Top Gummy Manufacturers: The Complete Guide In August 2025

Top Gummy Manufacturers: The Complete Guide In August 2025

As the gummy became so popular, there are more and more gummies and gummy candy which come in all shapes, sizes, and delicious flavors. Are you looking for the best gummy brands and manufacturers? What companies are you finding on the list of best gummy brands and manufacturers?

Who is the NO.1 that makes many of the most popular gummy treats in the world? Following the top gummy manufacturers list below, you will get the definitive list of the best gummy manufacturers that would suit your needs. Let us take a look now!

| RANK | TOP GUMMY MANUFACTURERS | LOCATION |

| 1 | HARIBO | Germany |

| 2 | Life Savers | USA |

| 3 | L'il Critters | USA |

| 4 | VitaFusion | USA |

| 5 | Welch's Fruit Snacks | USA |

| 6 | Albanese | USA |

| 7 | Black Forest | Germany |

| 8 | SmartyPants | USA |

| 9 | Jelly Belly | Germany |

| 10 | Trolli | USA |

| 11 | Goli | USA |

| 12 | Boston Fruit Slices | USA |

| 13 | eFrutti | Germany |

| 14 | Startburst | USA |

| 15 | Smart Sweets | Canada |

| 16 | Herbert's Best | Germany |

| 17 | Zahlers | USA |

| 18 | Natrol | USA |

| 19 | Yum Earth | USA |

| 20 | Olly | USA |

1.HARIBO

Company Background:

HARIBO is a German candy company that makes over 1,000 products worldwide, including gummies, jelly sweets, candy bears. It is famous for inventing the gummy bear in 1922, and their flagship product is still produced today for your consuming.

The company created the first gummy candy in 1922. Their gummy fruit candies are now available in more than 120 countries, including Austria, Belgium, Germany, Denmark, Spain, France, Great Britain.

Key Products

- Haribo Gold Bears Gummi Candy

- HARIBO Gummi Candy Twin Snakes

- Haribo Gummi Candy Sweet & Sour Hearts

Recommend Reason

- Haribo has been making the gummiesand jelly sweet since 1920.

- Their best gummy candiesare renowned for their mouthwatering flavor combinations.

- All their gummy products use natural flavors and high-quality ingredients.

- The company has successfully cultivated a dedicated following of customers who consistently choose their gummy candies

2.Life Savers

Company Background:

Life Savers is one of the top gummy brands producing and offering fruit-flavored gummy bear candies around for over 100 years. It is a famous brand of ring-shaped hard, soft candy and gummy rings. Life Savers gummy candy is created for those who can't decide on just one flavor.

The bear candy they made can offer you a great fun with your favorite in the ring shape. All the ingredients and nutritional information provided by manufacturer and considered accurate at time of posting.

Key Products

- Life Savers Wild Berries

- Life Savers Exotics Gummy Candy

- Life Savers Gummies Collisions Assorted Flavors

Recommend Reason

- After more than 100 years, Life Savers remains one of the leading candy brands in Americaby offering you the best gummies.

- Their gummy foods come in classic and new fruit and mint flavors.

- The candy jelly products are all naturally and artificially flavored.

- Life Savers always offer you the true flavor you expect from the fun of the jelly candy.

3.L'il Critters

Company Background:

L'il Critters is a brand of gummy vitamins and supplements for children that aims to make it easy for kids to get the vitamins and minerals they need. The brand was created over 10 years ago to prioritize kids' nutritional needs while offering fun and delicious supplements with various types of gummies.

The company makes fruit jelly sweets are free of artificial colors and flavors, and some varieties are made with organic ingredients.Their gummy bear candy is blended with passionflower, chamomile, and lemon balm in a yummy peach flavor.

Key Products

- L'il Critters Calcium + D3 Daily Gummy Supplement

- L'il Critters Multi Plus Digestion Gummy Daily Multi Vitamin

- L'il Critters Paw Patrol Gummy Vites Daily Gummy Multivitamin

Recommend Reason

- L'il Critters offer kids a blend of essential vitamins, minerals and supplementswith gummy bear flavors.

- Their organic gummy bears contain a powerful fusion of 13 essential vitamins and minerals giving kids what they need.

- The organic gummies they offer have naturally sourced colors derived from plants, fruits and vegetables, containing five natural flavors.

- With theircomplete multivitamin gummies and candy vitamins, kids can enjoy getting their daily multivitamin needs.

4.VitaFusion

Company Background:

Vitafusion is a brand of dietary supplements for children and adults that come in the form of gummy vitamins, natural fruit flavors, and organic gummy bear. Their goal is to make nutrition taste good, and they offer a variety of products, including sugar bear gummies, raspberry gummy candies.

The company covers the full spectrum of dietary supplements for adults and children with various sugar gummy bears. Their candy gummy bears are packed with delicious flavor and nutrients at a great value that you can find anywhere.

Key Products

- Vitafusion Magnesium Gummy Supplement

- Vitafusion Womens Multivitamin Gummies

- Vitafusion Fiber Well Sugar Free Fiber Supplement

Recommend Reason

- Vitafusion is the first gummy brand to clinically prove traditional vitamins and capsules.

- Their gummy products are regulated by the FDA and are tested in internal and external laboratories.

- They offer multivitamin gummies for sleep support, women wellness, gut health, etc.

- The gummy vitamins from them provide you a multivitamin that has been formulated to support the specific health needs.

5.Welch's Fruit Snacks

Company Background:

Welch's Fruit Snacks is a brand of fruit snacks made with real fruit and marketed as a good source of vitamins A, C, and E in gummies and gummy candies. Except for various of gummy candies and products, their other candies are also non-sticky, with a soft and delicious mouthfeel that gets better with every bite.

The company offers you the funny gummies and the gummy bears that all use natural flavors and colors from natural sources, which are gluten free, vegan, non-GMO.

Key Products

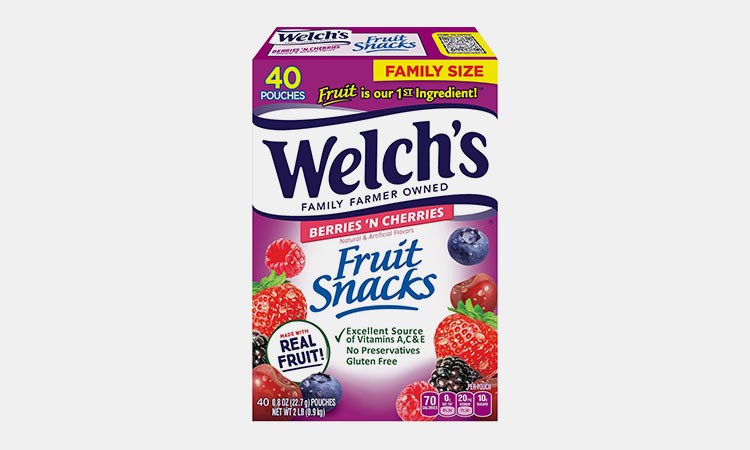

- Welch's Fruit Snacks Berries 'n Cherries

- Welch's Fruit Snacks Fruit Punch & Island Fruits

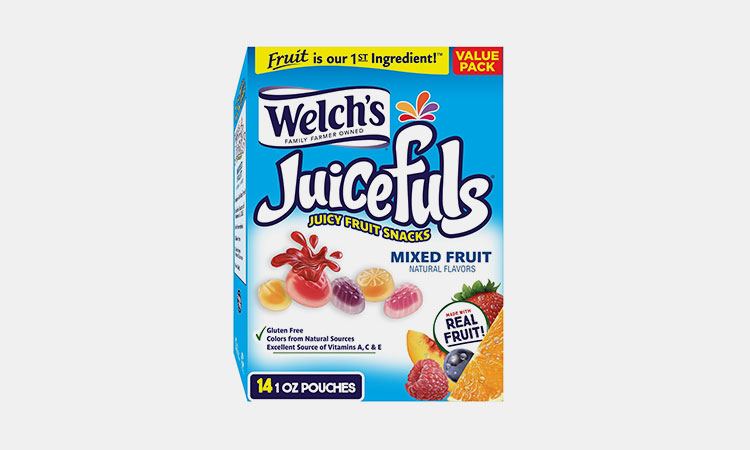

- Welch's Juicefuls Juicy Fruit Snacks

Recommend Reason

- Welch's Fruit Snacks come in a variety of flavors, including mixed fruit, berries, cherries, and fruit yogurt.

- Their products are made with real fruit and feature an excellent source of Vitamins A, C & E.

- All their gummy candies are gluten free, containing no preservatives, and are convenient to carry.

- Snacks and gummies are based on weighted scores for nutrition, ingredient and processing concerns.

6.Albanese

Company Background:

Albanese is a confectionery manufacturer with multiple gummy products for more than 30 years. They have made the world's best gummies and chocolates in the USA by using their simple recipe for success, including putting flavor and texture first.

The company specializes in the production of gummies and chocolate-covered goods. They have carried the family-owned company to innovation, growth, and recognition since launching in 1983 as a startup company.

Key Products

- Albanese World's Best 12 Flavor Gummi Bears

- Albanese World's Best Gummi Peach Rings

- Albanese World's Best Sour 12 Flavor Mini Gummi Worms Candy

Recommend Reason

- Albanese offers individually flavored gummy bearand jelly candies for you if you want to customize a candy buffet or party!

- The company offers chocolates, nuts, and candies products.

- What makes them unique is that they are the only candy company that offers a public tour for gummy manufacturing in the USA.

- They are so much fruitier, tastier and cheaper than all other brands.

7.Black Forest

Company Background:

Black Forest is a company that makes fruit snacks, gummies, and fruit strips. Their products are made with real fruit juice and natural colors and flavors, and some are USDA Organic certified. All their vitamin jellies products are organic and vegan.

The company makes organic black forest gummy bears and fruit flavored snacks that are made with at least 95% organic ingredients, and are sweetened with the help of organic cane sugar and organic tapioca syrup.

Key Products

- Black Forest Gummy Bears Candy

- Black Forest Gummy Worms Candy

- Black Forest Juicy Burst Fruit Snacks

Recommend Reason

- Black Forest gummies are made with real fruit juice and colors and flavors from real sources.

- All healthy jelly sweets are wholesome gummy treats made with pure ingredients.

- They make delicious, real snacks and bear candies that you can feel good about.

- All of their organic gummies and fruit flavored snacks are happily Gluten Free.

8.SmartyPants

Company Background:

SmartyPants is a Los Angeles-based company that designs and manufactures gummy supplements for the whole family. All their products are made with premium, responsibly-sourced ingredients and are free of synthetic colors, artificial flavors, artificial sweeteners, and preservatives.

The company offers a variety of gummy supplements for kids and adults, as well as supplements for specific life stages and dietary requirements. Their mission is to simplify health without sacrificing quality.

Key Products

- SmartyPants Women's Multivitamin Gummies

- SmartyPants Women's Masters 50+ Multivitamin

- SmartyPants Kids Multivitamin Gummies

Recommend Reason

- SmartyPants makes premium, science-backed gummy multivitamins for the whole family that taste delicious.

- The company also offers supplements that are tailored for different life stages and dietary requirements.

- They design various gummy and gummy vitamins with quality dense.

- All their gummy vitamins are third-party lab tested for purity and potency.

9.Jelly Belly

Company Background:

Jelly Belly is a gummy candy company who makes over 100 different types of gourmet candies, including jelly beans, chocolates, gummies, sour candies, and confections for every season. Founded in 1869, it has been a family-owned and operated gummy candy company.

The company is dedicated to producing the highest quality confections, gummy candies, delivering superior customer service and creating a reliable and enjoyable product line to you. It is famous for 100 flavors of jelly beans.

Key Products

- Jelly Belly Gummi Bears

- Jelly Belly Assorted Gummies

- Jelly Belly Gummies Sours

Recommend Reason

- Jelly Belly offers you various gummy beans with number of flavors, the smaller size, the brilliant colors.

- It is a well-known brand of jelly beans that is often considered a premium product compared to traditional, lower-priced jelly beans.

- Their sweet candies and gummies that have a soft middle and a hard outer shell, and come in many different flavors.

- They offer more than 100 types of candy, including 110 flavors.

10.Trolli

Company Background:

Trolli is a German confectionery company that makes gummy candies, jelly bears, gelatin candy, and worm gummies. Founded in 1948, it is famous for its unique consistency, fruity-sour taste, and iconic products.

The company offers you the perfect balance of sweet and sour, in every candies and gummies. It is a German brand that has been making its mark for decades in the confectionary industry with its playful, detailed and unique fruit gummy creations.

Key Products

- Trolli Sour Brite Crawlers Candy

- Trolli Sour Brite Crawler Mini Candy

- Trolli Sour Brite EGGS Assorted Gummies

Recommend Reason

- Trolli are the best sour gummy worms on the market.

- Their gummies come in weird shapes and psychedelic colors.

- You may fall in love with their sweet and sour gummy worms, bears, candy in the shapes and textures.

- Whether you're young or old, their gummy candies are a fun and delicious treat that is perfect for anyone looking for a tangy and sour snack.

11.Goli

Company Background:

Goli is a wellness and fitness gummy company that makes nutritional supplements and products to help people consume essential nutrients. Their goal is to make taking gummy supplements simple and enjoyable by using organic, vegan, and gluten-free ingredients.

The company offers customized advice to help you reach your nutrition goals. It is an inventive, people focused nutrition company committed to providing innovative products that make taking your daily gummy supplements simple and delicious.

Key Products

- Goli Apple Cider Vinegar Gummy Vitamins

- Goli Ashwagandha & Vitamin D Gummy

- Goli SuperGreen Vitamin Gummy

Recommend Reason

- Goli is a brand of gummies that come in different varieties, including apple cider vinegar (ACV), ashwagandha, and superfruits.

- Gummies they provide are made in the US with top quality ingredients that have been locally and globally sourced.

- Their gummy products are formulated with quality ingredients you can pronounce and flavors your taste buds will enjoy.

- All their nutrition products are vegan, gluten-free, non-GMO, and gelatin-free.

12.Boston Fruit Slices

Company Background:

Boston Fruit Slices is a family-owned company that makes and sells gummy candy fruit slices. They are known for being the first company in the United States to make and sell fruit gummy slices, and have been doing so for over 80 years.

The company produces sugar-free slice gummy and candies for the health conscious or individual who needs to watch their sugar intake. Each piece of their products is individually wrapped, and available in four flavors.

Key Products

- Boston Fruit Slices Spring Summer Fruit Slices

- Boston Fruit Slice Assorted Fruit Flavored Slices

Recommend Reason

- Boston Fruit Slices were the first company to make and sell fruit gummy slices in America.

- They are the classic American gummy candy and candy brand that still proudly handmade in the USA!

- Using only the finest ingredients and flavors, these gummy candy slices closely resemble actual fruit pieces in size.

13. eFrutti

Company Background:

Efrutti is a family-owned German company that makes gummy candies, fruit gum, and marshmallow confections. It is famous for its innovative flavors and products, and is dedicated to providing high-quality candies that meet the needs of today's families.

The company works with local governments and third-party labs to ensure their ingredients and production practices meet dietary restrictions. Their manufacturing plants are also certified to the International Food Standard (IFS) Quality Management System.

Key Products

- Efrutti Watermelon Splash Fruity Jelly Gummies

- eFrutti Gummi Candy Variety Lunch Party Gift Set

- E Frutti Gummy Hamburger and Hot Dog Variety Pack

Recommend Reason

- eFrutti is renowned for developing innovative gummy confections and flavors made with a sense of fun & dedication to quality.

- The company is passionate about creating quality gummy snacks and gummy hamburgers that are different and unique.

- Their gummy worms candy manufacturing plants are certified to the highest standards in line with the food industry's IFS Quality Management System.

- The gummies they provide do not contain any gluten-containing grains or ingredients derived from gluten-containing grains.

14.Startburst

Company Background:

Startburst is a gummy candy brands for manufacturing fruit-flavoured soft taffy gummy candy with many different varieties, such as tropical, sour, watermelon, berry, super-fruit, summer blast and original. All their products are wrapped in wax paper, which is stiff enough to keep them supported.

They are the popular brand of fruit-flavored chewy candies and gummies. By wrapped individually in rainbow colors will surely brighten up your day or a gathering with friends and family.

Key Products

- Starburst Original Gummies Candy

- Starburst Gummies Sours

- Starburst Gummy Candy Duos

Recommend Reason

- Starburst, with its chewy texture and variety of fruit flavors, has long been a favourite among candy lovers for years.

- They are the popular brand of fruit-flavored chewy jello candy that was first introduced in the UK.

- With its popularity spanning across the globe, their jelly worms are commonly found on grocery store shelves in various countries.

15. Smart Sweets

Company Background:

SmartSweets is a candy company that makes low-sugar gummy candy. They have innovated the first delicious candy without the sugar, and promise to you that the candy gummy are free from sugar alcohols, artificial sweeteners.

The company is driving innovation through creation of the first candy products that kick sugar naturally. They always know how to make the delicious candy you know and love. There gummies and candies are now available at around 150,000 retailers.

Key Products

- SmartSweets Fruity Gummy Bears

- SmartSweets Sweet Fish

- SmartSweets Gummy Worms

Recommend Reason

- SmartSweets focuses on creating low-sugar gummy candy.

- The company offers a variety of candies, including gummy and hard candies, that are free from sugar alcohols, and artificial sweeteners.

- The candies and gummies are non-GMO, and are coloured with natural ingredients.

- It is easy for you to find their products all over the world now!

16. Herbert's Best

Company Background:

Herbert's Best is a company that makes gummy candies for you with dietary restrictions. They work with local governments and laboratories to ensure that their ingredients and production practices meet the needs of your families.

Founded in 1948, the company is committed to providing you with the chance to enjoy their candy without compromising on taste and texture.

Key Products

- Herbert's Best Gummi Eyez

- Herbert's Best Planet Gummi

Recommend Reason

- Herbert's Best is always dedicated to offering you best gummy candies.

- Each of their gourmet gummies has a spongy fruit-flavored exterior that gives way to a delicious liquid center.

- They are the top-selling gummy candy in USA.

- You actually get to enjoy the perfectly chewy consistency longer with their gummy candies.

17. Zahlers

Company Background:

Zahler is a family-owned company that makes kosher nutritional supplements like gummy vitamins. All their products are based on scientific research and consumer feedback, and are intended to address underlying deficiencies rather than symptoms.

The company offers you a wide range of gummy nutritional products for the whole family, including categories such as women's health, children's health, and digestive health.They have developed a line of their very own, pure and natural, full-of-goodness nutritional supplements.

Key Products

- Zahler Chapter One Vitamin D 3

- Zahler Chapter Six Melatonin Gummies

- Zahler Beet Root Gummies

Recommend Reason

- Zahler is one of the renowned brand of dietary supplement products and gummy products that are pure and natural.

- They are a company that uses science to present nature at its best.

- The gummy nutritional supplements are formulated with vitamins and minerals that promote health and enhance energy.

- Their vitamin gummies and supplements have helped thousands live their best life.

18. Natrol

Company Background:

Natrol is a US-based company that manufactures and distributes gummy vitamins, minerals, and supplements for five health areas. They are considered as the pioneer in formulating gummy dietary supplements to help support and maintain health and wellness.

The company is a leading vitamin, mineral and supplement maker with gummies to aid sleep, mood and stress in US. They have a quality control process that includes testing every lot of finished products for safety, quality, strength, composition, and consistency.

Key Products

- Natrol Melatonin

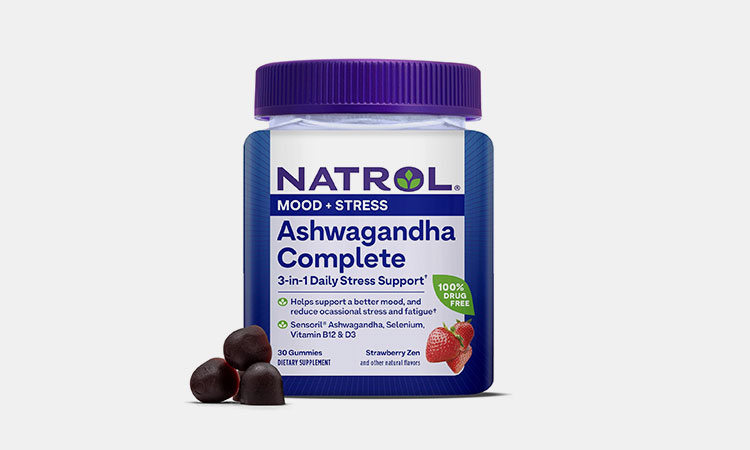

- Natrol Ashwagandha Complete

- Natrol Sleep+ Immune Health Gummy

Recommend Reason

- Natrol is driven to become the most desired nutritional supplement brand by creating products that support your healthy life.

- They offer a full range of gummy vitamins and supplements for sleep, mood, stress, brain health, and more!

- Their products are drug-free, non-GMO, free of artificial flavors and sweeteners.

- Their gummy nutritional supplements are made with clean ingredients.

19. Yum Earth

Company Background:

Yum Earth is a privately held company that makes organic, allergy-friendly treats and gummies. Their products are free from the top eight allergens, including peanuts, tree nuts, milk, fish, shellfish, egg, soy, wheat, and sesame.

The company offers a variety of organic, allergy friendly sweets. They offers the natural and organic lollipops, fruit snacks, gummies, candy drops, licorice, sour jelly beans and other treats and gummies.

Key Products

- YumEarth Organic Fruit Flavored Gummy Bears

- YumEarth Organic Tropical Flavored Fruit Snacks

- YumEarth Gluten Free Gummy Bears

Recommend Reason

- YumEarth is not just tasty organic candy.

- All their candy gummies and worm candies are made from organic ingredients and without the top 8 allergens.

- You can enjoy lollipops, licorice, gummies, sour gummy candy, and more!

- Their promise is to keep innovating and creating friendly sweets, yummy treats and gummy candies for you.

20. Olly

Company Background:

Olly is a wellness and fitness company that makes premium nutrition and wellness gummy products, including vitamin supplements and other products. Their mission is to make gummy nutrition easy to understand and create products that are effective, delicious, and delightful.

The company always brings the ensured gummy nutritional supplements with quality and safety in serious oversight with a team of scientific, quality, and regulatory experts

Key Products

- OLLY Hello Happy Gummy Worms

- OLLY Metabolism Gummy Rings

- OLLY Women's Multivitamin Gummy

Recommend Reason

- OLLY is a professional maker of premium nutrition and wellness gummy products.

- Their products are independently tested by third-party labs to ensure they meet quality, safety, and label claims.

- They also work with suppliers and manufacturers who meet their requirements for transparency.

Conclusion

After knowing about all those top gummy manufacturers and brands, you may have learned their features and key products. With so many gummy manufacturers and brands for your choice, if you do not know how to choose, just contact us now and we will offer you free consultation!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Top Gummy Manufacturers: The Complete Guide In August 2025 Read More »