Cooked Egg Yolk Counting Machine: The Complete Buying Guide in 2025

Cooked Egg Yolk Counting Machine: The Complete Buying Guide in 2025

Love the cooked egg yolk? A small egg yolk commonly holds a huge potential in your kitchen and regular life. It is tasty with multiple positive health effects. Cooked egg yolk has gained popularity in various countries such as China, Japan, and Australia and is used in leading food trends.

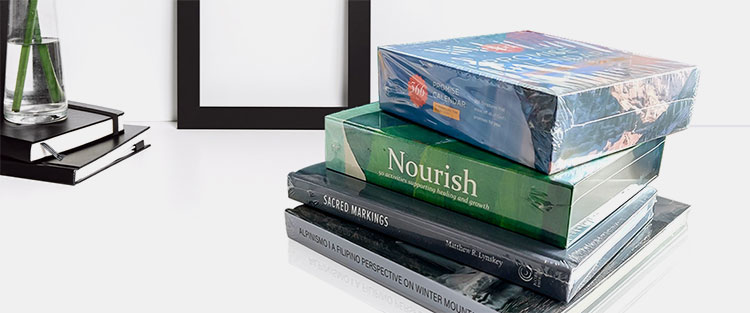

An easy way to grab them is simply by unboxing them that are carefully prepared by your manufacturer. Do you know how it is packed? It is done by advanced technology known as a cooked egg yolk counting machine.

Planning to purchase a reliable solution? You’re at the right place! This article is about inquiries and suitable explanations about cooked egg yolk counting machine. The cooked egg yolk machine is among the best innovative technologies that improve your productivity with boundless features.

In this comprehensive buying guide, you will examine the technical details, including its significance, design, applications, and much more. So, have a look!

1.How do you describe a cooked egg yolk counting machine?

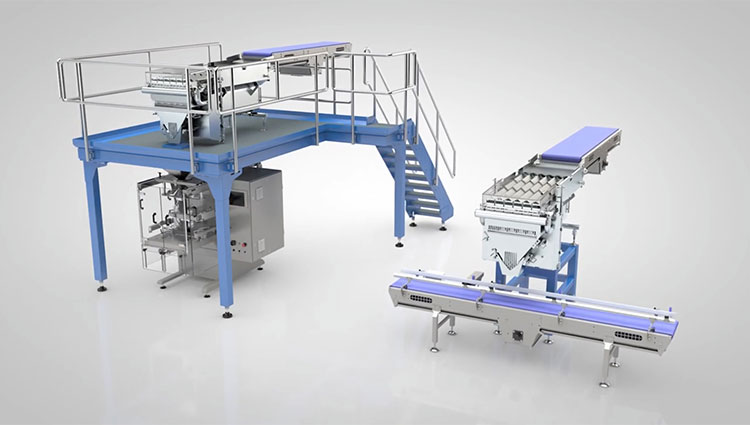

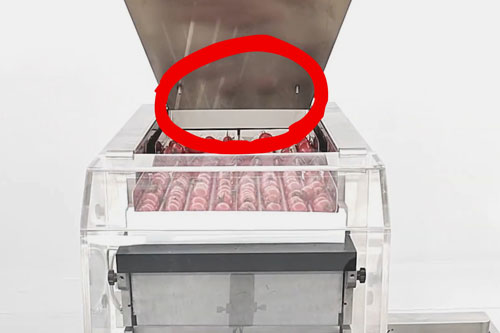

Cooked egg yolk counting machine

A cooked egg yolk counting machine is an optimal device specifically designed for tallying a number of cooked egg yolks by effective methods. It is constructed with food-grade materials to carry out counting tasks safely and cleanly.

Due to its high safety features, this machine is hooked to significant demand in the food and health sectors. The swift handling of tasks is mainly based on equipped sensors or detectors that identify the yolk once it drops or passes by the unit. If there are no containers, trays, or packing material; there won't be counting.

So, it is a flawless machine with promising results and reduced labor intensity as it nullifies or rejects the egg yolk if it is defective and contributes to gaining entire productivity.

2.Why should you install a cooked egg yolk counting machine in your industry?

A cooked egg yolk counting machine outperforms various other associated units in the industries with a flexible approach to operating your production line. Moreover, it is helpful to bring the task in a large quantity within a limited time. Certain useful reasons are showing its significance in the manufacturing and packaging industries.

Consistent Process Results and Maximum Efficiency

Cooked egg yolk

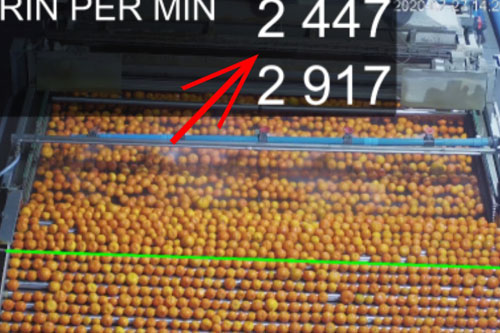

With the unparalleled speed of the cooked egg yolk counting machine, it simply allows you to keep a high counting demands in packaging materials such as bottles, pouches trays, etc. It has the ability to accommodate various quantities of products due to its variable number of counting channels that deliver maximum output without compromising the quality or affecting shape. That is the reason, it can yield and fill up to hundreds of cooked egg yolks per minute.

Raise quality standards with inspection and reject system

Upgrade product counting- picture courtesy: MM Bon Apetit

With a phenomenal inspection system and rejection unit associated with the cooked egg yolk counting machine, the defective cooked egg yolk can be immediately identified and rejected by the machine. Therefore, it ensures that each package contains high-quality products once you deliver them for marketing. The vibratory channels with an equipped inspection system allow sufficient time for the detection of unwanted items and bring output without compromising the overall output. So, once it is installed in your facility, you should be confident that the dealt product is properly catered to the highest standards.

Revolutionary Performance Via cutting-edge tools

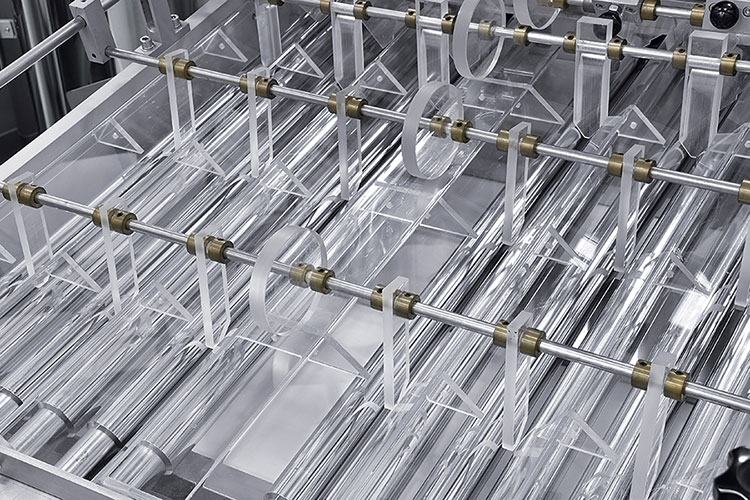

Tremendous counting tech- Picture courtesy: Force. fuge

From single vibratory channel with various numbers of channels allows a hassle-free working process. Thanks to modern technology which ensures easy maintenance. With the presence of PLC notifications, you can get signals to manage calibration or format parts to improve efficiency. The servo-driven equipment with an impressively fast and consistent flow of cooked egg yolk minimizes the workload and brings the unaffected item with excellent counting accuracy.

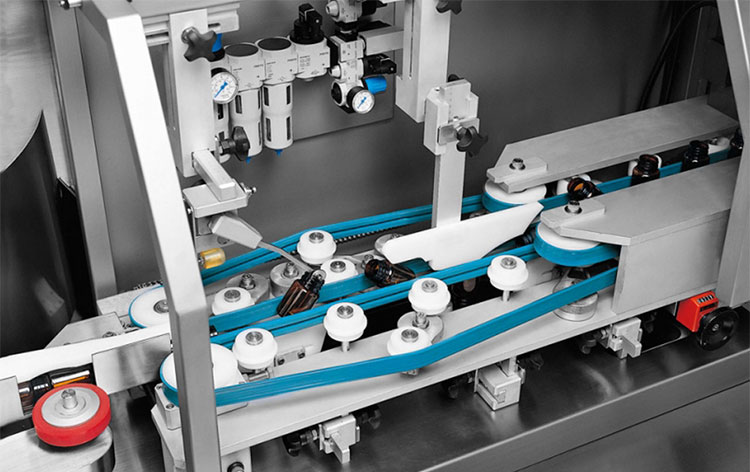

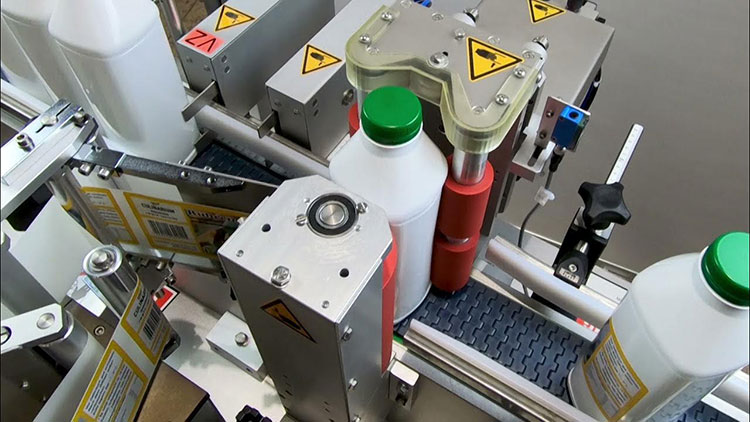

Unproblematic integration into the overall plant

Flexible to join with other units

From bottle unscrambler to final packaging machines such as labeling machines; a cooked egg yolk counting machine provides easy to be integrated feature. By this, you can connect it with the remaining units of your production line which are commonly required in a larger industrial plant for operating batch to batch processing with consistent output.

High flexibility with product types

Easy counting for Multiple items- Picture Courtesy: Cremer

The surprising property of a cooked egg yolk counting machine is that you can subject various other products to count without interruption. For example, if you have changed your mind about bringing other items, this machine never disappoints you in counting and packing them in various packaging formats.

3.What are the uses of the cooked egg yolk counting machine?

There are several applications of cooked egg yolk counting machines in industrial sectors. We have enlisted them below:

Pharmaceutical and Medical Items Industry

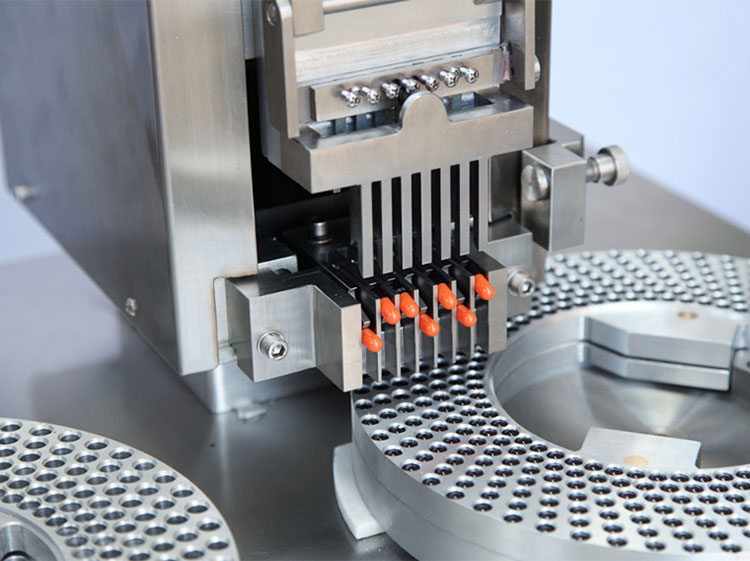

Pharmaceutical applications- Picture Courtesy: UMP Pharmaceuticals

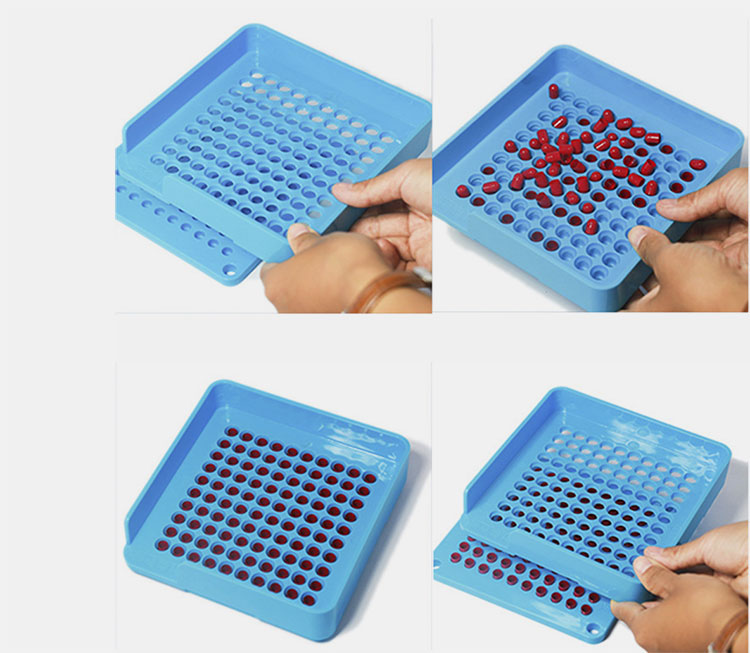

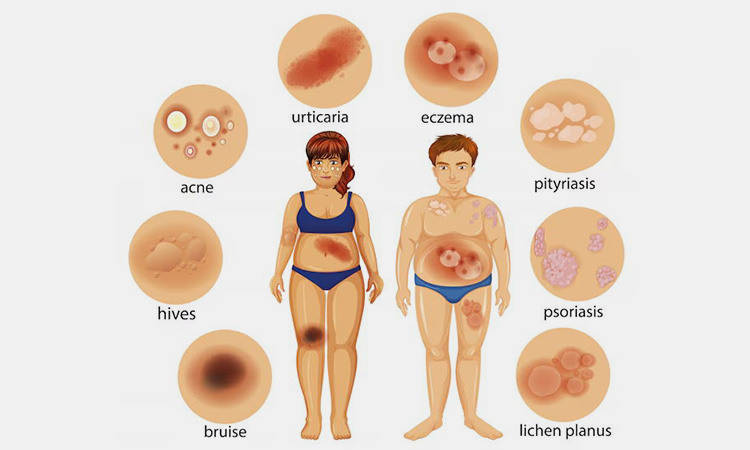

Production and packaging of pharmaceutical materials require hygiene and accuracy. Any small error or contamination directly affects the quality of medicines and may harm the patient’s life. For that, any machinery that has to be installed in a medicinal or healthcare setup should be promising in terms of safety, precision, fast output, and date-to-date memory record.

A cooked egg yolk counting machine is exactly the one-stop solution for dealing medical medical-related formulation and medical items for their final packaging. For example, tablets, pills, granules, and capsules are mainly subjected to this machine. You cannot ignore their importance in this field as it has shown high demand rise notably since COVID-19.

Food Industry

Food applications- Picture Courtesy: Dutch Valley Food

The production cycle of the food industry never stops. Whether dry food products or frozen foods, a good egg yolk counting machine plays a significant role in the final counting and packing. We know you love meatballs, cheesy bites, sausage, finger chips, spring rolls, dried fruit, coffee beans, egg yolk, and many other products. All of them are carefully counted with this machine efficiently.

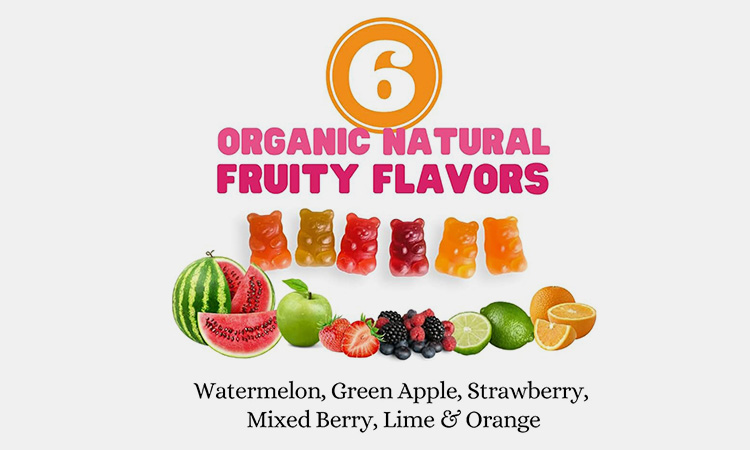

Nutraceutical Industry

Health supplements

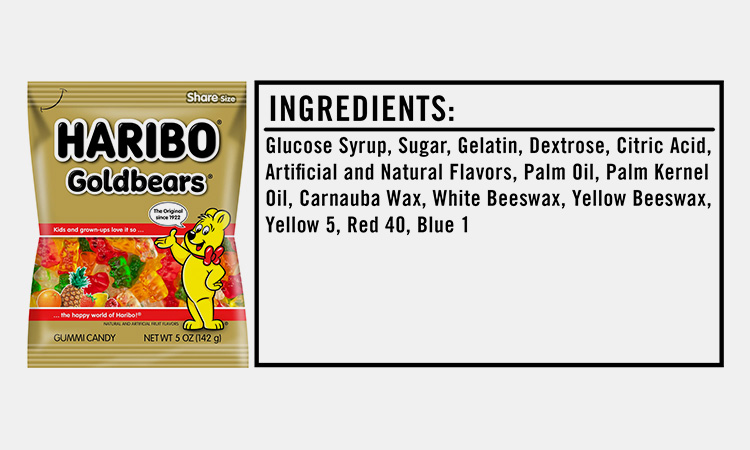

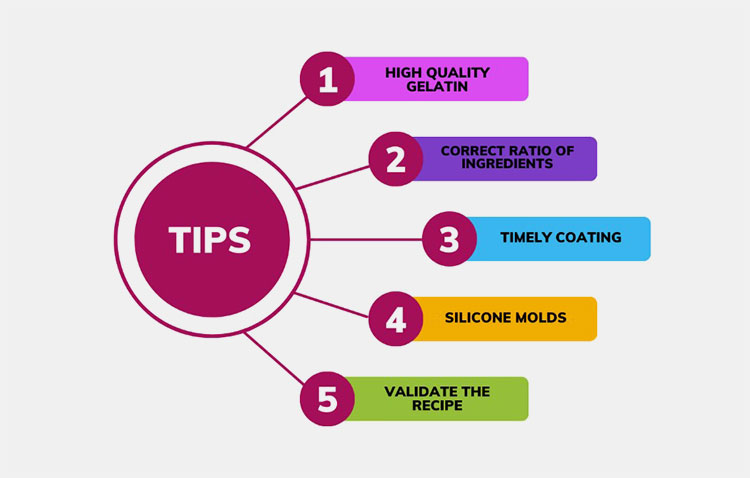

You all love to have balanced health to enjoy life and bring regular life chores well. That is the reason nutraceutical supplements have demonstrated a high surge among the general public. There are several items that are manufactured in solid dosage form, this includes tablets, soft and hard gelatin capsules, various flavor granules, soft and yummy gummies, and pills. They are commonly packed in jars, pouches, and sachets by using a cooked egg yolk counting machine. We assure you this machine offers a promising solution when it comes to counting and packaging of nutraceuticals strictly following high-quality standards.

Cosmetics Industry

Cosmetic applicator

The most popular industry brings astonishing cosmetics items in excellent packaging with an exact quantity as promised on their packaging. A cooked egg yolk counting machine is mainly installed in cosmetic sectors for the counting of products, such as skin cleaning bars, makeup applicator tools, mini lip balms, artificial nails, manicure and pedicure cleaning items, etc.

Agriculture Industry

Agriculture pills- Picture courtesy: Gardening know how

You cannot ignore the blessing of this industry in every aspect of your routine life, such as fruits, vegetables, grains or pulses, spices, etc., all of them originated from agricultural resources. The farmers usually require preventive measures like pesticides and insecticides as well as plant supplements for healthy crops. Remember, all these related items are available in the form of tablets, granules, and capsules and are mainly subjected to cooked egg yolk counting machine for their counting and packaging before it reaches you.

Hardware Industries

Hardware Tools

You will be surprised to know the remarkable applications of cooked egg yolk counting machine in the hardware industry for the counting and packaging of tools like nuts, screws, bolts, switches, batteries, and others.

Herbal Industry

Herbal Supplements- Picture Courtesy: Dr. David Billstrom

You know that the herbal industry is the most captivating field among individuals who prefer to opt for organic sources for their health treatment. The cooked egg yolk counting machine is required to count herbal tablets, capsules, pills, and many other related formulations in its packaging accurately.

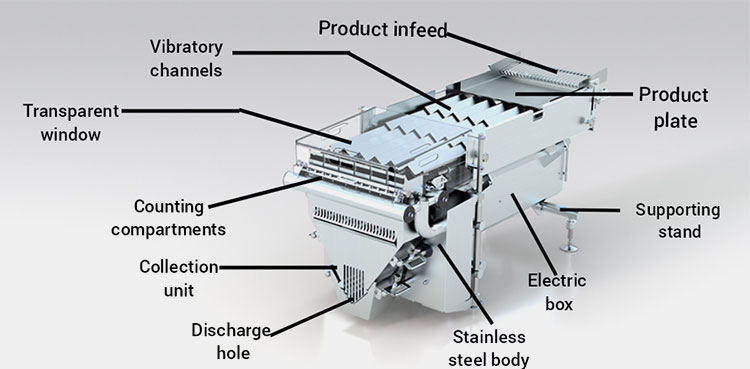

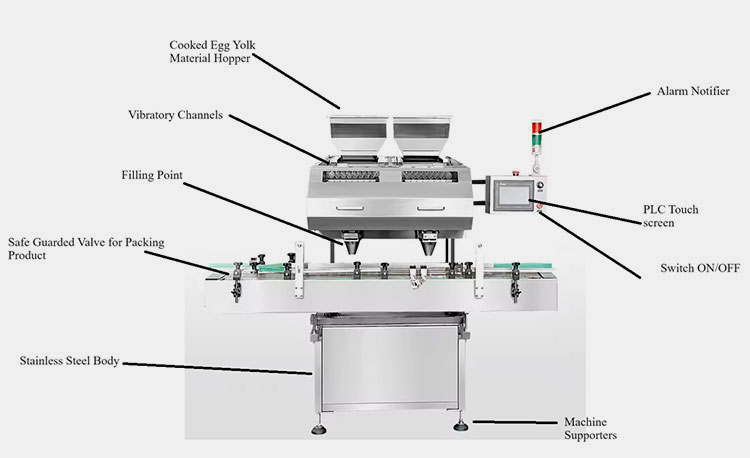

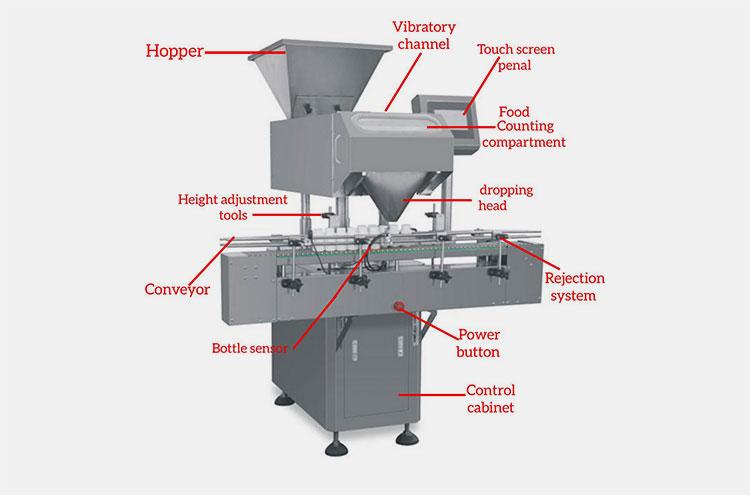

4.What basic components comprise a cooked egg yolk counting machine?

| Parts | Description |

| Cooked egg yolk material hopper | This is a specialized tank that is used to store bulk quantities of cooked egg yolk for temporary storage. The machine has an output unit in the bottom allowing the gentle movement of material toward the vibratory channels for further processing. |

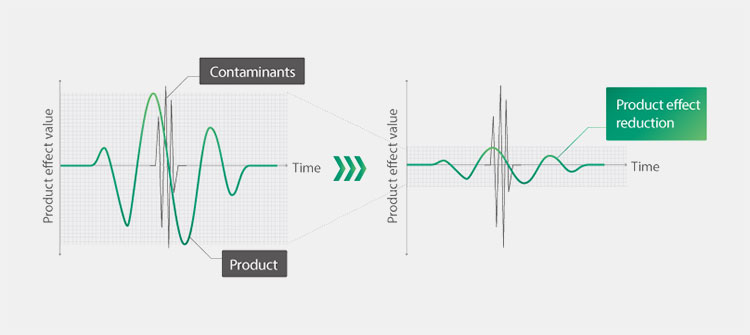

| Vibratory channels | Usually, vibratory channels are integrated with the Hi-inspection system as well as scanners. The primary purpose of the following equipped units is to scan the entire cooked egg yolk that is passing by the channels. The slow shaky movement not only transfers the product from the hopper to the filling nozzle but also helps in the detection of defective products, for example, size, color, or any physical problem. If any issues are present, the machine senses and sends it to rejection units without interrupting the counting process. |

| Alarm notifier | The machine is equipped with a smart alarm notifier that allows you to detect and respond to any emergency and halts the process. In the case of an unwanted situation, a red light blows, a yellow light is meant for alertness while a green light signifies that system is OK for operation. |

| PLC Touch screen | This is a programmable logic controller that is mainly responsible for running the major tasks associated with counting and filling processes. This unit not only manages the major tasks but also aids in the determination of work processes, and management troubleshooting.

It enables you to feed your requirements into the machine and interpret the machine simply by reading the messages displayed on the touch screen. For example runtime, number of counting items per minute, feeling speed, memory, etc. |

| Filling Point | These are the small nozzles for filling packaging material, mostly equipped with sensors that detect the presence of cooked egg yolk that drops and is marked as counted. This unit is mainly equipped with photoelectric detectors that support counting simply by spotting out the presence of items by blinking the light and directly dispensing to the packaging material. |

| Switch ON/ OFF | This is a unique and prominent button designed near a touch screen. It helps in switching OFF and ON the machine. In case of emergency, you can directly stop the machine just by pressing this button. |

| Safeguarded Valve for packing product | Today the modern cooked egg yolk counting machine is equipped with lockable or safeguard valves for the purpose of holding packing material such as bottle jars pouch. It facilitates the stability of packing products against falling or displacement |

| Stainless steel body | The machine structure is composed of food-grade stainless steel which is mainly suitable for food and health-related fields. This material allows you to maintain and clean the equipment very easily in everyday production. |

| Machine supporters | The entire frame network of the cooked egg yolk counting machine lies on casters allowing stability during work, flexible movement during installation, and shifting from one facility to another. Moreover, the machine casters are fixed with strong grippers to avoid the generation of vibration during the work process. |

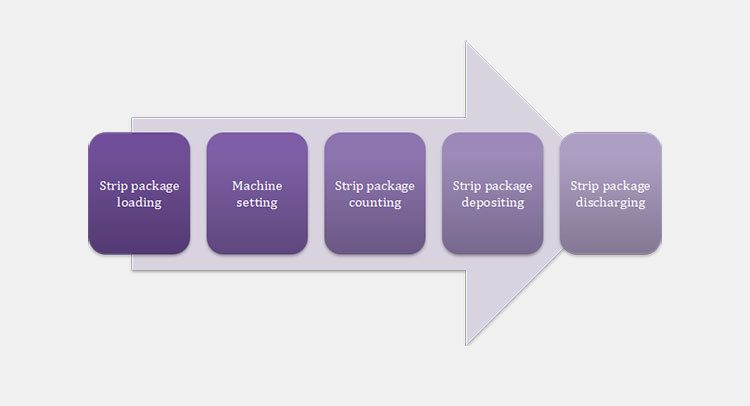

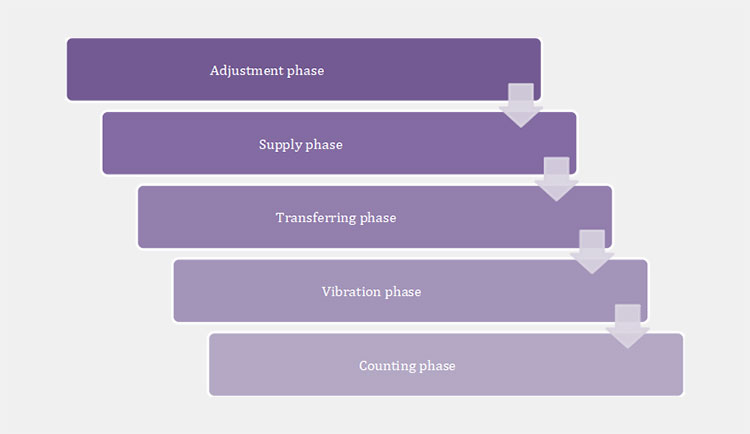

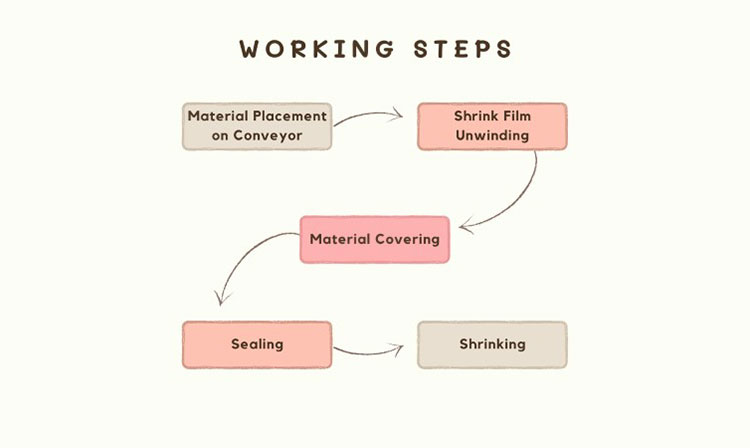

5.How does a cooked egg yolk counting machine operate?

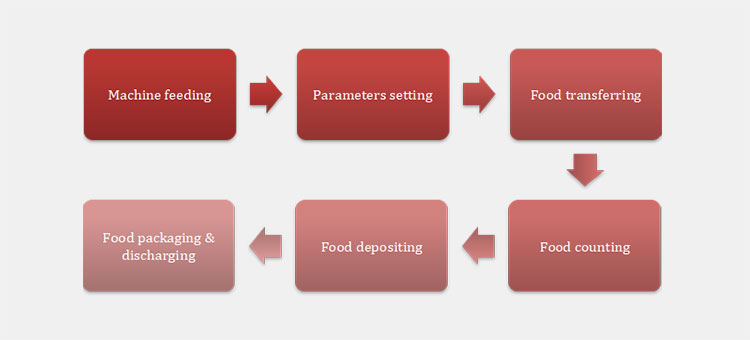

The working process of a cooked egg yolk counting machine is based on the following steps, just have a look for a clear understanding of the working principle.

| Step | Description | Picture |

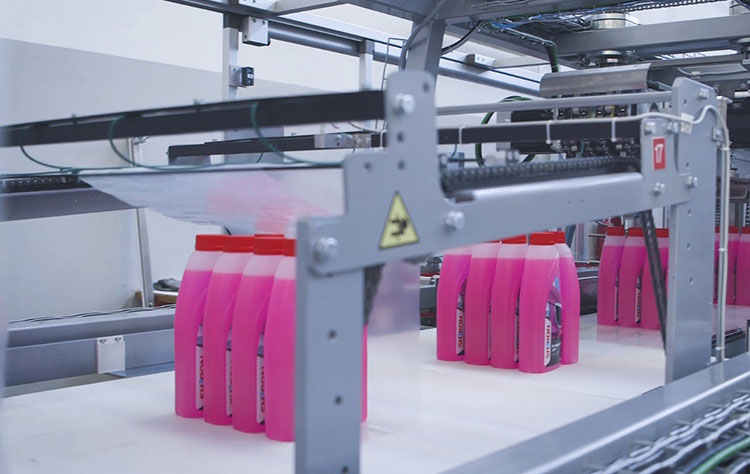

| Step 1: Preparation | This is the first phase that requires your participation e to load the sample either manual loading or automatic conveyor setup. |  |

| Step 2: Product Movement | Once the machine hopper is loaded with products to be counted, you can initiate the procedure just by clicking the button on the PLC touchscreen.

With the help of automatic processes, the machine hopper controls the movement of items from the bottom toward the vibratory channels. A slow and gentle shaky movement of vibratory channels lets the cooked egg yolk pass from the unit and drop into the counting nozzle unit for counting. This is the major step you cannot ignore as scanning can pick the faulty items and simply reject them. while in case of correct items machine can allow a tallying item. By this, the machine ensures the ultimate and correct material packaging. |

|

| Step 3: Counting | In this section, you must monitor two important parameters, first the movement of packaging material on the conveyor belt, second, the counting of products which is being identified as the corrected item with the help of sensors and photoelectric light. The machine system is based on a computerized electronic display which helps in the marking of the required cooked egg yolk and lets it dispense into the packing material. |  |

| Step 4: Discharging | The counted and filled items leave the system simply using an exit using a conveyor belt. It can either be connected to other machines or can simply by manual unloading. |  |

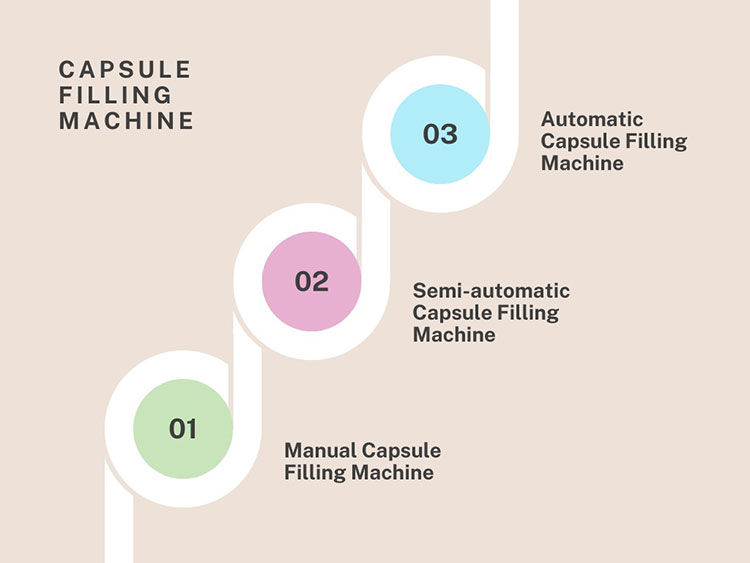

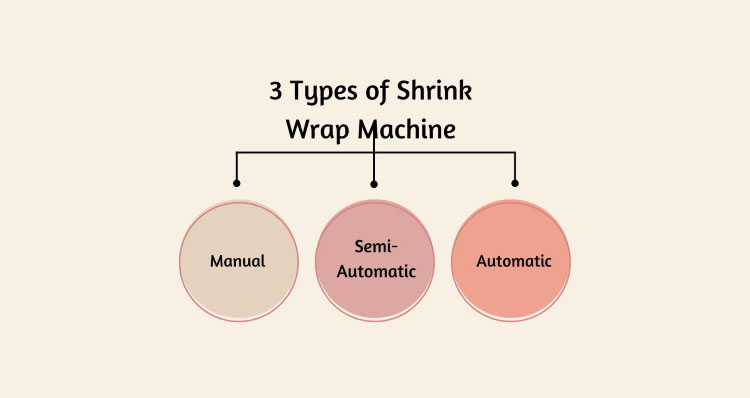

6.How do you classify a cooked egg yolk counting machine?

A cooked egg yolk counting machine is designed in many ways to cater solution for your high requirements related to food packaging business. Find below the flexible approach of various machines related to counting cooked egg yolk packing.

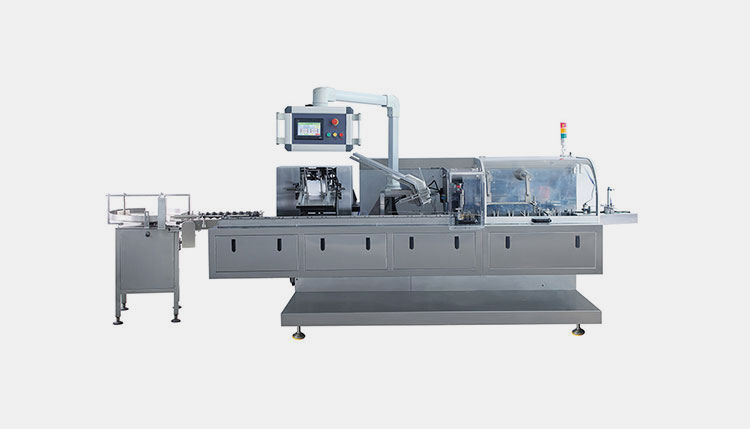

High Speed Automatic Cooked Egg Yolk Counting Machine

Cooked egg yolk counting machine- picture courtesy: Cremer

A revolutionary phenomenal addition in the counting technology as this machine has raised your facility production by advance standards related to processing and ensuring high quality in counting egg yolk. It is mainly designed with computerized system with hassle free operation and greater efficiency; the most impressive property is the detection sensors, visual provision, dealing items with tremendous speed with optimal performance every time.

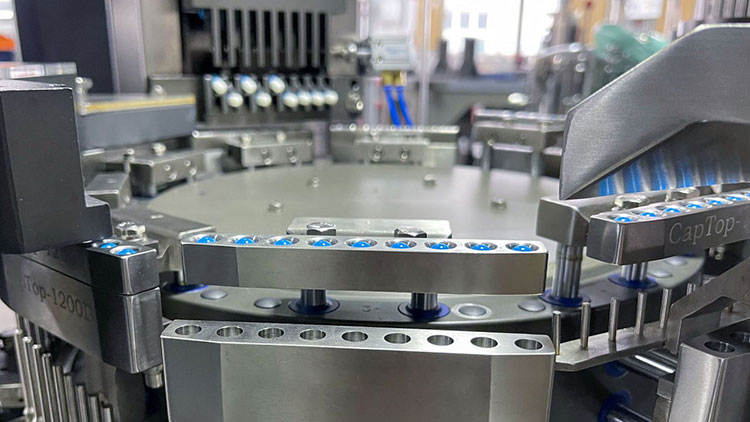

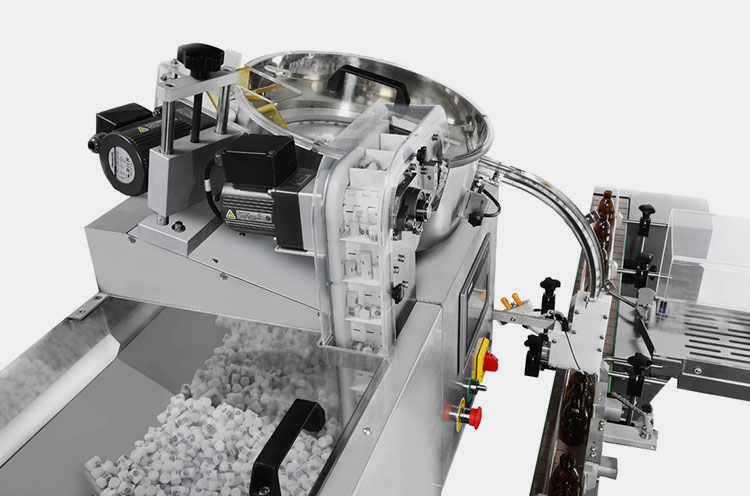

Automatic Cooked Egg Yolk Counting Machine

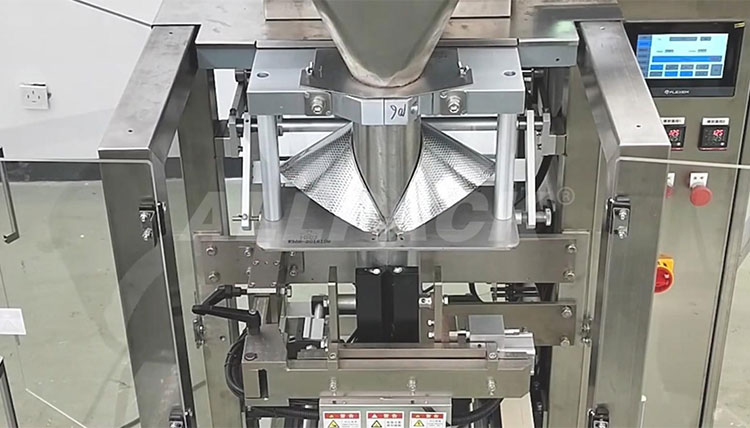

Allpack Automatic Cooked Egg Yolk Counting Machine

Thanks to modern advancement it has offered an automatic cooked egg yolk counting machine that is considered a vital component in the packing process. This is the most popular machine mainly applied for foods, and non-food products devoid concerning various shapes, sizes, and transparencies. You can combine this machine with other units of the facility to enjoy large batch-size production. This kind of machine is mainly designed with various channels and several filling nozzles to have unparalleled counting of egg yolks in a limited time.

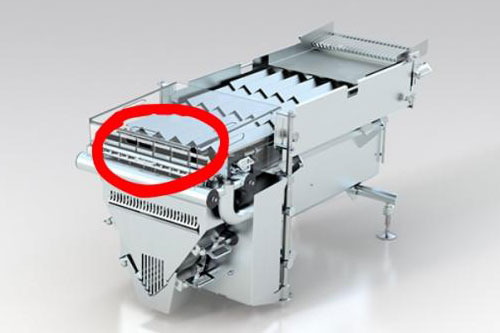

The machine is mainly designed with a bulk hopper with the finest dosing gate and vibratory channels equipped with infra-red photodetectors to ensure error-free product packing.

Multi Head Multi Weigher Cooked Egg Yolk Counting Machine

Multi-head weigher cooked egg yolk counting machine- picture courtesy: Zon-Pack

A giant piece of equipment is used for various items across the various production fields for counting purposes. It can count the hundreds of objects in each minute due to possessing multiple weighing heads with excellent detection units to sense unusual errors in the cooked egg yolk.

If you are thinking about safety or product damage, then this machine is very safe in many ways such as it handles products gently, and construction is from food grade material so there would be lesser to no chance of contamination during the counting process.

If you want to change the weights, by touchscreen you can feed the protocol, therefore, this machine is ideal for counting not only cooked egg yolks but also various other items.

7.What products can be counted by a cooked egg yolk counting machine?

The newly designed cooked egg yolk counting machines are not confined to counting cooked egg yolks but are capable of counting many other products which are mentioned below.

Seeds

Seed Counting and Packaging Solutions: Picture Courtesy: Cremer

Cooked egg yolk counting machines surpassed the technically outdated methods of counting seeds of different sizes with high precision and incomparable speed. These advanced machines have facilitated counting

Chocolate Bars

Chocolate bars

Other than counting cooked egg yolks, it can count chocolate bars of various sizes and shapes. By this, you can save a lot of time and increase efficiency.

Nuggets

Nuggets

Nuggets are loved among youngsters and available in frozen states. A cooked egg yolk counting machine suitable for counting processes of nuggets hence proving its significance when counting frozen items without harming the quality.

Lancets & Needles

Needles

Cooked egg yolk counting machines are featured with an all-inclusive system that can advantageously provide counting solutions for safety lancets and pen needles. It is a quick way to tackle the counting challenge of these items.

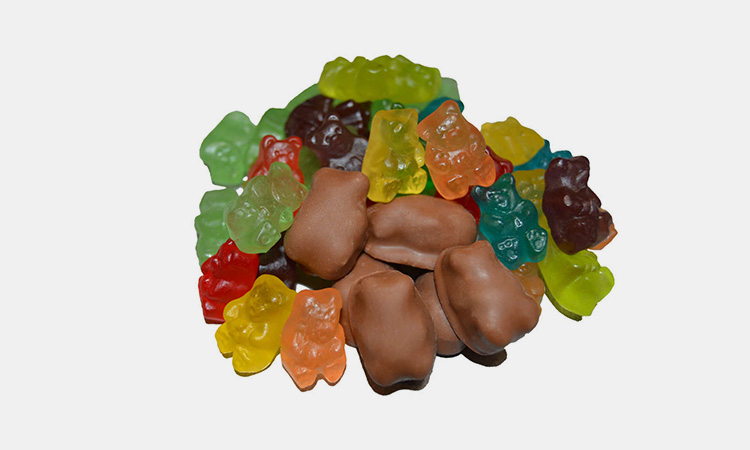

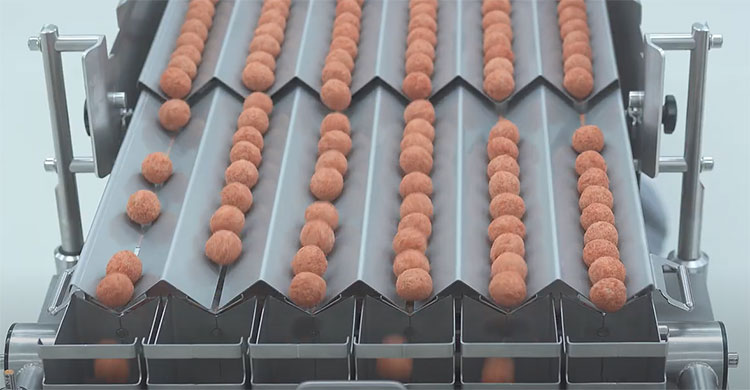

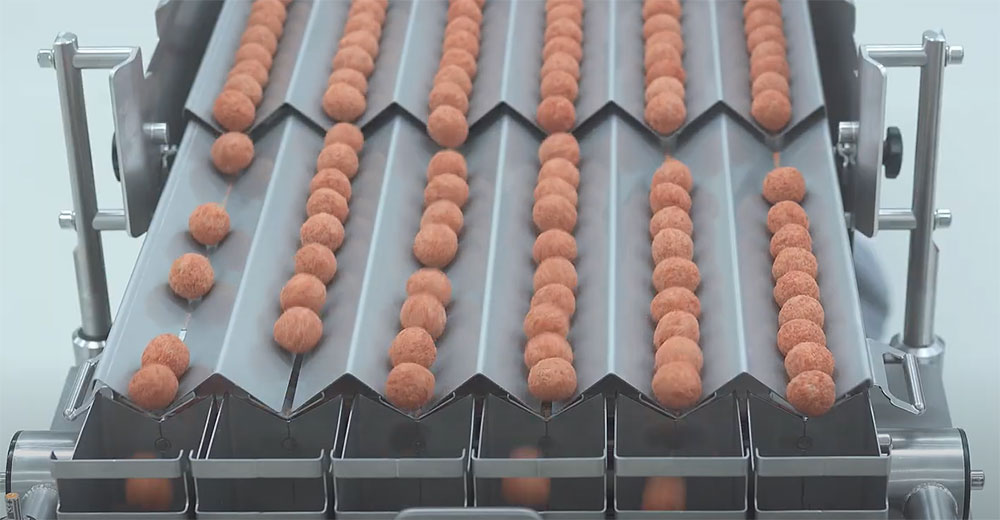

Meat or Cheese Balls

Meat Balls

The cooked egg yolk counting machine is used by different industries throughout the world for the counting of meat and cheese balls. It is a convenient way of counting to perfectly manage them and saves labor intensity.

Chinese Zongzi

Chinese Zongzi

The cooked egg yolk counting machine is crafted using food-safe materials that have demonstrated it’s effectiveness for counting Chinese zongzi due to its modern specification.

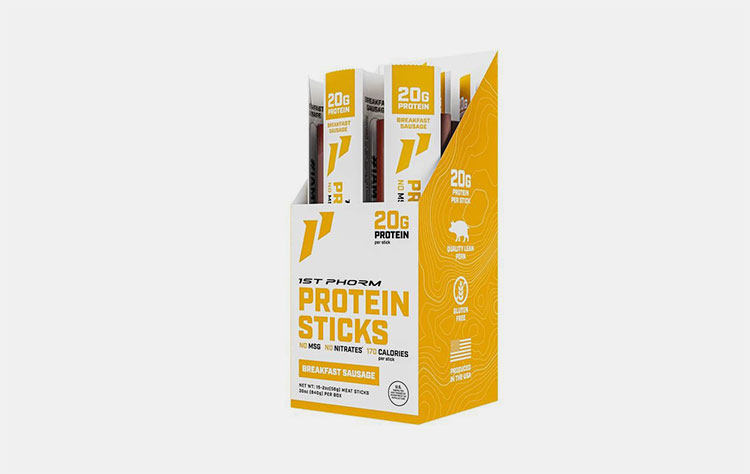

Frozen Sausages

Sausages- Picture Courtesy: Meatless Farm

Achieving frozen sausage counting is a safety concern as it can profoundly impact consistency. Using this cooked egg yolk counting machine, because of its distinctive features, makes the counting process easy and feasible on a large scale.

Frozen Cheesy Fish

Cheesy Fish- Picture Courtesy: RecepieTin

A cooked egg yolk counting machine is a smart machine that is widely adopted by nutritional packaging industries to count frozen cheesy fish. The machine is a fantastic craft of the modern era that is practically used for counting them.

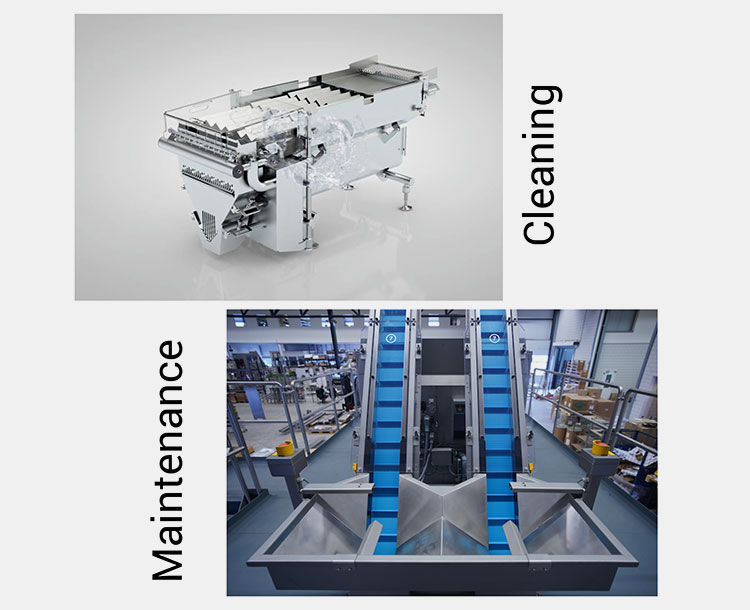

8.What are the cleaning and maintenance pointers to enhance the efficiency of the cooked egg yolk counting machine?

Cook egg yolk counting machine- Picture Courtesy: Cremer

When it comes to handling count food-related products, it is mandatory for you to have a regular checkup of the machine. This is not only essential for a good quality product but also useful for extending the quality of the machine. Remember! if you take care of the machine, it will ultimately take care of your entire business and consumers. For this, we have mentioned some key points that you must follow to get an efficient shelf life of the system.

Regular cleaning and maintenance

Step 1: This is mainly included with a regular cleaning by using dry and soft cloth, and isopropyl alcohol spray 70% which is absolutely safe for you as it evaporates parallel to eliminate dirt and germs piling up on the surface of the machine. Plus, sometimes light water spray can help you to clean the surface and remove stains.

Inside structure of cooked egg yolk counting machine- Picture Courtesy: Cremer Video

Step 2; There are some basic types of maintenance which include ‘primary, secondary, and tertiary ‘maintenance.

| No. | Maintenance Type |

| 1 | The primary maintenance includes frequent monitoring of your machine and replacing damaged parts to make it fully efficient and uninterrupted. |

| 2 | The secondary maintenance included weekly monitoring and application of lubricants around movable parts that are subjected to frequent movement for example vibratory tray bolts, parts of the driven motor, etc. followed by calibration which is required for accurate functionality. |

| 3 | The tertiary maintenance included the changing of entire worn-out parts, opening or dissembling the machine, cleaning and oiling the parts, and re-adjusting for the final operation. |

9.What are the critical parameters to consider before investing in a cooked egg yolk counting machine?

Cooked egg yolk counting machine

We understand the type of anxiety you may face whenever plan to purchase equipment that can either boost the fate of profitability or may cause trouble if fail to offer desirable results.

Indeed, a good machine can entirely impact the picture of your business. Therefore, you should always work out in order to make the right choice. There are certain factors that must not ignored for selection:

| Pick a good vendor

|

It is not wrong to say that a good vendor is just a blessing! they understand your need and try to provide possible solutions even with an astringent budget. To catch them, we would suggest opening up your laptops and finding good manufacturers, and suppliers on Google, following their sites, focusing on customer reviews, what they offer to you, as well as types of machines they have in their list, etc., |

| Your Production Requirement

|

As we discussed, there are many various types of cooked yolk counting machine varying from small to large badges. Before purchasing a machine, you can estimate your production requirement discuss it with your vendor and directly opt for the right one |

| Certified with international quality compliance | A good machine must be made up of food-grade materials such as stainless steel which ensures safe working in the entire cycle of production as it is very easy to clean, and simple to use, and it must be compliant with international quality requirements. |

| Your workspace measurement

|

This machine is available in various sizes, and models, that vary from company to company and manufacturer. Therefore, you should know the appropriate estimation of the area where you have to install the machine and should know the size of the unit. These factors will help you to make a correct purchase and trouble-free installation in your facility. |

Conclusion

In conclusion, a cooked egg yolk counting machine provides a solution beyond counting. With this innovative machine, you can meet unwavering demands toward production success and boost your profile like never before. Allpack doesn’t just supply machines- though offers production strength through tremendous machinery series related to cooked egg yolk counting. Our experts have added solutions for all your demands that exceed your expectations. To check our cutting-edge technology and unparalleled customer services, just contact us now to avail guidance anytime.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Cooked Egg Yolk Counting Machine: The Complete Buying Guide in 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours