Pallet Wrapper: The Complete Buying Guide In 2025

Are you tired of spending hours wrapping pallets by hand? Are you concerned about the safety and stability of your shipments?

In this blog post, we delve into the benefits of using a pallet wrapper, including increased efficiency, reduced labor costs, and improved pallet stability during transportation. Our comprehensive guide will provide you with all the information you need to make an informed decision on purchasing a pallet wrapper. Join us in exploring the world of pallet wrapping and revolutionize your shipping process today.

1.What Is A Pallet Wrapper?

A pallet wrapper is a machine that helps securely bind items to a pallet for transport. It uses either plastic or paper stretch film to tightly wrap the goods, providing protection from weather and other elements during shipment.

This process can be automated with machines like pallet wrappers, which are quick and efficient in wrapping the load on the pallet. The benefit of the pallet wrapper is that it ensures the goods are safe and secure, which helps prevent damage during transit. Pallet wrappers also help to reduce waste by using minimal material to protect a load, resulting in cost savings.

This machine can be used for both in-house and outside applications, making it an ideal choice for a variety of industries because it is easy to use and requires minimal setup, making it the perfect solution for businesses looking for an efficient way to secure palletized loads.

With its potentiality to securely wrap pallets, the pallet wrapper can help ensure successful delivery and prevent potential losses from damaged goods. Finally, it is the best solution for businesses that need to transport goods safely and securely.

2.What Are Some Of The Most Common Pallet Wrapper Features?

Stretch Film Dispenser

The pallet wrapper usually features a large stretch film dispenser for the wrapping material, making it easier to apply.

Pre-Stretch System

A pre-stretch system ensures that the wrapping material is efficiently used and stretches to its full potential before each wrap cycle begins, ensuring maximum efficiency and performance.

Film Cutters

Most pallet wrappers feature a built-in film cutter for easy disposal after each wrap cycle has finished. This helps to reduce wasted material and ensure safety in the workplace.

Programmable Controls

Pallet wrapper models with programmable controls enable you to customize wrapping cycles and film tension to suit the needs of your product.

Photo Eye

Many pallet wrappers also feature a photo eye, which helps ensure that the wrapping process is completed correctly and efficiently. The photo eye detects when the load has been fully wrapped and stops the cycle automatically.

Safety Features

Most pallet wrappers include a variety of safety features, such as built-in emergency stops and motion sensors. These help to ensure the safe operation of the machine and protect personnel from potential hazards.

Robust Design

A robust design is essential for any commercial product wrapping machine, especially for those that will be used in busy factories and warehouses. Most pallet wrappers on the market are designed for heavy duty use, so you can be assured of reliable performance and long-lasting durability.

Ergonomic Design

An ergonomically designed machine is key to a productive and safe workplace environment. Look for a pallet wrapper with adjustable height settings and easy to reach controls to make the wrapping process as smooth and easy as possible.

3.How Does A Pallet Wrapper Work?

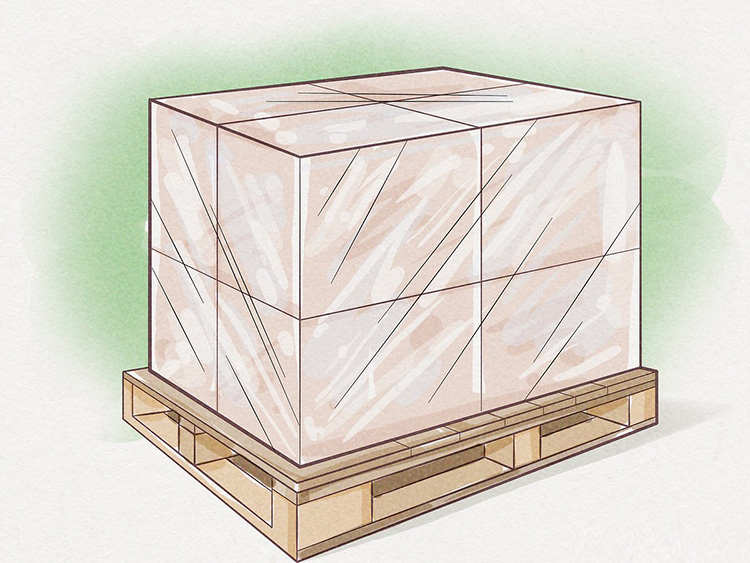

A pallet wrapper, also known as a stretch wrapper or pallet banding machine, is a device used for securing and stabilizing goods on a pallet before shipping. It works by wrapping plastic film around the items on the pallet in order to keep them from shifting during transport. This reduces damage and lost inventory while ensuring that the goods arrive safely at their destination.

The pallet wrapper works by spinning film around the pallet load, stretching it tight and securing it with a heat-sealing process. This is done in several steps:

The operator loads the items onto the pallet and sets up the machine for wrapping. This includes manually adjusting the height of the film dispenser and tension arms.

The film roll should be set up now by the operator, threading it through the dispenser arm and locking it into place.

The machine is powered on, initiating the wrapping process. It will wrap in a spiral pattern or with overlapping horizontal bands depending on the settings.

As the machine wraps, it applies tension to the film roll and presses it against the pallet load to ensure a tight wrap. The tension is controlled by adjustable arms that can be manually adjusted from the operator’s station or using hands depending on the type of wrapper being used.

When finished wrapping, the machine will then heat-seal the film to keep it in place, and cut off any excess length.

The pallet is now ready for shipping or storage.

4.What Are The Fundamentals Of Wrapping That The Pallet Wrapper Consider?

The pallet wrapper must consider a number of fundamentals when wrapping a pallet. This includes pallet wrap film, stretch of the film, strength, film yield, film memory, load retention, puncture resistance and visual clarity.

The pallet wrap film is the material used to secure and stabilize the load.

The stretch of the film should be able to accommodate for any size of load and allow for a secure, tight wrap.

The strength of the film should be able to withstand external forces such as wind or vibration during transportation.

The film yield should be sufficient to retain the load and provide a secure wrap.

Film memory is an important factor as it can help to increase the expected performance of a wrap.

Load retention is also important as it helps to keep the pallet intact during transportation.

Puncture resistance is also important as it helps to protect the load from sharp objects or rough terrain.

Finally visual clarity is also something that must be considered, as it helps to identify any potential issues with the pallet wrap.

Additionally, a good pallet wrapper will also consider factors such as environmental conditions, pallet size, and the type of load being wrapped to ensure that the wrapping is done correctly.

5.What Are The Benefits Of Using A Pallet Wrapper?

The benefits of using a pallet wrapper are numerous and they are:

Enhanced presentation

Using a pallet wrapper to wrap items can help create an aesthetically pleasing and professional presentation that reflects positively on the business.

Increased protection

Wrapping goods with a pallet wrapper provides an extra layer of protection by helping to guard the goods from dust, dirt and other external factors.

Improved efficiency

Pallet wrappers can help to speed up the packing process, allowing businesses to get their goods packaged and ready for shipment more quickly.

Improved quality

By securely wrapping items on a pallet with a high-quality wrapping material, businesses can ensure that goods remain securely held and protected during transport.

Cost savings

Using a pallet wrapper can significantly reduce the amount of material and labour required to package goods, resulting in a cost savings for the business and also reducing the cost goods due to damage control.

6.What Are Some Of The Pallet Wrapper Applications Available?

The pallet wrappers are primarily used for industrial, commercial and retail applications. They are designed to wrap boxes, skids and pallets securely with stretch film or shrink wrap. This prevents the items from being damaged during shipping and handling.

In agriculture, pallet wrapper machines are used to wrap and secure loads of milk, eggs and other perishable items for distribution.

Automotive companies use them to secure engine components, tools and auto parts.

In the retail sector, pallet wrappers are used to stabilize and secure products for shipping and seasonal storage. Finally, manufacturing companies use them to wrap heavy-duty equipment and materials for safe transport.

Pallet wrappers are essential tools for any industry that needs to secure, store or transport pallets. They help prevent accidents and damage to the items on the pallets, reducing the risk of losses due to mishandling or improper storage and transportation. Pallets are an effective way to that goods arrive safely and securely at their destination.

7.What Are The Different Types Of Pallet Wrappers Available?

There are a variety of different types of pallet wrappers available, depending on the automation and the most common types are;

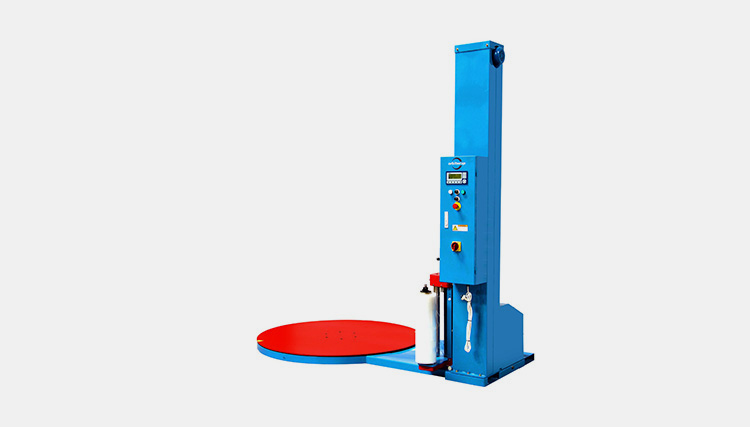

Manual Pallet Wrapper

These machines require the operator to manually secure the film around the pallet. This type of pallet wrapper is typically used in small-scale applications and is not recommended for high-volume packaging operations.

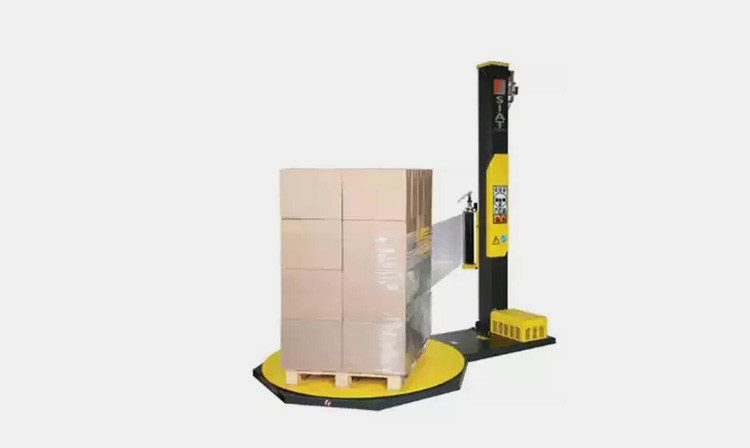

Semi-Automatic Pallet Wrappers

This equipment provides the operator with assistance in securing the film and controlling the wrapping process. This type of pallet wrapper is typically used in medium-scale packaging operations and allows for improved efficiency.

Fully Automatic Pallet Wrappers

They are the most advanced type of pallet wrapper and offer the greatest level of automation and efficiency. This type of pallet wrapper requires minimal operator input, allowing for a fast and efficient wrapping process. It is ideal for high-volume packaging operations.

There are a variety of different types of automatic pallet wrappers that can be used in the warehouse environment. These include:

Rotary arm wrappers

These machines use a rotating arm to apply the film to the pallet. The arm wraps in an overlapping spiral pattern, creating a uniform wrap that is strong and secure.

Turntable Wrapping

This type of pallet wrapper uses a turntable to hold the pallet in place while the arms rotate at various angles, wrapping the film around the pallet in a tight, secure manner.

Robotic Wrappers

Robotic wrappers are automated machines that use robotic arms to apply the film to the pallet. These wrappers can be programmed to wrap any size or type of pallet, and are highly efficient and accurate.

Straddle Wrapper

Straddle wrappers are specialized machines that use two arms to apply the film to a pallet. The arms wrap around the pallet in an alternating pattern, creating an effective and secure wrap.

Ringer or Orbital Wrapper

Ringer wrappers are machines that use a circular arm to wrap film around the pallet in an overlapping pattern. This type of wrapper is ideal for pallets of irregular shape, as it can be adjusted to accommodate the size and shape of the pallet

Ring Straddle Wrapper

This type of pallet wrapper uses two arms that wrap around the top and bottom of a pallet simultaneously, creating an even and secure wrap.

8.What Is The Difference Between Automatic And Semi-Automatic Pallet Wrappers?

Automatic pallet wrappers are machines that require a minimal amount of manual labor to operate, while semi-automatic pallet wrappers require more manual labor.

Automatic pallet wrappers are programmable and can wrap a large number of pallets in short periods of time. They are able to adjust the wrapping process according to the size and weight of each package, making them an efficient solution for businesses with a large volume of outgoing shipments. Semi-automatic pallet wrappers are simpler machines that require more manual labor to operate. They are most commonly used in warehouses or other locations where a automated pallet wrapper may not be practical.

With an automatic pallet wrapper, the machine can be programmed to wrap a certain number of pallets at once, with each pallet receiving the same wrapping specification. This can help reduce labor costs and increase efficiency. Semi-automatic pallet wrappers, on the other hand, require manual labor to load the film onto the pallet and activate the wrapping process. This can be more labor-intensive, but can be beneficial when wrapping individual shipments or products that require special specifications.

9.What Is The Difference Between Stretch Wrapping And Shrink Wrapping?

There are two types of wrapping that can be used: stretch and shrink wrapping. Stretch wrapping involves using a stretch wrap film around the pallet in a continuous winding motion. This provides strong protection from dust and moisture, as well as providing support for the items on the pallet.

Shrink wrapping, on the other hand, involves using a heat sealing machine to shrink plastic wrap around the pallet. This provides an airtight and water-resistant barrier that is less likely to tear or be damaged while in transit. When selecting a pallet wrapper machine, it’s important to consider the type of wrapping needed and what will best suit your business needs.

10.What Are The Most Common Pallet Wrapper Materials Used?

Each material mentioned here has its own unique properties and benefits, so it's important to consider which is best suited for your needs and that’s why selecting the right pallet wrapper material can help protect your products and ensure they reach their destination safely. The most common pallet wrapper machine materials used include:

Polyethylene Film:This is a strong and stretchable plastic material that is used to tightly wrap items for shipping and storage. It offers a secure seal and protection, while also keeping the cost of packaging low.

Polypropylene Film:This is often used in combination with polyethylene film to provide an even stronger seal. It is also water-resistant and provides excellent protection.

Foam Sheets:They are materials that are lightweight and water-resistant in nature and therefore they are used as a cushioning material on pallets, as they provide extra protection from shocks and impacts.

Kraft Paper:This is typically used to wrap pallets in a more aesthetically pleasing manner, as it is visibly smoother and often comes in different colors.

Corrugated Cardboard:This type of packaging material is lightweight and offers good protection. It is often used to provide an extra layer of protection against shocks and impacts.

11.What Type Of Items Can Be Wrapped Using A Pallet Wrapper?

Items that can be wrapped on pallets depend on the size and weight of the items. Generally speaking, lighter items such as clothing, paper goods, and boxes of small parts can be safely wrapped with a pallet wrapper.

Bulkier items like furniture, appliances, and industrial machinery parts can also be wrapped on pallets using a more robust wrapping solution. Additionally, boxed food and beverages can also be safely secured with a pallet wrapper.

It is therefore important to match the size and weight of the items to be wrapped with an appropriate wrapping solution of an appropriate wrapper. If not, the items or commodities may not be adequately secured and can become damaged during the shipping process.

Ensure the best possible protection for your items when using a pallet wrapper, be sure to select the proper size wrap and use a pallet wrapping machine with enough tension for your items.

12.How Do I Choose The Right Pallet Wrapper For My Needs?

Choosing the right pallet wrapper machine can be a daunting task, ensure you are making the right decision for your needs and here are some key points to consider;

Determine The Size Of Your Pallets.

The size and weight of the pallets you need to wrap will determine the type of machine needed for the job. If you are wrapping light-weight pallets, you may consider a manual or semi-automatic machine. If your pallets are heavier and more awkward to handle, an automatic pallet wrapper is likely your best option.

Consider The Types Of Film You Will Use.

Different pallet wrap machines work with different types of film. Consider what type of film you are wanting to use and make sure the machine you choose is compatible. If you are unsure the type of film you need, your supplier should be able to provide advice.

Think About How Often You Will Use The Pallet Wrapper.

If you are looking for an occasional solution, a manual or semi-automatic machine may be the best option but also if you plan to use it frequently, an automatic machine may be a better choice.

Read Reviews And Ask For Advice.

It is always a good idea to research the model you are considering, as well as reading customer reviews. Additionally, asking for advice from industry experts or peers can be a great way to make an informed decision to choosing your preferable wrapper.

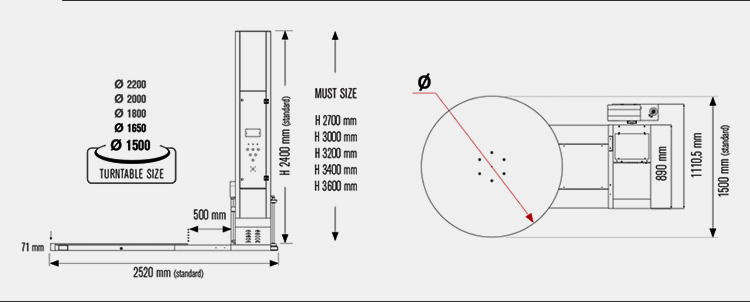

13.How Do I Choose The Right Pallet Wrapper Size?

Selecting the right pallet wrapper machine to meet your business needs size is a major factor. The bigger the wrapping equipment, the more powerful and efficient it will be. But it’s important to choose a size that fits your business’s needs – you don’t want to invest in a machine that’s too large or too small.

Choosing a preferable pallet wrapper, consider the size of your most commonly shipped and received pallets. Make sure you choose a machine that will adequately wrap the size of pallet your business uses. If you need to regularly ship or receive pallets of different sizes, then a machine with adjustable width and height settings may be better suited for your needs.

Also, consider the speed you need from the machine, as different models will offer wrapping speeds of varying levels. For example, a machine with a lower speed may be suitable for businesses that only need to wrap pallets every few hours. Alternatively, businesses that require higher speed machines may need to invest in a more powerful model, especially if they need to wrap dozens of pallets per hour.

Finally, make sure to consider any additional features that you may need from the pallet wrapper such as those that offer extra security or environmental benefits. Investing in a machine with the right features can help to protect your products during storage and transport, as well as helping your business to reduce its carbon footprint.

Conclusion

And there you have it, the end of our journey through the wonderful world of pallet wrappers! We hope you've enjoyed this post as much as we've enjoyed exploring the ins and outs of this amazing piece of equipment. Whether you're a seasoned veteran in the packaging industry or a newbie looking to up your game, a reliable pallet wrapper is essential. And if you're looking for the best quality, affordable options, don't hesitate to contact Allpack! Their team of experts is more than happy to help you find the perfect machine to suit your business needs. Happy wrapping!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide