Powder Granulator Machine: The Complete Buying Guide In 2025

Powder Granulator Machine: The Complete Buying Guide In 2025

Are you looking for an efficient way to produce granules from dry powder? If so, then a powder granulator machine may be just what you need. You’ll be able to quickly and easily create pellets out of your raw materials with minimal effort, reducing the amount of time spent in the production process and improving efficiency.

In this blog post, we will discuss why opting for a powder granulator is one of the smartest decisions when it comes to producing precisely ground powders along with its impressive range of advantages compared to other methods available. Read on if you want an insight into how this specialist equipment could potentially revolutionize your production line!

1.What Is A Powder Granulator Machine?

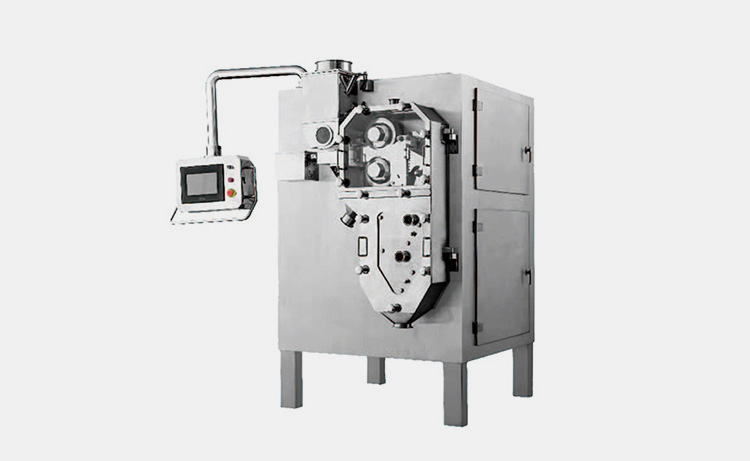

A powder granulator machine is a piece of equipment used to process powder into granules. It works by breaking up powder materials into smaller particles in order to form uniform-sized pellets or granules. The powder granulator machine can be used for various applications, from pharmaceuticals and agricultural products to food processing and more.

The powder granulator machine provides an efficient and cost-effective way to process powder materials into granules of uniform size and shape. This equipment is easy to operate, requires low maintenance, and produces consistent results.

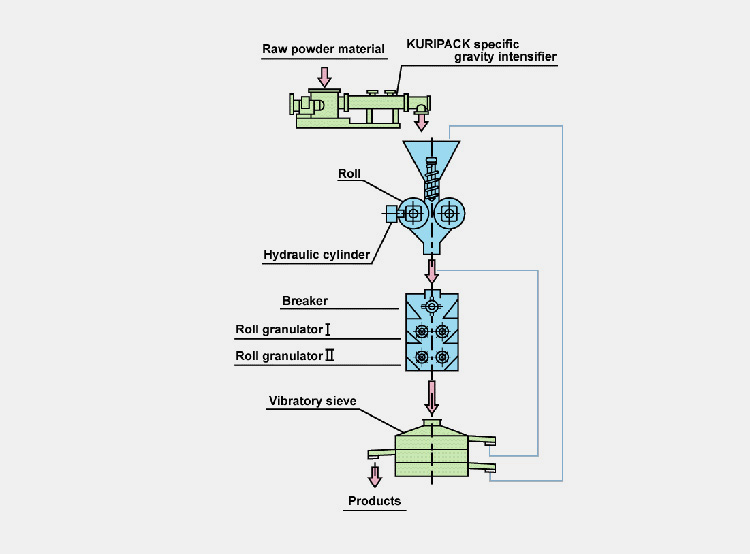

2.What Are The Components Of A Powder Granulator Machine?

Feed Hopper

The powder granulator machine typically includes a feed hopper which is used to load the powder material into the machine.

Roller

The powder granulator machine also includes a roller which compresses and forms powder particles into desired shapes, depending upon the size of the particles.

Cutter

A cutter is then used to cut the formed powder particles into smaller pieces for further processing or packaging.

Vibratory Sieve

After cutting, a vibratory sieve is usually included in powder granulator machines to separate out materials that are too large or too small for further processing.

Discharge Chute

A discharge chute is included at the end of a powder granulator machine to collect powder particles that have been cut and sieved.

Control Panel

The powder granulator machine also includes a control panel which can be used to adjust the speed, pressure, and other parameters of the machine in order to achieve desired results. This typically includes buttons or levers for controlling the various aspects of powder granulation.

Motor

Powder granulator machines include a motor which is responsible for driving all of its components and making them work together in order to produce powder particles according to the user’s specifications.

3.What Are The Advantages Of A Powder Granulator Machine?

Cost Savings

Powder granulator machines can reduce powder waste by up to 50%, which effectively cuts costs for powder production. This is because powder granulator machines are designed to process powder efficiently and evenly, ensuring the most accurate results.

Enhanced Quality Control

With powder granulator machines, it’s easier to control powder size and uniformity, ensuring a consistent quality of powder products. As powder granulator machines are designed with automation capabilities, they can accurately follow the production process according to certain settings that guarantee precision results.

Improved Efficiency

Powder granulator machines enable powder production processes to be carried out with faster speeds and higher accuracy, leading to improved production efficiency. This helps businesses save time and money, while still producing quality powder products in the most efficient way.

Uniformity and Consistency

Powder granulator machines are designed to increase powder consistency by evenly distributing ingredients, improving particle size distribution, and increasing powder flow ability. This helps to provide a more uniform powder throughout the entire production process.

Reduced Waste

Powder granulator machines are designed to reduce powder waste by evenly distributing ingredients, improving particle size distribution, and increasing powder flow ability. This helps to minimize powder losses during production.

4.How Can Powder Granulator Machines Be Used In Different Industries?

Powder granulator machines can be used in a variety of industries to improve powder handling and process efficiency. Here are some of the ways powder granulator machines can be used:

Pharmaceutical Industry

In the pharmaceutical industry, powder granulator machines are used to create powder-based formulations for tablets, capsules, and other medications. The powder is blended in the powder granulator machine and then compressed into tablets or capsules.

Food Industry

Powder granulator machines are widely used in the food industry for producing a variety of powder products such as seasonings, nutrition powder, energy drinks and coffee powder. These machines help ensure powder products have uniform particle size distribution and consistent flavor.

Chemical Industry

Powder granulator machines are used in the chemical industry for producing powder products such as detergent powder, fertilizer powder, additives powder and powder coating materials. These machines help reduce powder production costs by reducing powder waste.

Agriculture Industry

In agriculture, powder granulator machines are used for powder production of animal feed, powder fertilizer and powder pesticides. These machines help to improve powder handling efficiency, reduce powder waste and improve powder quality.

Cosmetics Manufacturing

Powder granulator machines are commonly used in cosmetics production to create powder-based cosmetics such as powder foundation, powder blush, powder eye shadow, and other powder-based makeup. This helps to create a consistent product with an even distribution of powder particles throughout the mixture.

5.How Does A Powder Granulator Machine Work?

The powder granulator machine works by using a combination of mechanical forces and heat to break down the powder particles into smaller, more uniform pellets or granules. This machine utilizes a die-roll system, which contains multiple rollers that shape the powder into uniform cylinders, discs or stripes.

Once the rollers shape the powder particles into the desired shape, they are forced through a die, which forms them into pellets of uniform size and shape. The powder granulator then cools the pellets and ejects them from the machine.

6.What Are The Different Types Of Powder Granulator Machines Available On The Market?

There are several types of powder granulator machines available on the market, each offering unique advantages for powder processing. The most common powder granulator machines include:

Roller Compaction Granulators

This type of powder granulator machines utilizes rollers to compact powder into granules. The powder is fed into the machine, where it is compressed by the rollers before being discharged as a finished product. This type of powder granulator can produce uniform-sized and high-density granules in an efficient manner.

Rotary Drum Powder Granulators

This type of powder granulator uses a rotating drum to mix solid and liquid components together with an agglomeration powder. The powder is then processed through a screen to create uniform particles. This type of powder granulator is commonly used for pharmaceutical applications and food industries, as well as in the production of fertilizers and agricultural chemicals.

7.What Is The Difference Between A Dry Powder Granulator Machine And A Wet Powder Granulator Machine?

a) Dry Powder Granulator Machine

b) Wet Powder Granulator Machine

A dry powder granulator machine is an industrial equipment used to convert dry powder into granules while a wet powder granulator machine is a tool commonly used in the pharmaceutical industry that helps to produce uniform, wet granules from wet powders.

Another difference between a dry powder granulator machine and a wet powder granulator machine is the way in which they process materials. A dry powder granulator utilizes mechanical force to compress powder particles into desired shapes and sizes, while a wet powder granulator uses liquid and heat to mix powder ingredients together before shaping them into pellets.

Also, dry powder granulator machines are often used for producing large or irregular sized particles, while wet powder granulators are generally better suited for smaller and more uniform particle sizes. Additionally, dry powder granulator machines are typically used for larger batch production runs, as they require less time to process materials than wet powder granulators.

When it comes to cost-effectiveness and efficiency, both types of powder granulator machines provide unique advantages for manufacturing powder products. Ultimately, the most suitable powder granulating method will depend on the individual requirements of the production process.

8.What Materials Can Be Used With A Powder Granulator Machine?

A powder granulator machine can be used to process a wide range of materials, including:

- Organic compounds such as herbal powder or plant extracts

- Inorganic chemicals like fertilizers, pesticides and other powder materials

- Pharmaceutical powder ingredients and excipients

- Food powders like milk powder, juice powder, powder snacks and flour

- Fibers and powder plastics for plastics manufacturing.

9.What Products Can Be Produced Using A Powder Granulator Machine?

Pellets

Powder granulators can be used to produce pellets out of powder-like materials such as chemicals, pharmaceuticals, food and feed additives, fertilizers, detergent powder, etc. By using the roller compaction method.

Granules

Powder granulator machines can also be used to produce granules from powder materials such as fertilizers, chemicals, pharmaceuticals and food additives by using the wet granulation method.

10.How Does Powder Size Affect Output From A Powder Granulator Machine?

The size of powder particles affects various aspects of the powder granulation process, including uniformity of mixing, particle size distribution and ultimately output rate.

When powder particles are larger, they tend to clump together more easily. This can decrease the efficiency of powder granulators since this clumping impedes powder mixing and affects the accuracy of particle size distribution. Additionally, large powder particles can lead to blockages in powder granulator machines which can reduce output rate.

In contrast, powder particles that are too small may not be evenly distributed within a powder granulator system. This reduces the effectiveness of the powder granulation process since powder particles are not evenly mixed. Additionally, powder particles that are too small may be difficult to handle and can cause powder granulator machines to become clogged and reduce output rate.

Therefore, the ideal powder particle size for powder granulators depends on the specific powder being used as well as the type of powder granulation process being employed. In general, powder particles between 250 and 1000 microns are recommended for powder granulators. This size range ensures that powder particles mix well, particle size distribution is even and output rate remains consistent.

11.How Does Powder Formulation Impact The Performance Of A Powder Granulator Machine?

The powder formulation used in powder granulator machines affects the performance of powder granulator machines. The powder formulation is a key factor that determines how well a powder granulator machine works, and it can determine the quality of end products produced by powder granulators.

Powder formulations come in a variety of types, such as crystalline powders, powder composites, and powder blends. The type of powder formulation used for a powder granulator machine determines the flow rate of powder through the granulator blades, as well as the size of powder granules produced by the powder granulator machine.

For example, crystalline powders are more likely to form larger granules than powder composite or powder blends. The powder formulation also affects the powder’s ability to be separated during powder granulation, which impacts the powder granulator machine’s efficiency and productivity.

The powder formulation must contain sufficient flow ability so that it can be separated from other powders in the powder granulator blades and form separate particles, which then can be further processed into granules. If the powder formulation does not have enough flow ability, then powder granulation will be inhibited and powder granulator machines won’t be able to achieve optimal performance.

Finally, powder formulations used in powder granulator machines should also contain enough binding agents so that powder particles are held together when they are compacted and shaped into pellets or granules. If the powder formulation does not contain enough binding agents, then powder granulation will be inefficient and powder granulator machines won’t be able to produce high-quality pellets or granules.

12.What Are The Maintenance Requirements For A Powder Granulator Machine?

Proper maintenance is essential to ensure a powder granulator machine operates at peak performance. Here are some tips for keeping your powder granulator machine in good working condition:

Lubrication

All powder granulator machines should be lubricated regularly according to the manufacturer’s instructions. This is essential to prevent wear and tear on the moving parts, as well as ensuring smooth operation of the machine.

Cleaning

The powder granulating machine should also be cleaned thoroughly on a regular basis in order to avoid contamination or clogging of powder particles. This can be done with a brush, vacuum cleaner, or by blowing out any powder particles from around the exterior and interior surfaces of the machine.

Inspection

All powder granulator machines should be inspected frequently for signs of damage, wear or corrosion. Any loose bolts or components should be tightened, and worn parts replaced if necessary. user-friendly and easy for operators to operate without needing extensive training or expertise.

13.How Can You Choose The Right Powder Granulator Machine For Your Application?

When it comes to powder granulation, having the right powder granulator machine can make all the difference in your process. It is important to consider a number of factors when selecting a powder granulator machine, including: throughput capacity, powder properties, and desired end product quality.

Throughput capacity is an important factor to consider when choosing a powder granulator machine. The machine should be able to handle the desired throughput rate of your powder and provide consistent results with minimal downtime.

Also, it is important to ensure that the powder granulator machine you choose is suited for the powder properties of your application, such as whether it is sticky or abrasive. Different powder properties require different powder granulation technologies, so it is important to make sure the powder granulator machine you choose can handle these properties.

Finally, the desired end product quality should also be taken into consideration when selecting a powder granulator machine. For example, if you are looking for a powder with high bulk density and consistent particle size distribution, then you may need a different powder granulator machine than if you are looking for a powder with high surface area.

Different powder granulation technologies can produce powders with different characteristics, so it is important to choose the right powder granulator machine for your specific application.

CONCLUSION

A powder granulator machine is an essential piece of equipment for many industries, as it can quickly and efficiently turn powders into pellets. This allows companies to achieve faster production rates with increased safety and reliability. Also, this machine offers an economical solution for bulk production needs and the desired physical properties and product quality. If you’re interested in learning more about powder granulator machine or would like to purchase one of your own, be sure to contact the experts over at Allpack for more information.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Powder Granulator Machine: The Complete Buying Guide In 2025 Read More »

LMUHP Powder Filling Machine

LMUHP Powder Filling Machine

Automatic Powder Filling Machine

Automatic Powder Filling Machine

A/3400 Powder Filling Machine

A/3400 Powder Filling Machine

B400 Powder Filling Machine

B400 Powder Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours