Tray Lidding Machine: The Complete Buying Guide In 2025

Tray Lidding Machine: The Complete Buying Guide In 2025

Businesses need dependable, high-quality packaging solutions in today's cutthroat marketplace so that their products are protected and their brand image is enhanced. The tray lidding machine is one such well-liked packaging method.

Tray lidding machines are a crucial piece of kit for food producers and packagers because they are made to safely seal and package food goods in trays. This comprehensive buying guide in 2024 will give you all the details you need to know if you should add a tray lidding machine to your packaging procedure. Learn more about tray lidding machines in the following.

1.What Is Tray Lidding Machine?

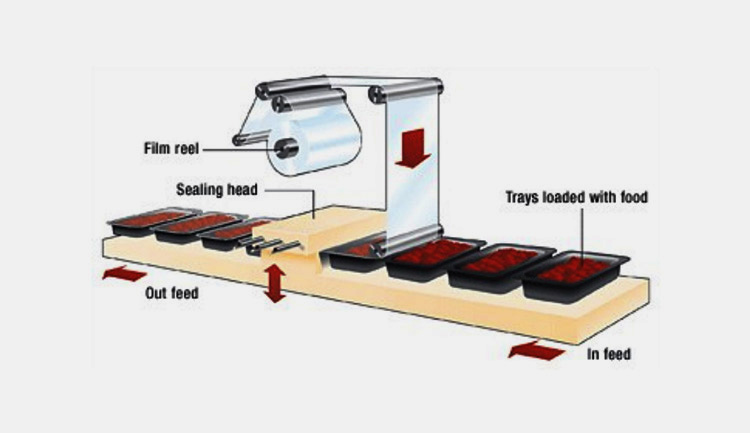

Tray Lidding Machine-Photo Credit Crawford Packaging

Tray lidding machines are cutting-edge packaging devices which are made to simplify the packing of food items such as meats, fruits, vegetables, dairy products, and ready-to-eat meals. These machines are in charge of sealing pre-formed trays with lids made of various materials which including plastic, aluminum, and paperboard.

Tray lidding machines are used in packaging operations to seal food trays and containers. These machines are used to place a lid on the tray or container, seal the lid to the tray or container, and cut the lid to fit the tray or container.

2.What Are The Application of Tray Lidding Machines?

Tray lidding machines can be used for both food and non-food applications, such as:

- Food Industry:

Tray lidding machines are extensively used in the food industry to package and seal a wide range of food products such as ready-to-eat meals, snacks, bakery items, fresh produce, and frozen food items.

- Pharmaceutical Industry:

Tray lidding machines are also used in the pharmaceutical industry to package medical devices and other pharmaceutical products that require a sterile packaging environment.

- Personal Care Industry:

Tray lidding machines are used in the personal care industry to package cosmetic products, including creams, lotions, and powders.

- Electronic Industry:

Tray lidding machines are also used in the electronic industry to pack electronic components, such as semiconductors, printed circuit boards, and other electronic devices.

3.How Can Tray Lidding Machines Benefit You?

Efficiency Gain:

By automating the packaging and sealing of pre-formed trays, tray lidding machines can considerably increase packaging efficiency. As a result, less manual labor is required, and output and production rates are both risen.

Increase Product Safety:

Product safety is improved because tray lidding equipment creates an airtight seal that keeps contaminants out and maintains the food's quality and freshness. By doing this, the possibility of spoiling, bacterial growth, and other food safety issues is decreased.

Versatility:

Tray lidding machines can seal a variety of trays and lids which made of plastic, aluminum, and paperboard. This makes them a versatile packaging solution that can be used in a wide range of food packaging applications.

Cost-effective:

Tray lidding machines can help to reduce the overall cost of packaging by improving production efficiency and reducing waste. They also require less labor and materials compared to manual packaging methods, which can help to reduce overall production costs.

Customizable:

Tray lidding machines can be customized to meet specific packaging needs, including the size and shape of the trays and lids. This makes them a flexible and adaptable packaging solution for different types of food products.

4.What Are The Different Types Of Tray Lidding Machines Available In The Market?

Tray lidding machines come in a variety of varieties, each one is created for certain packaging requirements and output levels. Here are a few examples of typical tray lidding machines:

Manual Tray Lidding Machines:

Manual Tray Lidding Machines-Photo Credits:Cilio 34

Manual tray lidding machines are easy to operate and require minimal maintenance, making them a cost-effective solution for small-scale packaging operations. However, they may not be suitable for large-scale production due to their limited production capacity.

Semi-Automatic Tray Lidding Machines:

Semi-Automatic Tray Lidding Machines-Photo Credits:TENRIT

Semi-automatic tray lidding machines are another type of tray lidding machine that offer a middle ground between manual and fully automatic machines. These machines require some level of manual intervention, but they also incorporate some degree of automation to speed up the packaging process.

In a semi-automatic tray lidding machine, the operator loads the trays onto the machine, and the machine automatically feeds and seals the film onto the tray. However, the operator is still required to manually remove the finished tray and load the next one.

Semi-automatic tray lidding machines are good options for companies that need to increase their production rates from manual methods, but may not have the budget for a fully automated machine.

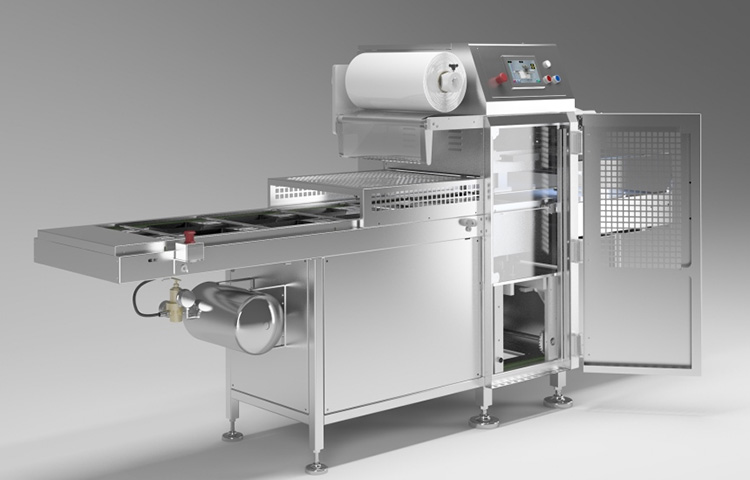

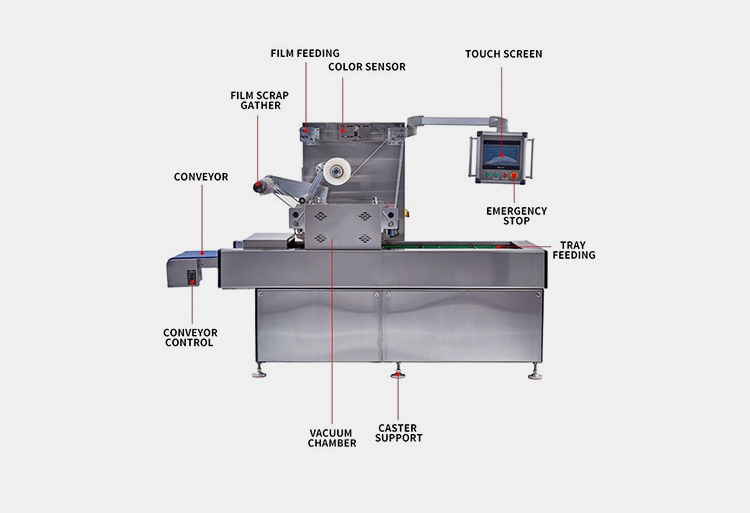

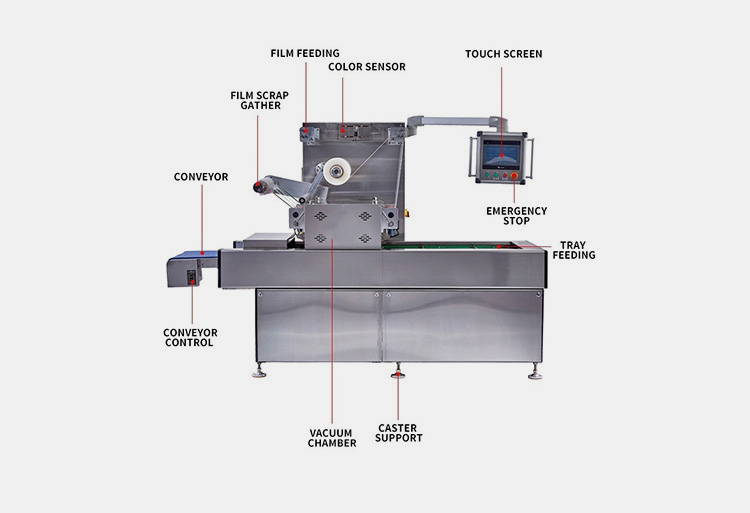

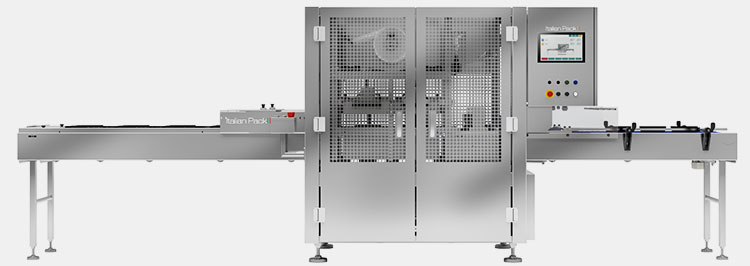

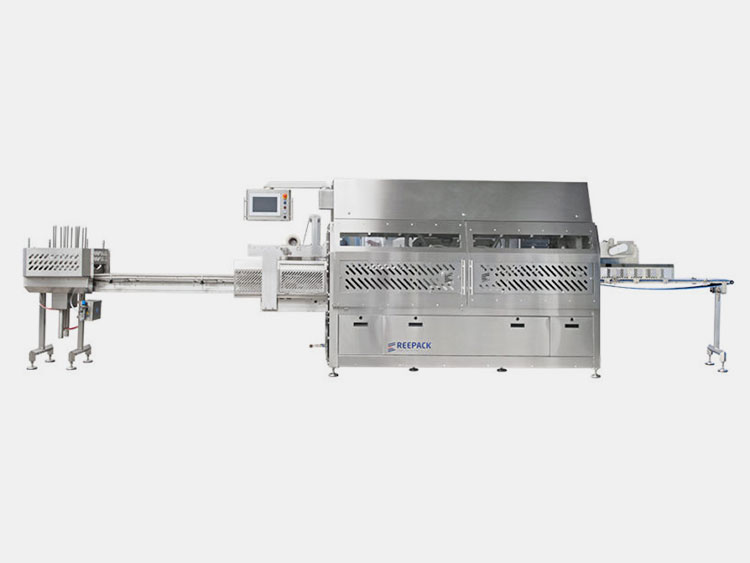

Fully Automatic Tray Lidding Machines:

Full-Automatic Tray Lidding Machines-Photo Credits:Rollex

Fully automatic tray lidding machines are designed for high-volume production and offer the highest level of automation. These machines can handle a wide range of tray sizes and materials, and can automatically feed trays into the machine, apply the lid material, and seal the tray.

They have features like touch screen controls, automatic tray and lid sensors, and programmable sealing and cutting parameters for precise and consistent sealing. Fully automatic tray lidding machines are ideal for large-scale production facilities where speed, efficiency, and accuracy are critical factors

Rotary Tray Lidding Machines:

Rotary Tray Lidding Machines-Photo Credits:China Sealer.

Rotary tray lidding machines are a type of fully automatic tray lidding machines. They are designed to handle a large volume of trays at high speeds.

The machine has a rotary table that moves the trays through the filling, sealing, and lidding process. The rotary table can have multiple stations for filling, sealing, and lidding, allowing for high production rates. These machines are suitable for large-scale production and are often used in the food and beverage industry.

Inline Tray Lidding Machines:

Inline Tray Lidding Machines-Photo Credit:Platinum Packaging Group

Inline tray lidding machines are similar to rotary tray lidding machines but are designed to be used in-line with other packaging equipment, such as filling machines, conveying systems, and labeling machines. They can handle a wide range of tray sizes and materials, and some models can even accommodate different types of lidding materials on the same machine.

Inline tray lidding machines are highly automated and can achieve high speeds, making them suitable for large-scale production. They also offer flexibility in terms of customization options and can be tailored to meet specific packaging requirements.

Thermoforming Tray Lidding Machines:

Thermoforming Tray Lidding Machines-Photo Credit:perfectpack.gr

Thermoforming tray lidding machines are specifically designed to seal the lids onto thermoformed trays. Thermoformed trays are plastic trays that are made by heating and molding a plastic sheet to create a specific shape.

The machine first applies the lid onto the tray and then uses heat and pressure to create a tight seal between the lid and the tray. These machines are typically fully automatic and can process a high volume of trays per hour.

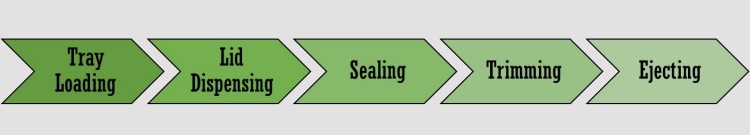

5.What Is the Working Principle Of Tray Lidding Machines?

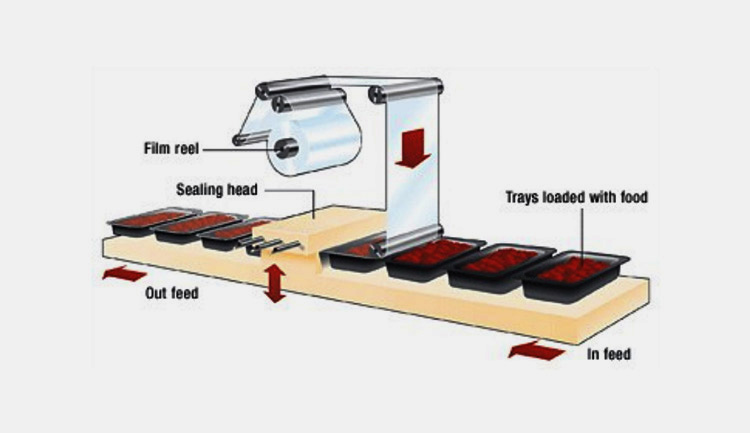

- Tray Loading:

The machine's conveyor belt accepts the pre-formed trays and transports them down the packing process.

- Lid Dispensing:

Each tray's top is covered with a lid that is dispensed from a roll or stack.

- Sealing:

The lid is then heated and compressed while being moved beneath a hot sealing plate or roller, which joins the tray and lid together.

- Trimming:

Trimming off the extra material around the tray's and lid's edges creates a neat, polished seal.

- Ejecting:

The machine ejects the sealed trays and moves on to the following step in the packaging procedure.

Depending on the type of machine, the materials being used, and the unique packaging requirements, the exact operating principle of tray lidding machines can change. However, regardless of the type of tray lidding machine used, the fundamental idea of sealing pre-formed trays with lids is the same.

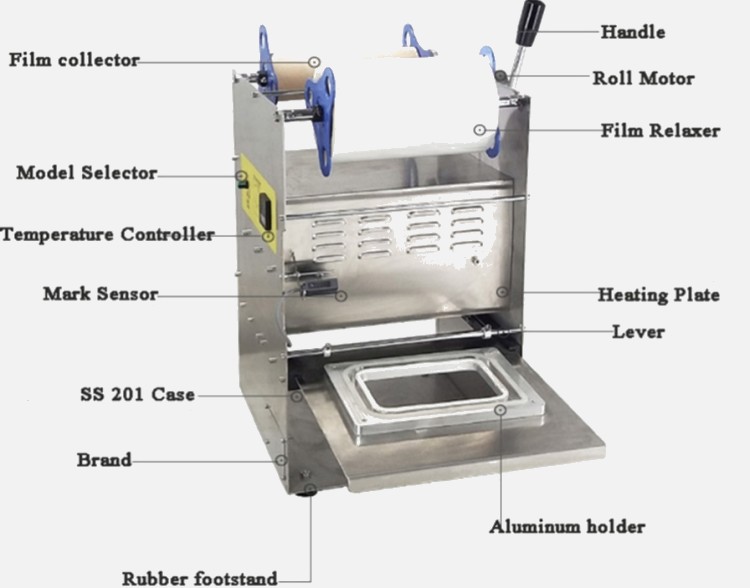

6.What Are the Components of Tray Lidding Machines?

Tray lidding machines are intricate pieces of machinery that use a number of different parts to seal pre-formed trays with lids. Some of the key elements of tray lidding machines are listed below:

Key Components of Tray Lidding Machines-Photo Credits:Chinasealer & Helix Packaging

- Film Collector: Collects the film material that will be used to create the lid for the trays.

- Model Selector:Allows the operator to select the appropriate settings for the type and size of tray being used.

- Temperature Controller:Controls the temperature of the heating plate to ensure that it reaches the correct temperature for the type of film being used.

- Mark Sensor:Detects marks or notches on the film to ensure that it is aligned properly with the tray.

- Rubber FootStand: Provides stability and prevents the machine from slipping during operation.

- Handle:Allows the operator to open and close the machine.

- Roll Motor:Powers the mechanism that pulls the film from the film collector.

- Film Relaxer:Reduces the tension in the film to prevent it from wrinkling or tearing during the sealing process.

- Heating Plate:Heats the film material to activate the adhesive and seal it to the tray.

- Lever:Presses the heated film onto the tray to create a tight seal.

- Aluminum Holder:Holds the tray in place during the sealing process.

7.What Are The Differences Between Tray Lidding Machines And Heat Sealing Machines?

Differences between Tray Lidding Machines & Heat Sealing Machines-Photo Credit: huaqiaopm & platinumpkggroup

| Feature | Tray Lidding Machines | Heat Sealing Machines |

| Function | Designed to seal pre-formed trays or containers | Can seal a variety of packaging materials, such as pouches, bags, and containers |

| Application | Typically used for sealing food products pre-packaged in trays or containers, such as ready meals, meat, poultry, and seafood | Can be used for sealing a wide range of products, including food, pharmaceuticals, cosmetics, and industrial products |

| Sealing Method | Uses a pre-cut lid that is heat-sealed onto the tray or container | Uses heat and pressure to seal the packaging material |

| Flexibility | Limited in terms of the size and shape of the tray mold. | Can accommodate a wide range of packaging sizes and shapes |

8.What Is The Operation Procedure Of Tray Lidding Machine?

Here is a general overview of the operation procedure for a tray lidding machine:

Preparation:Ensure that the machine is clean and in good working condition. Check that the required materials, such as trays and lids, are available and properly loaded.

Set-up:Adjust the machine settings according to the tray and lid sizes. This typically involves adjusting the positioning of various components, such as the conveyors, sealing mechanisms, and sensors.

Loading:Place the empty trays onto the conveyor system of the machine. The trays move along the conveyor belt to the sealing station.

Lid Placement: The machine automatically picks up a lid from the lid magazine or stack and positions it correctly above each tray as it reaches the sealing station. This can be done using suction cups, mechanical arms, or other mechanisms.

Sealing: Once the tray and lid are properly aligned, the sealing process begins. Depending on the machine, the sealing can be done through heat sealing, pressure sealing, or other sealing methods. The sealing mechanism applies the necessary heat, pressure, or both to create a secure seal between the tray and the lid.

Inspection:After sealing, the machine may include an inspection system to ensure the quality of the seal. This can involve checking for proper adhesion, lid placement, or any defects in the trays or lids. If any issues are detected, the machine may reject the tray for manual inspection or adjustment.

Discharge: The sealed trays are then discharged from the machine, either onto another conveyor or into a collection area. The trays can be further processed or packaged as needed.

Maintenance and Cleaning:Regular maintenance and cleaning of the machine are essential to keep it in good working condition. Follow the manufacturer's guidelines for maintenance procedures, including lubrication, replacing worn parts, and cleaning the machine after use.

9.What Kinds Of Trays Can Be Sealed By Tray Lidding Machines?

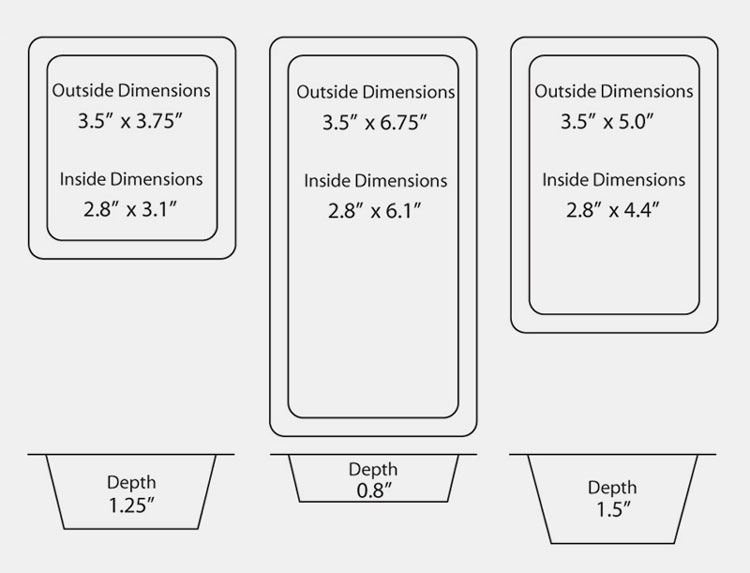

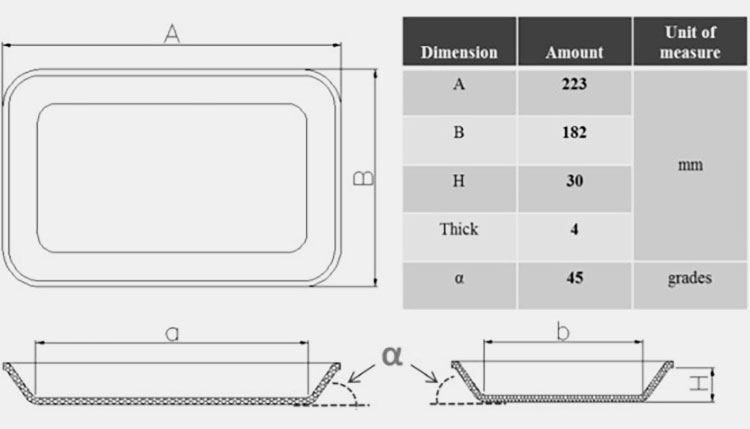

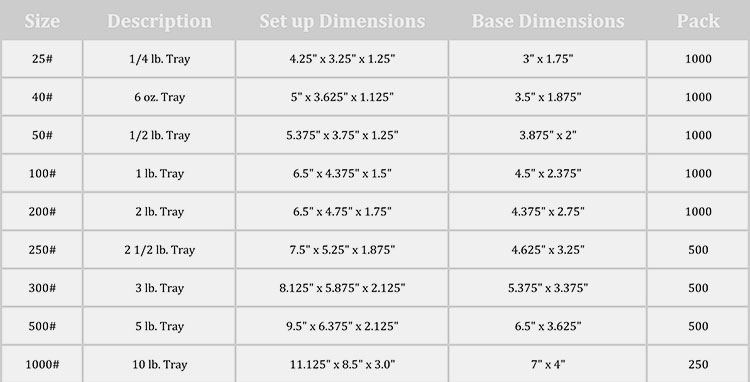

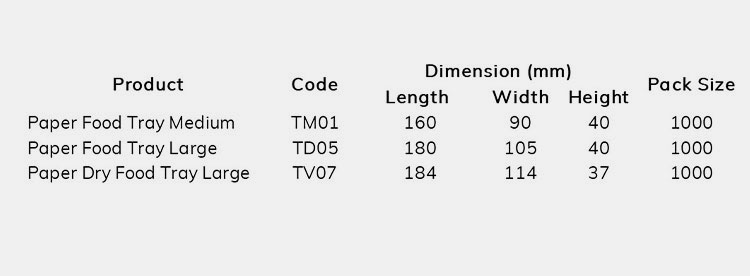

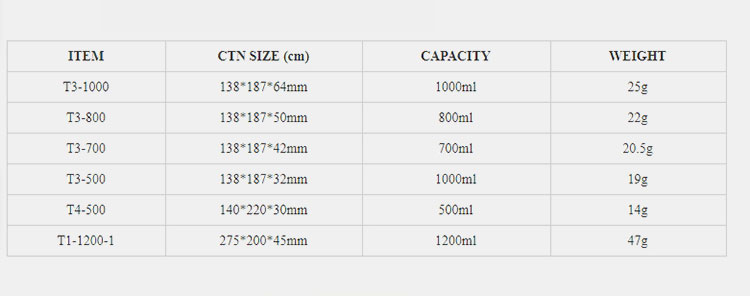

Tray lidding machines can seal a variety of trays made of different materials, here are some common types of trays that can be sealed by tray lidding machines:

- Plastic Trays:

These are the most commonly sealed trays and can be made from various plastics such as PET, PVC, and PP. They are commonly used for packaging fresh produce, meat, poultry, seafood, and ready-to-eat meals.

- Aluminum Trays:

These trays are commonly used for packaging food items that need to be cooked or reheated, such as frozen meals, pies, and baked goods. They are lightweight, durable, and have excellent heat resistance.

- Paperboard Trays:

These trays are often used for packaging dry goods, such as cereal, snack foods, and confectionery. They are lightweight and eco-friendly, making them an attractive option for environmentally conscious consumers.

10.What Kinds Of Lidding Films Can Be Used During Tray Lidding Process?

Here are some defined types of the films which are designed to securely cover trays or containers, ensuring product freshness, protection against contaminants, and extended shelf life.

Peelable Films:

These films have a sealing layer that can be easily peeled off without leaving any residue. They are commonly used for products that require easy opening, such as ready-to-eat meals, fresh produce, or dairy products.

Barrier Films:

Barrier films are used when the product requires excellent protection against moisture, oxygen, and other external factors. These films help in extending the shelf life of the packaged product. Common materials used for barrier films include aluminum foil, metallized films, or multi-layer laminates.

Retort Films:

Retort films are designed to withstand high-temperature processing methods, such as sterilization or retort packaging. They are used for packaging products that require long shelf life without the need for refrigeration, such as canned goods or pre-cooked meals.

Anti-Fog Films:

Anti-fog films are used when the packaged product is refrigerated or stored in a cold environment. These films prevent condensation from forming on the film, ensuring good visibility of the product.

Chillable Lidding Films:

These films are specially designed to withstand lower temperatures and are typically used for packaging refrigerated food products like meat, cheese, and deli items. They help maintain product freshness and prevent moisture loss.

High Oxygen Lidding Films:

These films are used in modified atmosphere packaging (MAP) applications where the product requires higher concentrations of oxygen gas. They help maintain the freshness and quality of the product by keeping oxygen levels within the packaging at optimal levels.

Freezable Lidding Films:

These films are designed to resist ultra-low temperatures and are used for packaging frozen foods such as ice cream, frozen vegetables, and meat. They prevent freezer burn and maintain the quality of the product during storage.

Ovenable Lidding Films:

These films are designed to withstand high temperatures and can be heated in an oven or microwave. They are commonly used for ready-to-eat meals and other food products that require heating. Ovenable films provide convenience and allow for direct heating of the product within the tray.

Self-Venting Lidding Films:

These films are designed to allow steam to escape from the container when heated in an oven or microwave. This helps prevent the container from bursting and maintains the quality of the food. Self-venting films are commonly used for products that release steam during the heating process.

High-Clarity Films:

High-clarity films are used when the visibility of the product is essential for marketing or display purposes. They provide excellent transparency and clarity, allowing consumers to see the product inside the tray clearly.

Reclosable Films:

Reclosable films have built-in features such as zippers, sliders, or resealable adhesive strips, allowing consumers to open and close the packaging multiple times. These films are commonly used for products that require portion control or for convenience-focused packaging.

11.What Kinds Of Food Products Can Be Packed By Tray Lidding Machines?

Tray lidding machines are widely used in the food packaging industry due to their versatility and efficiency in sealing pre-formed trays with lids made of various materials. Here are some main type of food products which can be packed by tray-lidding machines.

Dairy Products:

Tray lidding machines are often used to package dairy products such as yogurt, cream cheese, and butter. The airtight seal provided by the machine helps to extend the shelf life of these products and prevent spoilage.

Meat and poultry:

Tray lidding machines are used to package various types of meat and poultry products, including ground beef, chicken breasts, and pork chops. The machines provide a secure seal that helps to prevent contamination and maintain the freshness of the meat.

Fruits and vegetables:

Tray lidding machines are used to package fresh fruits and vegetables such as strawberries, blueberries, and baby carrots. The machines help to protect the produce from damage and contamination, and extend their shelf life.

Bakery products:

Tray lidding machines are used to package bakery products such as cakes, pastries, and muffins. The machines provide a secure seal that helps to protect the baked goods from moisture and other environmental factors that can affect their quality and texture.

Overall, tray lidding machines are a versatile packaging solution that can be used in a wide range of food packaging applications, helping to improve the efficiency and effectiveness of the packaging process while ensuring the freshness and safety of the packaged products.

12.What Are Some Common Problems That Can Occur With Tray Lidding Machines, And How Can They Be Resolved?

Poor Seal Quality:

If the tray is not sealed properly, it can cause leaks and spoilage of the product. This problem can be resolved by adjusting the temperature, pressure, and time settings of the tray lidding machine.

Jammed Trays:

Sometimes, the trays can get stuck in the tray lidding machine, which can cause downtime and affect productivity. So you need to ensure that the trays are loaded correctly and the machine is properly maintained.

Wrinkled Lids:

If the lidding material is not applied properly, it can cause wrinkles on the lid, which can compromise the seal and affect the appearance of the package. This problem can be resolved by adjusting the temperature, pressure, and time settings of the tray lidding machine, or by using a different type of lidding material.

Misaligned Lids:

If the lids are not applied properly, they can be misaligned, which can affect the seal and cause leaks. You need to ensure that the tray lidding machine is properly calibrated and the trays are loaded correctly.

13.What Are The Key Features To Look For When Purchasing a High-Quality Tray Lidding Machine?

| KEY FEATURES | DESCRIPTION |

| Speed and Efficiency | High-speed output and efficient sealing to increase productivity and reduce downtime |

| Versatility | Can handle a wide range of tray sized and materials, as well as different types of lids |

| Ease of Use | User-Friendly and easy to operate with intuitive controls and minimal training required |

| Maintenance and Service | Easy to maintain and service, with readily available replacement parts and responsive technical support |

| Safety Features | Can be customized to meet specific packaging requirements, including adding or modifying features |

| Size and Footprint | Fits within available space and can be easily integrated into existing packaging line |

| Energy Efficiency | Reduction in energy consumption in overall cost |

Conclusion

Tray lidding machines play a crucial role in the food packaging industry, providing a reliable and efficient method for sealing trays and ensuring the freshness and safety of packaged products.It is important to carefully consider the specific needs and requirements of your business before selecting a particular type of tray lidding machine, as each machine has its own advantages and limitations. If you have some puzzles, welcome to contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tray Lidding Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours