Vertical Band Sealer VS Horizontal Band Sealer

Strict regulatory guidelines have deemed necessary the use of measures that provide safety and stability of products that are intended for human consumption or pose health hazards. In packaging industry band sealers are key instruments that are employed to seal a variety of bags, pouches and containers made of polythene, plastic, foil etc.

Bands sealers are not only employed in pharmaceuticals but also in food, veterinary and chemical industries to ensure safety and integrity of the product. In term of orientation there are two types of band sealer i.e. horizontal and vertical; we have discussed in detail the differences between both orientations in this blog VERTICAL BAND SEALER VS HORIZONTAL BAND SEALER. Without further delay let’s proceed.

1.Are there any differences between horizontal and vertical band sealer?

As a matter of fact, horizontal and vertical band sealers are same equipment having different orientation however, you will find few differences between both horizontal and vertical band sealers. These are;

|

|

| HORIZONTAL BAND SEALER | VERTICAL BAND SEALER |

| Bags or pouches are laid on conveyer for sealing. | Pouches or bags are sealed in an upright position. |

| Require more space in terms of area. | Best piece of equipment in case of space restraints. |

| Horizontal sealers process packages having low volume capacity. | As compared to horizontal band sealer vertical sealers can work on high volume packages. |

| Used for products that have a low chance of spillage. | Ideal for products that have a chance of spillage. |

| Recommended pouch or bag size is small. | Typically bags of height less than 300-400mm is recommended. |

| Adjustable conveyer that can be adjusted vertically and angularly. | Adjustable height for large bags. |

2.Technical specifications; a detail comparison between horizontal and vertical band sealer.

Horizontal band sealer and vertical band sealer are both available as bench top and standing unit. Bench top are low – mid production capacity equipment whereas standing units can meet high production requirements.

Below are some technical specifications of both horizontal and vertical band sealer (standard version), however for accurate specifications contact our representatives at Allpack or consult equipment manuals.

| SPECIFICATION | HORIZONTAL BAND SEALER | VERTICAL BAND SEALER |

| Sealing speed | Horizontal band sealer can seal approximately 13 meters in a minute. | Vertical band sealer has similar sealing speed of 13 meters per minute. |

| Sealing Width | Sealing width is adjustable i.e. 0.125 – 0.625 inches. | Sealing width of vertical band sealer can reach up to 10 inches. |

| Max load | Maximum a load capacity is approximately 15 pounds or 7.5 kg. | Max load capacity can increase up to 55 pounds or 25 kg. |

| Dimensions | Typical horizontal band sealers have a dimension of L44″ x W24″ x H41″ | Vertical band sealers usually differ in height; adjustable according to pouch type. |

| Pouch Height | 6″minimum bag height maximum 15″. | 6″ minimum bag height can seal bags up to 29.5″ |

| Weight | Weigh of horizontal band sealer is about 350 lbs. | Weigh of vertical band sealer is about 550 lbs. |

| Power | This equipment is powered by a three-phase motor 500W / 4.55A. | Vertical band sealer is powered by a 750W / 7A, three-phase motor |

3.Can you customize vertical and horizontal band sealer?

Yes of course you can! Most manufacturers such as Allpack offer customized solutions to their customers. Although a standard band sealer comes with technologically advanced features; you can always add certain features as per your requirement.

| UNIT | DESCRIPTION | PICTURE |

| Conveyer | You can order for your horizontal band sealer a modified conveyer that can extend approximately 10 – 12 inches from the sealer to incorporate large volume bags. |  |

| Vacuum sealing and gas flush unit | You can incorporate your machine with vacuum sealing and gas flush unit that increases shelf life of the product. |  |

| Seals | As per your requirement seals of different width can be ordered with your sealer. |  |

| Power supply | Usual band sealers are powered by a three-phase motor however, based on customers requirement this equipment can be provided with a single-phase motor. |  |

| Electronic display and HMI | Standard versions of band sealers are not equipped with electronic display and user-friendly HMI. However, you can always opt for touch screen and HMI to adjust working conditions of your machine. |  |

4.What to look for? Accessories that can be attached to vertical and horizontal band sealer.

Standard versions of both vertical and horizontal band sealer have built-in features that facilitate a smooth operation without increasing equipment cost. However, you can always upgrade your machine with additional accessories as per your need. Accessories that can be added to standard equipment without customizing them include.

Temperature controller

This unit regulates sealing temperature of the machine. Typical standard version can be equipped with a temperature controller that can change temperature between 0 – 300OC.

PTFE bands

You can always upgrade your machine to a PTFE band sealer. PTFE bands are economical, light weighed, can resist temperature up to 260 OC and have non-sticking properties.

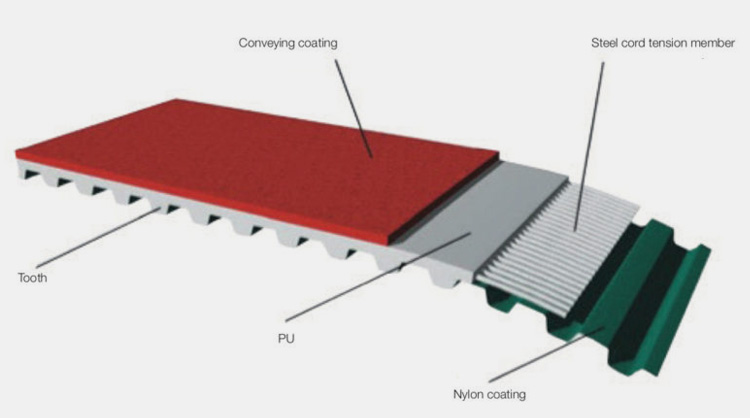

Poly Urethane drive belts

Poly urethane drive belts are stiff having a good overall stability with least chances of belt ratcheting. These belts are also chemically resistant to most acids and alkalis and are recommended in machines that are installed in contamination free zones.

Sensors

Standard modules of band sealers are not provided with sensors but they can be equipped with aftermarket advanced sensors such as photoelectric sensors that detect product, change in surface etc.

Embossing pinwheel

Standard band sealers are equipped with ink heating and printing block however, you can also equip your band sealer with embossing pin wheel that embosses characters on poches providing high seal quality and embossing.

5.Possibility of conversion of vertical band sealer to horizontal band sealer or vice versa.

You would have known by now that both vertical and horizontal band sealers are same machines having different orientation. So, the next question would be whether their orientation can be changed.

The answer is Yes! It is possible to change their orientation i.e. from vertical to horizontal and vice versa in few steps within few minutes. All you have to do is order a do it yourself conversion kit.

However, you have to make sure that your sealer is compatible with the conversion kit since this conversion is not applicable on all versions.

Here is how you do it.

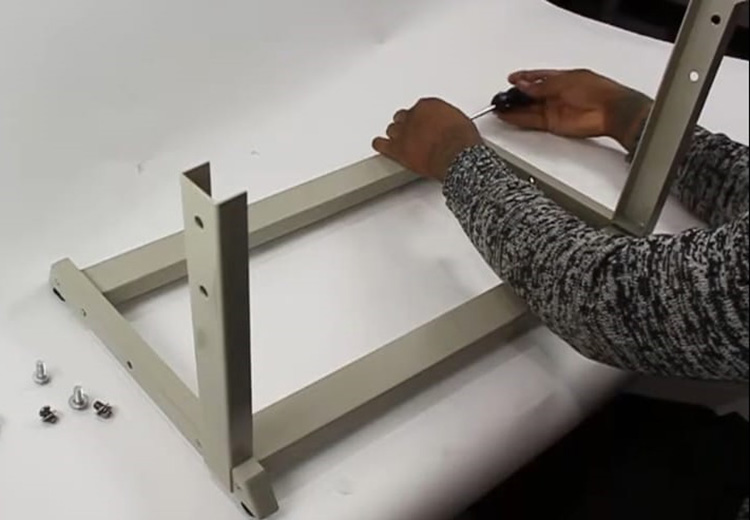

Assemble the vertical stand.

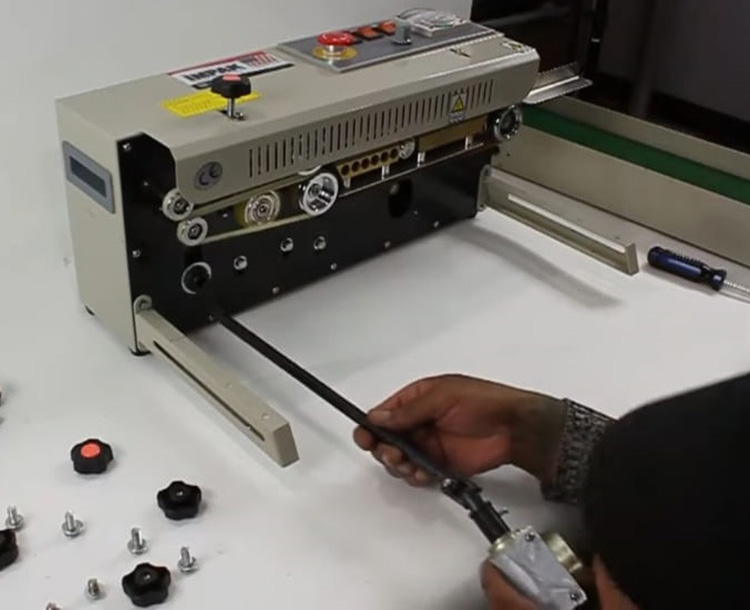

Remove the conveyer and install moving mechanism.

Attach the vertical stand to the sealer head.

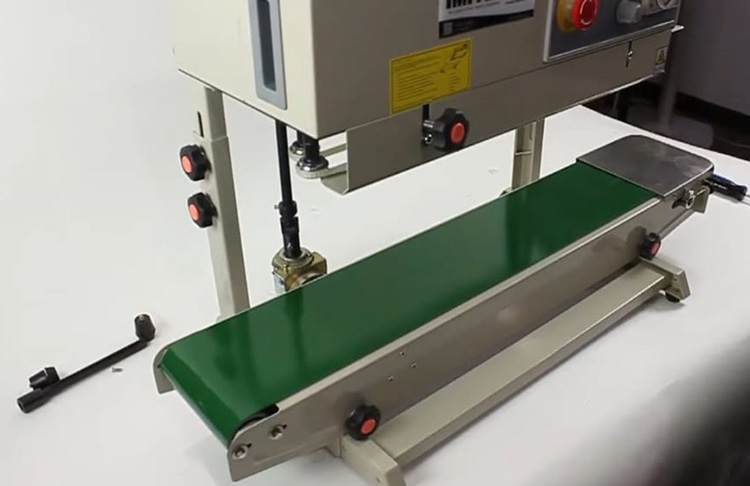

Re-attach the conveyer.

Conversion from horizontal to vertical orientation completed.

If you have installed a do it yourself conversion kit, just remove it in the similar manner and you will get yourself a horizontal band sealer.

Conclusion

Both horizontal and vertical band sealers are same equipment with minor differences in orientation and capacity. Both types can fulfill low to high production demands, can be customized and upgraded with aftermarket parts. Our 24/7 customer service at Allpack works diligently to provide solutions and service to potential buyers. If you want to order or customize band sealer or want to know more about them contact us; we will help you out.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours