container using an auger or an impeller.

The vibratory weight fillers can be changed to measure out a specified amount of product due to their ability or nature to handle both dry and wet products with minimum waste or spillage. They are very flexible to suit your production line.

3.Powder Filling Machines

Powder filling machines are used to fill containers with powdered products such as detergents, baking powder, and some cosmetic products. The powder filling machine can be either rotary or auger depending on the product being filled.

Working principles of powder filling machines

Ideally, the working principles behind these machines vary depending on the type and configuration of the machine. All use some combination of gravity-fed or vacuum-assisted powder transfer and volumetric/gravimetric filling techniques.

Gravity-fed machinesuse a combination of vibration and hoppers to move powder from the supply hopper into the container, while vacuum-assisted systems rely on an adjustable suction force that draws powder from the supply hopper directly into the container. The type of machine used depends on the desired production rate and the properties of the powder being filled such as its texture and other properties.

Volumetric filling systemsinvolve a system of rotating paddles that measure out a specific volume of powder into each container, while gravimetric filling systems use weight sensors to determine how much powder is needed for each container.

The machines jointly move the container under the filling head, and powder is transferred either through a gravity-fed or vacuum-assisted transfer system. Once the container is full, it moves to another station where it is sealed and labeled before being discharged from the machine depending on the production line customization.

Based On Their Level Of Automation.

Here are some of the different types of container filling machines in terms of automation:

Manual container filling machines

These are the simplest and most basic types of filling machines. They are operated manually by a human operator. They may require the operator to place the products in the infeed tank and also the container under the filling nozzle and press a button to initiate the filling process. Manual filling machines are suitable for low-volume production industries and for products that require a high degree of customization.

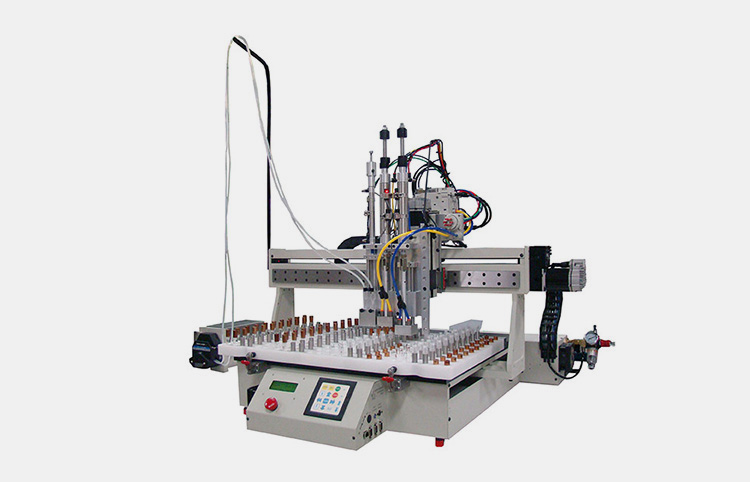

Semi-automatic container filling machines

These ones are filling machines that require some level of human interaction to operate, but are partially automated. These machines typically have a filling nozzle that is positioned over the container, and the operator manually places the container under the nozzle and sets up the filling process.

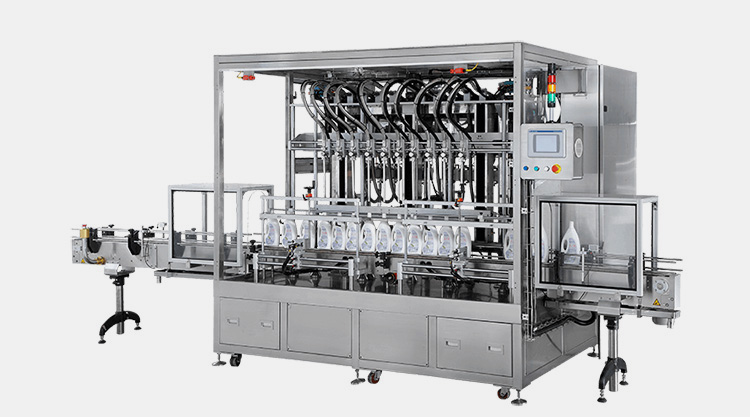

Automatic container filling machines

These machines are fully automated and require less human interaction or intervention to operate. They can be programmed to fill containers with a precise amount of product and can operate at high speeds. Automatic filling machines can be collectively used into a production line for high-volume production of consistent products.

Robotic container filling machines

These machines use robotic arms to pick up and place containers under the filling nozzle. They can be programmed to fill containers with a variety of products and can be customized to handle different container shapes and sizes. Robotic filling machines are suitable for high-volume production lines with a higher degree of customization.

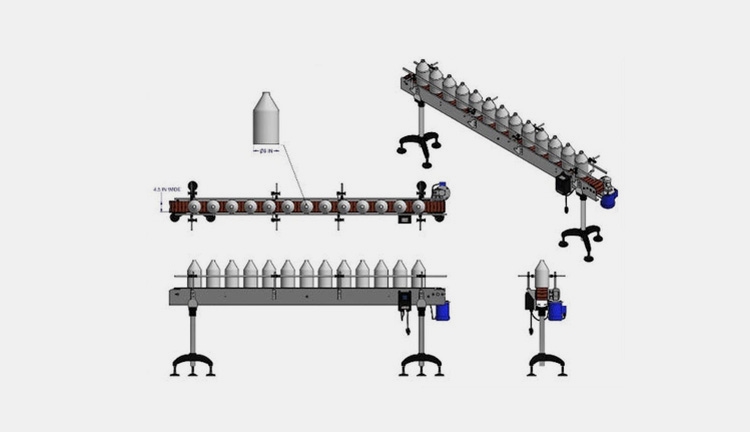

Inline container filling machines

These machines are integrated into a production and are designed to fill containers automatically as they move down the line. They can be set up to fill a variety of container sizes and shapes and can operate at high speeds. Inline filling machines are suitable for high-volume production.

Rotary container filling machines

These machines use a rotary indexing system to move containers through the filling nozzles process. They are configured to fill a variety of container sizes and shapes and can operate at high speeds. These devises are suitable for high-volume production industries because of their high degree of automation and customization.

7.What Is The Difference Between Manual And Automatic Container Filling Machines?

Manual and automatic container filling machines are used to fill containers with various products, such as food, beverages, and other liquids. Manual container filling machines require an operator to manually control the flow of product into each container. Automatic container filling machines use programmed settings to automate the process and can be operated at a much higher speed than manual models.

Manual container filling machines require an operator to manually control the nozzle, speed of movement and flow rate of product into each container. This requires precise manual handling and can be time-consuming. Manual machines are ideal for low-volume production with many different types of containers or sizes that need to be filled.

In contrast, automatic container filling machines use programmed settings to automate the process. These machines utilize sensors and computer-controlled actuators to control the speed, movement, and flow rate of product into each container. This can significantly reduce labor costs while allowing for high-speed production with consistent results. Automatic container filling machines are commonly used in mass production operations where uniformity is essential.

Both of these machines have their advantages and disadvantages in such away manual machines are ideal for low-volume productions with many different types of containers or sizes that need to be filled, while automatic machines offering a cost-effective solution for mass production operations where uniformity is essential. It is important to consider the individual needs of a production operation before deciding which type of container filling machine is best suited for the job.

8.What Kind Of Products That Can Be Filled By Container Filling Machines?

Liquids, powders and granules are some of the items that can filled into containers by this special filling machine.

Liquids

Examples of liquid products that can be filled include juices, smoothies, wine, beer, milk and many more.

Creams

Cream being one of the products that can be filled, products may require additional components such as pumps or nozzles to ensure accurate measurement when being filled.

Pastes

Examples of the pastes are like toothpaste, adhesives and sealing compounds. Specialized pumps may be needed for pasty substances.

Powders

Powders such as spices, detergents and milk powder are good examples of items that can be filled by this device.

Granulated/Pelletized Items

Examples of granulated items that can be filled include sugar, rice and animal feed.

9.What Are The Different Types Of Containers That Can Be Used By A Container Filling Machine?

Container filling machines come in many shapes and sizes to accommodate different types of containers. Commonly used containers include jars, bottles, cans, cartons and bags. Because of their differences in shapes and sizes they will need also need to be used with different types of machines for filling purposes.

Jars may need a machine that can cap them securely while bags require a machine that can fill them accurately and at a high speed.

Cartons must be filled to the correct weight while cans need to be sealed with a lid. A different level of cleaning and maintenances is also required for the various containers. When choosing a filling machine, it is important to consider all of these factors. The right machine for your application will depend on the size, shape and type of container you are working with.

Conclusion

Container filling machines are an essential part of many production lines, and their benefits cannot be overstated. Our container filling machines offer high accuracy, efficiency, and reliability, helping businesses to streamline their production processes and increase their product quality while reducing labor costs. At Allpack, we provide a range of container filling machines to suit your different production needs and requirements. Contact us today to learn more about our container filling machines and how they can benefit your business!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide