Tape Dispenser Near Me|Top Tape Dispenser Nearby

Tape Dispenser Near Me|Top Tape Dispenser Nearby

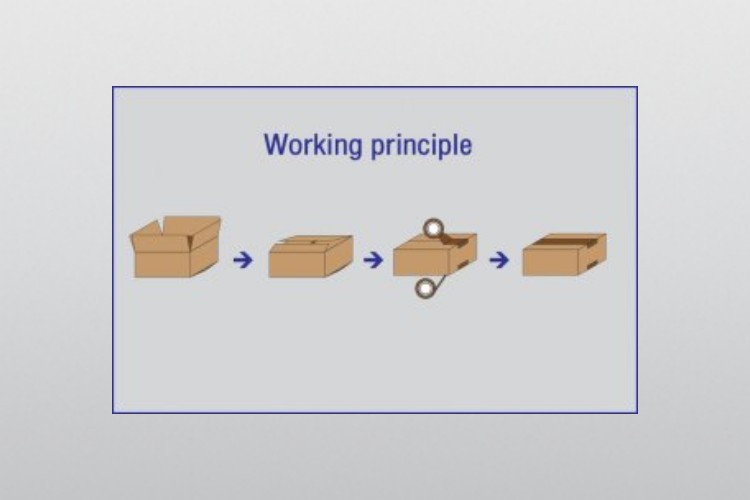

Imaging when you need to move house,you need to put your luggage and sundries into boxes,and for the purpose to protect them,you need to seal the boxes with tape,however,simply using the tape by hand can be cumbersome,so you need a tape dispenser.

In fact,tape dispenser is very common,especially in express industry, it is used frequently.How can you get a tape dispenser quickly and conveniently?The most efficient method is to find a tape dispenser near me.

1.What Is Tape Dispenser Near Me?

Tape dispenser near me,that is,tape dispensers which can be founded close to your address,such as super market,retail store,hardware store,even stationery shop,these locations all have possibilities to sell tape dispensers.

By finding tape dispenser near me,you can get a tape dispenser quickly and conveniently,different from buying online,you don’t need to wait for 2-3 days.Maybe you think this thing is not so important to you,however,when you do need a tape dispenser but don’t have one at home,it will be a little troublesome.

2.What Is Tape Dispenser?

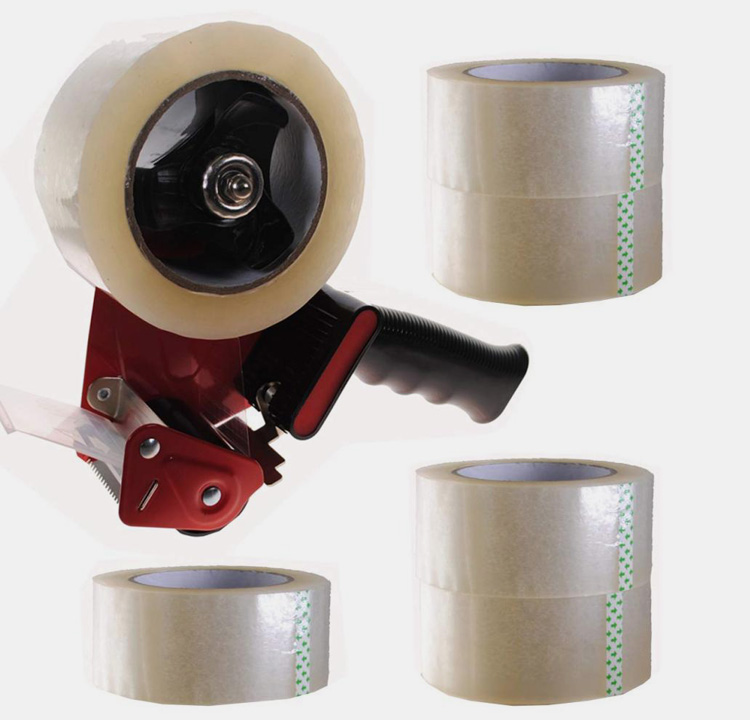

As the picture shows,tape dispenser is a simple device which can hold a roll of tape,it is equipped with a blade,when you need to use it,you can find the opening of the tape easily,and when you finish using it,it is also convenient to cut off the tape.

In general,tape dispenser is designed compact and light,therefore,it can be held by people’s hands,let the taping process more simple and the taping track will be more accurate.

3.What Are The Benefits Of Tape Dispenser Near Me?

Perhaps,you feel very curious about how can tape dispenser near me help you,how will it benefit you.Well,the benefits of tape dispenser near me are as follows:

Timeliness

As is mentioned that,when you need a tape dispenser in hurry,it has no enough time for you to order it online and wait for delivery,the most efficient method is to find a closed store to buy a tape dispenser.Therefore,one benefit of tape dispenser near me is timeliness.

Possibility of Promotion

Sometimes,some supermarkets and stores may have promotions,may have high discounts,so,the benefit of tape dispenser near me occurs,you can find these promotions at once,and buy a tape dispenser in a lower price.

Get Professional Advice from Assistants

Even if tape dispenser is a simple device,you need to choose one carefully,when you look through the different goods,it will be difficult for you to choose one,so you need a tape dispenser near me,the assistants of the store will give you professional advice,to help you choose your tape dispenser.

Ease of Assessment

As a matter of fact,if you buy a tape dispenser online,you can only assess its quality by others’ comments,but if you go to a physical store to choose a tape dispenser by yourself,you can observe the goods directly,and you can assess their quality according to your feeling,this can help you choose a good device.

Convenient After-sales

When you buy a tape dispenser,it may occurs problems during the using process or it originally had quality problems,at this moment,you need a after-sales service.If you buy it from a store near by,you can go ahead and ask for changing a high quality one,while it is inconvenient if you buy a tape dispenser online.

4.How To Find A Tape Dispenser Near Me?

Having said all that, are you ready to find a tape dispenser near by?Wait a minute,but you don’t know how to find?Actually it is easy,as the modern technologies develop,there are more and more helpful mobile apps,tape dispenser near me is such an app.

It can locate all the stores which provide tape dispensers near you,you can see these stores directly on your mobile interface,you can choose the closest one to you,and then you can get a navigation service,which will guide you walk to the store step by step,isn’t it convenient?

5.How To Choose A Tape Dispenser Near Me?

To choose a tape dispenser near me,the distance is not the only factor to be considered,there are also other factors for you to consider,for the purpose to find the best one.

Year of Establishment

The first thing you need to notice is the year of establishment,in other words,how many years does the store exist,it is better to find a store who has a longer history,it will be more reliable for a new store.

Qualifications and Licenses

Before choosing a store, you must clarify whether it has sales qualifications and licenses,that is, you need to figure out whether it is operating legally,you should never choose a store that doesn’t have any licenses.

Store Environment and Decoration

Generally speaking,there will be real pictures of the surrounding environment and interior decoration of the stores on the APP,try to choose those well-decorated shops with good surrounding environment,if a store looks too run down around or inside,then it’s not a good choice.

Customers’ Reviews

Besides pictures of the stores,there are also customers’ reviews one the APP,this is very important for you,look through the reviews carefully,to see how others evaluate these stores,about their services,the quality of their goods,etc.These reviews will help you quickly judge a store is good or bad.

Top Tape Dispenser Manufacturer Online: Rank

5.0

IPG

Description:

IPG is a international manufacturer and supplier of packaging equipment,it provides various solutions such as paper and film-based pressure-sensitive and water-activated tapes, stretch and shrink films, protective packaging, woven and non-woven products and packaging machinery.

The headquarter of IPG is in Sarasota, Florida,and the company has hundreds of distributions which located in North America,Europe and Asia,which means it can provide service for the whole world.

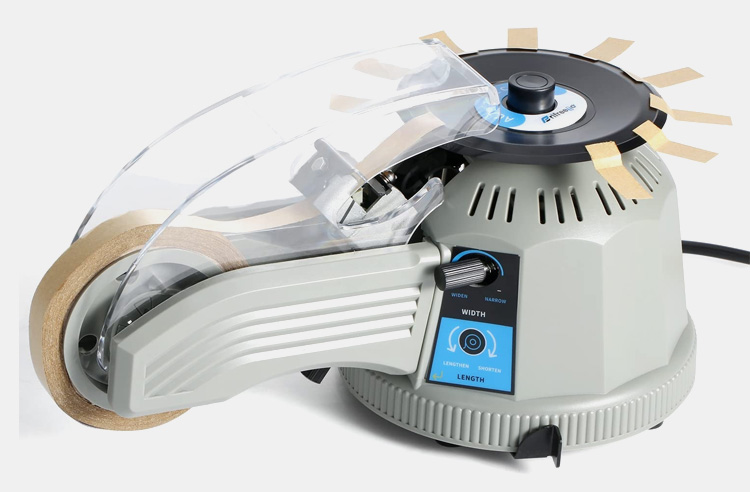

IPG provides different series of tape dispensers,such as handheld type and tabletop type,which are suitable for different applications,can meet all your packaging demands.

Recent Review:

‘High quality products!I’ve packed many boxes with this and it work absolutely perfect with, it is very happy with this!’

5.0

Allpack

Description:

Allpack is one of the leading packaging machine manufacturer in the world,it has a 12 years history,it provides a large range of packaging machines,such as sealing machines,filling machines,strapping machines,vacuum packaging machines,capping machines,labeling machines and so on.

The company provides machines for all kinds of industries,which include pharmaceutical industry,food and beverage industry,chemical industry,express industry,etc.Based on its professional attitude and high quality equipment,Allpack has a high reputation in packaging industry.

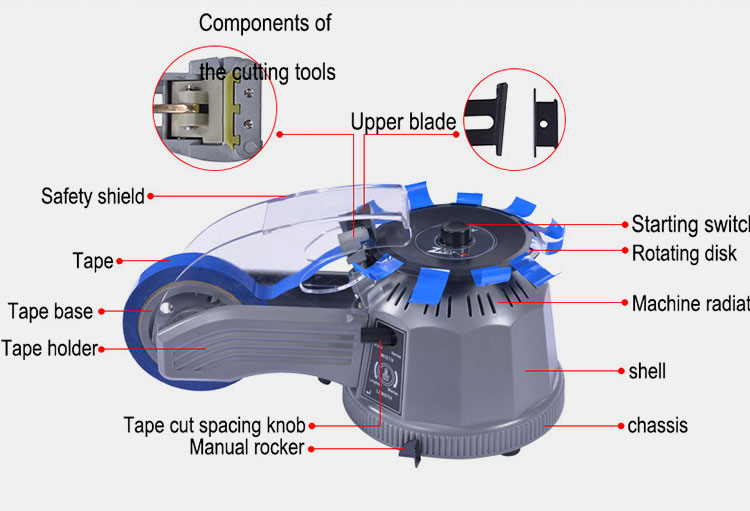

The tape dispenser of Allpack can help you use and cut tapes quickly,and they are designed reasonable,very suitable for human to operate,can largely save your time and reduce waste.

Recent Review:

‘It’s a very good experience to use a machine provided by Allpack,it is so fast and quite easy to operate.’

5.0

Crawford Packaging

Description:

Crawford Packaging has been established in 1963,until now it is almost 60 years,during the 60 years,the company has devoted itself to packaging and delivery industry,to provide flexible and effective packaging solutions for customers.Crawford aims to enhance the businesses for its customers,and gains excellent effects.

Crawford has experienced specialists and world class packaging equipment,it provides a complete series of services which include installation,automation and technical services.

Crawford mainly provides water-activated tape dispensers,these devices can dispense tapes quickly,they can pack over 50 boxes,these tape dispensers are very easy to operate,so you don’t need to receive training,which is very convenient.

Recent Review:

‘Working with Crawford is a very glad thing,it always provides good products.’

5.0

3M

Description:

3M was established in 1972,it is a family-owned company which provides all kinds of tapes and tape dispensers,it is a outstanding producer and importer of these items.The tapes of 3M can be used in a variety of industries cause they are designed for different applications.

3M has established cooperation with many famous international companies,and the scale of itself is also larger and larger,with such a strong cooperation network,the company has abundant sources.

The tape dispensers of 3M have small size,reasonable and compact design and sharp blades,can cut tapes quickly and neatly,and there are different shapes of tape dispensers for you to choose,tabletop type and pistol type.

Recent Review

‘Good products and good service,the tape dispenser is durable and practical.’

5.0

IndustriTAG

Description:

IndustiTAG is a division of GA International,it was founded in 1999,until now it has been 23 years,it is a leading manufacturer in packaging and printing industry,it mainly provides labeling and taping devices.The company provides flexible and efficient packaging and printing solutions for customers.

The company provides custom design for customers according to their requirements,it has many experienced engineers to help with the customized service.In addition,the company can realize worldwide shipping,can send products to you no matter where you are.

IndustiTAG doesn’t only provide 1 wide″tape dispenser,it also provide 4 wide″and 6 wide″tape dispensers,which can meet different types of demands.These tape dispensers have stable and hard bases,so they can adapt to different usage environments.

Recent Review

‘This is a nicely made tape dispenser. At first glance it is sturdy, and looks like it will last.’

Conclusion

A tape dispenser near me can save you much time,by reading this blog,hope that you can know the importance of tape dispenser near me and get substantial help about how to find and choose tape dispenser near me.And if you still have puzzles about it,welcome to contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tape Dispenser Near Me|Top Tape Dispenser Nearby Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours