Milk Powder Packaging Machine: The Complete Buying Guide In 2025

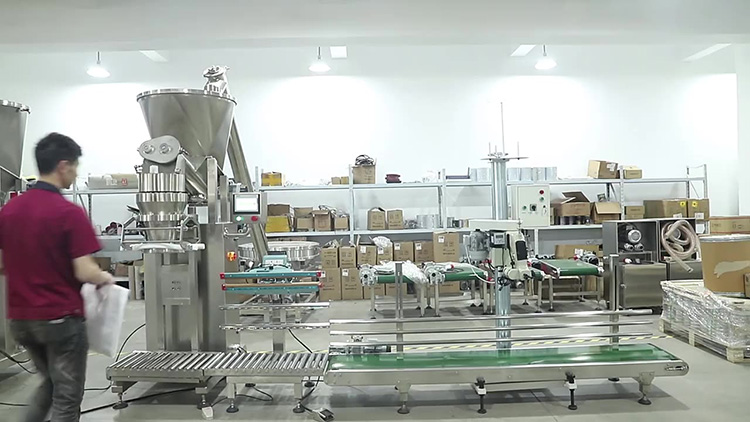

The global demand of milk powder packaging machines are steadily growing due to the increase in population and advancement in technology. Manufacturers of milk powder are also now heading towards modern techniques like milk powder packaging machine to increase their productivity and meet the global demand.

Allpack also provides solutions for milk powder packaging. We are providing you a detailed buying guide for proper understanding of what milk powder packaging machines are and how they can be useful in modern days. Go through the complete guide and take the most of it.

1. What Is Milk Powder Packaging Machines?

A milk powder packaging machine packs milk powder in various types of bags, cans, containers and bottles that are also of different sizes. This allows the milk to remain fresh and contamination free for a longer period. Powdered milk is filled in the packaging material and then sealed with high precision.

Some milk powder packaging machine also includes labeling systems that are used to generated identity of each package. Milk powder packaging machines are used in all small, medium and large scale food, pharmaceutical, agricultural and cosmetics industries.

2. What Types Of Milk Are Packed Using A Milk Powder Packaging Machine?

Some of the types of milk that are packaged using a milk powder packaging machine are

- Skim Milk

Skim powder milk is made up of skim milk and has less content of fat in it. The milk is more often used as a byproduct in low-fat foods, nutrients and protein powders.

- Whole Milk

Natural components of milk like protein, lactose and fats are present in whole milk powder and can easily be packed using a milk powder packaging machine. Whole milk can be using in pharmaceutical, food and child health care industry.

- Non-fat Dry Milk

This type of fat does not have any fat content and is removed with a highly efficient biological method. Non-fat dry milk powder can easily be packed using a milk powder packaging machine with high precision and product safety.

- Instant Milk

Specially formulated milk to be able to dissolve in water easily is instant type powder milk. Instant milk is used as a substitute in cocoa, cereals and tea products.

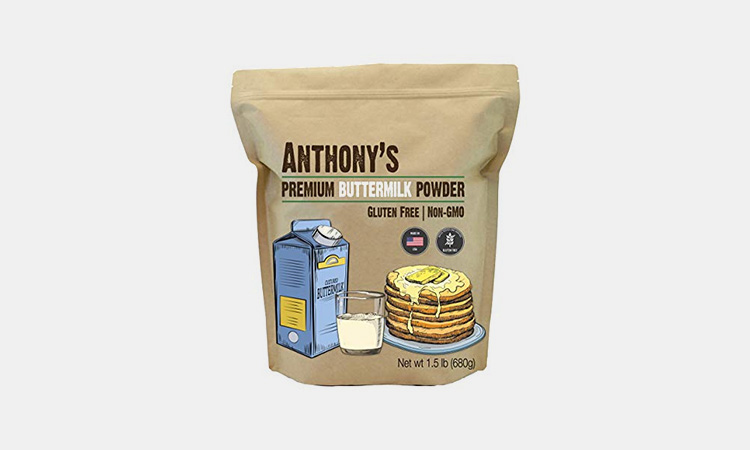

- Butter Milk

Butter milk is made up of butter milk and is prepared by the liquid that is left after churning of butter. Butter milk is used as an agent for flavoring baked goods and also in food processing industries.

3. What Are The Different Packaging Types Available For Milk Powder Packaging?

Some of the types of milk powder packaging are

- Canning

Canning is a process in which milk powder s are packaged in cans or containers that are made up of light or thick metal sheet. These cans are ideally used for milk powder packaging because it assure long lasting purity of milk powder as it directly blocks the entry of microbes. Areas where unavailability of fresh milk is present mostly use canned milk powder packaging as it maintains the nutritional value of prepared milk powder.

- Bagging

Bagging on the other hand refers to packaging of milk powder in bags, sachets or pouches mostly made up of plastic, paper and aluminum. Each of the bags protects milk powder from being contaminated and blocks entrance of atmospheric oxygen. The process of bagging fits different sizes of bags and is likely to preserve the quality and shelf life of milk powder.

- Sachets

Sachets are the most economical packaging option available for milk powder packaging. It contains milk powder ranging between 10g to 100g and is consumed easily by people. Sachets that are filled with milk e are mostly made up of plastic and aluminum.

- Stand up Bags

One of the types of bags is the stand up type milk powder packaged bags. These bags are designed in a way that they can be easily displayed in any shelf of a shop of retail business. Stand up bags for milk powder is made up of paper, aluminum and plastic.

- Stick Bags

Stick bags are made up of plastic has are filled with low volume milk powder. Mostly tea milk powder is packaged in stick bags.

- Pouches

Like bags, pouches are also made up of plastic and aluminum and paper and are packaged in highly efficient manner.

4. What Are The Applications Of A Milk Powder Packaging Machine?

Milk powder packaging machines are widely applied in industries for filling and packaging of different types of milk in an efficient, accurate and secure manner. Some of the industries that use milk powder packaging machines are

- Food Industry

Food industry is the one which uses milk powder packaging machines the most. Powdered milk is used as a byproduct of different foods, nutritional drinks, infant formulas, and beverage products.

Milk powder packaging machine ensures effective packaging of powdered milk products to ensure preservation of quality and freshness of milk. All condensed and powder milk can be packaged in food industry.

- Pharmaceutical Industry

Excipients are used along with active pharmaceutical ingredients (API) to prepare medicinal products. These excipients are packed using a milk powder packaging machine. Standards of packaging of pharmaceutical products can also be enhanced using a milk powder packaging machine.

- Cosmetic and Chemical Industry

Some of the non-food products used in chemical and cosmetic industries is also packaged using a milk powder packaging machine. Chemical products specifically sucrose and sodium benzoate that are extracted from milk in the form of powder are packaged in different sizes and shapes using a milk powder packaging machine.

- Agricultural Industry

Agricultural industry packages powdered milk for feeding of animals and livestock using a milk powder packaging machine.

5. What Are The Advantages YouCan Get From A Milk Powder Packaging Machine?

Following are the benefits that can be provided to a manufacturer by using milk powder packaging machine

- Packaging Accuracy

Milk powder packaging machines are highly automated that it provides highly precise and accurate packaging options. The milk powder is filled in a consistent form and remains same throughout the processing duration.

- Product Shelf Life

Packaging done by a milk powder packaging machine prohibits the entrance of microorganisms and bacteria which directly increases the life of milk powder. As milk remains direct concern to human health so its poor quality can cause severe reactions.

- Quality Controlling

The quality of milk powder remains for a longer period if it is packed using a milk powder packaging machine. The freshness of milk also lasts longer with keeping its chemical composition the same.

- Branding

Labeling and stamping machines associated with milk powder packaging machine provides highly attractive label on the product which benefits in its marketing. The customer can also be attracted towards the brand through this technique.

Following benefits are from the machine itself, including

- Adjustable Filling

The most important feature that a milk powder packaging machine offers is that the filling volume of milk powder is adjusted according to the size of bag or containers. The machine has a capability to suit the requirements of specific packaging.

- Accurate Filling

Milk powder is dispensed to an accurate level in each package and ensures consistent packaging using a milk powder packaging machine. The weight of each bag remains the same with high quality parameters.

- Variety of Bag Sizes

A single milk powder packaging machine allows packaging of powdered milk in multiple type and sizes of bags that makes it stand out.

- Flushing System

Some of the milk powder packaging machine include flushing systems in there structures to release inert gases like nitrogen. These gases are then useful to increase products life and maintain its quality.

6. What Is The Working Principle Of Milk Powder Packaging Machine?

A milk powder packaging machine operates with a simple working principle. The steps involved in its operation are

- Initially the feeder or hopper present at the top of milk powder packaging machine is filled with the prepared milk powder.

- The containers or bags are placed at the opening of conveyor and are then fed into the system.

- As the material reached the filling nozzle, the pre-determined quantity of milk powder is filled in the desired bags or containers by volumetric, auger and multi-head mechanism.

- After filling of milk powder, the containers are then sealed in a way that it prevents any type of leakage or contamination.

- Once the sealing of material is completed, the containers are taken out of the system either manually or by automatic conveying system.

7. What Are The Main Components Of A Milk Powder Packaging Machine?

Main components of a milk powder packaging machine that are necessary to perform proper operations are

- Hopper

Big, round containers known as hoppers or feeders are present at the top of milk powder packaging machines that are used to fill powdered milk in bulk quantity.

- Filling System

The powdered milk material is travels through this filling system when it leaves the hopper. The filling system of a milk powder packaging machine uses variety of techniques like gravity, volumetric or auger filling. The material is then filled into bags or containers.

- Filling Nozzle

This is the part underneath which the filling bags or containers are placed and then the powdered milk leaves the system through it.

- Sealing System

The bags or containers that are filled with milk powder are then sealed using heat, mechanical or ultrasonic sealing

- Powder Weighing System

To ensure proper and accurate filling weight of milk powder, some of the milk powder packaging machines have this weighing system incorporated in their structure.

- Pneumatic System

Milk powder packaging machines use pneumatic system for filling, sealing and pressing purpose.

- Conveyors

Conveyors are present at the opening and closing ends of a milk powder packaging machine for automated and smooth travelling of containers.

8. What Types Of Milk Powder Packaging Machines Are There?

Types of milk powder packaging machines depend upon the production requirement and its application. Some of the types of milk powder packaging machines that are commonly used are

Milk Powder Packaging Machine Type

- Semi-Automatic Milk Powder Packaging Machine

A semi-automatic milk powder packaging machine involves both manual and automatic processes and can be use for filling more than 50 milk bags per minute. The operator fills the hopper with milk powder and completes the operation himself. The sealing and accurate filling is performed by the machine but that also depends on the performance of operator.

- Fully Automatic Milk Powder Packaging Machine

A fully automatic milk powder packaging machine provides high quality, quick and efficient milk powder packaging. These machines are preferred for high production volume industries where more than 100 bags are to be filled and sealed in a minute.

Fully automatic milk powder packaging machine has complete automated setup beginning from filling to sealing. All the tasks are performed by the machine itself. Labor involvement is almost reduced to zero in an automatic milk powder packaging machine.

- Vertical Milk Powder Packaging Machine

Vertical type milk powder packaging machines are operated in a vertical orientation. The packages are moved into the system and the filled milk powder falls from top down. Efficient floor are and precise packaging of milk powders is typically included in a vertical milk powder packaging machine.

- Horizontal Milk Powder Packaging Machine

Similarly the horizontal type milk powder packaging machines are orientated in horizontal direction. The design allows the operator to completely interface with the packaging and remain alert. The machine includes all the components but horizontally aligned.

Milk Powder Filling Machine Type

Filling machines for milk powder packaging machine can be either auger filling, gravity filling or volumetric filling. The purpose of these types of machines is

- Auger Milk Powder Filling Machine

Augers or screws are present in this type of milk powder packaging machine to dispense the powdered milk into the bag or container. For packaging of fine milk powders, auger filling machines are preferred the most.

- Volumetric Milk Powder Filling Machine

Volumetric filling machines have measuring cups which assure proper volume filling of milk powder in bags or containers. Industries those have large scale production setups or packaging of milk powder in different sized buckets prefers volumetric filling machines for their operation.

Milk Powder Filling Machine According To Packaging Type

Some of the milk powder machines also follow the same principle as automatic milk powder packaging one. The difference lies in the type of packaging they perform. Either the machines is filling milk powder in strips, sachets or bags, it completely depends on the requirement of the manufacturer. Some of the milk powder machines according to their packaging type are

- Strips Milk Powder Filling Machine

Strips milk powder filling machines one of the types of automatic milk powder packaging machine that fills powdered milk into same pre-made plastic strips. These strips are of small sizes and do not contain more that 50g of milk powder.

An accurate weighing system is associated with the machine that dispenses required amount of milk powder into each strip and then are sealed from the top. All types of food and pharmaceutical industry use strips milk powder filling machine.

- Bag Milk Powder Filling Machine

Bag milk powder filling machines also fills milk powder into pre-made plastic bags in a highly efficient manner. Machines are designed in a way that accurate amount of milk powder is dispensed into each of the bag and then they are sealed by zip or sealing.

Bag milk powder filling is an efficient and most importantly a cost-effective packaging solution for milk powder packaging. Auger Fillers and volumetric fillers are mostly compared with bag milk powder filling machines.

- Sachet Milk Powder Filling Machine

Sachets are filled with milk powder using a sachet milk powder filling machines. An accurately measured milk powder is dispensed into each of the sachets and packaged in a way that it attracts customers mind. Different design of sachets milk powder filling machines are available depending upon the size, capacities and weigh of sachets produced in any production line.

9. What Are The Differences Between Infant Milk Powder Filling Requirements With Ordinary Powder Filling Requirements?

Some of the differences between infant milk and ordinary powder filling requirements are

Controlling Contamination

Clear measures in regard of cross contamination and controlling of contaminants are to be taken by the industries that are packaging infant milk powder.

Substances that lie in ordinary powder category may sometimes not be packaged under such scenarios. Environmental conditions can be neglected in ordinary powder filling.

Packaging Material

Infant milk powder filling requires high level of sensitiveness as infants are much sensitive towards their feeding. Contaminated milk powder filling can cause severe health conditions to the infant.

Ordinary powder filling can be packaged in any type of material depending upon their environmental conditions.

Sterilization

Packaging lines of infant milk powder must be clear fully sterilized to eliminate environmental, bacterial and microbial presence.

Likewise, no particular sterilization is not after every batch in an ordinary powder packaging.

Hygienic Packaging

Higher level of hygiene should be ensured for pure and safe packaging of infant milk powder packaging.

Ordinary powder can be packaged in any type of environment despite that no environmental effect can change the quality of material.

10. What Are The Auxiliary Components That Are Associated With A Milk Powder Packaging Machine?

Some auxiliary units are used for providing assistance to machines operation. Some of the auxiliary components that are associated milk powder packaging machine to make sure it functions properly are

- Weighing Scales

To deliver accurate weight of milk powder, mostly semi-automatic milk powder machine have weighing scales from which the operator justifies accurate filling. While in an automatic milk powder packaging machine, the filling nozzle only releases specific amount of milk powder in an efficient manner.

- Data Coder

To give separate identity to each of the packaging material, milk powder packaging machines use data coder as an auxiliary component. This coder allows the printing of expiration and production date, batch in which the milk powder is filled, manufacturing details and other product related information.

- Sealer

Once the milk powder is filled in the container of bag it is then taken to the sealer to perform seal on it. Different types of milk powder packaging machines use different types of sealer like ultrasonic, heat or radio sealers.

- Compressed Air

Some milk powder packaging machines have air compressor in it which support in proper transportation of packaging material and also plays an important role while filling process.

11. What Common Factors Should Be Considered Before Purchasing A Milk Powder Packaging Machine?

Some of the factors that should be considered before purchasing a milk powder packaging machine are

Manufactures Production Requirement

Production requirement always remains a prior thing before selecting a machine because a machine that does not package the required number of volume can be a huge disaster for the buyer.

Compatibility with Different Sized Packaging

It is always necessary to select the best type of machine that is compatible to accommodate all types of packaging options. Size, shape, type of closure and type of material should be kept in consideration while buying a milk powder packaging machine.

Suitability to Milk Powder

Different types of milk powder are now available; each one has different particle size, flow rate, powder characteristics and moisture content. All these characteristics of milk powder should be considered before buying a milk powder packaging machine.

Conclusion

Buyers of milk powder packaging machines are increasing in numbers due to increase in global demand of milk powder products. Keeping this factor under consideration, we Allpack also provide variety of options related to milk powder packaging machines. If you are interested in purchasing these machines, our customer support facility is available 24/7 or visit our website http://www.allpackchina.com/ for further details.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide