Lubricants Oil Bottling Line: The Complete Buying Guide In 2025

Lubricants Oil Bottling Line: The Complete Buying Guide In 2025

It is not possible to drive a vehicle without using a lubricants oil?

Lubricant oils are efficient solutions for the life of any vehicle. They assist in the smooth functioning of both light-duty and heavy-duty vehicles. The oiling vehicle is beneficial for its efficiency and speed.

However, these oils must be packaged in suitable containers like bottles, and here is where the lubricants oil bottling line has a special place. It consistently and reliably packs all and sundry lubricant oils and engine oils. It is a complete turnkey solution to manage and process engine oil bottles with speed, efficiency, and precision.

Before setting up a lubricants oil bottling line, read this interesting blog post. In this guide, we will discuss all that there is to learn about the lubricants oil bottling line . Let’s begin an informative journey.

1.What is a Lubricants Oil Bottling Line?

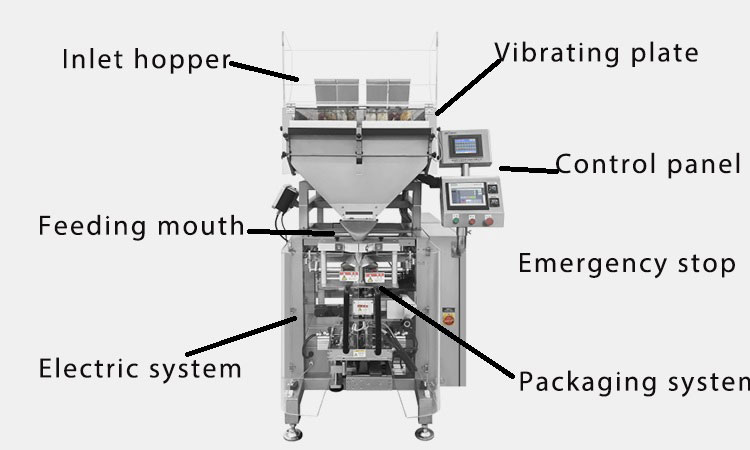

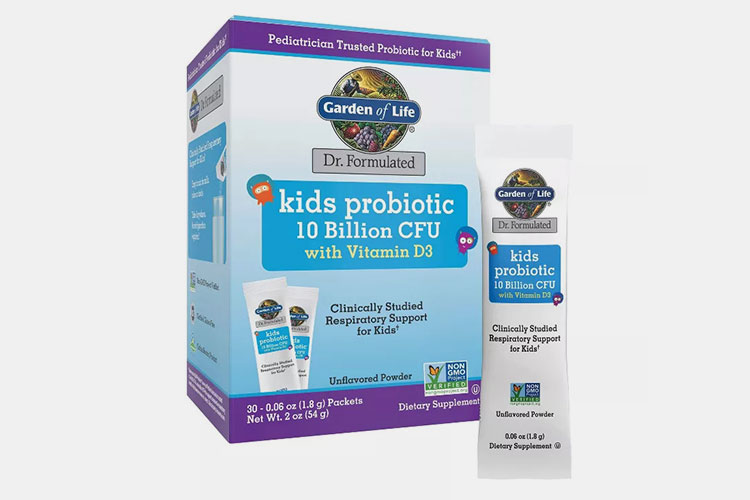

Lubricants Oil Bottling Line

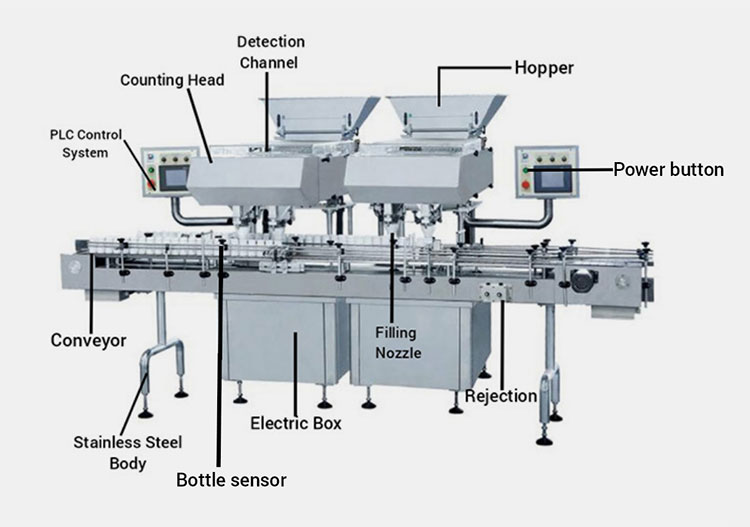

A lubricants oil bottling line is an assortment of series of machines that align, fill, cap, and label the lubricant oil and engine oil bottles.

Different units like the unscrambling machine, bottle filling machine, capping machine, and labeling machines are linked together for effective handling and uniform packaging of lubricant oils and engine oil bottles. Because of its proficient packaging, it is needed in every industry dealing with liquids.

2.How beneficial is lubricants oil bottling line to production?

A lubricants oil bottling line comes with a handy set of benefits that expands the success avenues of the businesses. With its skill, it offers extraordinary packaging outcomes. It maintains the packaging quality and integrity of lubricant and engine oils. Some of the incomparable benefits of the lubricants oil bottling line are listed below:

Accuracy with Precision

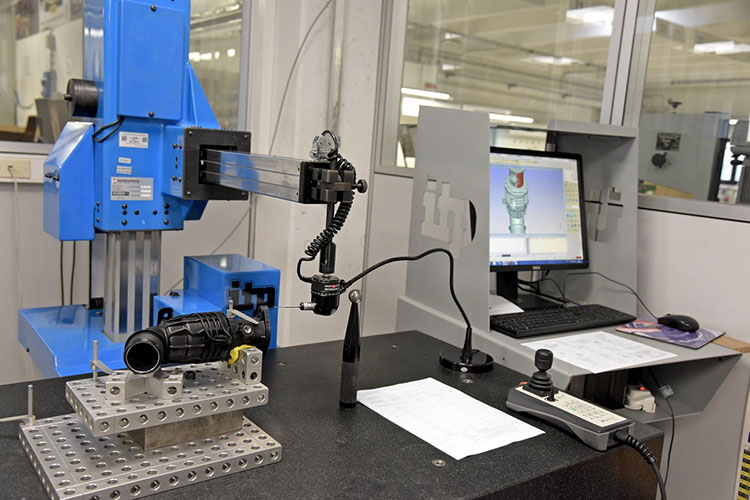

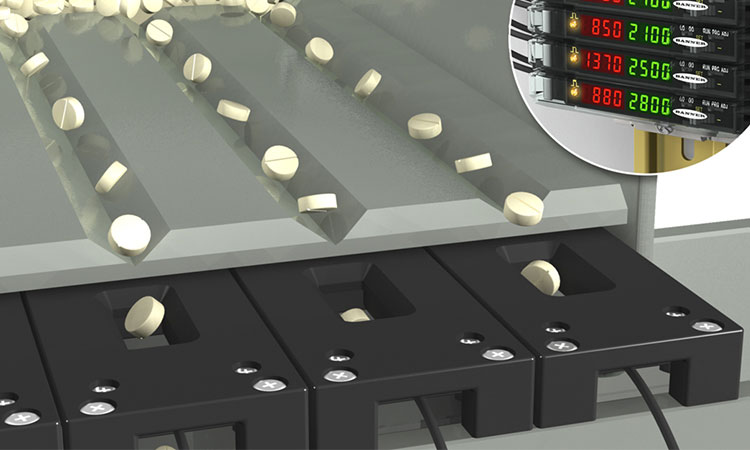

Accuracy with Precision- Picture Courtesy: GrabCAD

Packaging variations often result in a decrease in customer trust and product recall. Manual labor is filled with poor packaging results. However, there are extremely accurate sensors present in every machine in the lubricants oil bottling line, which offer extremely precise results every time. Filling, capping, and labeling processes are consistent with no packaging variation with this bottling line.

Single Click Setting

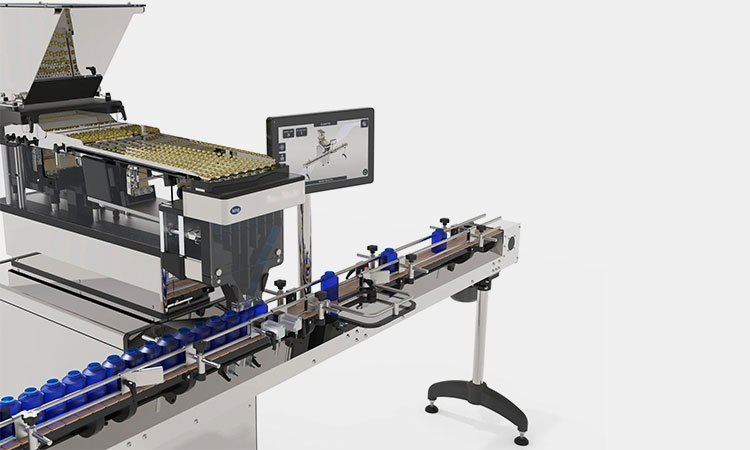

Single Click Setting- Picture Courtesy: Design and Packaging Inspiration Blog

With the integration of a lubricants oil bottling line, there is no need to watch and supervise different machines all day long. Operators simply have to click a few buttons, the rest of the packaging functions are carried out by the machines themselves. There is no need for a long line of operators to manage this bottling line.

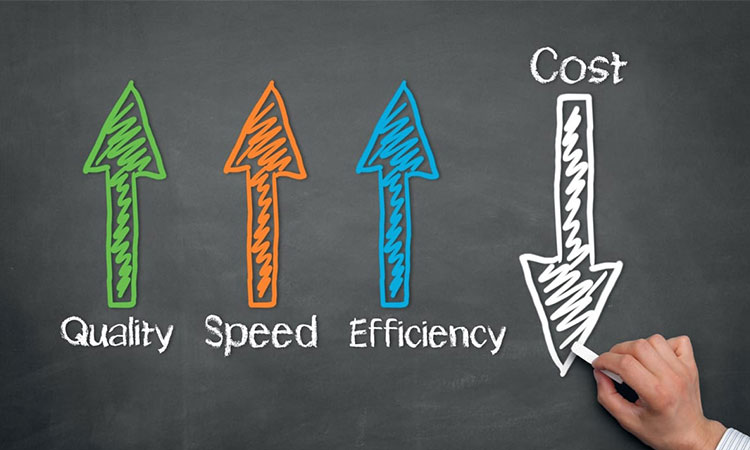

Cost-effective Solution

Cost-effective Solution- Picture Courtesy: Studio111design

Because it limits the necessity of manual labor, leading to saved labor wages. This feature makes lubricants oil bottling line a cost-effective solution. No packaging error means no product wastage in this bottling line, which in turn saves product expenses.

Adaptable Flexibility

Adaptable Flexibility- Picture Courtesy: Pinterest

Brands do not process a fixed set of bottle formats, instead, they handle a variety of bottles differing in their designs every day. Therefore, brands prefer to utilize the lubricants oil bottling line for its versatile adaptability. It is flexible in terms of its bottle handling due to its simple format changes.

Efficient Processing and Time-Saving

Efficient Processing- Picture Courtesy: Design and Packaging Inspiration Blog

Due to its automatic and swift format change, lubricants oil bottling line can handle hundreds of bottles per minute. With its fast-moving parts, it is extremely efficient in its processing. The high speed of this bottling line saves valuable time and effort, which results in more packed goods in the market.

3.What bottles and containers are supported by Lubricants Oil Bottling Line?

There are several packaging bottles and containers supported by the lubricants oil bottling line . Here are a few examples of bottles and containers supported by this bottling line.

Round Bottles

Round-shape Bottles- Picture Courtesy: fanxunpackaging

This bottling line can process round-shaped bottles having a cylindrical appearance. There are no corners present in the round-shaped lubricant and engine oil bottles.

Rectangular Bottles

Rectangular Bottles- Picture Courtesy: Westpenn

They have four distinct sides and four corners. Rectangular-shaped lubricant and engine oil bottles are wider than round-shaped bottles. They are frequently utilized for filling and loading a variety of automotive oils.

Intricate Shaped Bottles

Intricate Shaped Bottles- Picture Courtesy: packaging design & brand identity

They do not have any special shape; however, they are uniquely designed for attracting and engaging automotive users. Intricate-shaped bottles have distinct edges that offer better griping.

Jerry Can

Jerry Can- Picture Courtesy: Original Mockups

In addition to bottles, jerry cans are used far and wide for packaging lubricants and engine oils. They are large usually in rectangular shape and come with handling support. This handle provides an area for carrying, transporting, and pouring the engine oils.

Buckets

Buckets

They are bulk-capacity containers with a cylindrical shape. Automotive oil buckets have wide openings and are resealed with the lids. They usually have built-in handles that provide portability support.

4.What product types are handled by Lubricants Oil Bottling Line ?

Lubricants oil bottling line supports and handles a broad range of products such as:

Automotive Oils

Engine Oil Packaging

A variety of engine, motor, compressor, and hydraulic oils are processed by the lubricants oil bottling line. They are high-performance oils and protect different parts of automotive vehicles from wear and tear.

Cooking Oils

Cooking Oil Packaging- Picture Courtesy: Behance

They are a must for industrial and home-based cooking and frying. They contain healthy unsaturated fatty acids that are good for heart health. Cooking oils include palm, peanut, sunflower, sesame, olive oil, etc.

Water

Water Packaging- Picture Courtesy: Packaging Gateway

With precise filler and hygienic packaging, the lubricants oil bottling line also processes different volumes of mineral water bottles. This bottling line fills stylish water bottles.

Syrups

Syrup Packaging- Picture Courtesy: World Brand Design Society

The lubricants oil bottling line is capable of packaging different kinds of syrups into bottles for flavoring and medicinal purposes. These syrups include cough, fruit, flavoring, and herbal syrup.

Sauces

Sauce Packaging- Picture Courtesy; Roetell

Different delicious sauces are filled in creatively designed bottles by the lubricants oil bottling line . Chicken, soya, BBQ, and hot sauce are a few examples of sauces.

Condiments

Condiment Packaging- Picture Courtesy: UK News Group

Similarity, like sauces, lubricants oil bottling line is also used for processing different condiments with simple adjustments. Condiments include ketchup, mayo, mustard, chutneys, and many more.

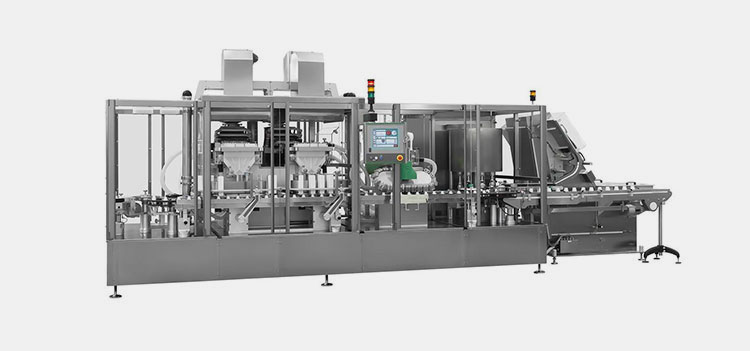

5.What is the series of units for the Lubricants Oil Bottling Line ?

There are a variety of series of units for the lubricants oil bottling line . These units are explained one by one below:

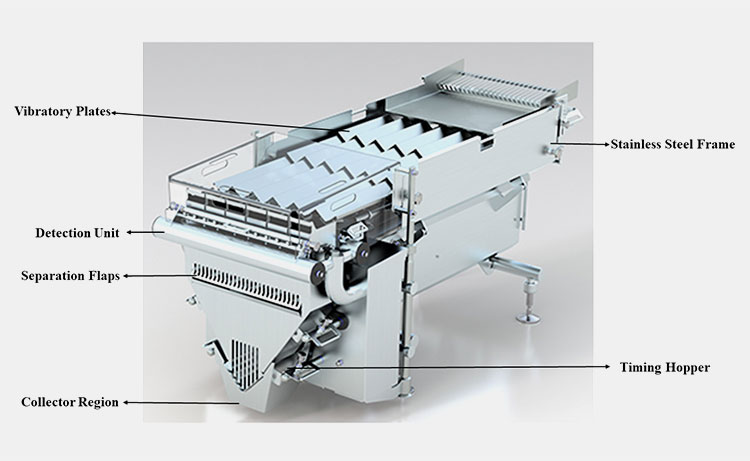

Bottle Unscrambling Unit

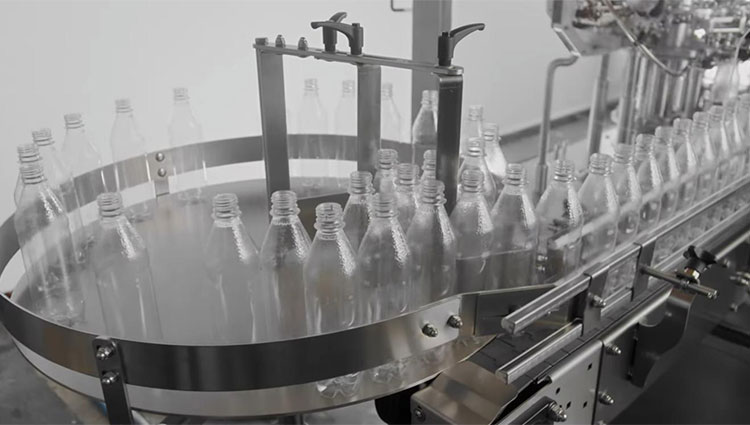

Allpack Bottle Unscrambler

It is the first in-line machine present in the production line of lubricants oil bottling line . This machine is employed for the proper alignment of the bottles and ensures a consistent supply of bottles to the other machines in the bottling line.

| Structure | Operation |

| It has a stainless steel body with four stable feet. It also consists of a hopper, rotary turn table, and conveyor. | It takes bottles randomly from the hopper and correctly loads them in an upside-down position on the conveyor. |

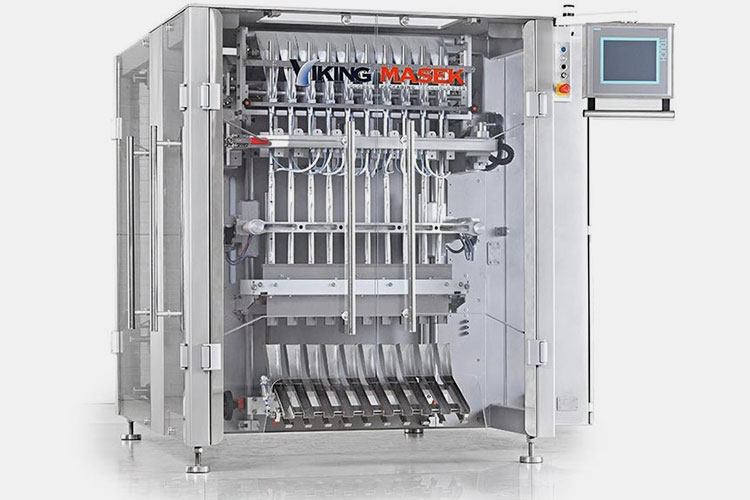

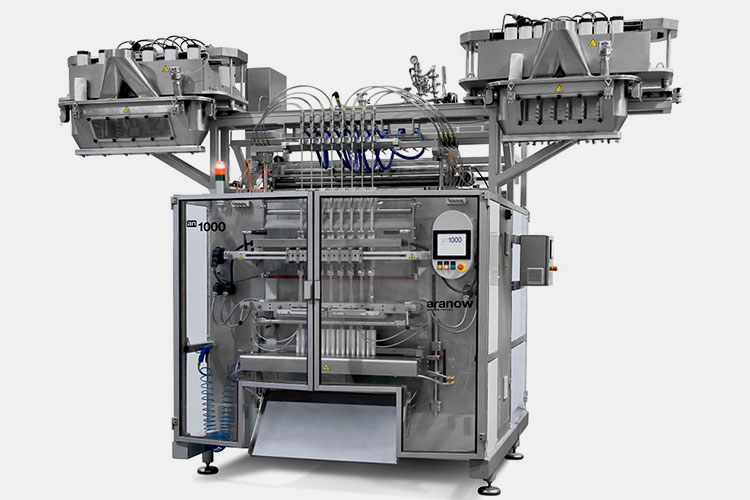

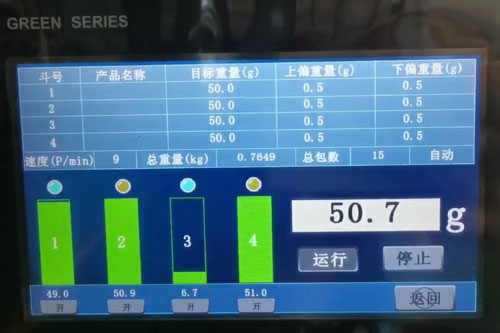

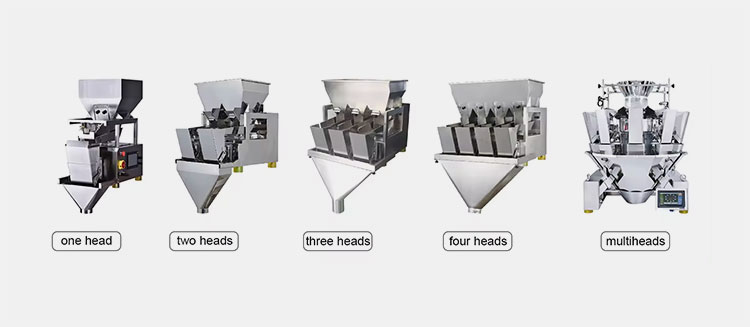

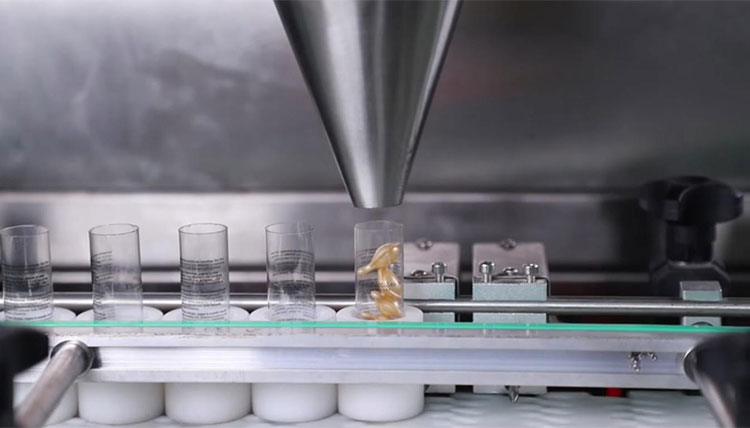

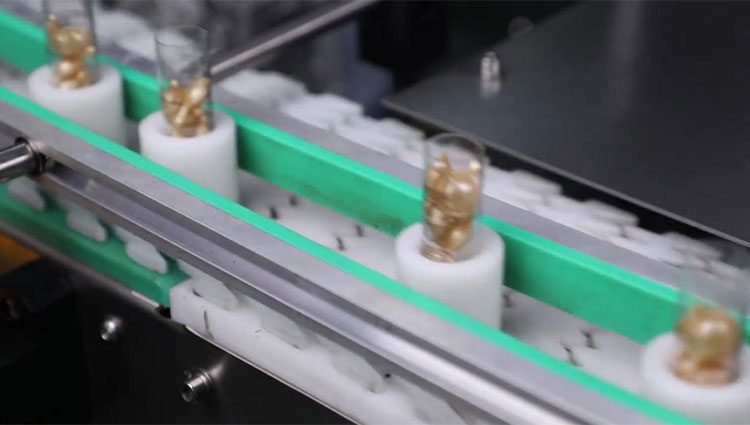

Bottle Filling Unit

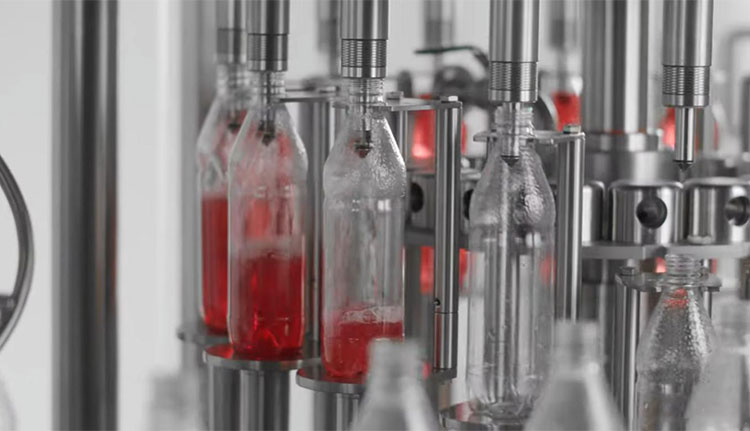

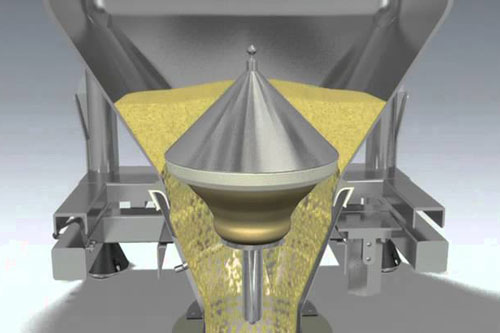

Bottle Filling Unit- Picture Courtesy: Pinnaxis

It is the main part of the lubricants oil bottling line . It loads accurate amounts of automotive oils into the bottles.

| Structure | Operation |

| The bottle-filling unit is equipped with different types of hoppers, filling devices, weight-checking systems, PLC systems, filling heads, conveyors, and sensors. | The bottles are loaded on the conveyor and reach one by one under the filling nozzles. Immediately after the detection of bottles under filling heads, the filling process begins. After attaining the required volume, filling stops, and bottles are discharged from the machine. |

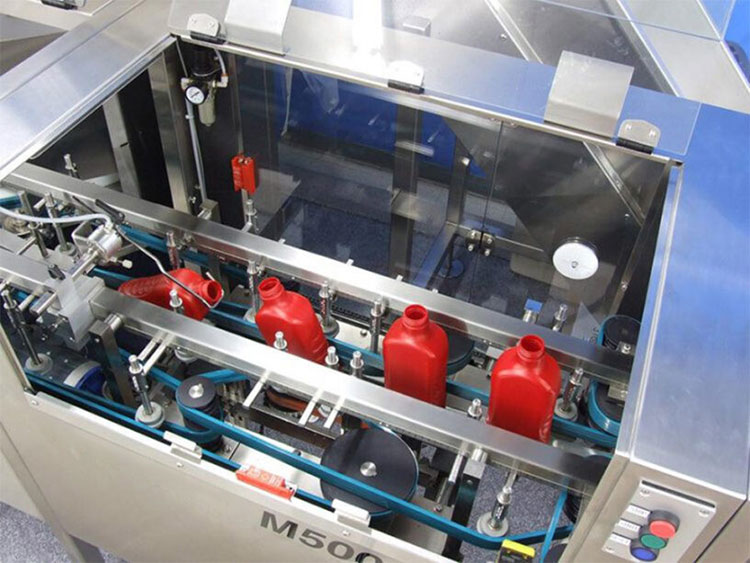

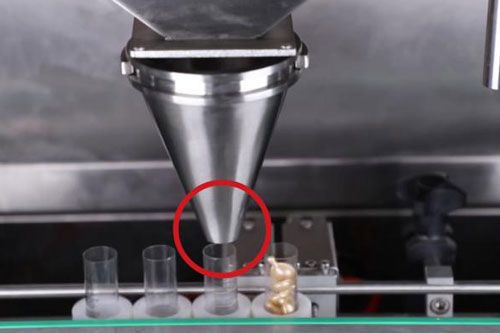

Bottle Capping Unit

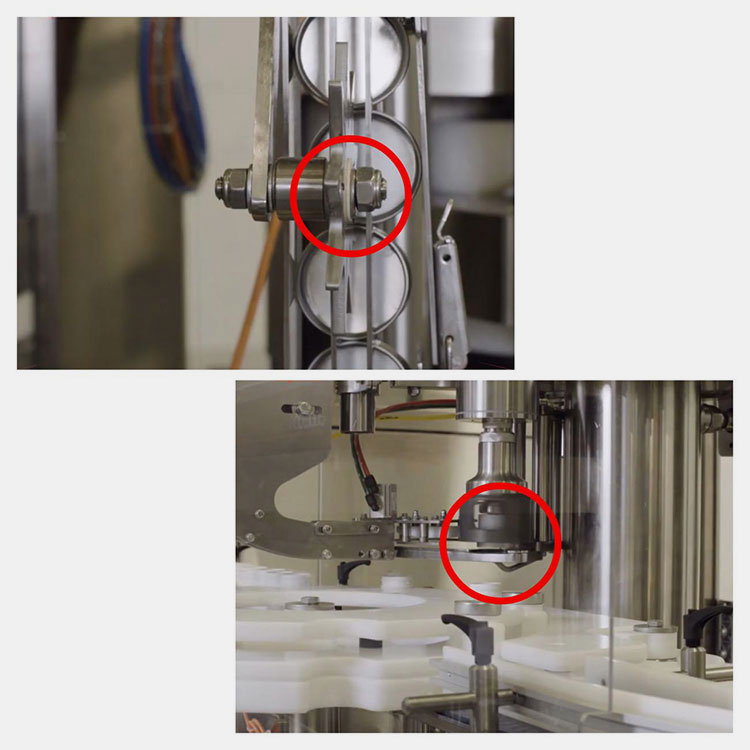

Allpack Capping Machine

It is a remarkable unit present in the lubricants oil bottling line for airtight and hermetic sealing of automotive oil bottles. Its main job is to decrease the chance of bottle leakage and spillage.

| Structure | Operation |

| This machine is an assembly of different types of sorters, rotating discs, grippers, chucks, shafts, and HMI. | Caps from the hopper are passed to the capping heads and rotating discs and chucks tightly seal these caps onto the bottle |

Inkjet Printer

Inkjet Printer

It is another handy machine integrated into a lubricants oil bottling line . Its function is to print different types of information on the exterior of bottles.

| Structure | Operation |

| It has a compact body with a few parts like sensors, a touch screen, nozzles, a main frame, a processor, and a printing head. | Tiny nozzles spray ink on the bottles, as the latter are transported through nozzles. This ink forms different letters. |

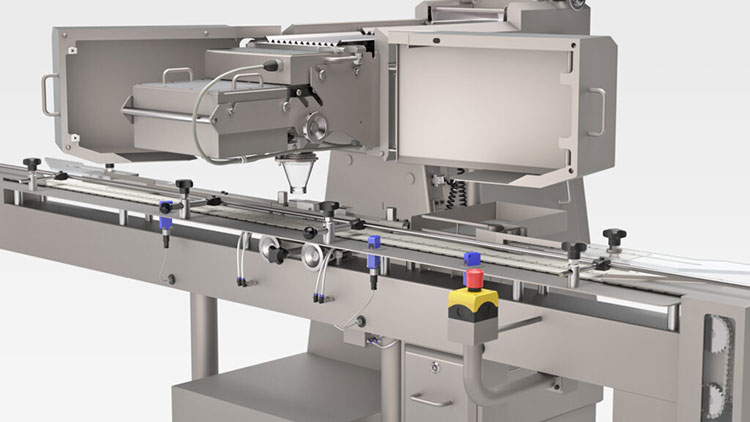

Bottle Labeling Unit

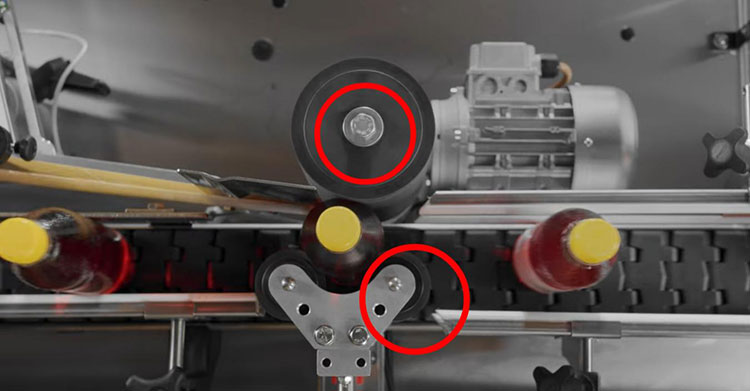

Allpack Bottle Labeling Unit

This machine is added at the end of the lubricants oil bottling line . It applies or affixes labels onto the information panel of automotive oil bottles.

| Structure | Operation |

| It is constructed from different components like a label presser, photo-electric eye, label applicator, label cutter, label film rotating disk, and PLC system. | First, labels are pulled from the labeling roll and are stuck to the surface of bottles by the label applicator. The back paper is peeled off at the same time and is collected in the waste collection unit. |

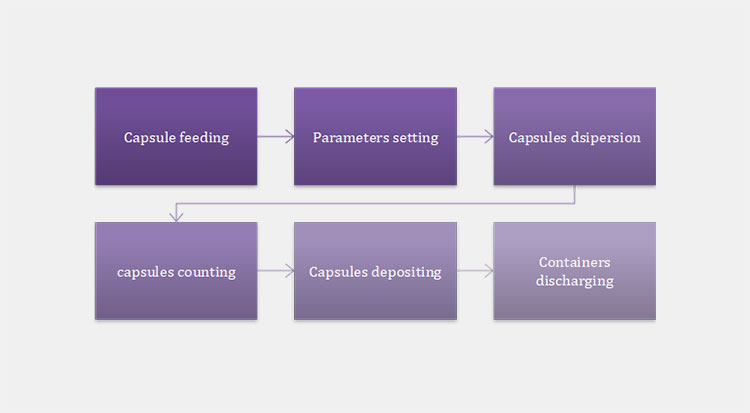

6.What is step by step processing of Lubricants Oil Bottling Line ?

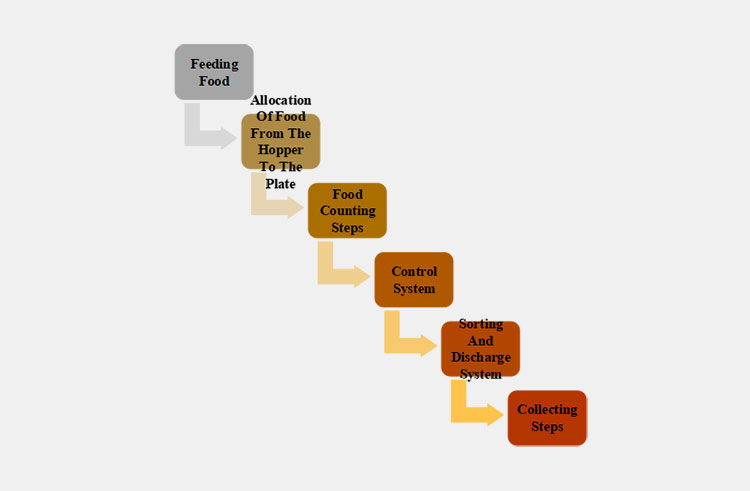

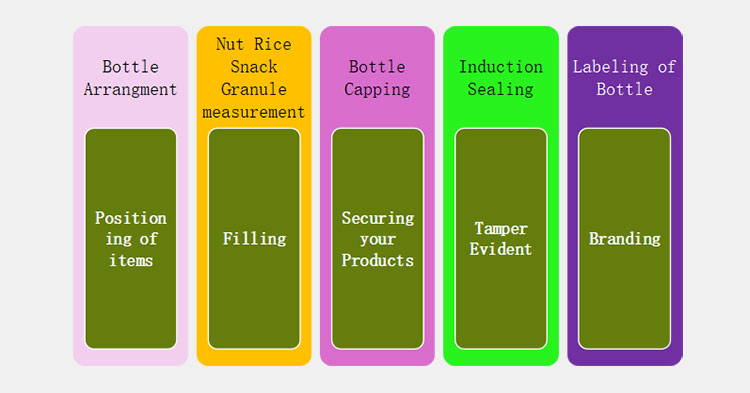

Different types of machines are added to the lubricants oil bottling line . These machines have specific jobs in the processing. Here is the step-by-step processing of lubricants oil bottling line .

Bottle Unscrambling

Bottle Unscrambling- Picture Courtesy: Tratech

This step is performed at the beginning of processing. In this step, the bottle unscrambling machine performs the placement of the bottles. These bottles are put at a fixed distance on the conveyor. At first, bottles are placed in the lying position and then are put in the standing position.

Bottle Filling

Bottle Filling- Picture Courtesy: Spheretech Packaging

The bottles are moved to the filling unit, where lubricant oil or engine oil is dispensed into the bottles. The filling devices facilitate the movement of oils from the hopper into the filling nozzle. It is the core step in the lubricants oil bottling line .

Bottle Capping

Bottle Capping- Picture Courtesy: Zalkin

Here, the rotating disk exerts torque on the caps of the bottle to tightly fix them at the opening of the bottles. In other types of capping units, the chuck part grips the caps and affixes them onto the automotive oil bottles by rotating the caps.

Bottling Printing

Bottle Printing- Picture Courtesy; DSI Printer

In this step, the capped bottles are conveyed to the inkjet printing devices. Different kinds of numerical data are printed on the bottles by spraying nozzles. This data includes manufacturing date, expiry date, lot number, etc.

Bottle Labeling

Bottle Labeling- Picture Courtesy: AL Tech UK

This is the final step in the lubricants oil bottling line . In some types of bottle labeling machines, the sticker labels are stuck on the exterior of bottles, whereas, in other types, plastic label sleeves are applied on the bottles and passed through the heat tunnel for shrinking and molding the labels.

Bottle Discharging

Bottle Discharging- Picture Courtesy: Quinti Bottling

At the last, filled, capped, and labeled bottles are ready for discharge. So, they are moved to the next series of steps like cartoning machines for packaging and transportation.

7.Where a Lubricants Oil Bottling Line is in high demand?

A lubricants oil bottling line is needed in every major industry of the world because of its bottle packaging. Its versatility has built a reputation for this bottling line in different global industries. Let’s discuss industries where this bottling line is high in demand.

Automotive Industry

Automotive Oil Packaging- Picture Courtesy: Studio One Eleven

First and foremost, lubricants oil bottling line is utilized in the automotive industry for packaging different types of lubricant oils, engine oils, transmission fluids, brake oils, and grease. It capably loads different types of automotive oils for high performance of engines and other parts.

Food Industry

Food Packaging- Picture Courtesy: Behance

Besides the automotive industry, this bottling line is increasingly employed in the food industry because of its precision and smooth filling, capping, and labeling processes. The lubricants oil bottling line has integrated bottle rinsing and washing machines that avert the risk of cross-contamination.

Beverage Industry

Beverage Packaging

People nowadays prefer drinking beverages like smoothies, juices, tea, and coffee instead of consuming different foods. Hence, the lubricants oil bottling line is high in demand in the beverage industry for housing a variety of beverages in sturdy and tamper-resistant bottles.

Agriculture Industry

Pesticide Bottle Packaging

The agricultural industry processes different types of liquid products like fertilizers, pesticides, herbicides, etc. A lubricants oil bottling line boosts the consistency and packaging quality of agricultural products and is a superb addition to agricultural units because it guarantees product safety.

Chemical Industry

Chemical Packaging- Picture Courtesy: Behance

This industry is involved in the packaging of different types of household and laboratory chemicals. So, for accelerated packaging of different chemicals in bottles, a lubricants oil bottling line is utilized in the chemical industry. It loads dishwasher, bleach, liquid detergent, and other cleaning agents.

Cosmetic Industry

Cosmetic Packaging

Lubricants oil bottling line has also shown its worth in the cosmetic industry. Different liquids like shampoos, gels, body washes, dyes, hair color, lotions, and creams are packaged by this bottling line in the cosmetic industry.

8.How is Lubricants Oil Bottling Line user-friendly?

User-friendliness of Lubricants Oil Bottling Line - Picture Courtesy: impeller.net

There are numerous design features present in the lubricants oil bottling line, which makes it more user-friendly. The machines in this bottling line have a built-in intuitive control panel, smart touch screen and clearly labeled press buttons. The touch screen helps in easier navigation and inputting operational parameters.

This bottling line is equipped with various safety features like safety interlock doors, alarm systems, digital display lights, and safety screens. These features assist in preventing different hazards. It has ergonomic workstations, reducing the chance of work strain.

Furthermore, the lubricants oil bottling line is easily inspected, monitored, cleaned, and maintained, supporting quick dismantling of parts.

9.What are the quality certifications of the Lubricants Oil Bottling Line ?

There are several quality certifications to ensure the quality and performance of the lubricants oil bottling line . Some useful certifications are:

| CE Marking

|

It is an important marking for the bottling line sold in the European Union. It notifies the manufacturers that devices are designed under the specific guidelines of safety, quality, and environmental regulations. |

| UL (Underwriters Laboratories) Listing

|

It is the international standard, relevant for the lubricants oil bottling line operated in the United States. Having this certification means that the bottling line has undergone rigorous quality testing and is safe for use. |

| ISO

|

It ensures the implementation of quality control processes during the processing and packaging of lubricant oil engine oil bottles. Moreover, it is the mark of consistent performance of the manufacturer. |

| ATEX

|

ATEX certification is necessary if the lubricants oil bottling line is processing inflammable oils. It ensures that machinery is resistant to explosives. |

| GMP

|

It ascertains hygienic processing during the packaging of automotive oils. Production of quality products is the main goal for acquiring GMP certification. |

10.How to troubleshoot problems in the Lubricants Oil Bottling Line ?

The lubricants oil bottling line is a sophisticated unit in which occasional problems arise, which result in inconsistencies in the flow of packaging and decreased profit margins. Therefore, we are presenting some troubleshooting tips to tackle these problems on time.

Improper Alignment of Bottles

Improper Alignment of Bottles- Picture Courtesy: Pace Packaging

Causes

There are variations in the designs of bottles, causing improper orientation.

Improper feed rate leads to wrong orientation.

Guide rails are not adjusted correctly.

Misalignment of bottles due to high vibrations.

Incorrect movement of the conveyor.

Defective bottle unscrambler.

Solution

Consult manufacturers so that there is uniformity in the bottle design.

Fix the feed rate so that bottles are properly oriented.

Adjust and align the guard rails.

Minimize the rate of vibration in the bottle unscrambler unit.

Adjust the movement of the conveyor.

Repair the bottle unscrambling machine.

Jamming of Conveyor

Jamming of Conveyor- Picture Courtesy: Traktech

Causes

Out of synchronization bottle unscrambler and speed of conveyor.

Improperly aligned guides and rails.

There is dust and debris on the conveyor, causing jamming.

Non-uniformity in bottle geometries and dimensions.

Solutions

Adjust the speed of the conveyor, so, that there is synchronicity between the bottle unscrambler and the conveyor.

Properly align guides and rails.

Clean the conveyor.

Purchase the uniform size and shape bottles.

Filling non-uniformity

Filling non-uniformity

Causes

Poor functioning nozzles.

Filling devices have the wrong calibration.

Inaccuracies in pressure.

Filling parameters are wrongly input.

Solutions

Repair the filling nozzles.

Correct the calibration errors of filling devices.

Adjust the pressure rate.

Readjust the fill inputs.

Inconsistent Capping Torque

Inconsistent Capping Torque- Picture Courtesy: Penglai Packaging

Causes

Differences in the speed of the conveyor, impact the application of torque.

There are variations in the sizes of bottles and caps.

Defective capping heads.

Improper settings of capping inputs.

Solutions

Adjust the speed of the conveyor.

Ensure the compatibility in the sizes of bottles and caps.

Repair or replace capping heads.

Properly set the capping parameters.

Labels Peeling Off bottles

Labels Peeling Off Bottles- Picture Courtesy: SOLUCIONES | Tu Smart Pyme

Causes

Inadequate temperature and pressure.

Presence of dust and debris on the labels.

Faulty labeling heads.

Poor label adhesivity.

Solutions

Provide sufficient pressure and temperature for labeling.

Clean the surface of labels.

Repair faulty labeling heads.

Properly apply glue or other adhesive on labels.

Misaligned Labels

Misaligned Labels- Picture Courtesy: CTM Labeling System

Causes

Bottles are not positioned properly.

Incorrect settings of label applicator.

Labeling heads and label press are damaged.

Solutions

Implement procedures to properly position bottles.

Adjust the settings of the label applicator.

Check and maintain labeling head and label press.

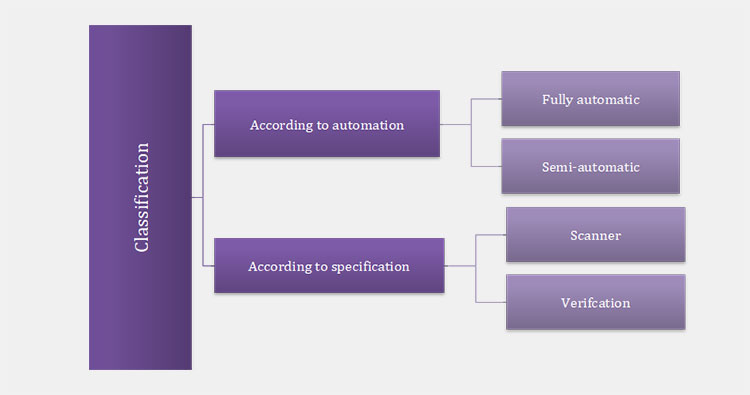

11.What are the buying factors for Lubricants Oil Bottling Line ?

There are advanced-level machines and components in the lubricants oil bottling line . These machines have high-grade technology and features, resulting in greater buying costs. Therefore, it is essential to consider the following buying factors when purchasing a lubricants oil bottling line .

Determine Production Capacity

Production Capacity of Lubricants Oil Bottling Line - Picture Courtesy: Armor Lubricant

Production capacity is dependent upon the level of automation. Different equipment in the lubricants oil bottling line has diverse kinds of automation. Hence, determining the production capacity for the project leads to an estimate of the correct automation level.

Access Flexibility of Bottling Line

Flexibility of Lubricants Oil Bottling Line - Picture Courtesy: Tehnopol

There is a diverse range of bottles for lubricant oil and engine oil. They come in different forms and designs. Lubricant oil engine oil must be flexible to accommodate different types of bottles. It should have adaptable features and quick changeover that increase its versatility.

Long Operational Life

Long Operational Life- Picture Courtesy: Linkedin

Consider the dependability and durability of lubricants oil bottling line by looking and searching for machines with high-quality components. Superior quality materials like stainless steel play a significant role in boosting the shelf-life of the bottling line.

Consider Brand Reputation

Brand Reputation- Picture Courtesy: Marketing91

Brand reputation is the most important buying factor. It can make and break your deal. By reading customer feedback, you have a clear idea about brand standing. Brand reputation determines the performance of the machines present in the bottling line.

Conclusion

In short, a lubricants oil bottling line is a must-have production line when dealing with and processing automotive oils. With diverse and efficient machines featured in this bottling line, fine automotive oil packaging is achieved. Integrating it, allows you to achieve superior standing among your competitors. Keen on investing in a lubricants oil bottling line, then contact our Allpack sales representatives just now. We will offer you the most economical and superior quality solution.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Lubricants Oil Bottling Line: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours