Syringe Filling Machine: The Complete Buying Guide In 2025

If you own a medical laboratory or physical therapy center or drug manufacturing company, then you already know that syringes are an essential part of your operation. Without them, your business and its operations would not run smoothly. Luckily for you, syringe-filling machines have been designed to make the process of automatically refilling hundreds of syringes more efficient than ever before!

Also, these amazing machines offer businesses impressive increases in speed and accuracy in their everyday operations. This blog post explores this exciting technology; what it is, how it works, and which types are available on the market today!

1.What is a syringe?

A syringe is a medical instrument used for injecting or withdrawing fluids from the body. It typically consists of a cylindrical barrel, a plunger, and a needle. The barrel holds the fluid, the plunger controls the flow of the fluid, and the needle allows for precise delivery or extraction of fluids. Syringes are commonly used in healthcare settings for administering medications, delivering vaccines, drawing blood samples, and performing various medical procedures.

2.How does a syringe work?

A syringe works by utilizing the principles of pressure and suction to draw or expel fluids. The precise mechanism may vary depending on the specific type of syringe, such as whether it has a luer lock or a slip-tip design, but the basic principles of pressure and suction remain consistent.

3.What are syringes used for?

Syringes are used for a variety of medical purposes. Some common uses include:

Administering medication

Syringes are frequently used to deliver medications directly into the body. This can include injections given subcutaneously (under the skin), intramuscularly (into the muscle), or intravenously (into a vein).

Vaccinations

Syringes are essential for administering vaccines, which help prevent infectious diseases. They allow healthcare professionals to accurately measure and deliver the appropriate vaccine dosage.

Collection of blood

It's quite useful to note that different types of syringes may be used for specific purposes to ensure accurate dosage delivery, maintain sterility, and meet the requirements of various medical procedures.

4.What types of syringes are available?

Several types of syringes are available, each designed for specific purposes. Here are some common types:

Standard syringes

These are the most common syringes used for general medical purposes. They typically have a lured slip tip or lured lock tip, allowing for the attachment of various sizes and types of needles.

Insulin syringes

Insulin syringes are specifically designed for administering insulin injections. They have a very fine and short needle, and the syringe is calibrated to measure insulin units accurately.

Tuberculin syringes

Tuberculin syringes are used for administering and reading the Mantoux tuberculin skin test. They have a small capacity (typically 1 ml) and fine graduations for precise measurement.

Safety syringes

Safety syringes incorporate features to minimize the risk of needlestick injuries. These can include retractable needles that automatically retract into the syringe barrel after use or needle shields that cover the needle after injection.

Pre-filled syringes

pre-filled syringes come pre-loaded with a specific medication or vaccine. They are ready to use and eliminate the need for drawing up medication from a vial.

Catheter-tip syringes

Catheter-tip syringes have a tapered tip specifically designed for attaching to catheters or other tubing systems for efficient and controlled fluid delivery.

Oral syringes

Oral syringes have a long, curved tip and are used for accurately measuring and administering oral medications to individuals who have difficulty swallowing or require precise dosing.

Irrigation syringes

Irrigation syringes have a large capacity and are used for cleansing wounds or body cavities by delivering a steady flow of fluid.

5.What are the safety requirements when handling syringes?

When handling syringes, it is important to follow certain safety requirements to minimize the risk of injury and ensure proper usage. Here are some brief safety guidelines:

Needle safety-Handle syringe needles with caution to avoid accidental needle sticks. Never recap a used needle. Dispose of used syringes and needles in designated sharps containers immediately after use.

Hand hygiene-Practice proper hand hygiene by washing hands with soap and water or using an alcohol-based hand sanitizer before and after handling syringes.

Sterility-Ensure that syringes and needles are sterile and individually packaged before use. Do not use a syringe if its packaging is damaged or compromised.

Needle disposal-Dispose of used syringes and needles in puncture-resistant containers specifically designed for sharps disposal. Follow local guidelines and regulations for proper disposal methods.

Needlestick prevention-Take precautions to prevent accidental needlestick injuries. Avoid recapping needles, use needle safety devices if available, and handle syringes with care to prevent needle injuries.

Remember, these are general safety requirements, and it's important to follow specific protocols and guidelines established by your healthcare facility or local regulations to ensure safe syringe handling practices.

6.Which Methods Are Commonly Used To Fill Syringes?

There are several methods commonly used to fill syringes depending on the context and purpose. Here are a few methods:

Direct filling from a vial-This method involves inserting the syringe needle directly into a vial containing the desired medication or fluid. The plunger is then pulled back to create suction, drawing the fluid into the syringe barrel.

Withdrawal from a container-In some cases, syringes may be used to withdraw fluids from an IV bag or container. A needle or a specialized spike may be inserted into the port or septum of the IV bag, and the plunger is pulled back to draw the fluid into the syringe.

Transfer from an ampoule-Ampoules are small sealed glass or plastic containers that hold a single dose of medication. To fill a syringe from an ampoule, the ampoule is broken open, and the syringe needle is inserted into the ampoule to draw out the medication.

Use of syringe filling devices-Transfer devices can be used to aseptically transfer fluids from one container to another. These devices provide a closed and sterile system for filling syringes, minimizing the risk of contamination.

Pre-filled syringes-Some syringes come pre-filled with medication or vaccines. These syringes are ready to use, and filling is not required. They are typically provided in sterile packaging.

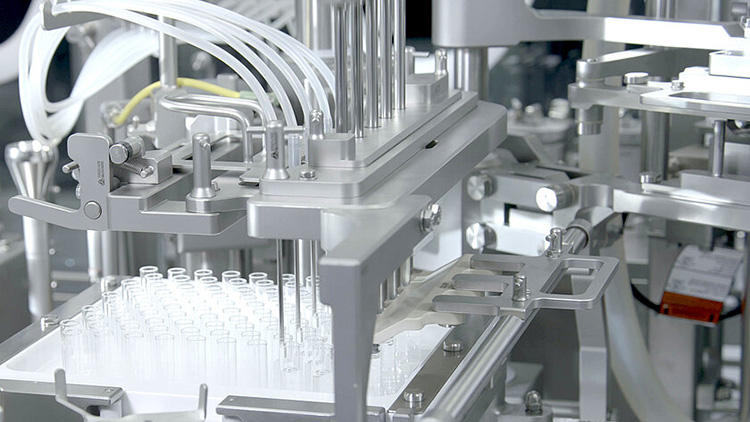

7.What Is A Syringe Filling Machine?

A syringe filling machine is a device used to fill a variety of syringes with liquids or semi-solid materials. These machines are commonly found in manufacturing and healthcare settings, where they are used to fill large quantities of syringes with exact dosages for medical treatments or production processes.

Syringe filling machines are typically automated, requiring only minimal human intervention to ensure correct operation. They offer many advantages over manual syringe-filling techniques in terms of speed and accuracy, making them an essential tool for many industries.

8.What Are The Components Of A Syringe Filling Machine?

The components of a syringe machine are:

Pump Filler

The filling pump is responsible for delivering product from the material hopper to the syringe. This component can be configured in either a positive displacement or peristaltic mode depending on the application and fluid compatibility requirements.

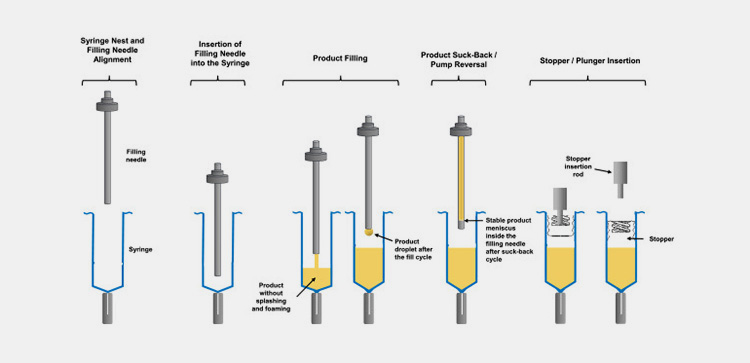

Filling Needle

The filling needle is critical to ensuring accurate and repeatable filling as it functions as the gateway between the delivery pump and the syringe. The needle size and shape will be dependent on the application.

The Hopper

The material hopper, usually made of stainless steel or plastic, holds the product that is to be filled into syringes. This component can also include automated filling systems to ensure a consistent supply of product to the filling needle.

Syringe Ejector System

After each syringe is filled, it must be ejected from the machine and collected in a tray or container. This is typically done using an automated system of pneumatic cylinders and other components to ensure that each syringe is accurately placed in its collection container.

Filling Head

This is where the liquid transfer takes place. It is usually equipped with sensors that detect when a syringe has been filled to the correct level.

Labeling System

This component helps in adding labels to each syringe before they are packaged for sale.

9.What Are The Benefits Of Using A Syringe Filling Machine?

The advantages of a syringe-filling machine include:

Multiplied Efficiency

A syringe-filling machine is designed to fill many syringes in a fraction of the time it would take to do it manually. This makes it ideal for high-volume production tasks, allowing medical practitioners to save time while ensuring they are able to meet demand.

Intensified Accuracy

Syringe-filling machines are accurate instruments that eliminate the potential for human error when filling syringes. This ensures consistency in measurements, making it easy to deliver precise doses of medication or other substances as needed.

Expenditure Reduction.

Using a syringe filling machine is incredibly cost-efficient, as it eliminates the need for manual labor and allows medical professionals to fill more syringes in less time. This reduces the amount of money spent on materials and labor, allowing practitioners to save money.

Versatility

A syringe-filling machine is designed to be versatile, allowing it to fill various types of syringes with different substances and fluids.

10.What Are The Applications Of A Syringe Filling Machine?

A syringe-filling machine can be used in a variety of industries. Here are some of the applications:

Pharmaceuticals Industry

In the pharmaceutical industry, syringe filling machines can be used to fill and package pharmaceutical products such as drugs, vaccines, and other liquid medications. These tools can accurately fill and deliver precise dosages with speed and efficiency.

Veterinary Industry

Animal health products such as vaccines, antibiotics, and other medications can be filled into syringes with a syringe filling machine.

Food Processing

Syringe-filling machines are used to fill food items such as sauces, jams, purees and pastes into syringes for packaging. This helps to ensure that the product is filled accurately and consistently while also improving safety standards.

Cosmetics Industry

In the cosmetics industry, syringe filling machines can be used to fill containers with creams, lotions, gels, perfumes, and other cosmetic products.

Chemical Industry

Syringe filling machines can be used in the chemical industry to fill chemicals, reagents, and other hazardous substances such as acids and bases.

Automotive Industry

Syringe-filling machines are used in the automotive industry to accurately dispense lubricants, adhesives, sealants, and other fluid products into syringes.

11.What Are The Working Principles Of A Syringe Filling Machine?

When the machine starts up, it will first sort through the syringes and dispense them onto its assembly line. The syringes are then placed into a hopper, which feeds them, one at a time, into the machine’s filling chamber. From there, the syringe is filled with either liquid or solid medications that have been pre-measured.

Once the syringe has been filled, it is then placed onto its platform. At this point, a sensor will detect the presence of the syringe and verify that it has been properly filled. If so, the machine will move the syringe further down the assembly line for capping and labeling.

Once this is complete, the machine will drop the syringe onto an exit conveyor belt for further processing.

12.What Are The Different Types Of A Syringe Filling Machine Available On The Market?

There are several types of syringe filling machines on the market. These include:

Automatic Syringe Filling Machine

Automatic syringe filling machines are designed to fill multiple syringes accurately and quickly. This type of machine features a digital control panel, a hopper for loading the liquid, and an automated system that injects the liquid into the syringe.

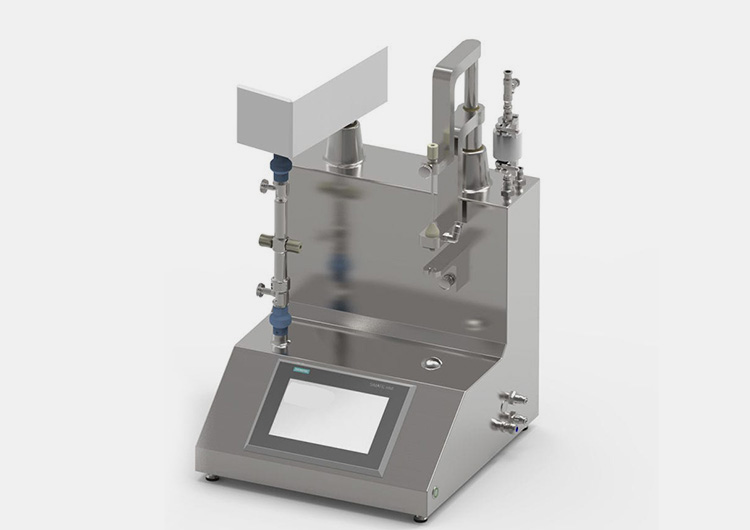

Semi-Automatic Syringe Filling Machine

The semi-automatic syringe filling machines are designed for medium production runs, as they require an operator to monitor the filling process and make adjustments to ensure the syringes are filled with the desired amount of liquid.

13.What Is The Difference Between A Manual Syringe Filling Machine And An Automatic Syringe Filling Machine?

The main difference between a manual syringe filling machine and an automatic syringe filling machine is the speed at which they fill syringes. Manual machines are operated by hand and require users to manually insert each individual syringe into the tray for it to be filled, while automated machines can fill multiple syringes simultaneously in just seconds.

Automated syringe filling machines are also much more accurate and efficient than manual machines, as they can be programmed to precisely measure each dose. Additionally, automated syringe-filling machines allow for greater flexibility with the type of syringes that can be filled, as they feature interchangeable parts that can accommodate different sizes and shapes.

Manual syringe filling machines, on the other hand, typically have a fixed size and shape. Furthermore, automated machines can be used to fill any type of fluid or liquid including water, gels, creams, and sterilizers; whereas manual syringe-filling machines are limited to only certain types of fluids and liquids.

14.What Is The Difference Between An Automatic Syringe Filling Machine And A Semi-Automatic Syringe Filling Machine?

An automatic syringe filling machine is a fully automated system that can perform the entire process of filling, sealing, and capping a syringe without manual input. This type of machine typically utilizes advanced technology such as robotics and vision systems to ensure accuracy and speed. The overall process usually requires just one operator who monitors the output and quality control.

A semi-automatic syringe filling machine is similar, but it requires manual intervention along the process. This type of machine typically makes use of a simple conveyor system to move the needle from station to station and a person must manually add or subtract the product into the syringe at each stage. The operator must also be present for the capping process. Although manual labor is involved, semi-automatic filling machines can still fill and seal multiple syringes simultaneously, resulting in a higher output.

15.What Materials Can Be Filled With A Syringe Filling Machine?

Liquids

A syringe filling system is commonly used to fill containers with liquids, such as water, oil, juice, and alcohol.

Powders

Syringe-filling machines are also ideal for packaging fine or powdered materials such as flour, sugar, spices, and other small particles.

Gels

Syringe filling systems are also equipped to fill containers with gels such as lotions, shampoo, and toothpaste.

Creams

Products like face creams, shaving cream, and other similar products can be filled in syringe filling systems with ease.

Paste

These are thick smooth substances like nut kinds of butter, jam, peanut butter, and more that can also be filled in containers using a syringe filling system.

Adhesives

Syringe-filling machines can also be used to fill containers with adhesives, such as glue and sealants.

16.What Type Of Maintenance Is Required For A Syringe Filling Machines?

Syringe-filling machines require regular maintenance in order to ensure that they are operating efficiently and effectively. And this is the required maintenance;

Daily visual inspections should be done to make sure that the machine is free from any foreign objects or debris as well as to check for any damage or wear in the system. It is also important to inspect the syringes and needles used with the machine to ensure that they are not damaged or contaminated.

Weekly lubrication of parts should be done to keep all moving components working correctly and efficiently. Any oiling points, bearings, and other lubrication should be checked and oiled needed.

Monthly filter changes are necessary to keep the system clean and contaminant-free. The filters should be replaced or cleaned as needed in order to maintain the efficient operation of the syringe filling machine.

Finally, an annual full-service check should be done by a qualified technician to check all components of the syringe filling machine. This should include checks for any damage or wear and other maintenance requirements that may be necessary.

17.What Are The Common Problems Associated With Using A Syringe Filling Machine And The Possible Solutions.

Leakages

A common problem when using a syringe filling machine is the potential for leakage of the material being filled. This can happen due to worn-out parts, failure of seals or gaskets, incorrectly assembled components and defective valves.

Possible solutions include replacing worn or faulty parts; using new gaskets, seals, and valves that are designed for the specific task; and double-checking to ensure all components are correctly assembled.

Contamination

Contamination of the material being filled can occur if it comes into contact with other materials in the machine or is exposed to airborne contaminants.

Possible solutions include using proper cleaning procedures before filling; using separate parts and components for different material types; and using tools such as filters and screens to prevent contact between materials.

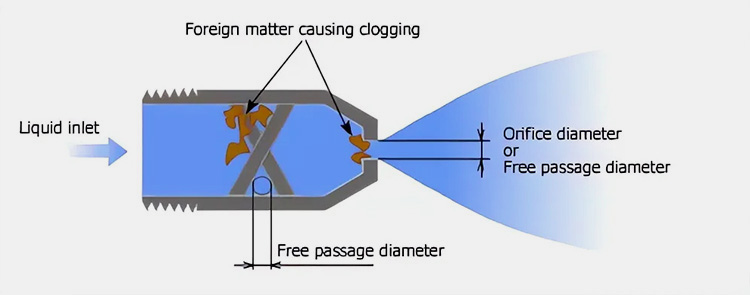

Clogged Nozzles

Syringe-filling machines can become clogged if the material being filled is not compatible with viscosity. Possible solutions include using materials of the right viscosity and cleaning nozzles regularly.

18.What Are The Considerations Before Purchasing A Syringe Filling Machine?

Production Capacity

The production capacity of the syringe filling machine is a crucial factor to consider before purchasing one. Always consider how much product you need to produce and whether the machine can meet your demands in terms of speed and accuracy.

Ease of Use

When selecting a syringe filling machine, it’s also important to consider how easy it is to use. You should consider the level of operator training required and the complexity of the setup.

Cost

The cost of the syringe filling machine is also another important factor to consider before purchasing one. Compare different models and their prices so that you can find one that meets your needs without compromising on quality. Also, consider the additional costs associated with maintenance and training.

Compliance

Make sure that your syringe filling machine meets all relevant safety and regulatory standards before purchasing it. Ensure that all necessary approvals are in place to guarantee a safe and compliant working environment.

Size

Syringe-filling machines come in a variety of sizes. You should consider the size of your production line and what space you have available to house the machine before deciding on a model.

CONCLUSION

Ultimately, a syringe-filling machine can be an incredibly valuable asset to any medical facility. It can help increase job satisfaction among workers as well as ease the strain of certain tasks that require precision and accuracy. The challenge now is finding the right machines for your facility’s needs. Luckily, many companies provide a full range of machines that will suit all budgets and requirements. There are lots of options available from manual fillers, to semi-automatic equipment and automatic solutions. So, you should be able to find something perfect for your organization’s needs. If you find yourself in need of an experienced supplier contact Allpack today.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide