10 Most Popular Types of Capping Machines

10 Most Popular Types of Capping Machines

Are you having trouble locating the ideal capping equipment for your packing operation? Do you possess any concerns regarding what kind of capping machine would be ideal for your particular industry? Choosing the best capping machine might be difficult with so many variations available.

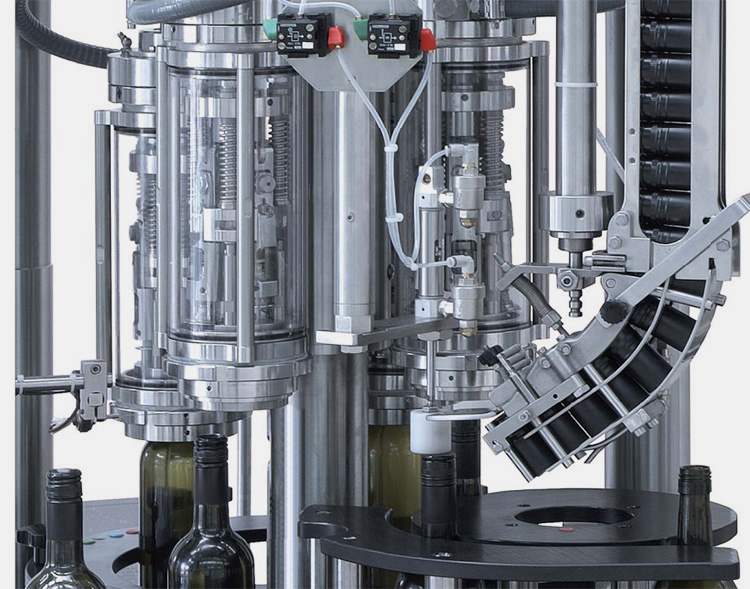

Picture Courtesy: Kandacork Glass

In the chaotic arena of production and packaging, efficient sealing is crucial in preserving product’s quality, safety, and customer contentment. The capping machines are designed to achieve the highest level of precision, speed, efficiency, and quality of the finished products. From beverages to medicines, these devices exist in a variety of designs, each suited to satisfy the demands of a particular sector.

In this blog post, we will describe the ten most popular and commonly used types of capping machines, highlighting their special features, uses, and advantages they offer to the packaging line. Join us in this unraveling journey!

1.Capping Machine

Capping Machine

The capping machine is an essential element of various production lines where receptacles are filled. It is a remarkable technological innovation which automatically apply seals, caps, and lids to the containers making them airtight and protects the material within them from the external environmental effects.

The device is a highly versatile and adaptable piece of equipment that can be personalized easily and is therefore, a popular tool across industries for varying applications.

2.Different Types of Caps/Closures

A capping machine can process a particular type or can be customized to handle multiple types of closures. There are various forms of caps applied based on the material type and packaging requirements. So, let’s get to know about common types of closures:

| Screw Closures

They are frequently applied closures for receptacles housing water, beverages, and food goods. |

|

| Pop Top Closures

Such closures are usually used for materials that require frequent openings, like shampoos, lotions, and food dressings. |

|

| Tamper Resistant Closures

These closures are applied for extra safety of the material. They provide proof if a receptacle has been tempered with. They are usually applied for medical items and cosmetic goods. |

|

| Spray Closures

Spray closures are applied to dispense liquids as a spray, like perfumes, hair sprays, and cleansers. |

|

| Trigger Closures

They are employed for distributing liquids in a splash. They allow for directed sprays and are typically used for floor cleaners, pesticide sprays, and other such chemicals. |

|

| Child Resistant Closures

These closures are applied to avert materials from the reach of children to avoid accidental ingestion. They are commonly employed for pharmaceutical and chemical goods. |

|

| ROPP Closures

The roll-on pilfer proof closures are usually applied to liquor bottles, producing a secure bolt. |

|

| Cork Closures

They are traditional fasteners for liquors and wines, offering a tamper-proof lock. |

|

| Crown Closures

These closures are employed for vessels containing soft drinks and beer. |

|

| Pump Closures

Pump closures are applied for dispensing viscous liquids, like lotions, soaps, shampoos, and dishwasher fluids. |

|

3.10 Most Popular Types of Capping Machines and their Functioning

There are heft of the options available on the market. Opting for the equipment is essential to preserve the product’s safety and quality. We will go over the 10 most popular types of capping machines and provide some important information along the way to assist you in making this choice.

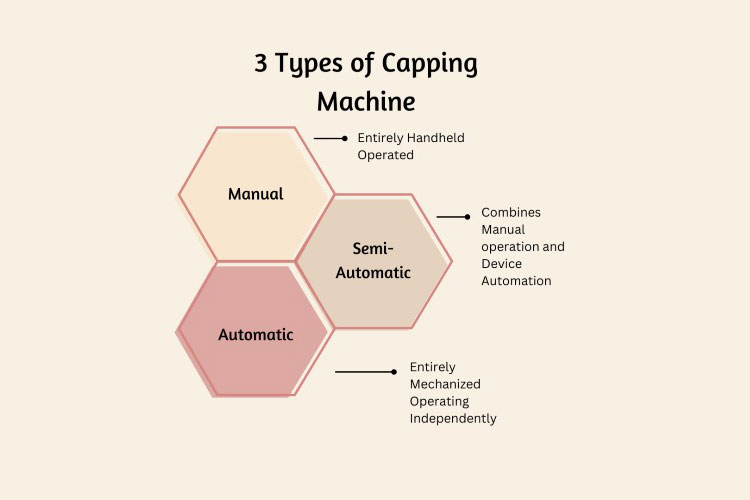

3 Capping Machine Types on the Basis of Automation

Manual Capping Machine

Manual Capping Machine

The manual capping machine is a handheld operated device. It is a perfect gadget for minor tasks. It has minimum processing capacity, relying upon the worker’s skills. It has a simpler design and an affordable price. Newly established businesses can hugely benefit from this easy-to-use tool.

Working

Each processing step is performed manually. The task initiates by putting receptacles on a flat surface. An appropriate lid is placed on the receptacle. A handheld tool is gripped over the lid. The device handle is pushed lower and the lob rotates to screw the cap.

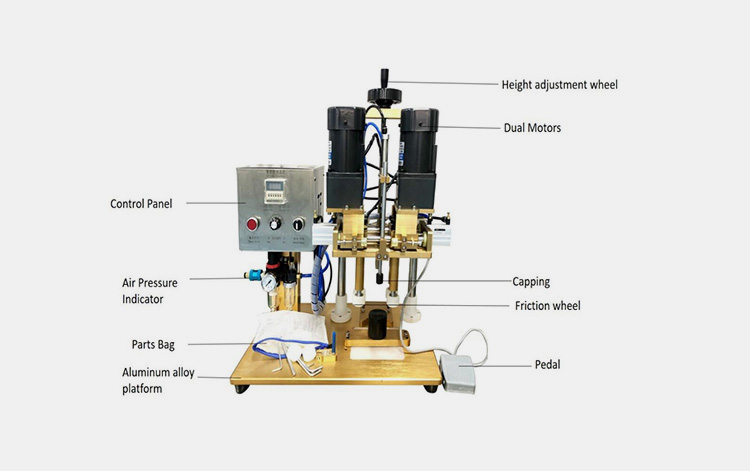

Semi-Automatic Capping Machine

Semi-Automatic Capping Machine

A combination of hand-operation and mechanized control is involved in the semi-automatic capping machine. The equipment is a best possible solution for modest operational needs. It has a processing capacity of about 25-30 receptacles per minute.

Working

The task is initiated by manually putting convenient lids on the vessel heads. The receptacles are then directed firmly toward the equipment. Next, you must turn ‘ON’ the gadget. The piston will regulate the lob to ascend and descend to close the caps.

When the lob comes in contact with the closure, a motor starts functioning. The lid is secured and then the device automatically stops. Now, the gadget can be turned ‘OFF’. The lob will set free the cap and you can take the receptacles.

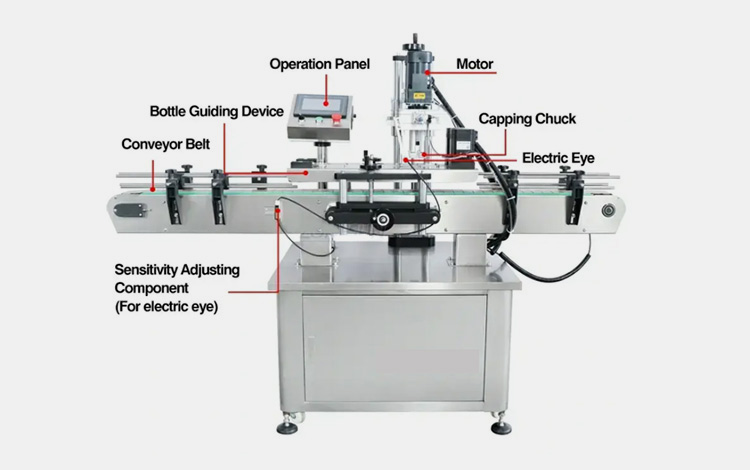

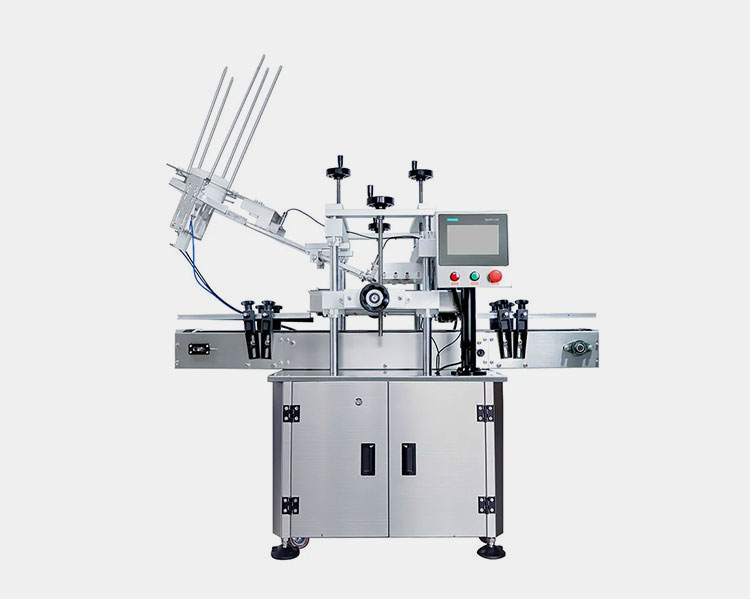

Automatic Capping Machine

Automatic Capping Machine

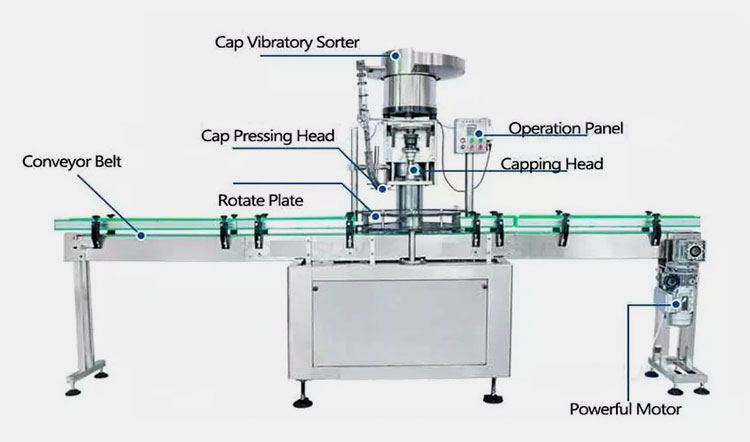

The automatic capping machines are tailored with the latest technological components, offering greater processing capacity (up to 200 receptacles per minute) and effectiveness. They consist of several capping and bottle feeding mechanisms.

Working

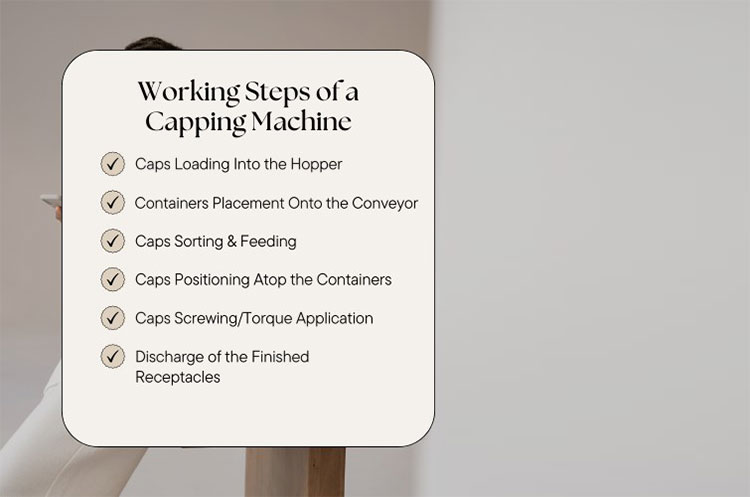

The containers are conveyed toward the capping segment on the conveyor. The best fitted lids are sorted and directed toward the capping head. The caps are then settled onto the receptacles, which then leave for the screwing segment.

The automatic gadgets also comprises gripping belts to clasp the receptacles and cap stabilizers to prevent closures from tumbling. The capping head grabs the settled caps and applies twists to screw them up.

The capped receptacles are set free and are transported to the next production phase on the conveyor belt.

5 Capping Machine Types on the Basis of Capping Techniques

Chuck Capping Machine

Chuck Capping Machine – Picture Courtesy: CVC Tech

The chuck capping machine is an efficient variant that comes in single and multi-head layouts. The device comprises several pivotal elements, including the capping and chuck/lob head, the conveyor platform, and the cap transporter.

Working

Chuck Capping Technique

The receptacles are transferred on the conveyor. The closures, loaded into the hopper, are dispensed to the chuck head, which hauls down and grasps the lid. A required amount of torque is applied to screw the lid. The chuck head liberates the lid and lifts up.

Spindle Capping Machine

Spindle Capping Machine – Picture Courtesy: Brightwin

The most renowned form of capper is the spindle capping machine. It has a similar structural design as the chuck capper with a different cap application approach, consisting of spindle discs.

Working

Spindle Capping Technique

The conveyor carries the receptacles. Caps are arranged and settled on them, followed by passing from the rotating spindle discs that applies torque, and screw the lids. The closed receptacles get an exit from the device while moving along the conveyor.

Snap Capping Machine

Snap Capping Machine – Picture Courtesy: Levapack

The snap capping machine makes use of a press-on tool to exert pressure on the lids and get an efficient seal. It is a popular device across several sectors, including personal care, beverages, and medical care.

Working

Snap Capping Technique

The moving belt directs the receptacles toward the capping segment. Lids are settled onto them. The capping head hauls down with a required amount of force and pressed the lids down onto the receptacles, securing a leak-proof closure.

ROPP (Roll-on Pilfer Proof) Capping Machine

ROPP (Roll-on Pilfer Proof) Capping Machine

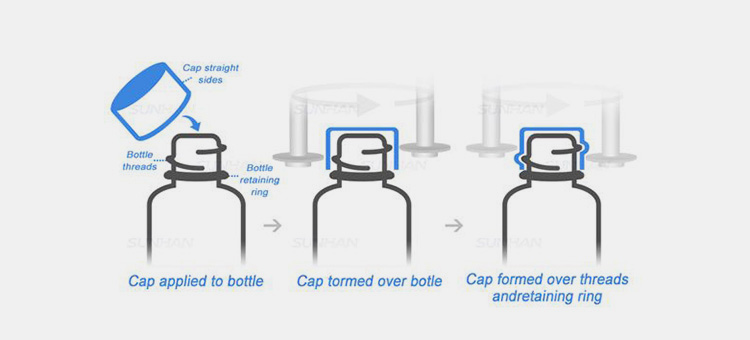

ROPP (Roll-on pilfer proof) cap is a form of bottle closure. It is typically made up of fine grade aluminum due to its ductile nature. The cap starts off as soft, silky, fringed cover. The device rollers mold the cap to fix into the grooves on the bottle neck.

The ROPP capping machine is a remarkable screw-type device which forms the strain by exerting pressure against the receptacle. This device is available as a single and multiple head arrangements. A huge advantage offered by this gadget is that it bottom-seals the closure as well, producing a tamper resistant setting.

The capping head of the device comprises a threading and overlapping rollers.

Working

ROPP (Roll-on Pilfer Proof) Capping Technique

The device works by precisely propping the receptacles under capping heads via the moving belt. The lids picked by the cap feeder are then accurately settled on the receptacles, followed by lowering of the capping head which grasps the lid, forming a drift and seal at the same time.

The head offers a leveled, consistent pressure, resulting in a firm cap and a tamper resistant seal. The receptacles are then set free to move along the conveyor.

Vacuum Capping Machine

Vacuum Capping Machine

The vacuum capping machine is a sublime piece of equipment typically employed to effectively seal glass caskets of varying dimensions. The device imparts a hermetic closure that preserves the material longer than usual. Vacuum casing increases the product’s shelf-life due to limiting the oxygen presence.

The capping head can be customized to adjust different forms of receptacles and closures.

Working

Vacuum Capping Technique

The vacuum capping machine is an easily operated device. The glass containers are conveyed into the vacuum chamber. The chamber is corked to generate a vacuum. Lids are suppled and settled over the containers. The capping head hauls down and screws the lid under vacuum. After capping, containers are liberated and exit the vacuum chamber.

2 Capping Machine Types on the Basis of Configuration

Inline Capping Machine

Inline Capping Machine

The inline capping machine is structured to handle and close the vessels in a linear configuration. The device comprises a moving belt to transit the receptacles in a symmetrical line. The gadget can hold different types of heads simultaneously.

Working

The vessels are conveyed on the moving belt and directed towards the capping section. Closures are put onto the vessel tops. The capping head hauls down, secure the closures and then liberate the heads.

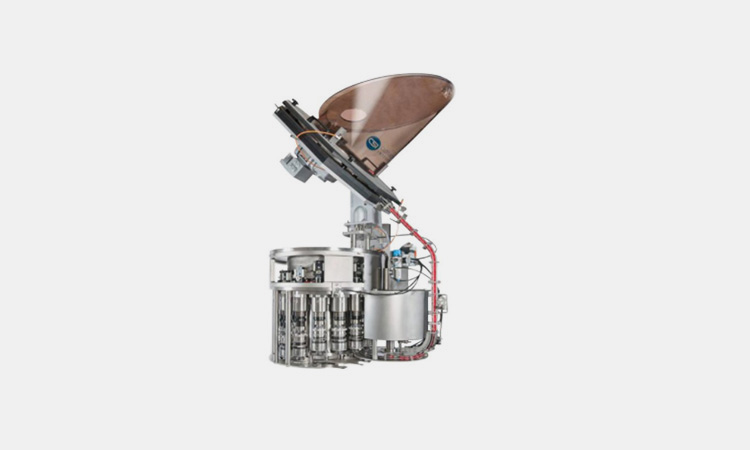

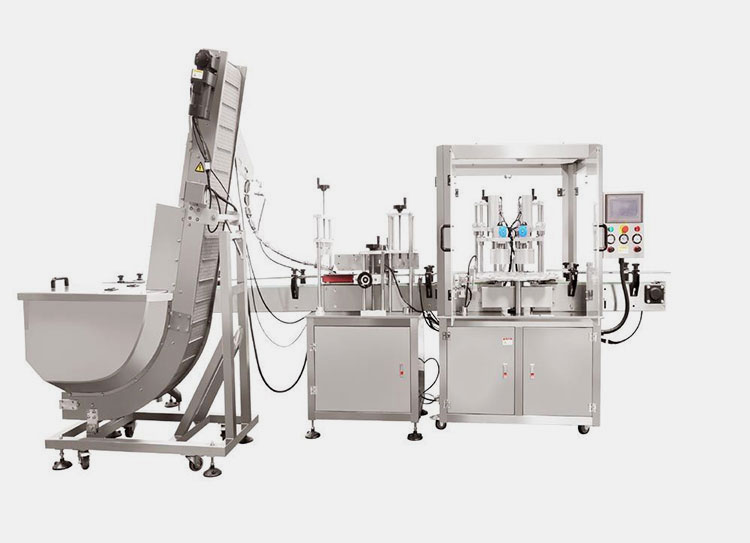

Rotary Capping Machine

Rotary Capping Machine

The rotary capping machine is engineered for huge processing volume and high working pace. It comprises a rotary disc instead of a conveyor for carrying receptacles.

Unlike linear capping machines, which can hold many types of heads simultaneously, applying several kinds of heads requires manually dismantling and reorganizing the heads.

Working

The receptacles are loaded onto the rotary disc, which positions them under the capping nobs. Closures are settled, the disc continues rotation, and each capping nob hauls down and close the vessel. The closed receptacles exit the spinning disc and move along the moving belt.

4.Applications of Capping Machines

Capping machine is an indispensable component of various production lines across industries. Their ability of handling numerous container types and closing them with personalized closure types make them popular in several sectors. Some common businesses are enlisted here:

Food Sector

Applications of Capping Machines in the Food Sector

A number of liquid (free-flowing and non-free-flowing) food items are contained in different form of vessels. They are precisely capped using a capping machine. Some common items are: soy-sauce, tomato ketchup, vinegar, BBQ sauce, food oils, and salad dressings.

Medical Care Sector

Applications of Capping Machines in the Medical Care Sector

In the medical sector, multiple products (liquid and solid dosage forms and other medical care products, such as pyodine and methylated spirit) are closed within different forms of vessels. Their effective sealing is crucial for maintaining the material’s inherent characteristics.

Beverage Sector

Applications of Capping Machines in the Beverage Sector

Several beverages are contained within various receptacles for retail and wholesale distribution. The capping machine applies effective closures on these receptacles. Some common beverages are: energy drinks, soft drinks, tea, coffee, and flavored juices.

Chemical Sector

Applications of Capping Machines in the Chemical Sector

Majority of chemicals cause skin abrasion and therefore must be efficiently packaged within their containers. Common chemicals capped within containers include: liquid detergents, pool chemicals, phenyls, dish washers, toilet cleaners, and laboratory chemicals.

Cosmetic Sector

Applications of Capping Machines in the Cosmetic Sector

Several cosmetic products, such as shampoos, conditioners, lotions, and moisturizers, are effectively closed within bottles using a capping machine to preserve the item’s characteristics.

Automotive Care Sector

Applications of Capping Machines in the Automotive Care Sector

Windshield washer fluids, mobile oils, and radiator coolants are hermetically capped within containers using a capping machine to avoid leakage and any incident.

5.Maintenance

Picture Courtesy: Levapack

Regular maintenance of every industrial equipment is essential to preserve its optimal functioning and a longer lifetime. Neglecting proper and timely maintenance will cause you experience more breakdowns and a possible early deterioration of the device. In this section, you will find some key tips to follow for maintaining your capping machine.

Cleaning: perform routine cleaning of your gadget to prevent dust accumulation that could result in reduced efficiency. Conduct deep cleaning programs periodically to wash out the components that are difficult to clean during regular maintenance.

Polishing: polish and scrub the device parts with a clean cloth for efficient and precise results.\

Greasing: oil the moving parts, such as the motor and the conveyor belt, to reduce friction and ensure smooth operation.

Inspection: timely inspect each component for any sort of damage. Immediately replace the broken parts to avoid costly incidents and breakdowns.

6.Tips for Investing in a Particular Capping Machine for Your Business

Every manufacturer wants their equipment to satisfy their needs and work smoothly and efficiently. Therefore, a right choice of equipment while shopping is the most critical for your production line and your business growth. Here we will unravel some tips or factors involved while selecting a particular capping machine for your packaging solutions.

Assess Your Requirements

Assess Your Requirements

You must assess your production needs before investing in a capping machine. If your demands are low or you own a newly established business, a manual or semi-automatic variant or an inline model would be a suitable option for your business. For huge production demands, an automatic rotary capping machine should be a go-to option for you.

Versatility and Adaptability

Versatility and Adaptability

If you deal with varying container and closure types, you need a device with greater versatility and flexibility. Therefore, you should know about your current dealings and your future objectives as well. Additionally, some models handles a specific type of closure and container, you must also take that into account.

Speed and Efficiency

Speed and Efficiency

If you own a large manufacturing facility and possess a huge manufacturing demands, an automatic rotary device is a recommended one for you. It offers greater speed and efficiency and is engineered for large processing needs.

Cost Factor

Cost Factor

It is the most critical factor involved in the shopping of a capping machine. Evaluate your budget and opt for the variant having a reasonable expense calculation and can effectively meet your demands.

Manufacturer Reputation and Support

Manufacturer Reputation and Support

Always buy your capping machine from a reputed and licensed manufacturer that provides maintenance and technical support to avoid unexpected troubles.

The Bottom Line

Now you have seen, there are a heft of variants of a capping machine. You must also have understood their unique features and applications. Selecting the best device for your business can significantly influence your overall production efficiency and product’s quality. Therefore, consider the tips mentioned in the blog before opting for a particular model. If you need further assistance in purchasing or want to know more about capping machines, feel free to contact Allpack, you will be guided better!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

10 Most Popular Types of Capping Machines Read More »