Pouch Packaging Machine: The Complete Buying Guide In 2025

Pouch Packaging Machine: The Complete Buying Guide In 2025

Are you planning to switch the mode of your packaging from rigid to flexible? Probably yes! May be because you want to reduce the packaging cost or the mesmerizing customization of pouches has created in you the desire to be known for your packaging. Well, this is a wonderful idea but requiring something more than wishful thinking and that is a Pouch Packaging Machine!

You can make the best possible use of pouch packaging machine provided that your experience and knowledge corelate with the emerging needs. But what if you are naive and striving to discover about pouch packaging machine? How the situation can be tackled? Definitely through information- given in this Buying Guide. So, let's delve deep into pouch packaging machine, its significance, types, applications and more!

1.What Is Meant By Pouch Packaging?

Various potato chips pouches display

Pouch packaging refers to the creation of most essential packages such as sachets, stick pouch, and gusset pouch from light weighted film. This film can be drived from plastic, aluminum foil, or paper. The primary purpose of pouch packaging is to provide a safe and handly way for the protection of various goods like food products, drugs, and cosmetic items from their manufacturing till end user.

2.Define Pouch Packaging Machine?

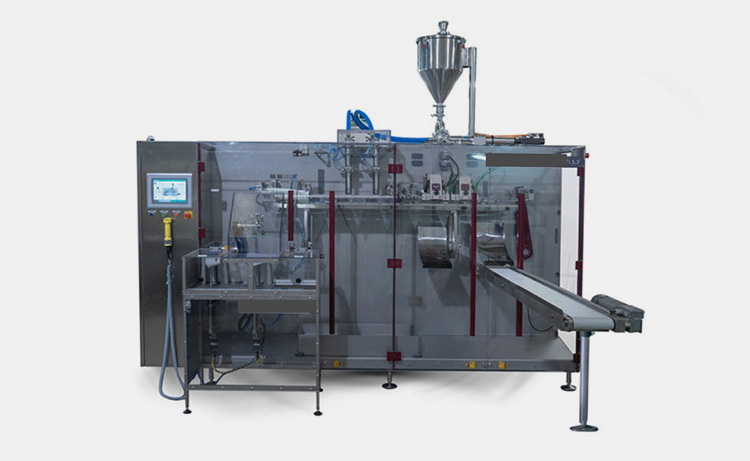

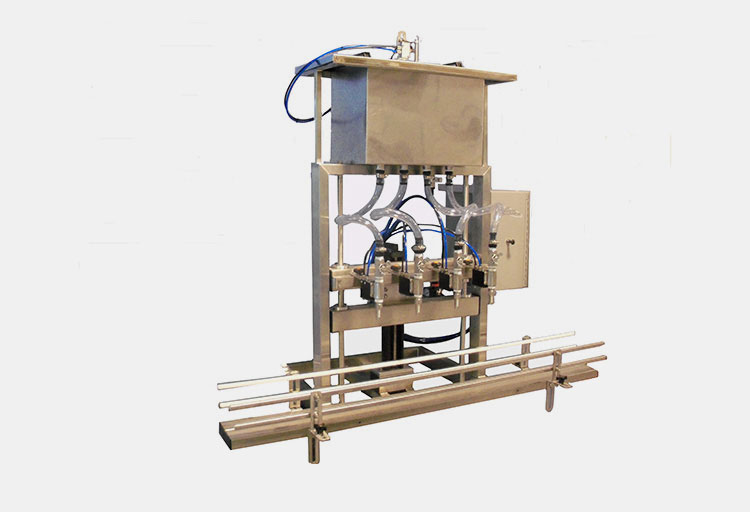

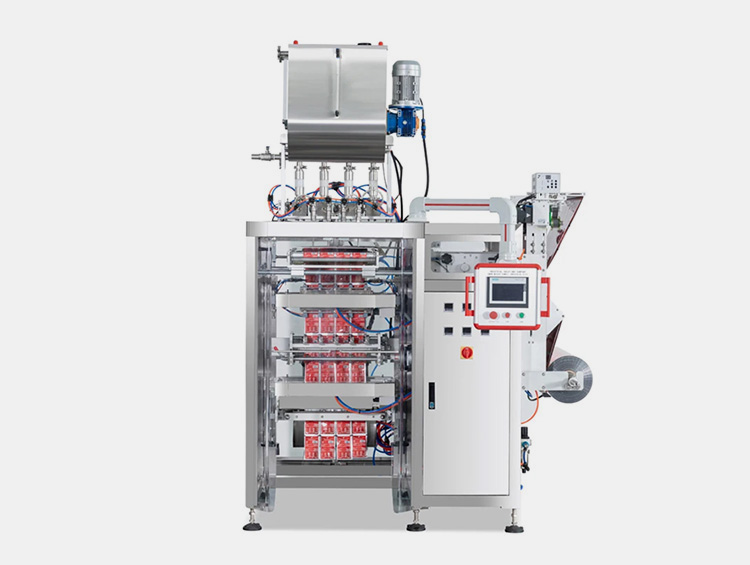

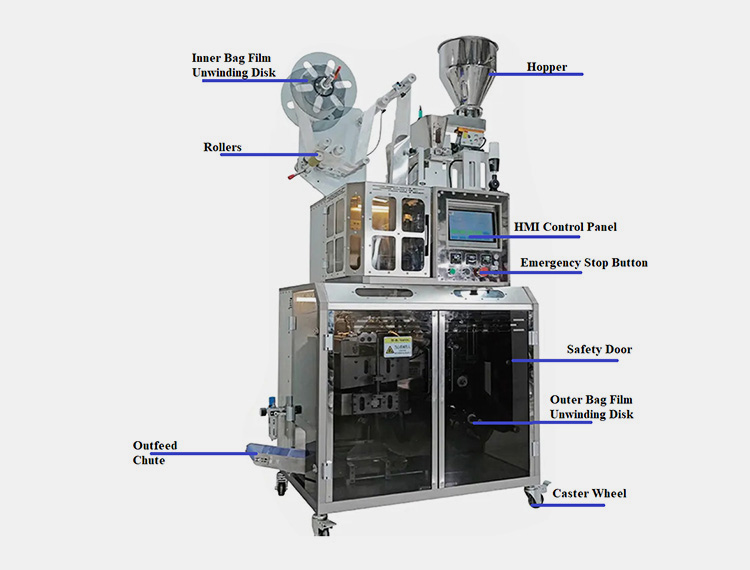

Premade Pouch Filling Machine- Allpack

An equipment designed to form and process pouch packages is known as pouch packaging machine. It is an automatic machine configured with sophisticated technology to enclose multiple food and non-food products into flexible pouches.

The machine is made up of 304 stainless steel body assembled with small to large components which together enable it to form, fill, and seal pouches or process premade pouches. Therefore, it is essential for conducting flawless packaging of hard to sterile goods in food, cosmetic, pharmaceutical, and chemical industry by providing safe and hygienic environment.

3.Enlist The Eclectic Features And Benefits Of Pouch Packaging Machine?

Pouch packaging machine has tailored with astonishing features which gives you plethora of benefits in one way or another. Let's look into these facets!

High Precision

Precisely packed flat pouch display- Picture Courtesy: packagingoftheworld.com

The integration of smart sensors and monitoring system into pouch packaging machine is contributing in the reduction of packaging errors. For instance, the machine ensures precise cutting and sealing of pouches and their filling with accurate volume of material.

Customization

Various customizable liquid sachet pouches

The most alluring attribute of pouch packaging machine is the customization which it offers. You can use the same machine for packaging multiple pouch formats, sizes, sealing types, and processing goods of varying nature by mere changing tools and setting.

Productivity

Multi color liquid pouches stock- Picture Courtesy: Behance

Pouch packaging machine uses automated technology to pack pouches in less time. This efficiency ultimately result in increasing overall productivity of your business.

User-friendly

Operater fixing machine parameters via HMI- Picture Courtesy: Viking Masek

The machine is user-friendly with a touch screen manual interface through which all the information can be fixed in machine. Its processing is smooth, straight forward and does not require complex techniques for application.

Product Protection

User squeezing honey pouch

The internal and external structure of pouch packaging machine is entirely safe from contamination, bacteria, and corrosion. Therefore, no matter how sensitive your products are it will process them in a protected environment while minimizing waste

4.What Are The Different Styles Of Pouch To Be Processed By Pouch Packaging Machine?

Pouches may be found in small to large sizes with varying shapes and sealing. Their styles are influenced by the product preserved inside. Hence, they can be categorized into underlying types which are processed by a pouch packaging machine. These include:

On The Basis Of Shape

Standup Pouch

Detergent pods standup pouch- Picture Courtesy: barteltpackaging.com

Standup pouch is also called doypack pouch. It is one of the most popular styles of pouch due to its durability and strength to stand up right on its own. It is made from combination of aluminum and plastic films. These pouches are commonly processed by a pouch packaging machine to pack pastes, drinks, and powders etc.

Gusseted Pouch

Side and bottom gusseted pouch display- Picture Courtesy: Behance

Another pouch format processed by a pouch packaging machine is gusseted bag. It is known for the provision of allowing more room to fit bulk volume through the pouch fold sides and bottom. Gusseted pouches are best suitable for pet food, tea powder, and detergent powder etc.

Pillow Pouch

Pop corn pillow pouch- Picture Courtesy: Dieline

Pillow pouch is another famous form of pouch usually used for small to large volume of food like potato chips, pop corn, cookies, and dry fruits. Pouch packaging machine provide the additional safety to pillow pouch by infusing nitrogen through flushing. Hence, they resemble pillow and provide safety for sterile foods.

Flat Pouch

3 sided sealed strawberry powder flat pouch- Picture Courtesy: bartletpackaging.com

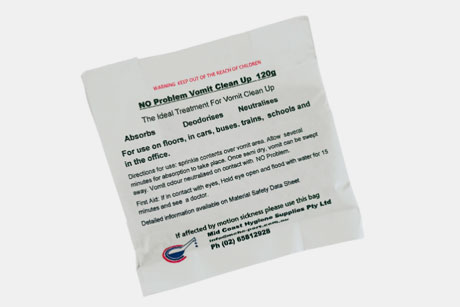

Flat pouch is sometimes called sachet for the reason that it has flat body with no folds and gussets. These flat pouches have 3 sides or sometimes 4 sides sealing to ensure stringent protection against humidity and air. Most of the single serving liquids and powders like spices, hair color, and protein powders are delivered in flat pouches through a pouch packaging machine.

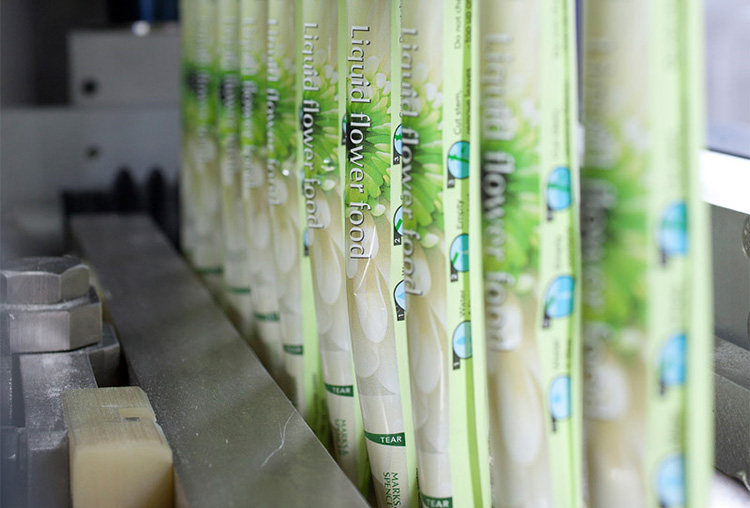

Stick Pouch

Various tea stick pouches- Picture Courtesy: graphics.com

Stick pouch is tubular shape small size pouch known for its capacity of holding unit dosage of powders, gels, and medication. Here, it is pertinent to mention that a pouch packaging machine can create wonderful stick pouches via single as well as multi-lane pakaging technology.

On The Basis Of Closure Sealing

Tin Tie Pouch

Tin tie pouches display- Picture Courtesy: Behance

Such type of pouch has a flexible adhesive tie at the top which can be easily adhere to the pouch opening. These tin tie pouches are recloseable after initial opening. Hence, the product freshness and quality can be retained in these pouches which are eligible to be processed by a pouch packaging machine.

Ziplock Pouch

Ziplock doypacks- Picture Courtesy: packagingoftheworld.com

Ziplock pouch is sometimes referred to as zipper pouch due to its sealing. There are two types of zippers; press to close and slider zipper. They are popular for being child resistant which makes them difficult to open by kids but can be easily opened by adults.

Spout Pouch

Multiple customized juice spouted pouches- Picture Courtesy: packagingoftheworld.com

Spout pouches are mostly used for liquids and pastes because of convenient way for using material multiple times due to a recloseable spouts. In this way, a pouch packaging machine is best suitable to create spout pouches and pack them with relevant substances.

Heat Sealed Pouch

Heat sealed garlic crackers doypack pouch- Picture Courtesy: Bartlet

Heat sealed pouches are another type of pouches whose opening is sealed via heat. The common example of heat sealed pouches are those pillow pouch, stick pouch, and flat pouch which are meant for delivering insensitive goods like candies, coffee, and detergent powder etc.

Cold Sealed Pouch

Cold sealed chocolate flow wrap pouches

Cold sealed pouch, on the other hand, is referred to the same class of pouches like pillow pouch, stick pouch, and flat pouch which contain sensitive materials, like chocolate or drugs, that might be affected by heat sealing. Hence, they are sealed via adhesive.

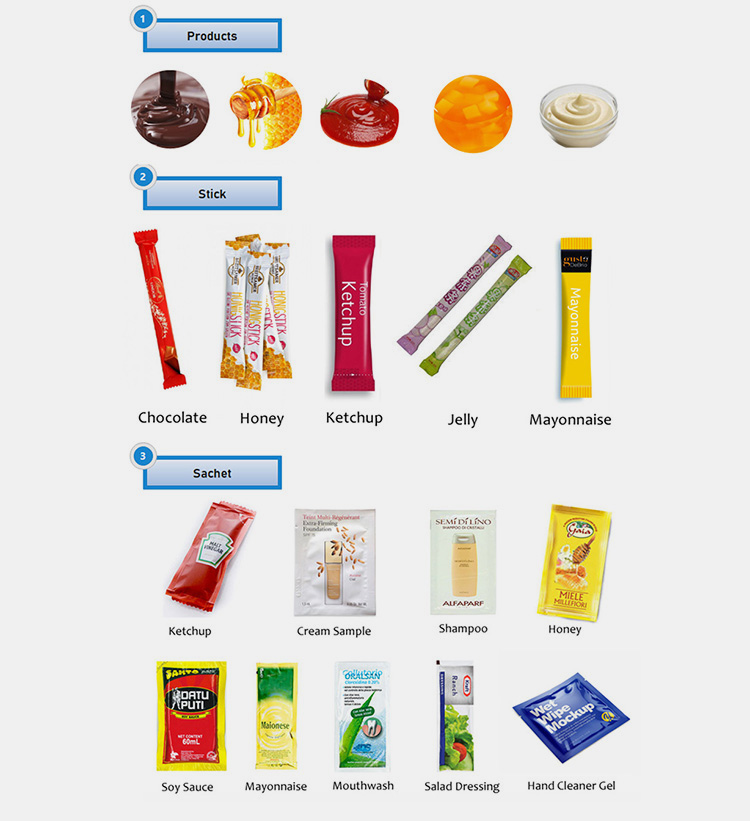

5.Name The Popular Products Which Can Be Processed By A Pouch Packaging Machine?

Pouch packaging machine has a broad spectrum in terms of processing multifarious food products encompassing liquid, solid, and semi-solid goods. Below description will provide a valuable insight in this way:

Drinks

Coffee drink standup pouch display- Picture Courtesy: Behance

All types of drinks including milk, coffee, juices, and spirits are suitable to be processed by a pouch packaging machine. For instance, the common packaging style employed for drinks include spouted doypacks.

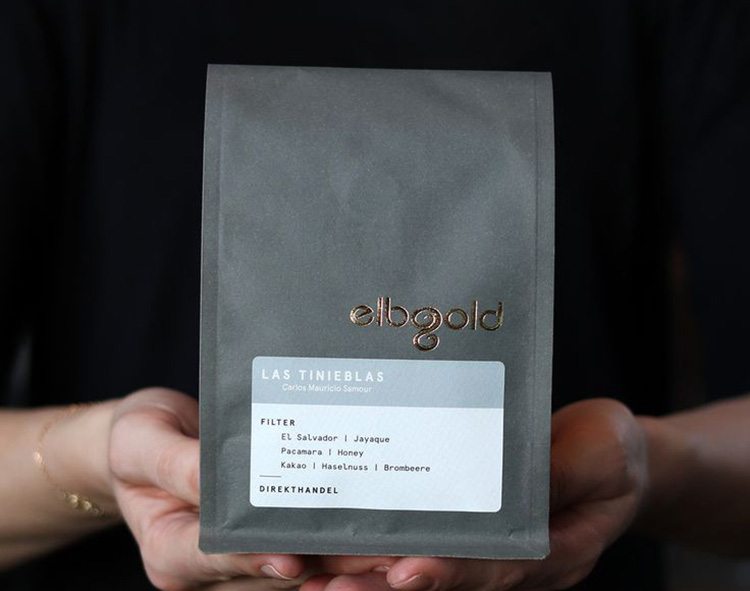

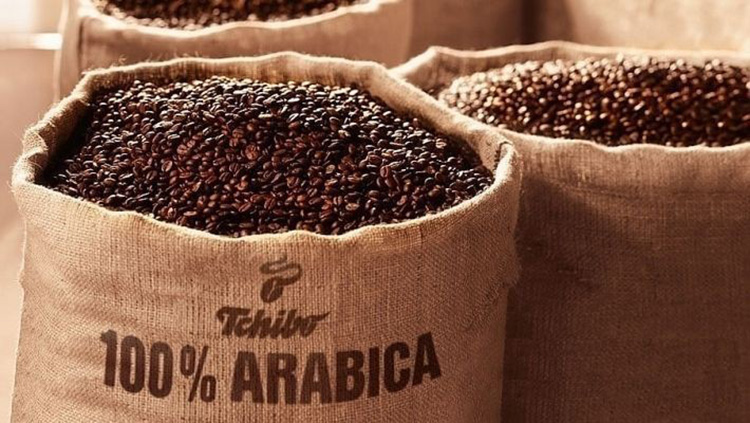

Powders

Coffee powder- Picture Courtesy: Bartlet

Powders are among other materials which you can easily pack while using a pouch packaging machine. Condiments, herbal powder, protein powders, and tea etc., are the common examples in this context.

Pastes

Tomato ketchup presentation idea- Picture Courtesy: fashion-kitchen.com

Handling pastes like ketchup, mayonnaise, seasonings, and peanut butter become quite difficult due to their high viscosity. However, pouch packaging machine has now transformed this area by providing one-step solution to pack these pastes in different pouch formats.

Granules and Flakes

Flakes in bowl

You can also pack your manufactured corn flakes, breadcrumbs, fish pellets, and grains etc., through pouch packaging machine.

Snacks And Confectioneries

Pretzels- Picture Courtesy: Bartlet

Preservation of snacks is what pouch packaging machine is well known for! So, whether these are candies, jellies, chips, chocolates, biscuits, crackers, potato chips and or anything under your production, you can use this machine for their remarkable packaging.

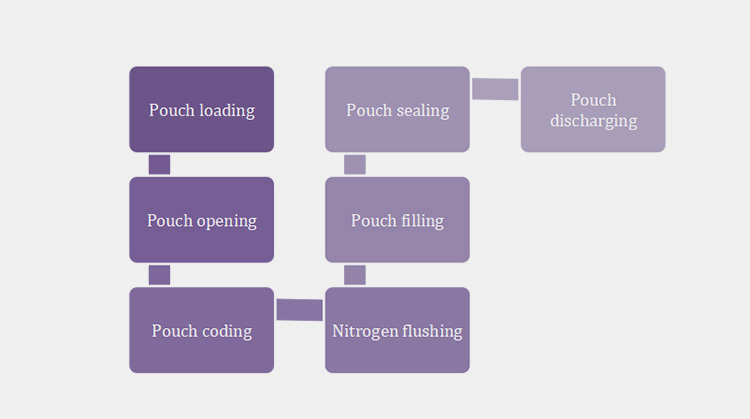

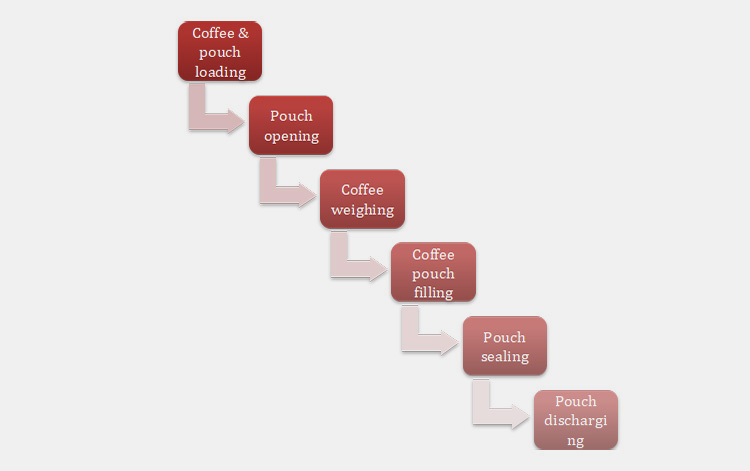

6.Elaborate The Working Principles Of Pouch Packaging Machine?

Mere opting for a right machine does not indicate the success of your business. But operating it on right principles is what determine the real victory. That's why we have explained below the accurate working principles of a pouch packaging machine:

Pouch Loading

Premade Pouch loading in machine magazine- Picture Courtesy: bartletpackaging.com

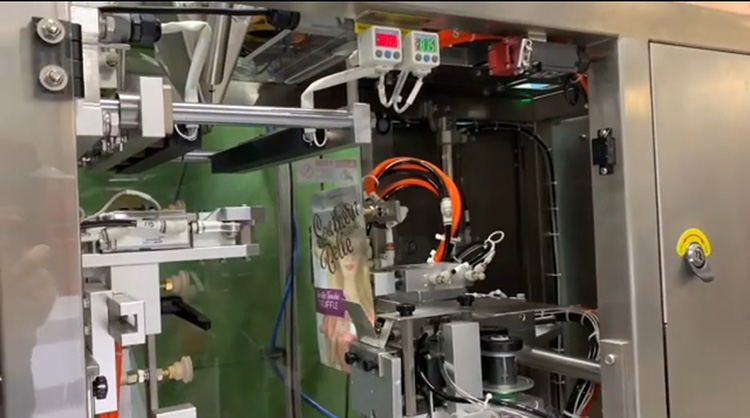

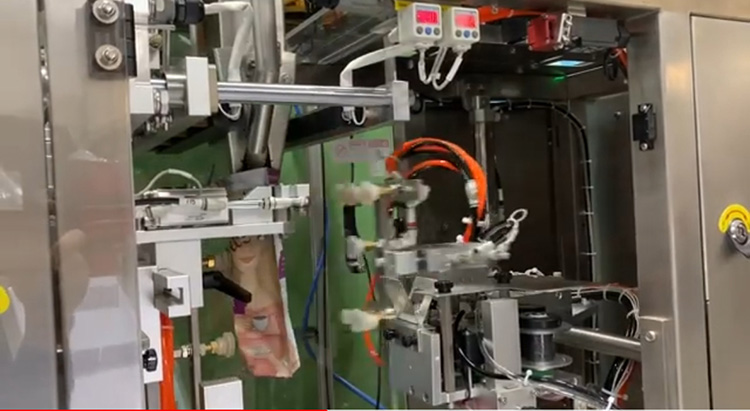

The working process begins with operator manually placing premade pouches in pouch magazine. From here, the bags are supplied into machine automatically via pouch feeding roller. Apart from this, the modern technology of robotic arm has produced much ease where this arm picks the pouch and deliver it to machine.

Pouch Opening

Premade Pouch opening process- Picture Courtesy: Viking Masek

Once the pouch is picked up from magazine, the grippers on both sides tightly grip the pouch from vertical opposite sides. At this point, the pouch is opened with the help of vacuum suction pad from top and is ready for filling.

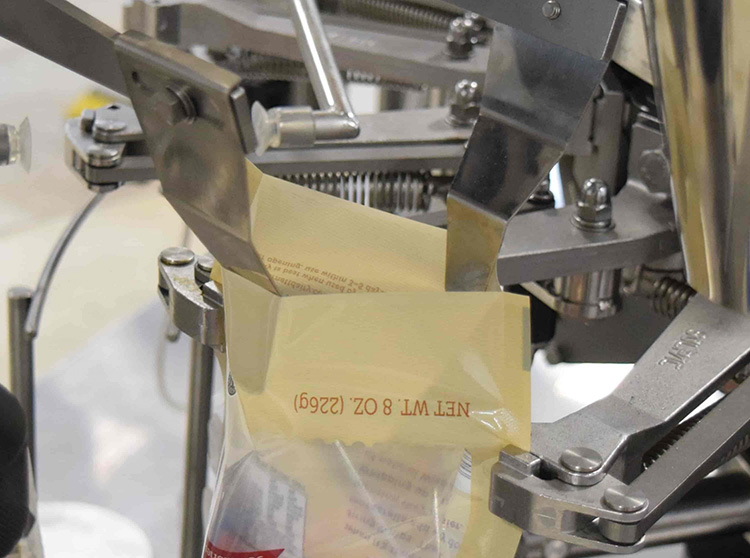

Pouch Coding

Pouch coding is optional yet important step where batch no and date of expiration is printed over pouches.

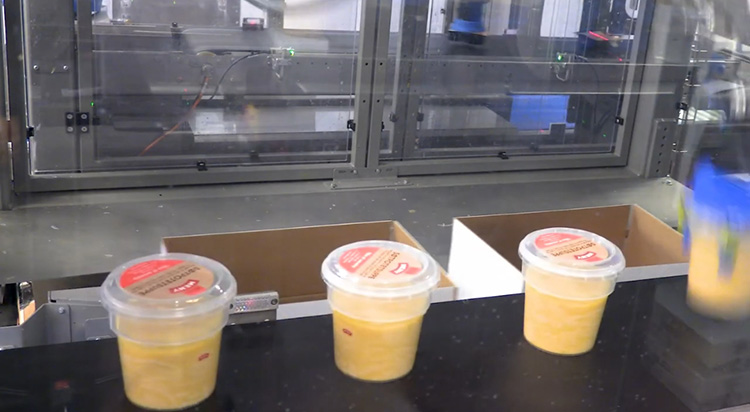

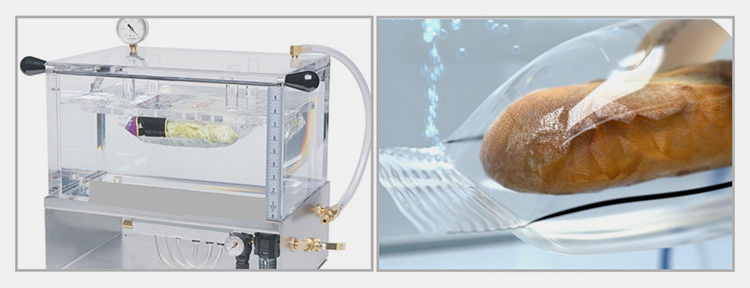

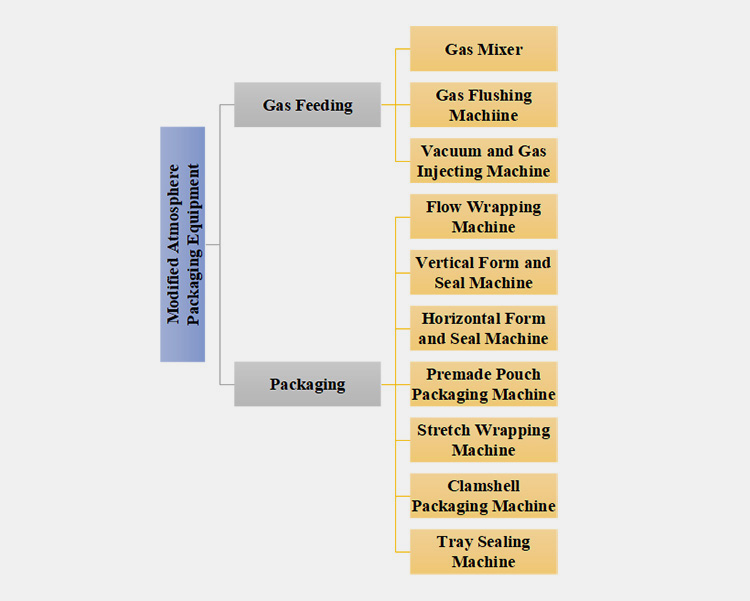

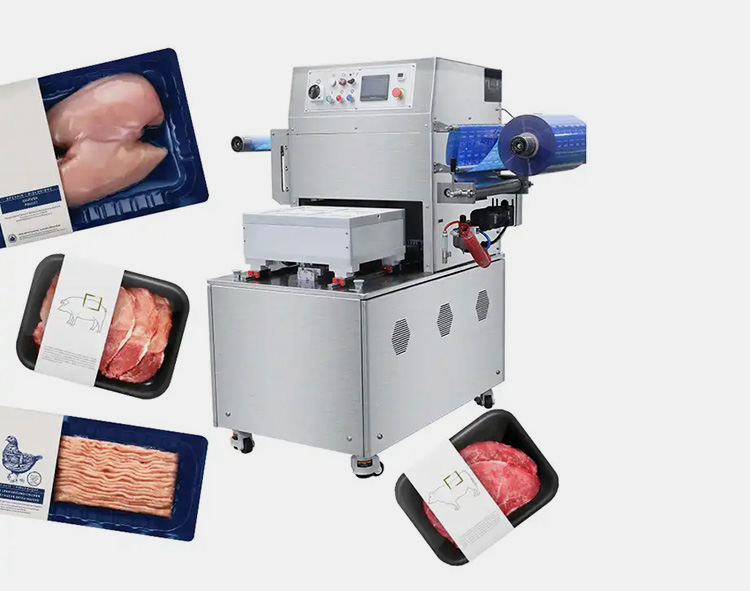

Nitrogen Flushing

Premade Pouch nitrogen flushing & filling process

Before filling, modified atmosphere packaging technique is employed for the displacement of oxygen from pouches through nitrogen flushing. The intermittent flushing of nitrogen releases the oxygen from pouch creating safe place for products stay.

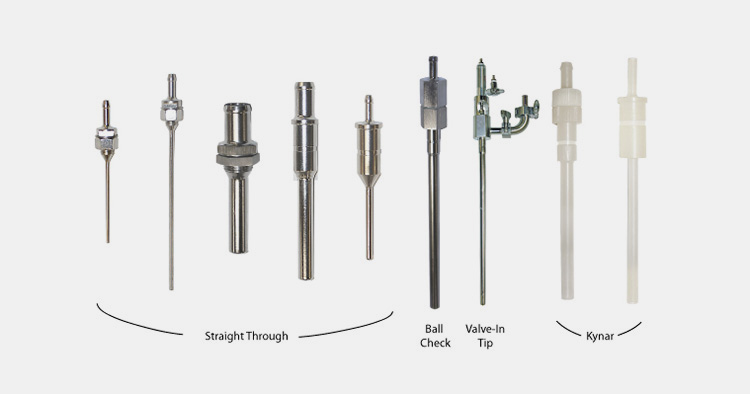

Pouch Filling

Premade Pouch Filling- Picture Courtesy: Viking Masek

In this stage, the presence of pouch is detected by the sensors which communicate signals to machine. Hence, a precise dosage of material is pumped into pouch. Liquid filling equipment is responsible for the accurate measurement as well as discharging of liquid materials. While as auger filler or other solid filling machine undertake the same step for powders and granules.

Pouch Sealing

Premade pouch sealing- Picture Courtesy: JDA Progress

The last step is carried out by sealing station to form a strong air-tight sealing on the top of pouch by using heated sealing jaws.

Pouch Discharging

Finished pouch discharging- Picture Courtesy: Weigh Pack

Finally, the finished product pouches are taken out of machine in a gradual manner and collected in a container with the help of conveyor.

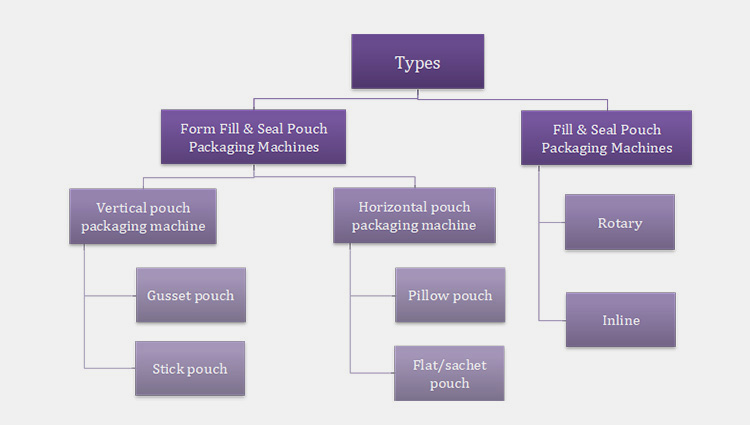

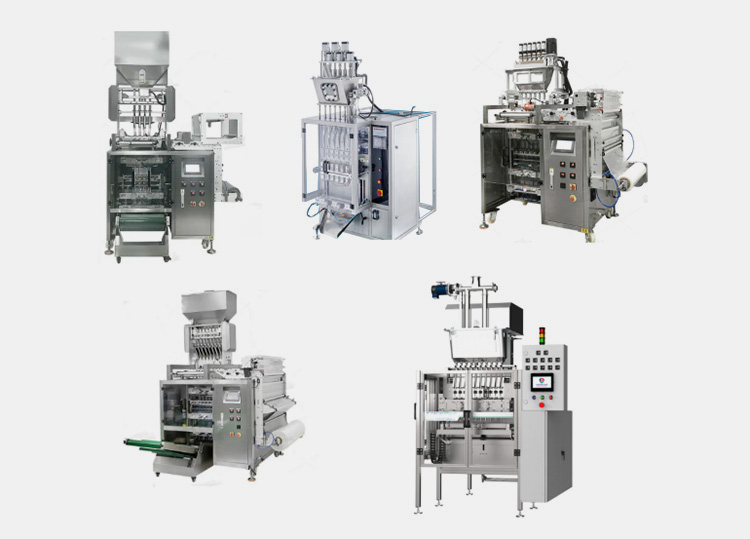

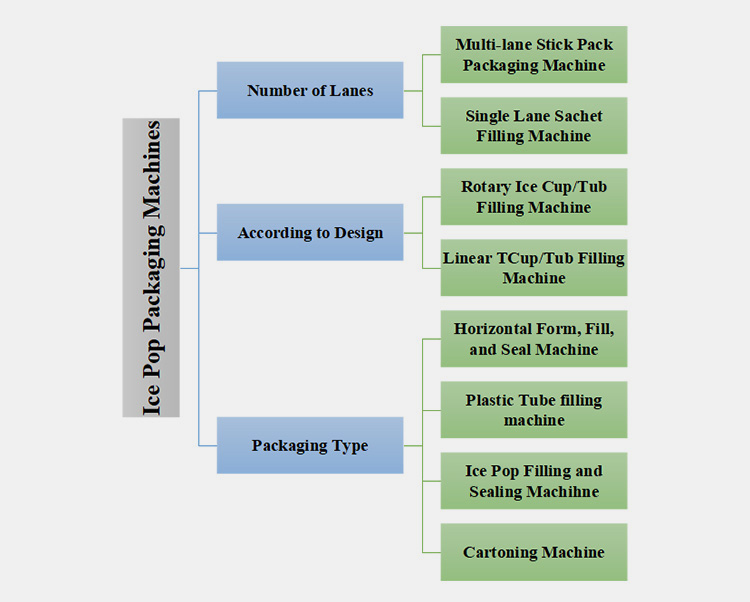

7.Are There Any Types Of Pouch Packaging Machine?

The term pouch packaging machine is broad enough that can be easily categorized into complex types. These are as follows:

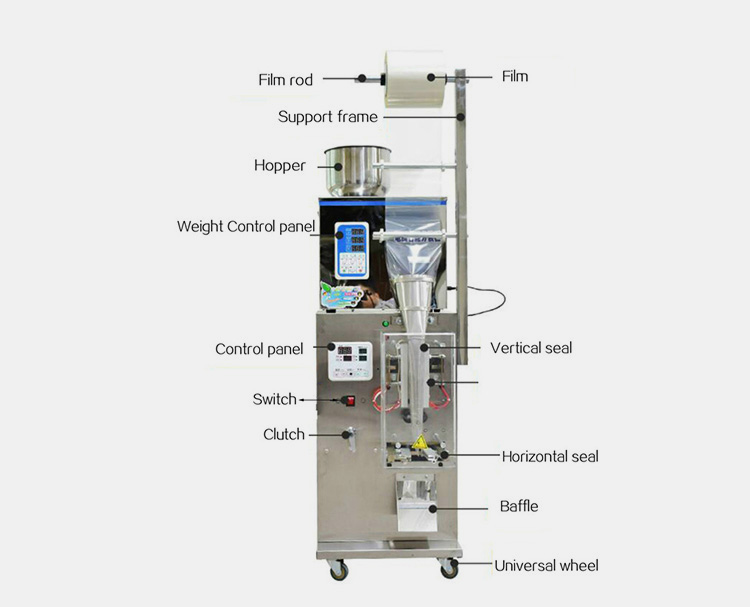

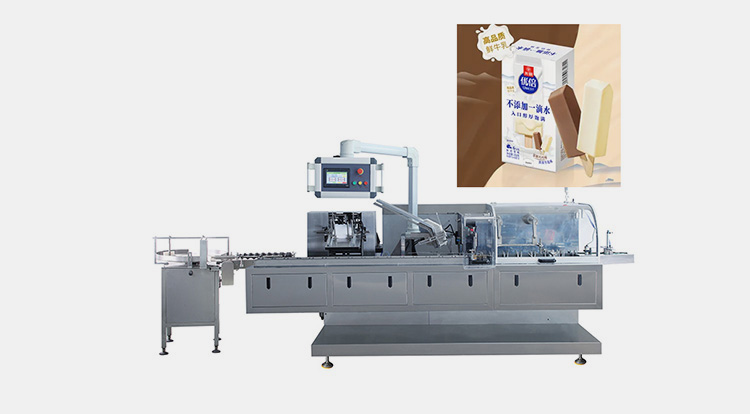

Form Fill And Seal Pouch Packaging Machine

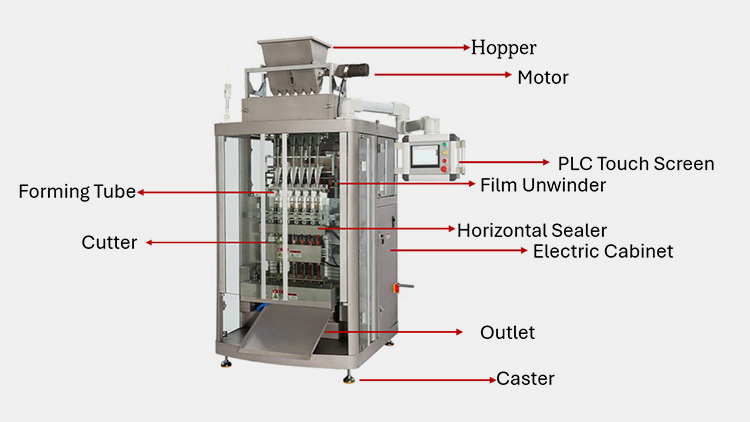

Vertical Pouch Packaging Machine

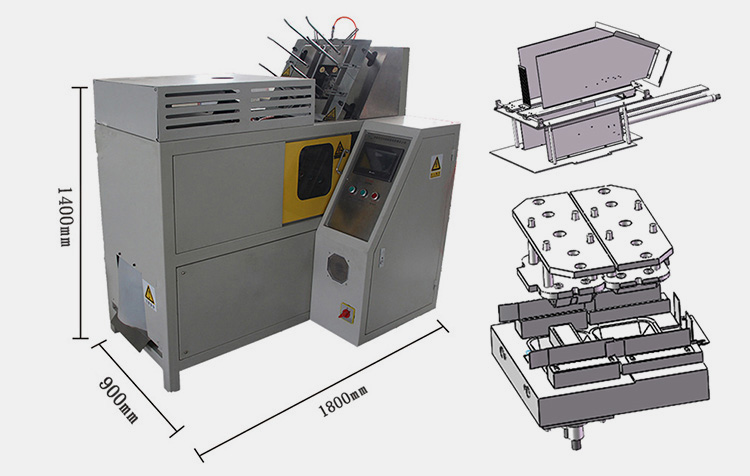

Automatic Vertical Gusset Pouch Packing Machine

Automatic Vertical Gusset Pouch Packing Machine

Automatic vertical gusset pouch packing machine is a significant apparatus utilized for packaging of gusseted bags. The machine is intelligent enough to alter the length and width of pouches and form small to large gusset pouches from film.

Structure

The machine is an assembly of multiple parts. These include a hopper for holding material, screw conveyor for transporting material, auger filler for weighing, touch screen for parameters setting, bag forming and sealing parts followed by finished product conveyor.

Working Principles

It simply begins the operation by forming a gusset pouch by pulling film from roll on one hand, while as, transporting the material from hopper to auger filler and its weighing on the other. Similarly, the bag is formed in a way that the side gussets remain folded inward to pouch, and the pouch is sealed vertically and from bottom. Proceeding further, material is poured into pouch, the pouch is sealed and discharged via conveyor.

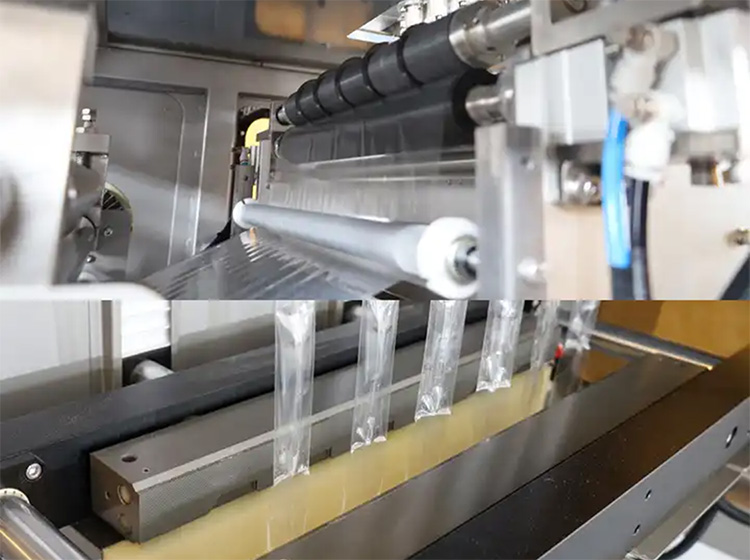

Vertical Pouch Stick Packing Machine

APK 2-220 Automatic Powder Vertical Pouch Stick Packing Machine- Allpack

Vertical stick pouch packaging machine is a form of Pouch packaging machine having specialized features to form and process long narrow stick packs. This machine by Allpack can be used for packing different powders and granules. Moreover, you may also process lquids and pastes by opting for a liquid vertical stick packing machine.

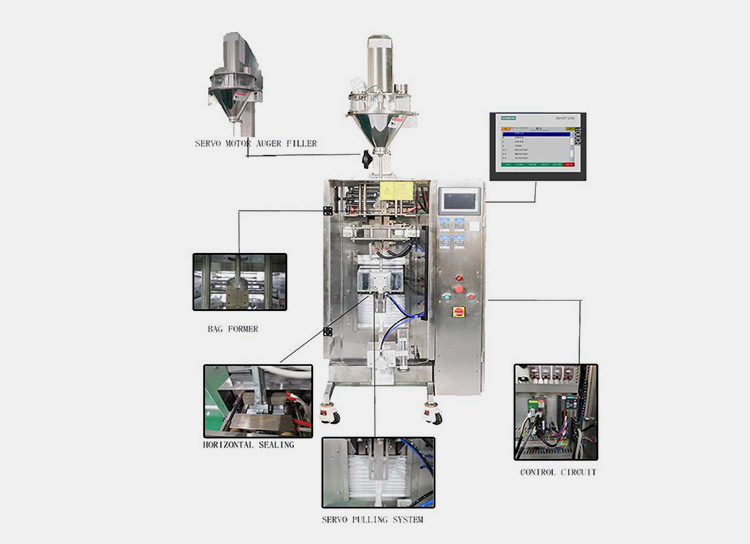

Structure

The machine has a small vertical structure comprising servo motor auger filler, bag former, horizontal sealing, servo pulling system, control circuit, human machine interface, and a stainless-steel body.

Working Principles

It works by unwinding film from stock and turning it into a long narrow stick pouch by creating bottom horizontal seal and back side vertical seal. After the formation of stick pouch precise dosage of powder, granules, or liquid is enclosed into pouch and it is sealed from top by using heat sealing. Finally, the pouch is ready to be placed on market shelves.

Horizontal Pouch Packaging Machine

Automatic Horizontal Pillow Packaging Machine

Automatic horizontal pillow packaging machine is an ideal equipment for packing your solid products individually. It can be easily integrated with other machines for supplying goods and further packaging the packed products.

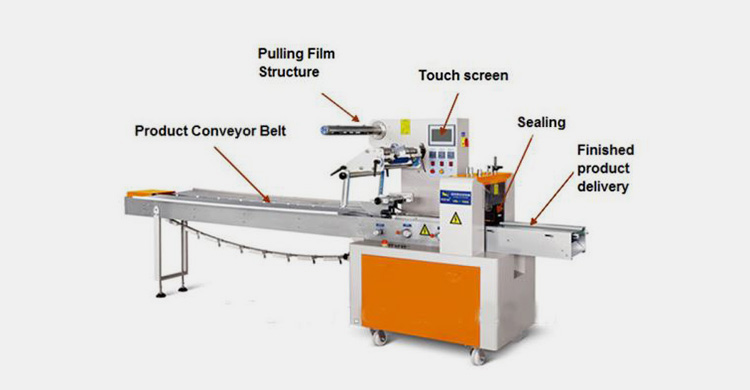

Structure

Horizontal pillow type packaging machine- Picture Courtesy: qualityfoodmachine.com

The machine is characterized by its horizontal structure made up of a robust frame, date printing function, a stainless-steel long conveyor belt, film roll, control unit, heat sealer, and PLC touch screen penal.

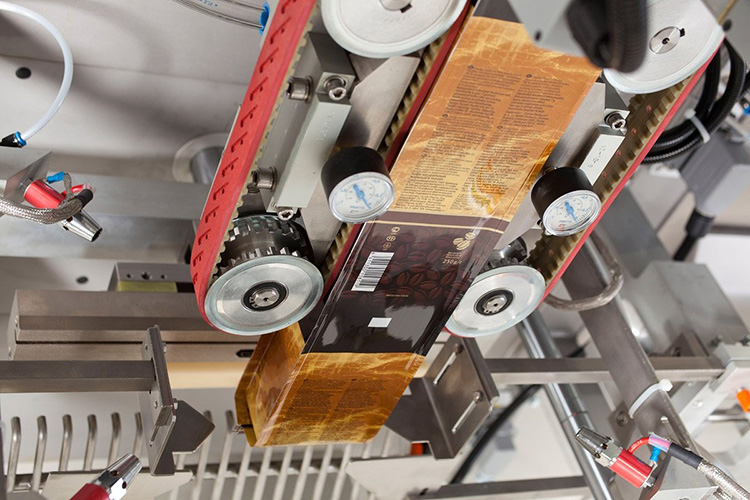

Working Principles

Its working process typically start with conveyor taking the product from infeed towards film reel where film is released over the products. Afterwards, the products, wrapped with film, pass through the sealing channel where they are sealed from top, bottom, and back side. During this process, the expiration date is printed over individual packs and these finished pouches get discharged through conveyor belt.

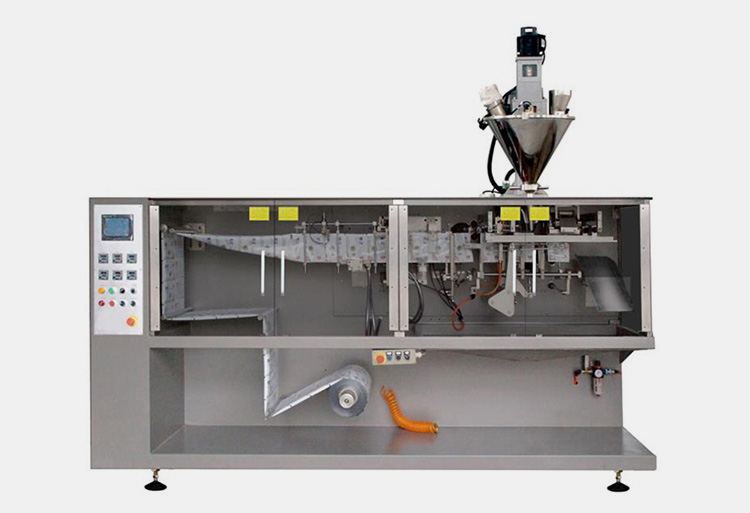

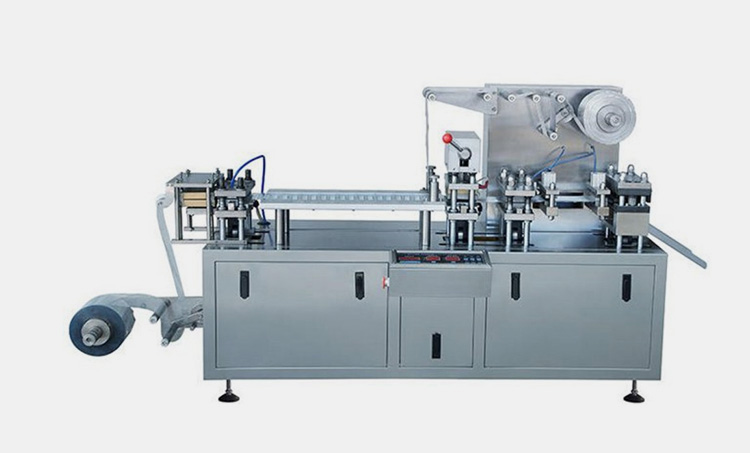

Flat Pouch Horizontal Sachet Machine

APK-110 Flat Pouch Horizontal Sachet Machine- Allpack

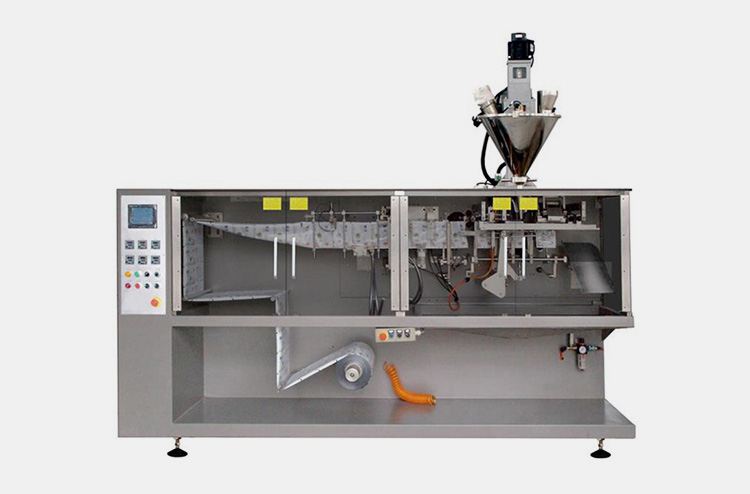

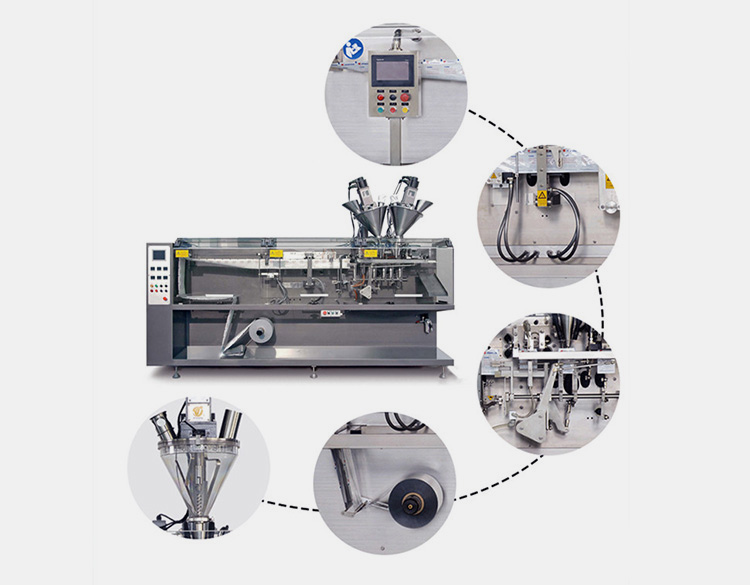

This pouch packaging machine is particularly designed to pack flat pouch or sachets. With small footprint and horizontal structure, the machine perform multiple tasks of flat pouch forming, filling, and sealing simultaneously. Furthermore, you can also create customized flat pouches such as sachets with crosswise corrugation, twin bag sachets, sachets with tear-off notch etc.

Structure

Automatic horizontal packaging machine- Picture Courtesy: foodmachinesale.com

Several components make the body of a flat pouch horizontal sachet machine including a feeding hopper, film roll, control board, stainless steel main frame, filling nozzle, and a coding device.

Working Principles

The working principles involve film unwinding from roll and its transportation towards forming station. Here, the formation of sachet takes place via vertical sealing. Afterwards, material is weighed and filled in sachets. At this point, sachets undergo last sealing of top side, ultimately, turning them into finished flat pouches.

Fill And Seal Pouch Packaging Machine

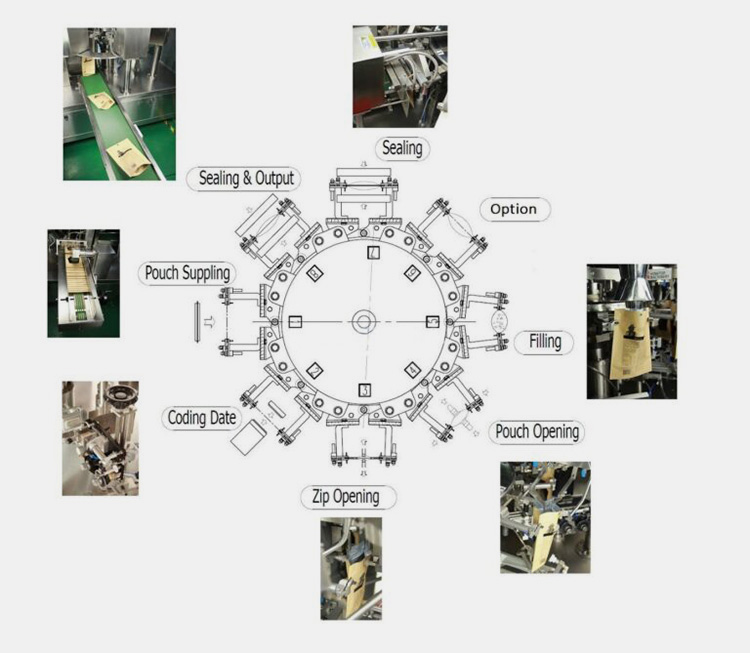

Rotary Premade Pouch Filling Machine

APKRL-GD-ZK130G Rotary Vacuum Premade Pouch Filling Machine- Allpack

Rotary premade pouch filling machine is a topnotch machine with fully automatic features to process premade pouches. The machine independently realizes the entire operation and give you an errorless output by detecting abnormalities and displaying them through control panel.

Structure

Structure of automatic rotary premade pouch packaging machine- Picture Courtesy: Makwell Machinery

It is made up of advance quality tools and components among which primary ones include a multihead weigher, material hopper, Z-shaped bucket elevator, and a doypack machine having multiple tools for filling, sealing, and coding pouches.

Working Principles

With extremely convenient working steps the machine automatically transfer material from hopper into multihead weigher. At the same time, a robotic arm pick up premade pouches from magazine, open these pouches, load them with accurately measured products, print date and batch no on these pouches, and finally seal them stringently before ejecting from machine.

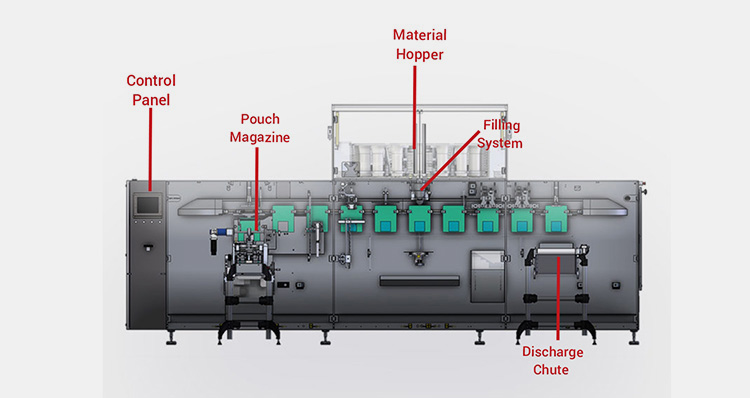

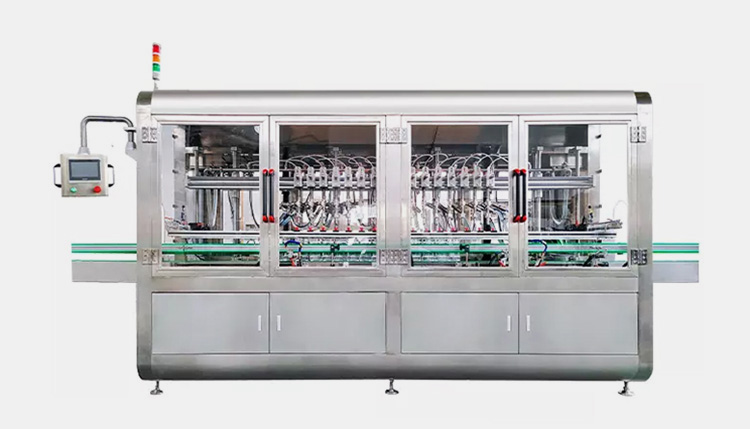

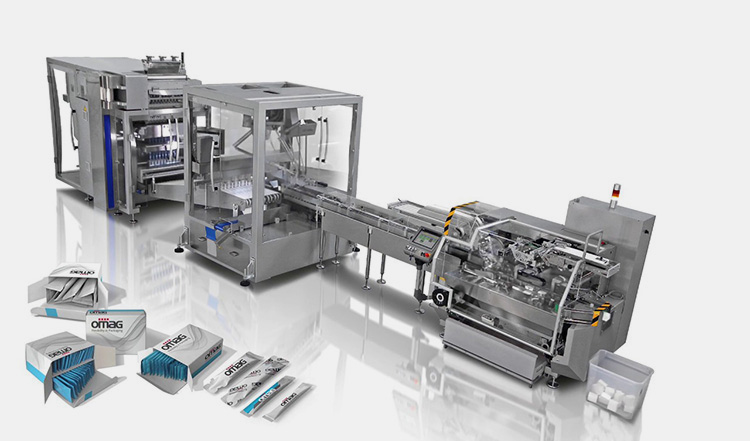

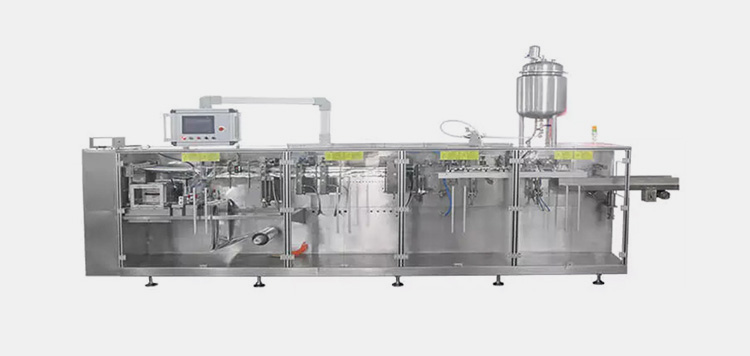

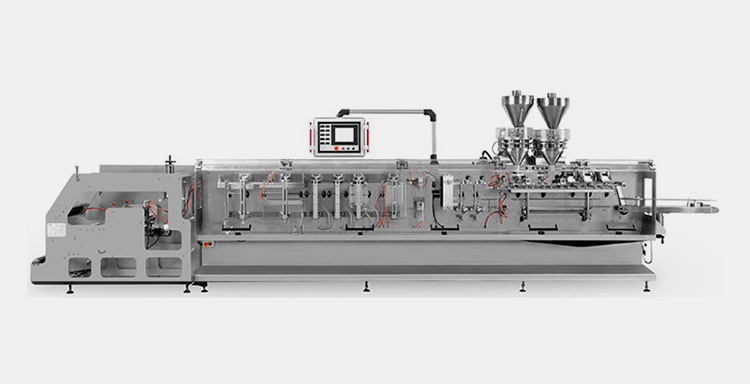

Inline Premade Pouch Packaging Machine

Inline premade pouch packaging machine- Picture Courtesy: bartletpackaging.com

Inline premade pouch packaging machine offers high speed processing of premade pouches. The machine follows linear way to fill and seal premade pouches with different sealing such as spouts and zippers.

Structure

The machine is characterized by a linear horizontal structure made from stainless steel. This structure has its subcomponents such as control panel, pouch magazine, material hopper, filling and sealing system, coding device, and discharge chute.

Working Principles

It follows the sequential order of taking premade pouch from magazine and passing it through multiple straight sections. Here the pouch is opened, filled with material, get sealed, printed and ultimately discharged by the machine.

8.Highlight The Diverse Sectors With Need For Pouch Packaging Machine?

The use of a pouch packaging machine is realized in multiple fields and industries. Some of the prominent are discussed below:

Food Industry

Chilli snacks pouch packaging presentation idea

Food industry is a broad term that include all sub-sectors encompassing coffee industry, confectionery industry, condiments industry, pet food industry, and beverage industry where the non-stop process of packaging food into pouch take place. This task is accomplished by a pouch packaging machine.

Cosmetic Industry

Shampoo & conditioner spouted doypack pouches- Picture Courtesy: hairburst.com

The versatility and convenience of pouch packaging machine has made it applicable to all kinds of cosmetics packaging into pouches. For instance, bleach powder, hair color, lotion, and shampoo are some of the cosmetic products which are regularly delivered in small to large pouches.

Medical Industry

Bulk capsules- Picture Courtesy: bartletpackaging.com

Medical industry is an area where hygiene is the top priority for the processing of drugs, powders, tools, and equipment. In this way, pouch packaging machine is always suitable for providing the protected and uncontaminated environment for the packaging of pharmaceutical and surgical related objects.

Hardware Industry

Jewelry in flat zipper pouches- Picture Courtesy: SHEIN

You may get surprised how hardware industry can get benefits from pouch packaging machine. Well, it is possible because of the customers proclivity to have their products, from stationary items to kitchen tools, and jewelry, packed in pouches processed by pouch packaging machine.

Daily Chemical Industry

Multiple laundry powder pouches

Daily chemical industry which commonly involves the manufacturing and processing of detergent powders, dish wash powder, and floor cleaning agents, is among other sectors where pouch packaging machine is popularly used.

9.Why Is Nitrogen Flushing Significant For Pouch Packaging Machine?

Continuous nitrogen flushing machine

Nitrogen flushing is the process of eliminating the presence of oxygen in pouches by continuously inserting and removing nitrogen gas. In this way, the excess oxygen is removed out making pouch free from bacteria. This is a common practice employed along with pouch packaging machine due to underlying reasons:

- Nitrogen flushing is excellent for fragile eatables like potato chips, flakes, and biscuits which might det distort during transit.

- Nitrogen is a safe gas that we inhale in our daily life due to its presence in atmosphere. Therefore, it provides safe environment for food products to stay fresh for a longer period of time.

- It gives the pouches beautiful bouncy appearance that appeal to consumers while laying on the shelves.

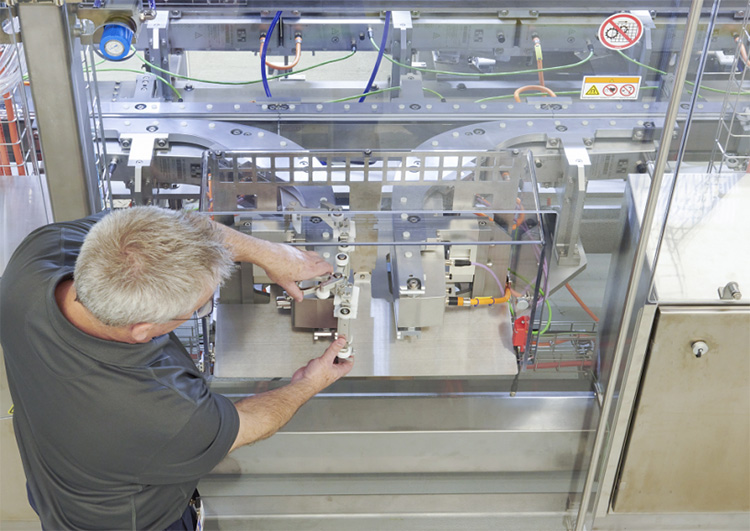

10.Tips For Routine Maintenance Of A Pouch Packaging Machine?

Operator maintaining pouch packaging machine- Picture Courtesy: bartletpackaging.com

The maintenance of Pouch packing machine is necessary because it improves the efficiency and the oveall performance of machine. It helps to prevent the unexpected breakdowns also extends the durability of machine. It can reduce the hazards by ensuring the safety of equipments. Following are some tips for routine maintenance:

Regular Cleaning: Cleaning the machine on regular basis will help to maintain the durability of machine. It includes the cleaning of conveyors, nozzles and other sealing components.

Lubrication: The moving parts of machine should be lubricated timely to avoid the friction which can damage the parts of machine.

Inspection: In inspection the sensors and switches of the machines are tested to ensure their functionality. Faulty switches and sensors can cause errros in packing process.

Replacing the Parts: Belts gaskets and parts like that can be worn. They have to be replaced by the new ones to avoid errors in the process.

11.What Are The Common Errors Of Pouch Packaging Machine?

What if you face sudden interruption during packaging while operating a pouch packaging machine? It might throw you in trouble. So, let's discover the possible solutions to the common errors:

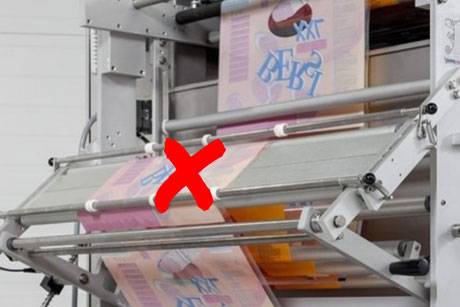

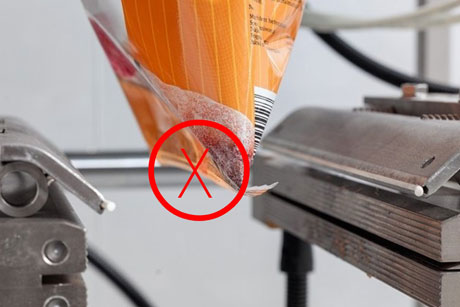

| No | Errors | Causes | Solutions | Pictures |

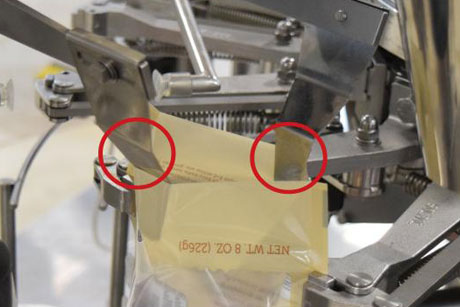

| 1 | Pouch feeding and opening errors | The possible causes include dirty sensor, breakdown of vacuum pad, or incorrect timing which are creating trouble in catching pouches | It can be resolved by adjusting the pouch picking time, cleaning sensors, modifying vacuum pressure or replacing vacuum pad if broken |

Encircled pouch opening bags- Picture Courtesy: Viking Masek |

| 2 | Defective sealing | This is one of the serious issues occur due to improper temperature of sealing bars and in some cases as a result of pollution and scratches over sealers | You can sort it out by modifying the sealing temperature to moderate and required level. Also, removing dirt will help in minimizing the effect of scratches. In case of damaged seals, replace them with new ones. |

Defective sealing- Picture Courtesy: Canadian Food Inspection Agency |

| 3 | Inaccurate material filling | The reasons vary from faulty machine setting to worn out cells of load cells and product density issues | Make sure the setting of machine is accurate as per product density. Also, examine damaged parts for correction |

Inaccurate liquid filling into pouch- Picture Courtesy: calex.co.uk |

| 4 | Product Jam | Another significant issue you may counter is he product jam caused by too large material size or accumulation of debris in hopper or nozzles | Alter the specifications of machine in accordance with material size. Along with that, keep your machine clean and free from debris |

Film pulling error- Picture Courtesy: Viking Masek |

| 5 | Pouch forming issues | It happens as a result of partial film pulling and misaligned film roll | Troubleshoot it by placing the film roll onright place and check the film pulling station for removing stagnancy |

Identifying pouch forming issues- Picture Courtesy: smartpackmc.com |

12.What Should Be Considered For Purchasing A Brilliant Pouch Packaging Machine?

Purchasing a sophisticated pouch packaging machine that is complete from every angle is a difficult but important task. You can take advantage of the below factors by considering them:

Type Of Material

Multiple confectioneries- Picture Courtesy: bartletpackaging.com

It is essential to consider the type of product you want to pack. It will simply cover the questions regarding product nature such as liquid or solid, free flowing or adhesive. In this way, you will be able to have a big insight regarding the type of pouch packaging machine.

Speed & Capacity

Automatic multi-lane liquid sachet packaging machine- Picture Courtesy: Landpack Packing Machine

Another aspect of pouch packaging machine to look for is its efficiency in terms of packaging and the amount of pouches it packs per hour. By determining these factors, you can opt for most compatible machine

Price

There are numerous machines available in market from fully automatic expensive machinees to cost-effective manual and semi-automatic machines. Moreover, if you want to purchase cheap but effective machine, there is option to go for heavy-duty second hand pouch packaging machine.

Quality & Warranty

Quality warranty icon

Before spending your money on pouch packaging machine look into the quality of machine, its compliance to national and international quality certification institutions. Furthermore, for your satisfaction warranty policy can also be checked to avoid fraudulent activities.

Conclusion

Now, it's time for closing up this detailed buying guide about Pouch Packaging Machine, which we hope has fulfilled the purpose of communicating information to you. Pouch Packaging Machine is a resilient machine and providing one-step solution to all your needs regarding pouch packaging. So, don't make delay in taking right step. We are always here to help you out by presenting the world's best pouch packaging machines offered by Allpack. Are you interested in exploring them? Just click on the given link!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Pouch Packaging Machine: The Complete Buying Guide In 2025 Read More »