Cereal Packaging: The Complete FAQ Guide In 2025

Cereal Packaging: The Complete FAQ Guide In 2025

Thinking of cereal packaging can take us to nostalgia for breakfast table!

Apart from cereal, the packaging has significant role beyond enclosing the product. With the help of excellent graphics and informative illustrations, the cereal packaging has improved productivity of anyone’s business in the term of boosting marketing and your brand’s identity. Did you know that cereal packaging is a key to opening the horizon of success, preserving, and attaining flavors of food products in the most convenient way. If you’re a manufacturing company employee or planning to start your own business then this article will bring you amazing information to widen your knowledge about cereal packaging.

1.What is Cereal? What Products are Designated as Cereals?

Healthy Cereal- Picture courtesy: Healthy food guide

Before jumping to the topic, take a brief view on what exactly cereal are? The term cereal is a nutritional food that are grown across the globe including rye, barley, maize, rice, corns, and so on. In fact half of the world’s population relies on cereal crops as the most significant source of eating.

Beside from its nutritional benefits, they come to you in finished form by milling and other processes such as milling, sifting, grinding, baking, and packaging.

Cereal derived from Milling: Wheat, rye, corn, rice, barley, oat, corn grits, etc.

Cereal Derived Products: pasta, crackers, cakes, pastries, chips, spaghetti, corn flakes, etc.,

2.What is cereal packaging?

A cereal Packaging

Cereal packaging is the packing of products in a moisture balancing act as well as most it provides barrier properties to the product against unwanted factors such as, light, gases i.e. oxygen, to present a nutritional product. This is achieved by using various packaging materials such as aluminum, plastic, paper, and others.

Always remember, a right cereal packaging is helpful in retaining originality of the product till end -user. That’s why packaging industry uses advance machines and multi-layer materials offering superior barrier and dead folds with notable protection.

3.What are the Functions of Cereal Packaging?

Now matter how diverse individual food products is, it conceptual and right packaging is well-agreed parameter that one must not ignored. There are various suitable functions that cereal packaging offers to their customers. E.g.,

Containment

Super containment cereal packaging

Well, this is the most important property that is commonly overlooked. The cereal packaging is the significant way that protects the cereal nutritional values, prevent them from loss and against progressing microbial growth.

Protection

Cereal packaging offer nutritional burst

Cereal packaging is offering protection to manufacturer as well as end user. It limits intrinsic as well as extrinsic factors to interact with cereals hence negative impacts cannot harm the products. Similarly, customers obtain final products with 100% safe with adequate nutritional values.

Convenience

A cereal packaging offers user-convenience- Picture courtesy: Delicious

Nevertheless, cereal packaging offers convenience to end-user in a practical aspect. for instance, you can unseal the product and microwave the food and have it. Similarly, easy to open, resealing, or naming the remaining portion with date and so on. Such functional features of cereal packaging is implemented in packaging designs to approach people such as elder, people with busy lifestyle, children etc.,

Tamper Evident

Cereal packaging offers original product- picture courtesy: livestrong

The most important function of cereal packaging is tampering evident property. With cereal packaging, manufacturer can claim that product is marketed in the original form. In case of any damage or product unsealing, retailer as well as user can identify the tampering.

Transportation

Cereal packaging offers easy transportation- picture courtesy: the newyorktimes

The cereal packaging offers manufacturer with ease to transport and distribute the product across the globe despite of worrying for harm or product loss. Therefore, it is of upmost important that cereal packaging is beneficial to achieve fresher and preserved food no matter how long to export them.

Communication

A cereal packaging with Better Illustration and communication

Last but not least, manufacture can send message and mention information about ingredients, or marketing communications via displaying on the packaging. For e.g., identifying logo, recipe, barcodes, ingredients, name of the products etc.,

4.What type of cereal packaging is common?

Innovative packaging is preferred by customers, both young and adult alike. Therefore, brands try to introduce different formats of cereal packaging in the market. These formats vary in their designs, shape, graphics, finish, and materials.

A detail of different cereal packaging types is penned below that you might find helpful.

Types Based on Packaging Style

Box

It is manufactured using thick cardboard or paper board material and typically comes in rectangular or square shape. There are two popular box styles for cereal packaging.

| Rectangular Box

It is typically designed in a rectangular shape and is the oldest packaging style for cereals. It is one of the most widely used packaging formats. This style offers a large display for graphics and branding. A thin sheet of plastic or paper is also present inside these boxes to reduce fat permeability. |

Regular Cereal Box- Picture Courtesy: H-E-B |

| Milk Carton Box

It is a rectangular shape with more height than width. This format has two different styles: a gable top and a tetra Pak. In the gable top design, the top portion is triangular for ease of pouring. Tetra Pak design is octagonal. This milk carton box for cereals is made of a combination of plastic, paper, and aluminum. |

Milk Carton Cereal Box-Picture Courtesy: David Taylor |

Pouch

This packaging style has been gaining popularity over the recent years due to its ease of use and its resealing.

| Flat Pouch

It is a simpler cereal packaging pouch style. Sometimes, this pouch is designed with a tear-away seal for convenience. A flat pouch for cereal packaging usually lies flat and is usually fabricated for single-serving cereals. |

Flat pouch cereal packaging- Picture Courtesy: Ken’z Kitchen |

| Stand-up Pouch

It is the most common pouch design for cereal packaging. It has a flat bottom that allows this pouch to stand upright on the retail shelves. This feature makes it perfect for display purposes. It also incorporates resealing options like Velcro tapes, sliders, etc. |

Standup pouch cereal packaging- Picture Courtesy: Cereal Number |

| Pillow Pouch

It is a flat lay type of cereal pouch packaging and is usually seal at two or three sides. It is suitable for packaging cereal bars. Once this pouch is filled with bar it resembles like a pillow with inflated center and flat edges. |

Pillow pouch cereal packaging- Picture Courtesy: Global Industrial |

| Qual Seal Pouch

It has four seams having gussets that allow the packaging of substantial cereals quantities due to its extra space. It resembles like a rectangle once filled with cereals. It has extra strength and is quite stable, therefore providing better display. |

Qual Seal Pouch- Picture Courtesy: Velteko |

| Flat Bottom Pouch

As the name suggest, this pouch type has a flat bottom, offering a better standing position to pouch. This pouch also comes with four folding gussets that expand on cereal loading. Due to its elegant and sophisticated appearance, flat bottom pouch is routinely used for premium and classy cereal packaging. |

Flat bottom pouch- Picture Courtesy: Pioneering Pack |

Cup

Cup Cereal Packaging- Picture Courtesy: Troopster.com

As the name indicates, it is a tub or bowl-shaped container, perfect for storing premixed cereals. It offers convenience and has a ready-made breakfast option while on the go. It usually contains single-serving cereals. Moreover, it is manufactured using high-barrier materials that uphold the nutritional quality of cereals.

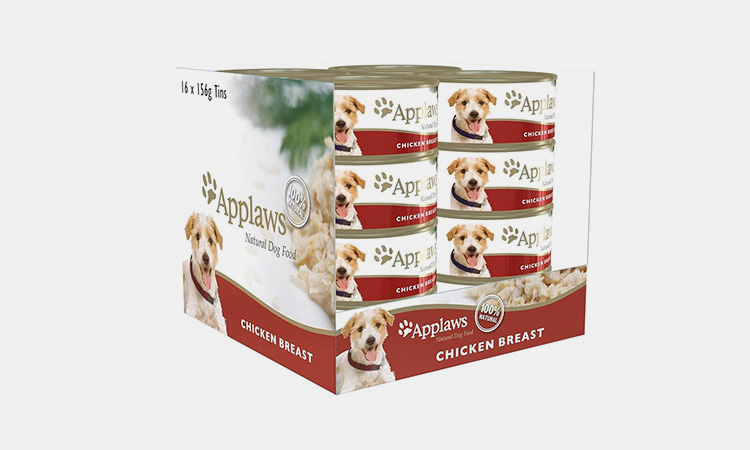

Cartons

Carton Cereal Packaging

It acts as a secondary packaging for cereals. A carton can hold a large number of cereal pouches or boxes for shipment and storage purposes. It is made with sturdy cardboard panels and provides additional support to cereal packaging during rough shipping conditions.

Types Based on Packaging Materials

An ideal material for cereal packaging is a tough barrier that provides total protection in all environmental settings. The types of cereal packaging depending upon manufacturing materials are detailed below:

Paper

Paper Pouch Picture Courtesy: Food Packaging

It is a sustainable and light material often employed in manufacturing kraft, coated, and offset cereal packaging. Food-grade paper is suitable for making cereal pouches and also serves as a liner in the cereal box. It has a smooth as well as embossed texture and has excellent printed-upon capability so there is no need for labeling with paper.

Aluminum

Aluminum Cereal Packaging- Picture Courtesy: Packaging Bag Manufacturer

It is used for engineering aluminum foil pouches as well as lids of the cups. Aluminum offers several advantages due to its tough barrier and heat-resistant features. Moreover, it is a flexible material with puncture and tear resistance. Also, it has 100% recyclability and is infinitely reused which lowers its environmental load.

Plastic

Plastic Cereal Packaging- Picture Courtesy: BEAPAK PACKAGING

With packaging evolution, plastic has become a preferred alternative for brands due to its flexible pouch cereal packaging. It is available at a fair price and thus is an attractive option for brands trying to optimize their expenses. Due to its malleability and ductility, plastics are readily used in packaging. Due to its ease in molding, it can be customized into any shape and size.

Cardboard

Cardboard Cereal Packaging- Picture Courtesy: Packaging Strategies

It is an ideal choice for cereal packaging as it is easily purchased and recycled without any difficulty. It is mostly used for creating box cereal packaging. It is a robust substance and can handle heavier cereal quantities. Moreover, its plain surface allows for vibrant printing.

5.What are cereal packaging machines?

As cereals have diverse kinds of packaging for accommodating distinct types, different makes and models of cereal packaging machines are available. These instruments have diverse working principles.

Some important cereal packaging machines are discussed below for your learning.

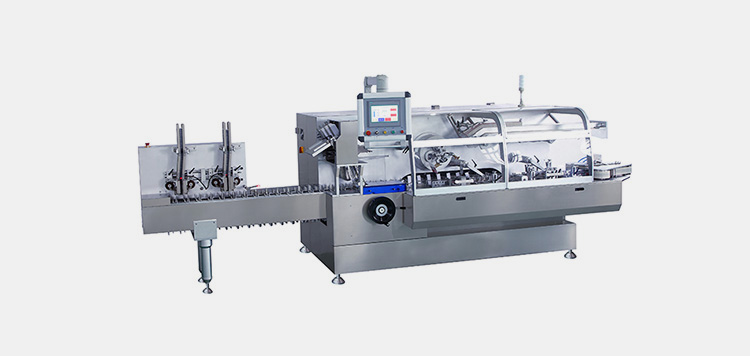

Box or Carton Packaging Machine

Box or Carton Packaging Machine- Picture Courtesy: SED Pharma

This is also known as a bag-in-box machine and it packs different pouches inside the box or cartons. This instrument is the first choice of manufacturer for boxed cereal packaging. It also packs cereals directly inside the boxes that are lined with plastic or paper liners. Top load and End load cartoners are used in cereal packaging.

Working Principle

First cardboard is placed in the bag magazine from where the grippers pick the cardboard, one piece at a time. Via gripper, it is transported to the folding and gluing area. At this station, the left and right edges of the carton are folded while the glue application applies adhesives at the bottom and sides of the carton to firmly close it. Then, this folded carton is covered with a liner, and cereal flakes are introduced inside the lined box. Finally, after a precise filling top seam is sealed using glue.

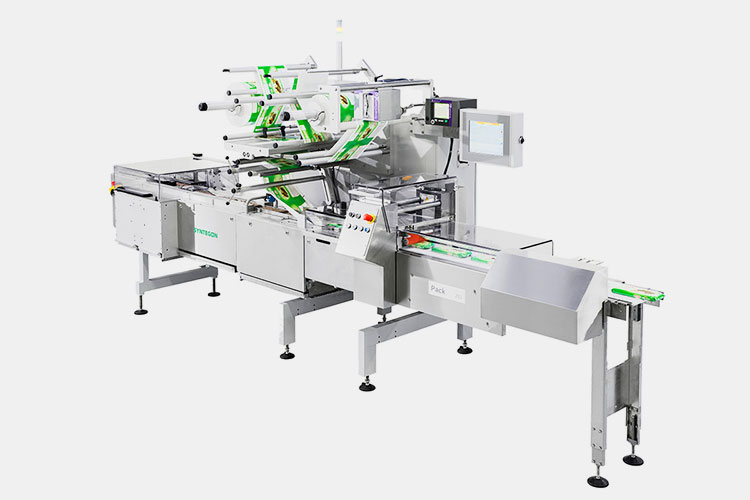

Flow Wrapping Machine

Flow Wrapping Machine- Picture Courtesy: Allma.net

For packaging individual granola bars or cereal biscuits, a flow wrapping machine is employed. This machine can handle large quantities of consumer goods and aids in the protection and safety of products. It encloses and tightly seals cereal bars with plastic, laminate, or aluminum film. Flow wrapping machine employs heating bars for firmly sealing cereals on both ends so that finished products look like a wrapped gift.

Working Principle

It adopts a very simple working principle which begins with the loading of items on the conveyors. In the forming station, the product is put at the center of the packaging film. Then, the film is folded around the bars in a tube-like shape. First, this tube-like structure is longitudinally sealed either as a fin seal or as a lap seal. Next, packed products are moved to the cutting unit that seals as well as cuts the wrapped pouches simultaneously.

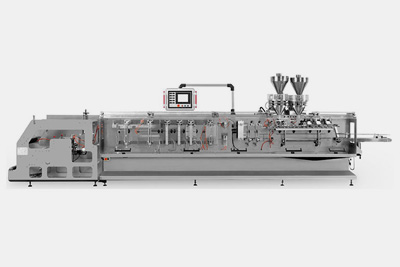

Horizontal Form and Seal (HFFS) Machine

Horizontal Form Fill and Seal Machine- Picture Courtesy: Weighpack

It is ideal for filling cereal bars or cakes inside pillow pouches. This equipment uses a film roll for forming tailor-made pouches. The packaging operation occurs in the horizontal direction so this machine is mostly employed for filling heavier items that could break if packed vertically.

Working Principle

Unwinding of the film takes place with the help of an unwinder. The dancer's arms and rollers keep the film under tension. The forming tube transforms films into pouches by folding and wrapping. The packaging item that is moving on the conveyors, is then loaded inside the pouches. Subsequently upon product loading, a pair of horizontal sealers seals the pouch edges together by firmly pressing them.

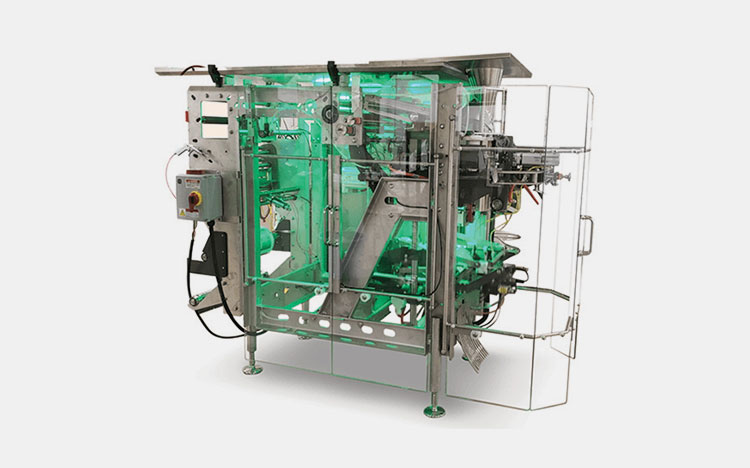

Vertical Form and Seal (VFFS) Machine

Vertical Form Fill and Seal Machine -Picture Courtesy: Propac Industrial

This machine accurately and precisely packs different varieties of cereals inside vibrant and elegant plastic or aluminum foil films. In packaging operation, the forming of pouches, and bagging of products occurs in a vertical direction hence this machine typically uses gravity for packing cereals. Due to gravitational force, cereal products freely fall inside partially formed pouches.

Working Principle

For unwinding of film roll, the unwinding disks rotate. This film goes to the forming tube present at the top of the machine. This component fashions film into a tube-like pouch by the action of vertical sealing bars that join the side and bottom seams of the pouch. Packing of cereal occurs by the fillers located at the top. Immediately after filling, the horizontal sealing bars seal the top edge of the pouches then cutting knives disjoin the two pouches from each other.

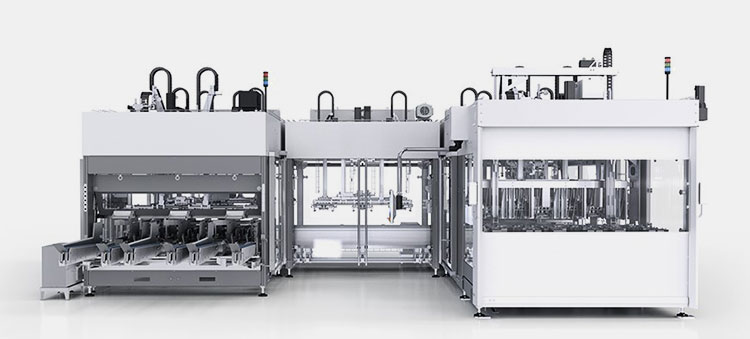

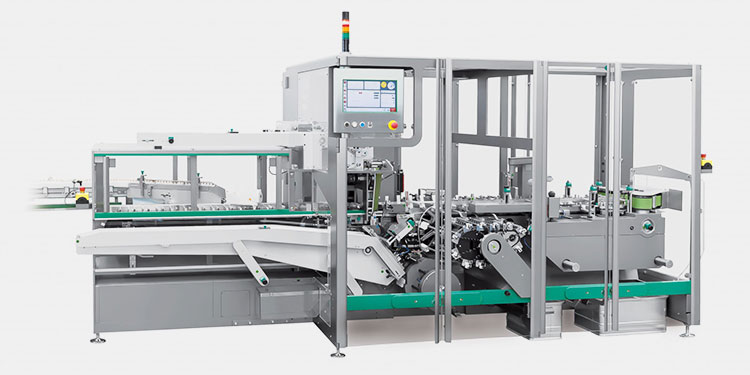

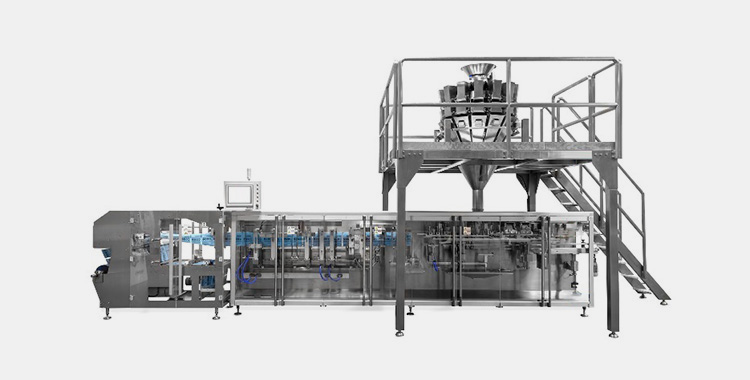

Premade Pouch Packaging Machine

Premade Pouch Packaging Machine- Picture Courtesy: LENIS MACHINE INC.

This machine packs cereals in already fabricated pouches. It is ideal when businesses process multiple pouch formats and styles. The premade pouch packaging machine is equipped with PLC systems, electronic and photo sensors, and weight measuring systems that ensure precision in every batch.

Working Principle

First, the pack of empty pouches is placed inside the bag magazine area and the bulk quantity of cereal products is filled inside hoppers. The empty pouch is grabbed by a gripper that takes the former to the inflation area. In this area, pairs of jaws open a pouch while air is blown inside for its inflation. In the next step, filling systems load the exact quantity of cereals inside the pouch, and it is sealed using heat sealers.

Cup Filling Machine

Cup Filling Machine- Picture Courtesy: Biaozan

This machine is constructed according to food packaging industrial standards and has a high processivity. It is also offered with cup disinfection systems such as UV, H2O2, etc. This machine fills viscous premixed into preformed cups. Moreover, it is equipped with intelligent dosing systems that ensure accurate fill and decrease cereal wastage.

Working Principle

The preformed cups are placed on the conveyor or in the cup infeed system from where they go one by one to the disinfecting area. UV light, pulsed light, or chemicals are used for sterilizing cups before dosing cereal. Next, the cups are transported to the dosing area where a precise number of premixed cereals are loaded inside the cups. Upon dosing, precut aluminum foil is put over the opening of cups and then heat is applied for their hermetic sealing.

6.How are cereal packaging bags sealed?

Cereal Packaging Bags

Packaging of the cereal bags must be carefully carried out to ensure food safety and hygiene. For this purpose, cereals are packed usually inside two layers of protective packaging ; one of them is a cardboard box and other is plastic bag.

The surrounding of the cereal packaging is glued using a FDA approved hot melt adhesive, which is necessary as it is considered an indirect food additive. Once the cereal is filled inside the plastic bag it is sealed using heat, adhesive glue or in a zipper seal. The sides of the bag are folded and tucked inwards using heat or adhesive sealing method. Once the plastic bag has been closed, the sealing of cereal box is further processed which is applied with hot molten glue but that is comparatively less adhesive than that applied to the bag so that it is easily openable by consumers.

7.Why doesn’t cereal packaging use zip-lock bags?

Although it might seem that packaging of cereal in a ziplock bag would be an ideal factor in preserving the freshness of the cereal, however it is not exactly true. Some brands still prefer to package their cereals in a zip tight plastic bag to deliver crisp quality of their product and also allow resealable and refillable option. However, mostly cereal packaging doesn’t come with the ziplock feature because:

- People prefer sustainable options while resealable zip lock bags clearly doesn’t offer this. Unlike plastic and glass, ziplock bags are not environment friendly and pose a threat that chemicals from it might penetrate inside the cereal.

- Such bags cannot be used for microwave purposes as they’re heat liable.

- Zipper seal bags are comparatively more expensive than applying adhesive sealing from manufacturers point of view. They wouldn’t surely prefer a costlier packaging option for this.

- It has also been found by customer reviews that ziplock oftentimes traps some grains or particles of the cereal within it or cause a problem in shutting close properly.

8.Paper or Plastic- Which is better for cereal packaging?

Cereal Packaging

Talking in terms of both maintaining crispiness and hygiene, and as an environmental safety concern paper is acceptable as a better option for cereal packaging. Typically cardboard boxes made up of kraft paper or bags made up of kraft paper are chosen.

Many multinational cereal brands are trying to replace or have entirely shifted from using plastic packaging material with using paper bags. Using paper liners for sealing of their cereal packaging has ensured freshness as well as proven to be easily recyclable.

However plastic bags made up of high density polyethylene , lined with polypropylene or other polymers are used to provide barrier against moisture and oxygen as the requirements for breakfast cereal quality needs to preserve it’s taste, crispiness and nutritional value. Additionally as a secondary packaging material, cardboard boxes are used. This has been the widely used form of packaging cereals until the revolutionary efforts of various brands came up to replace plastic overall.

9.Can you vacuum-seal cereal packaging?

Vacuum-Seal Cereal Packaging Picture Courtesy: Logos Packaging

Yes, there has been a modus operandi followed by all cereal packaging manufacturers that they prefer vacuum cereal packaging.

Well, the reason is that brands take special care while packaging cereals using vacuum sealing. The latter is a product of ingredients containing substantial amounts of fats. If these molecules are exposed to oxygenated air, then oxygen will react with fats leading to their rancidity. Moreover, oxygen in the cereal packaging promotes the growth of microorganisms like bacteria and fungi.

Rancid cereals have an unpleasant bitter taste and aroma that put off cereals lovers from eating, resulting in dissatisfied customers and products recalls. To avoid this problem, manufacturers use innovative equipment containing vacuum chambers. This chamber introduces a vacuum inside the filled package that causes the elimination of oxygen and water vapors from this filled package, consequently inhibiting growth of microbes and preventing rancidity. This process is called a vacuum-seal packaging. This 100% effective process is responsible for the chemical composition, structural integrity of cereals, and savouriness of cereal flakes and bars.

10.How long a cereal packaging last?

Shelf Life of Cereal Packaging Picture Courtesy: Logos Packaging

Before placing cereals in your grocery cart, first, check the best-before date present on the back of the cereal packaging. Cereals in packaging have an expiry date meaning that if these products are consumed before the said date then cereals lovers will make the best use of nutrition from cereals.

Cereal packaging is a way to protect the crispiness and crunchiness of cereals. As long as cereal packaging does not experience any physical damage, your packed cereals last till the expiry date.

An unopened cereal packaging placed in your pantry is good for 6-12 months but if you opened your cereal bags, then it is ideal to consume cereals within 3-6 months. If you want to increase the shelf-life by 2-3 months of cereals, then store packaging in the freezer.

11.What Plastic should be avoided in cereal packaging?

Plastics in Cereal Packaging- Picture Courtesy: Kiss my Keto

Due to their flexibility and customization, brands are now switching to plastics for manufacturing their cereal packaging. Nevertheless, according to food safety guidelines and recommendations, food-grade plastics should be used for manufacturing cereal packaging because they do not any risk to humans as well as the environment. Some types of plastics are a big no-no for cereal packaging such as:

- BPA

- PVC

- PS

- Non-food grade plastics

These plastics should not come in direct contact with foods because they often emit harmful chemicals such as chlorine gas on heating which can leach into food from cereal packaging making cereals inadequate for ingestion. These chemicals are also released into the environment that could go into freshwater systems or soils, consequently affecting wildlife and degrading the ecosystem.

Moreover, the chemical structure of these plastics is associated with infertility, and endocrine system disruption, such as deficiency in testosterone as well as cardiac diseases.

Conclusion

In conclusion, it is worth emphasizing that a success of any business doesn’t not only require an effective product but also it needs an interactive and perfect cereal packaging that is indeed a clever way to grab the attention of customers. By ignoring right cereal packaging can possibly results in weak product’s marketing and profitability. If you are confused in starting up the right cereal packaging, then do not worry! Allpack is right here to offer the best consultation and amazing cereal packaging line in an effective way. Message us now to avail free guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Cereal Packaging: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours